read thru these links and their sub links

http://garage.grumpysperformance.co...ng-at-the-circle-track-suppliers-helps.10978/

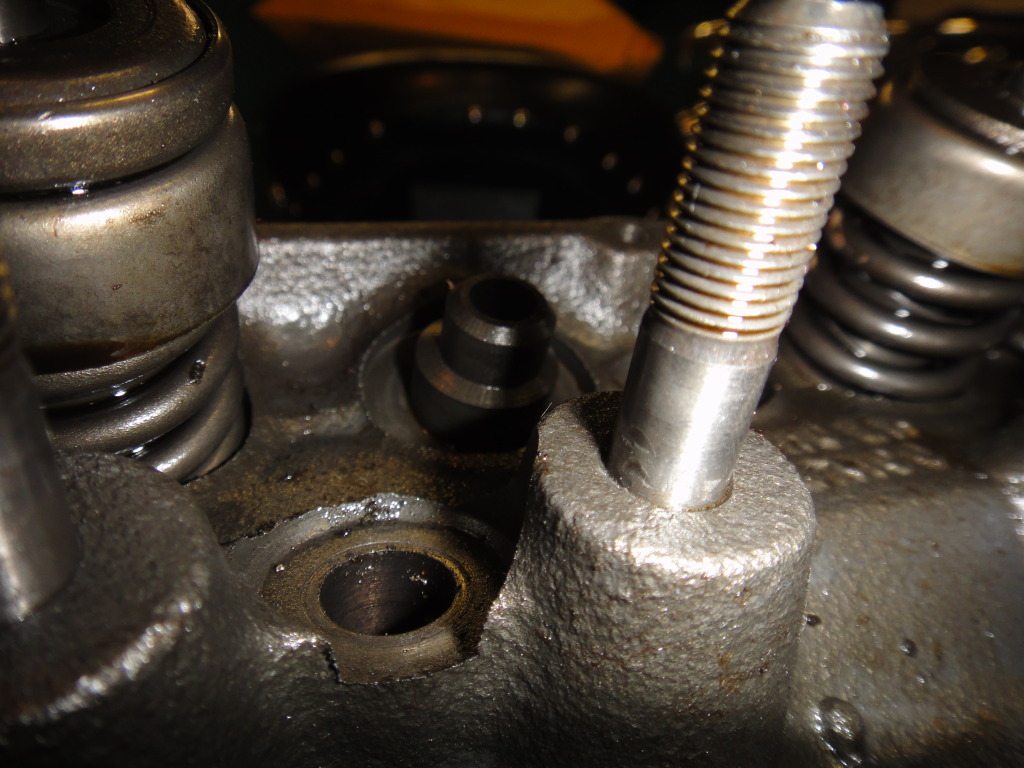

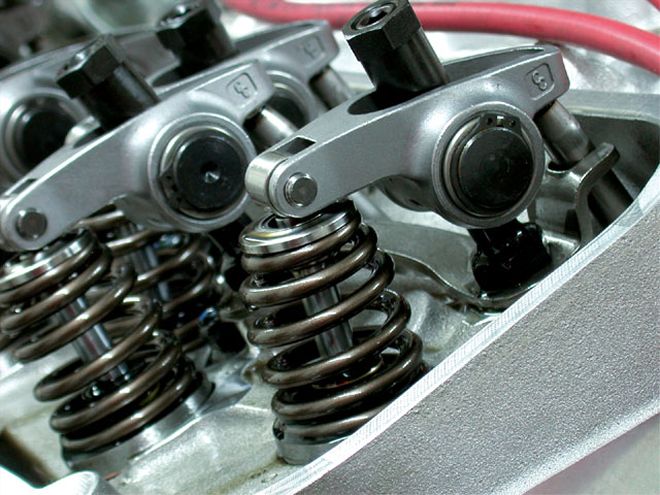

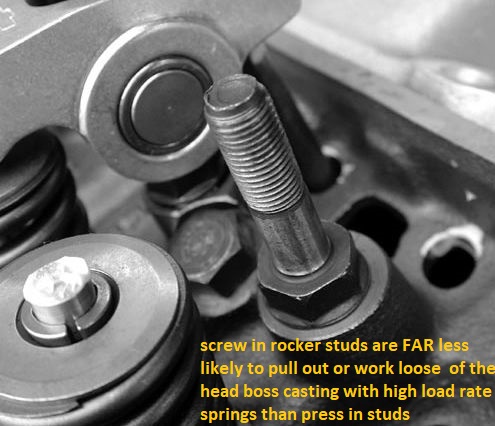

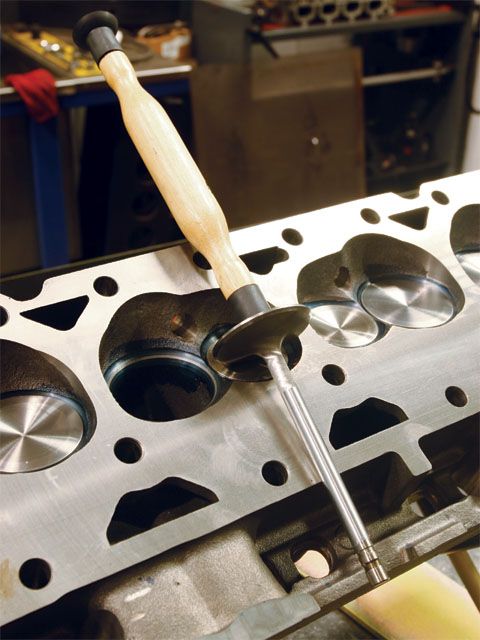

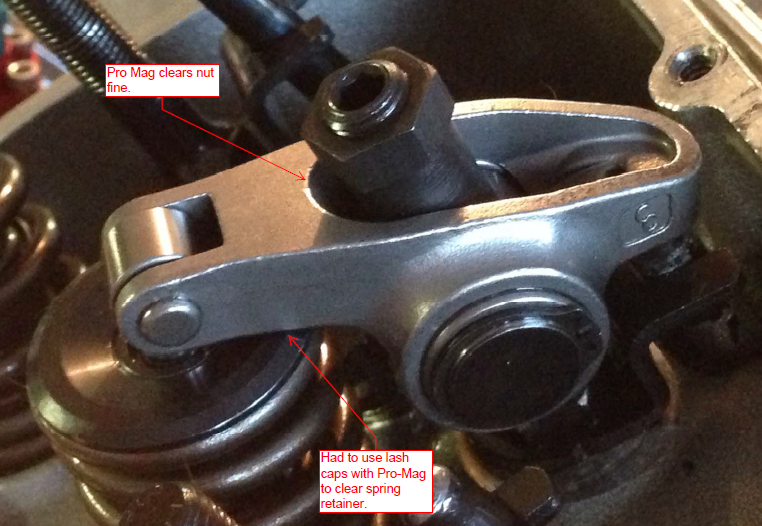

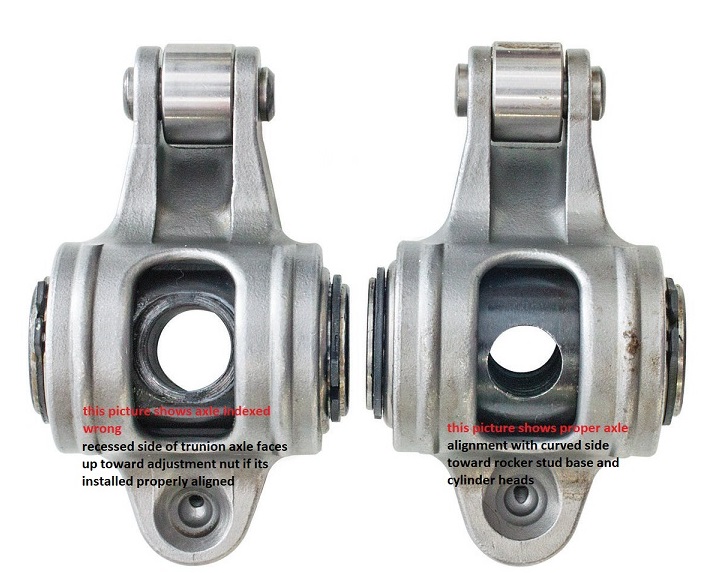

pictured above you see the last rocked badly out of alignment with the valve center line,

a good example why you need adjustable guide plates, this rocker if left too run off center like this, on the valve stem tip , will quickly destroy the valve guide and rocker

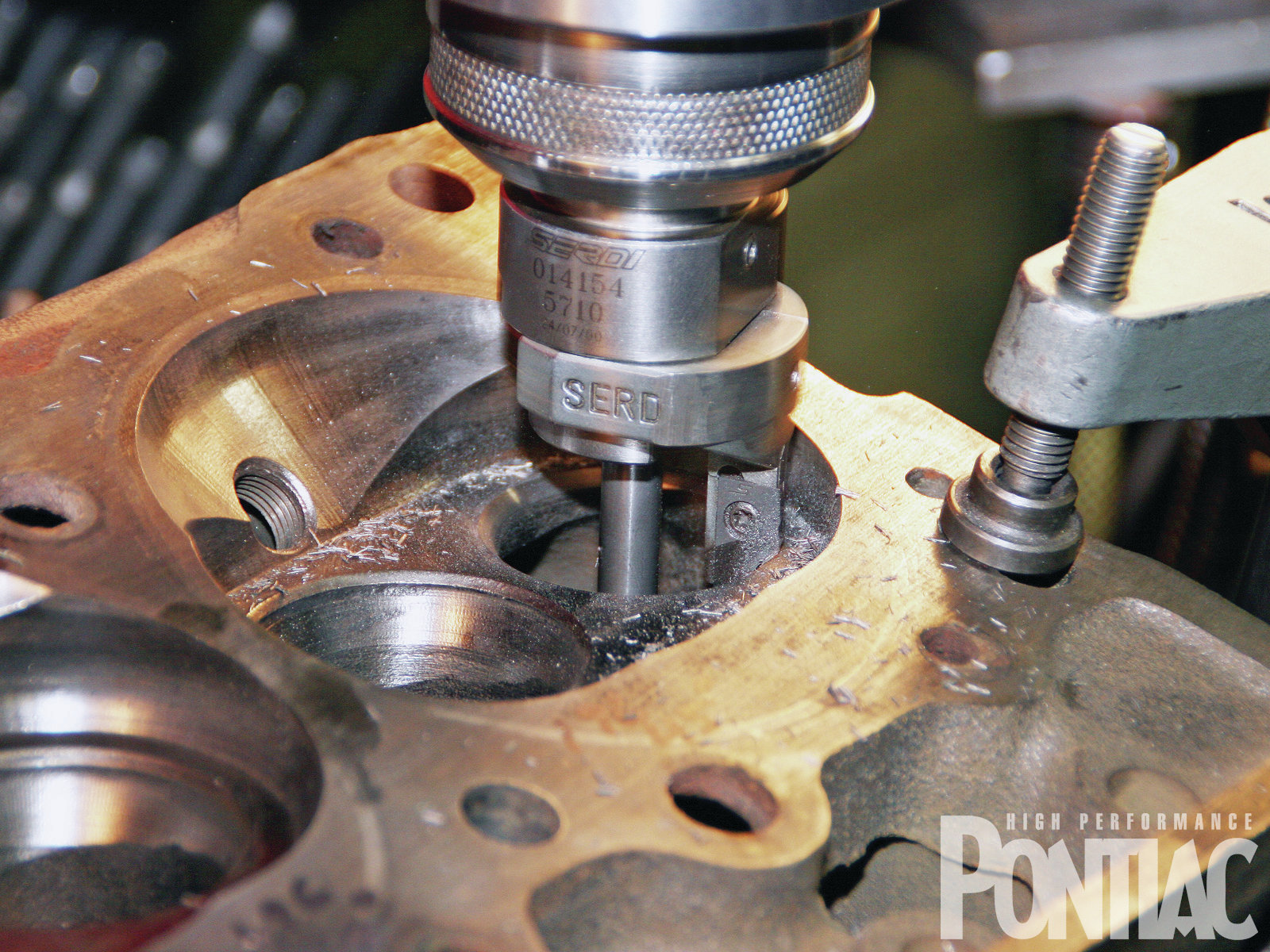

theres a good deal of useful info in this article

http://www.customclassictrucks.com/tech ... index.html

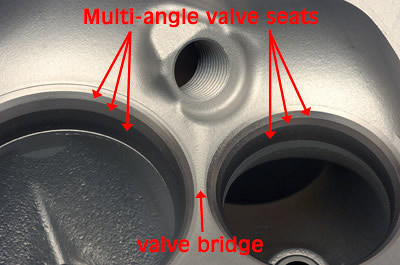

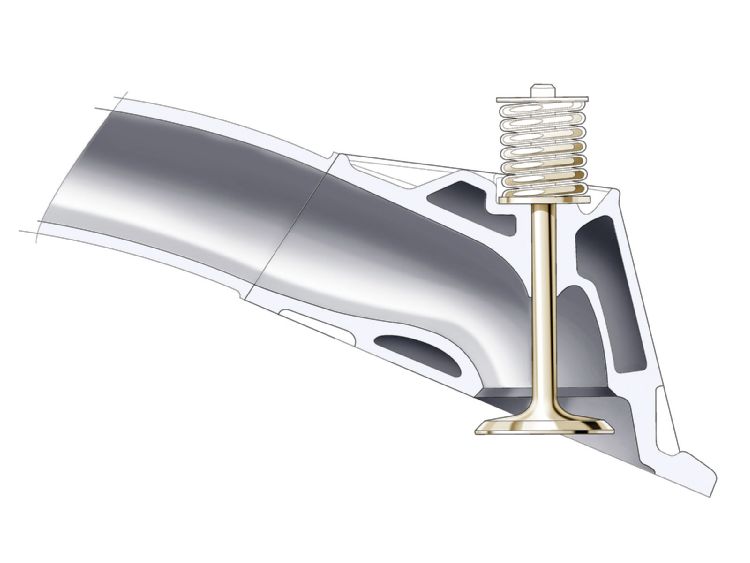

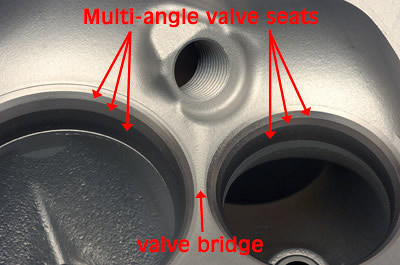

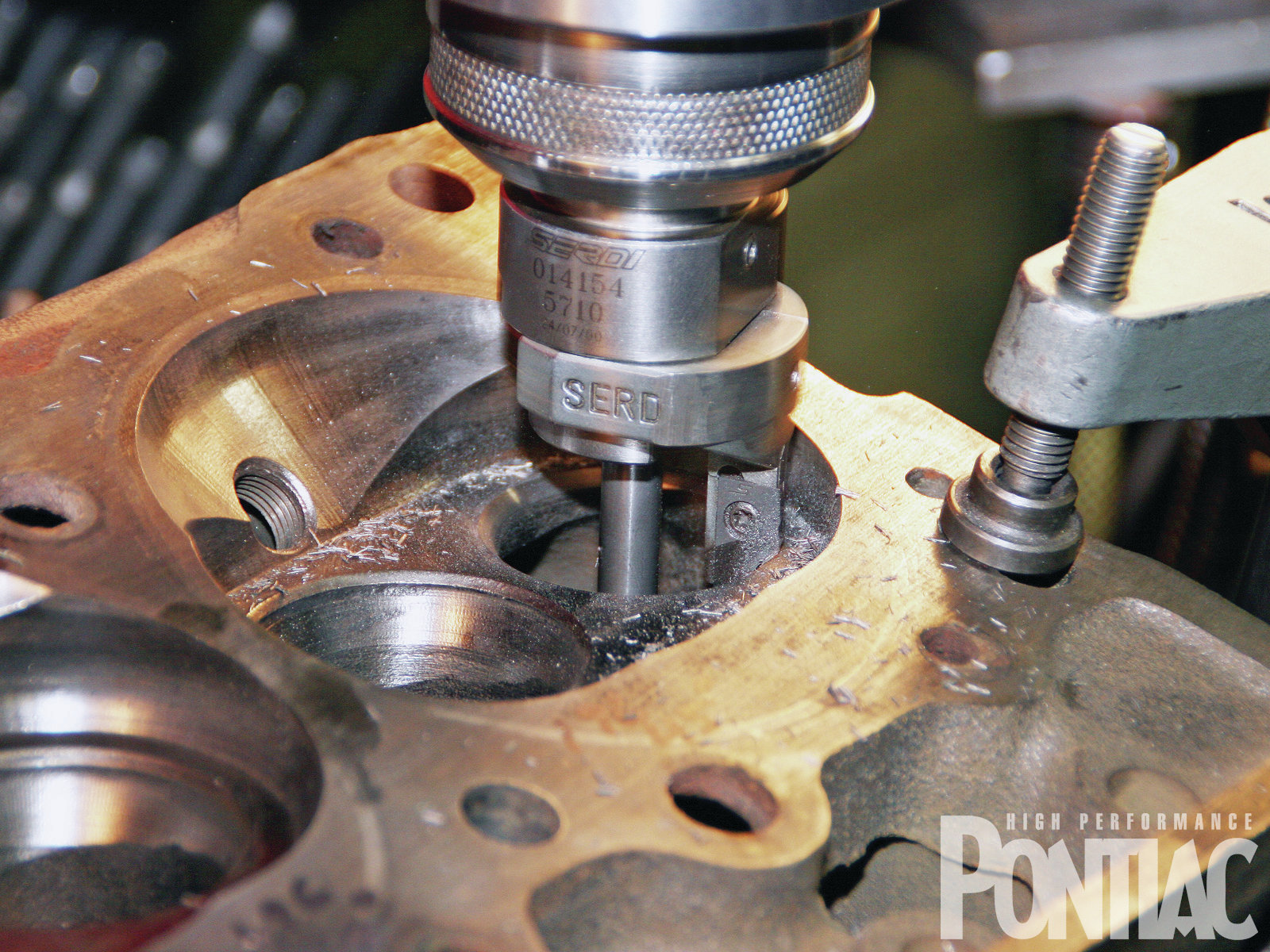

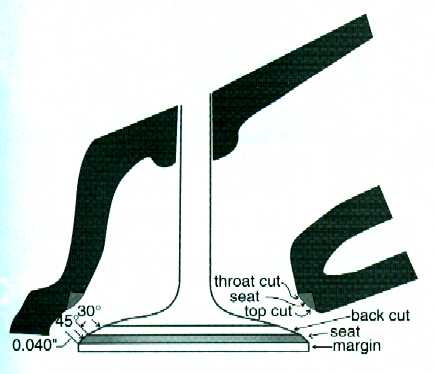

Aluminum does have advantages, like light weight, and easy of machining compared to cast iron, example,cracks in valve seats on iron heads ",usually the result of overheating,"tend to result in coolant leaks that are not easily repaired, so you need a new cylinder head even if you had hundreds of dollars in port work done previously.

but on aluminum heads a bit of tig welding and machining for new valve seats repairs the heads rather easily

heads might need to be milled to make then strait

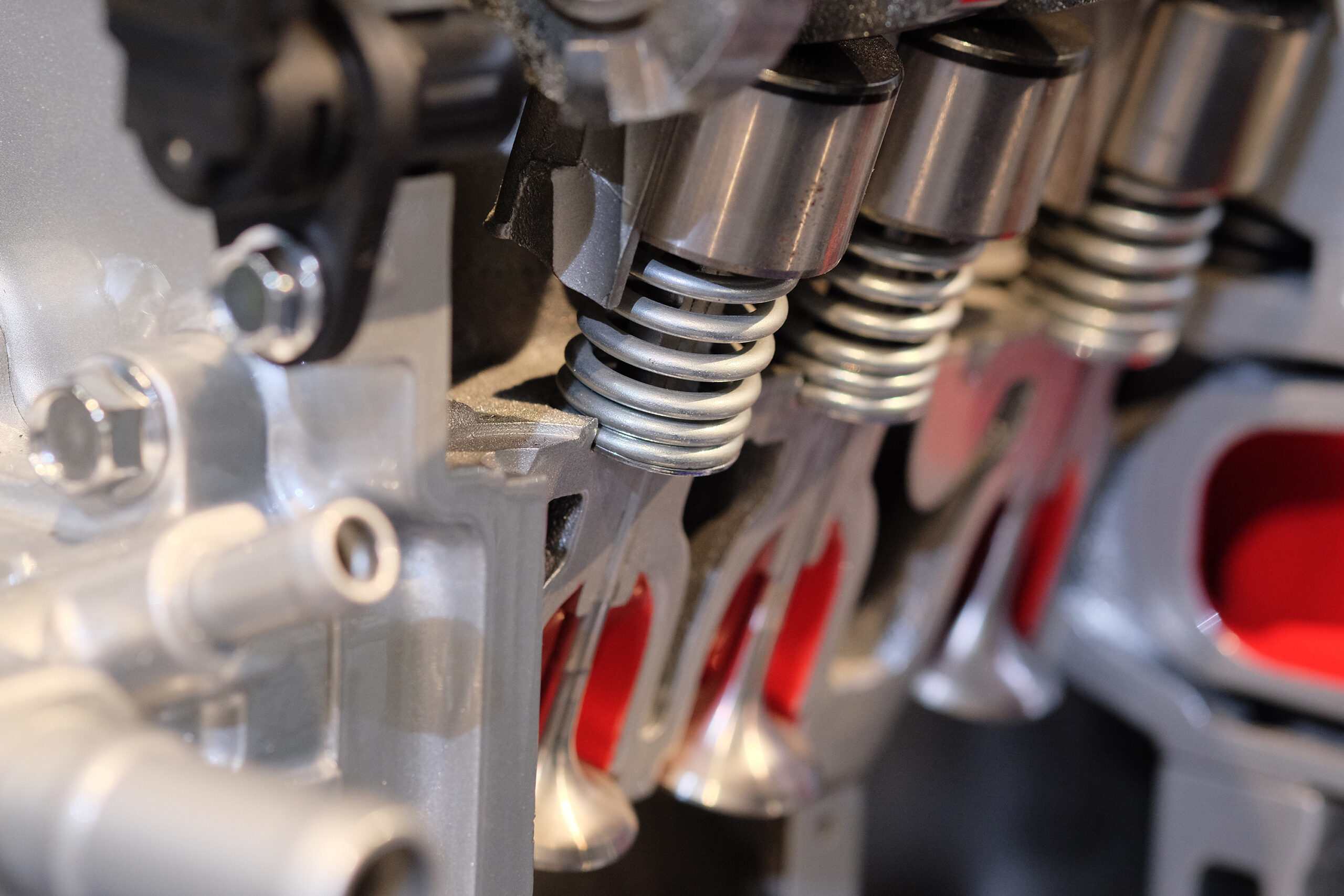

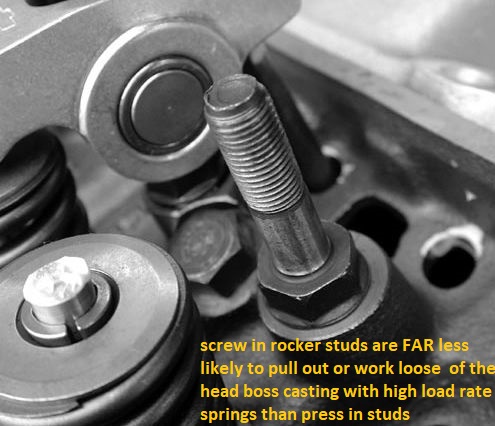

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant.

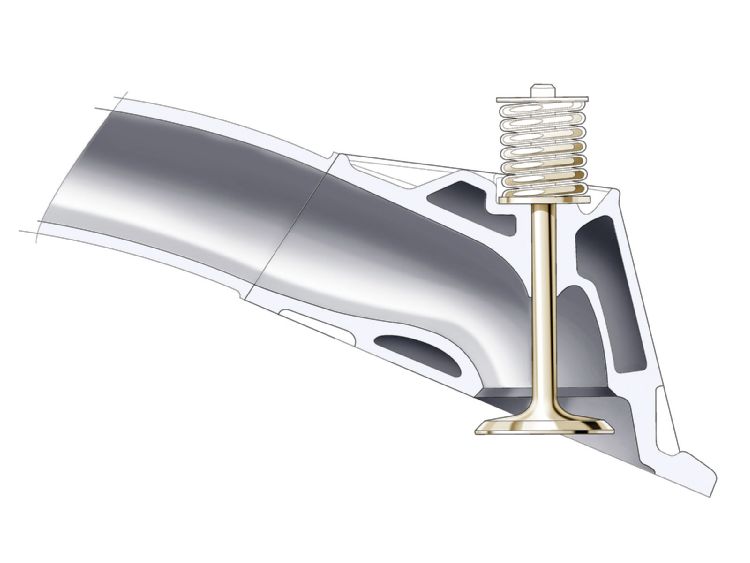

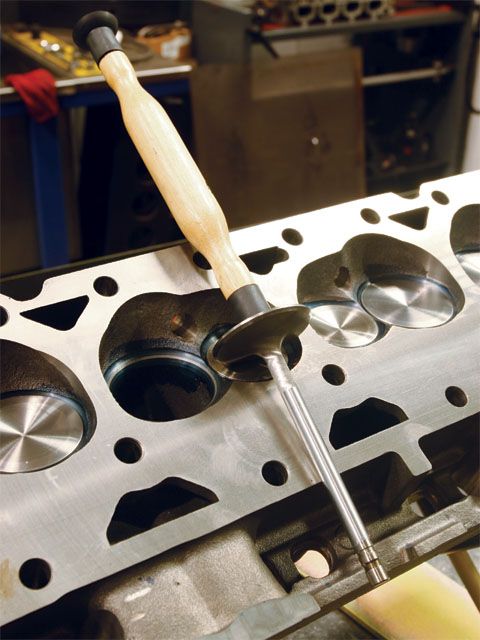

The valveguides for the Vortec heads are the same as all other small-block cylinder heads, but the Vortec heads come equipped with large valveguide seals.

The valveguide seals keep oil from running down both the valve stem and valveguide, and entering the combustion chamber through the intake port at high-engine vacuum and the exhaust port when the engine is not running. This cuts down on engine smoke and exhaust emissions.

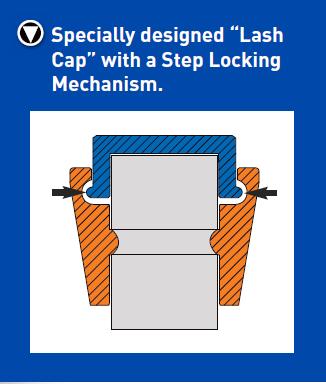

This is the valvespring retainer installed without the valvespring. The maximum amount of valve lift that the Vortec head will tolerate is the distance between the bottom of the retainer and the top of the valveguide seal.

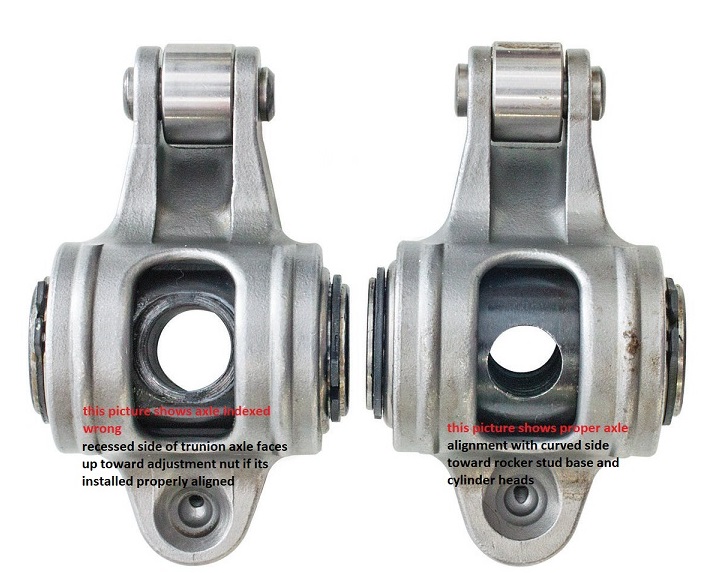

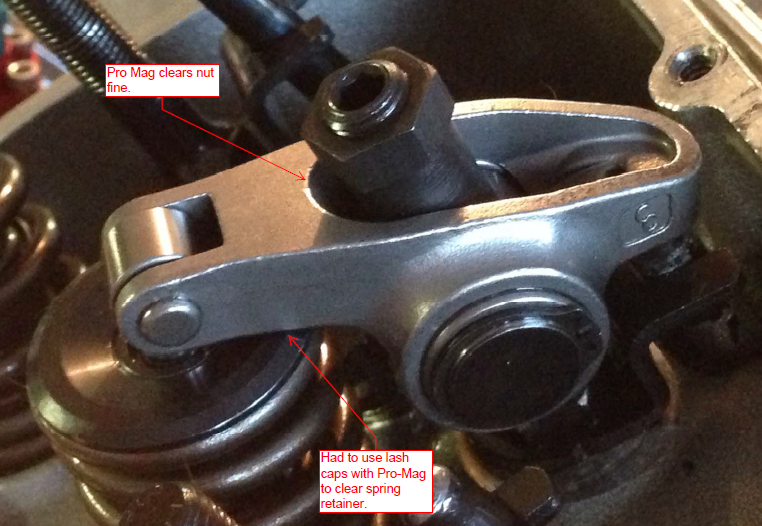

BE aware you need to verify rocker adjustment lock nut to rocker slot clearance and yes it varies even with the same manufacturers different rocker designs

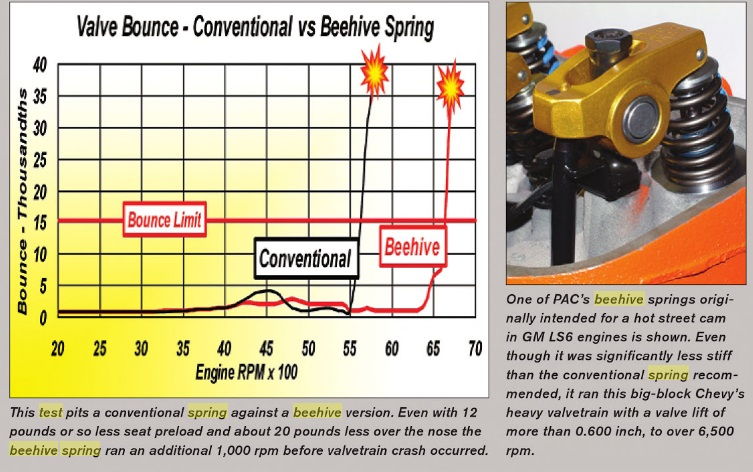

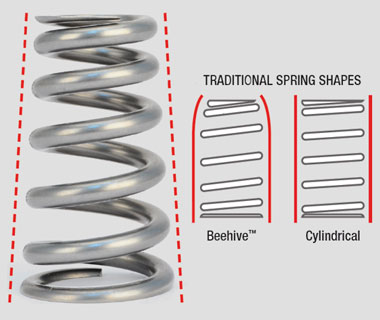

keep in mind the cam lobe ramp acceleration and valve spring load rates.

as any decent mechanic will tell you, you need to finish a race to win it and having a car that constantly breaks parts won,t be fun, and gets darn expensive very rapidly

if your valve train won,t remain stable and under control consistently and handle the stress at the cams intended max rpm, (plus a bit more) your almost sure to have low durability, lots of valve train wear and parts breakage!

lets say your comparing two similar cam,s with listed specs

ones got 215 duration with .450 lift,

the others got 215 duration with 510 lift

Id bet 90% of the guys reading that figure.....hey I get more lift with the second cam, thats obviously going to improve air flow & potential power, so thats the route to take....WRONG!!!

with flat tappet cams, if you exceed a certain lobe acceleration angle you tend to develop valve control and wear issues rather rapidly , mostly because the valve spring load rate required to maintain lifter to cam lobe contact at higher rpm ranges, potentially causes extremely high contact pressures between the two moving surfaces.

SPEND $10 and get a calculator ,in this hobby its a darn useful tool

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .50 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

ones got 215 duration with .450 lift,215/450=.47.7%

the others got 215 duration with 510 lift/215/500=43%

one factor I will mention is that each manufacturer tends to look at durability, ramp speeds and max lifter acceleration very differently, one reason I tend to prefer CRANE & CROWER is that they both company's in general realize the engine must finish the race to win and a busted valve train is a HUGE problem,they both realize, and design valve train components and cam lobes with DURABILITY and reliable valve control as top priority,s that are far more important than squeezing every possible potential HP from a cam lobe design at the expense of long term durability

http://garage.grumpysperformance.com/index.php?threads/cam-lobe-aceleration-rates.2627/#post-6777

http://garage.grumpysperformance.co...s-on-valve-spring-pressures.10268/#post-41364

http://garage.grumpysperformance.co...-rocker-ratio-help-your-combo.2632/#post-6790

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46737

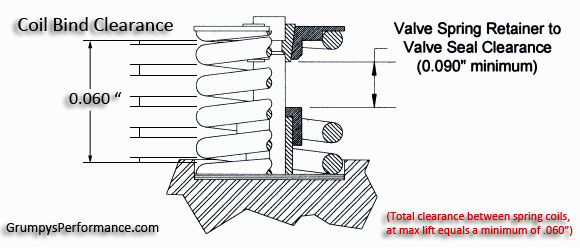

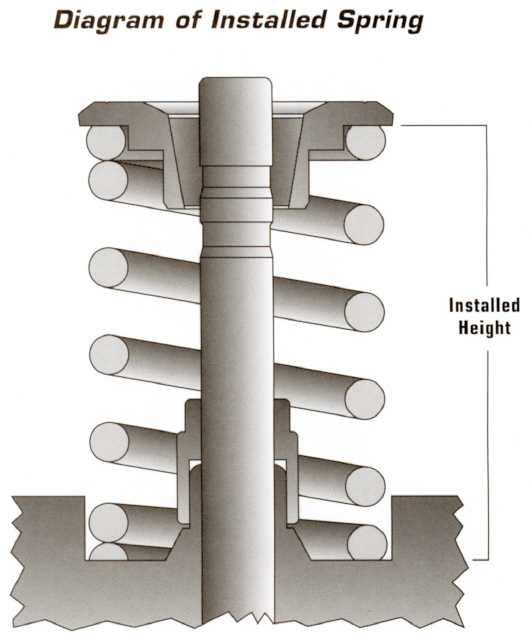

The maximum amount of valve lift before the spring retainer hits the valve guide seal is 0.530 inches. It is generally accepted that 0.060 inches clearance needs to be maintained between the retainer and seal (0.530 - 0.060 = 0.470 maximum valve lift). The Vortec heads, as they come with the large valve guide seals, are only capable of accepting a camshaft with a maximum valve lift of 0.470 inches.

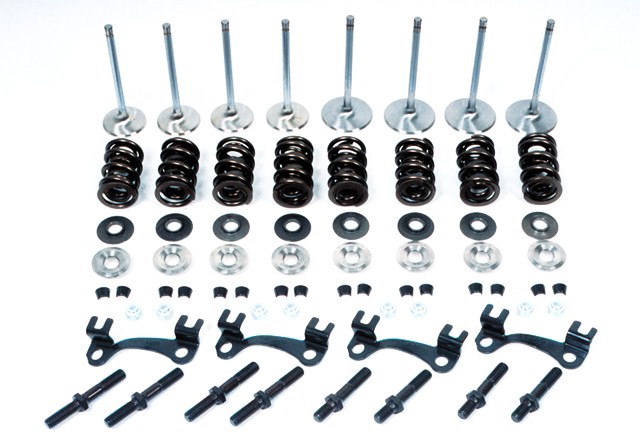

All small-block cylinder heads built before the '96 Vortec heads had two grooves on the valve stems.

The second groove accepts a quad ring. It sits just below the split lock retainers. The O-ring keeps the oil, which lubricates the rocker arm/valve stem tip, from running down the valve stem and into the valve guide.

Small Block Vortec Cylinder Heads Specifications - Heads Up!

The O-ring must be accompanied by a tin shield over the outside of the valve spring (left). The tin shield keeps excess oil from splashing on the valve stem and valve guide. The tin shield and O-ring must be used together to be effective. Installing the earlier double-groove valves, an O-ring, and a tin shield will allow the Vortec heads to use camshafts with 0.500 inches of valve lift, without machining the valve guides lower for clearance. View Related Article

reasonably safe valve train clearance for new 383 sbc cam instal

how much lift can one safly in a 383 with speed pro flat top with 2 valve relief pistons with a quench of .038 before you have to really worry about PVC. i know you should really check any time you change to a bigger cam my buddy has a vega with a 383 in it and its a pain to get engine out. its...

garage.grumpysperformance.com

valve train clearances and problems

you might want to read thru these links and sub links it will help you avoid costly mistakes http://www.summitracing.com/parts/pro-66830/overview/ https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...ng-at-the-circle-track-suppliers-helps.10978/

changing valve springs on the car

now most shops will rotate the cylinder to TDC and install an adapter for an air hose and pump a steady 100-130psi into the cylinder to hold the valves closed, but theres frequently clearance problems with headers and the adapters or hose and since you need to wack the valve retainer with a...

garage.grumpysperformance.com

pictured above you see the last rocked badly out of alignment with the valve center line,

a good example why you need adjustable guide plates, this rocker if left too run off center like this, on the valve stem tip , will quickly destroy the valve guide and rocker

theres a good deal of useful info in this article

http://www.customclassictrucks.com/tech ... index.html

Aluminum does have advantages, like light weight, and easy of machining compared to cast iron, example,cracks in valve seats on iron heads ",usually the result of overheating,"tend to result in coolant leaks that are not easily repaired, so you need a new cylinder head even if you had hundreds of dollars in port work done previously.

but on aluminum heads a bit of tig welding and machining for new valve seats repairs the heads rather easily

heads might need to be milled to make then strait

it should be noted that if the rocker stud protrudes into the port it should be trimmed to the port roof as any threads sticking down into the runner disrupt flow and don,t supply extra support to the rocker stud,and stud threads should use loc-tite tread sealant.

The valveguides for the Vortec heads are the same as all other small-block cylinder heads, but the Vortec heads come equipped with large valveguide seals.

The valveguide seals keep oil from running down both the valve stem and valveguide, and entering the combustion chamber through the intake port at high-engine vacuum and the exhaust port when the engine is not running. This cuts down on engine smoke and exhaust emissions.

This is the valvespring retainer installed without the valvespring. The maximum amount of valve lift that the Vortec head will tolerate is the distance between the bottom of the retainer and the top of the valveguide seal.

BE aware you need to verify rocker adjustment lock nut to rocker slot clearance and yes it varies even with the same manufacturers different rocker designs

keep in mind the cam lobe ramp acceleration and valve spring load rates.

as any decent mechanic will tell you, you need to finish a race to win it and having a car that constantly breaks parts won,t be fun, and gets darn expensive very rapidly

if your valve train won,t remain stable and under control consistently and handle the stress at the cams intended max rpm, (plus a bit more) your almost sure to have low durability, lots of valve train wear and parts breakage!

lets say your comparing two similar cam,s with listed specs

ones got 215 duration with .450 lift,

the others got 215 duration with 510 lift

Id bet 90% of the guys reading that figure.....hey I get more lift with the second cam, thats obviously going to improve air flow & potential power, so thats the route to take....WRONG!!!

with flat tappet cams, if you exceed a certain lobe acceleration angle you tend to develop valve control and wear issues rather rapidly , mostly because the valve spring load rate required to maintain lifter to cam lobe contact at higher rpm ranges, potentially causes extremely high contact pressures between the two moving surfaces.

SPEND $10 and get a calculator ,in this hobby its a darn useful tool

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .50 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

ones got 215 duration with .450 lift,215/450=.47.7%

the others got 215 duration with 510 lift/215/500=43%

one factor I will mention is that each manufacturer tends to look at durability, ramp speeds and max lifter acceleration very differently, one reason I tend to prefer CRANE & CROWER is that they both company's in general realize the engine must finish the race to win and a busted valve train is a HUGE problem,they both realize, and design valve train components and cam lobes with DURABILITY and reliable valve control as top priority,s that are far more important than squeezing every possible potential HP from a cam lobe design at the expense of long term durability

http://garage.grumpysperformance.com/index.php?threads/cam-lobe-aceleration-rates.2627/#post-6777

http://garage.grumpysperformance.co...s-on-valve-spring-pressures.10268/#post-41364

http://garage.grumpysperformance.co...-rocker-ratio-help-your-combo.2632/#post-6790

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46737

The maximum amount of valve lift before the spring retainer hits the valve guide seal is 0.530 inches. It is generally accepted that 0.060 inches clearance needs to be maintained between the retainer and seal (0.530 - 0.060 = 0.470 maximum valve lift). The Vortec heads, as they come with the large valve guide seals, are only capable of accepting a camshaft with a maximum valve lift of 0.470 inches.

All small-block cylinder heads built before the '96 Vortec heads had two grooves on the valve stems.

The second groove accepts a quad ring. It sits just below the split lock retainers. The O-ring keeps the oil, which lubricates the rocker arm/valve stem tip, from running down the valve stem and into the valve guide.

Small Block Vortec Cylinder Heads Specifications - Heads Up!

The O-ring must be accompanied by a tin shield over the outside of the valve spring (left). The tin shield keeps excess oil from splashing on the valve stem and valve guide. The tin shield and O-ring must be used together to be effective. Installing the earlier double-groove valves, an O-ring, and a tin shield will allow the Vortec heads to use camshafts with 0.500 inches of valve lift, without machining the valve guides lower for clearance. View Related Article

Attachments

Last edited by a moderator: