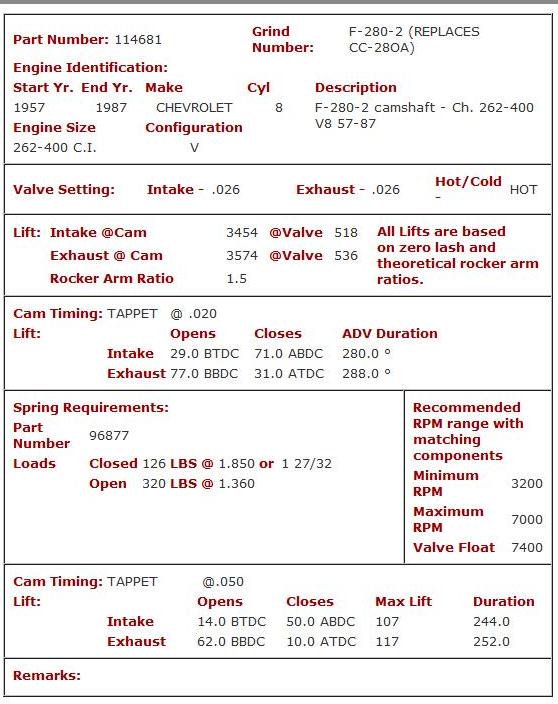

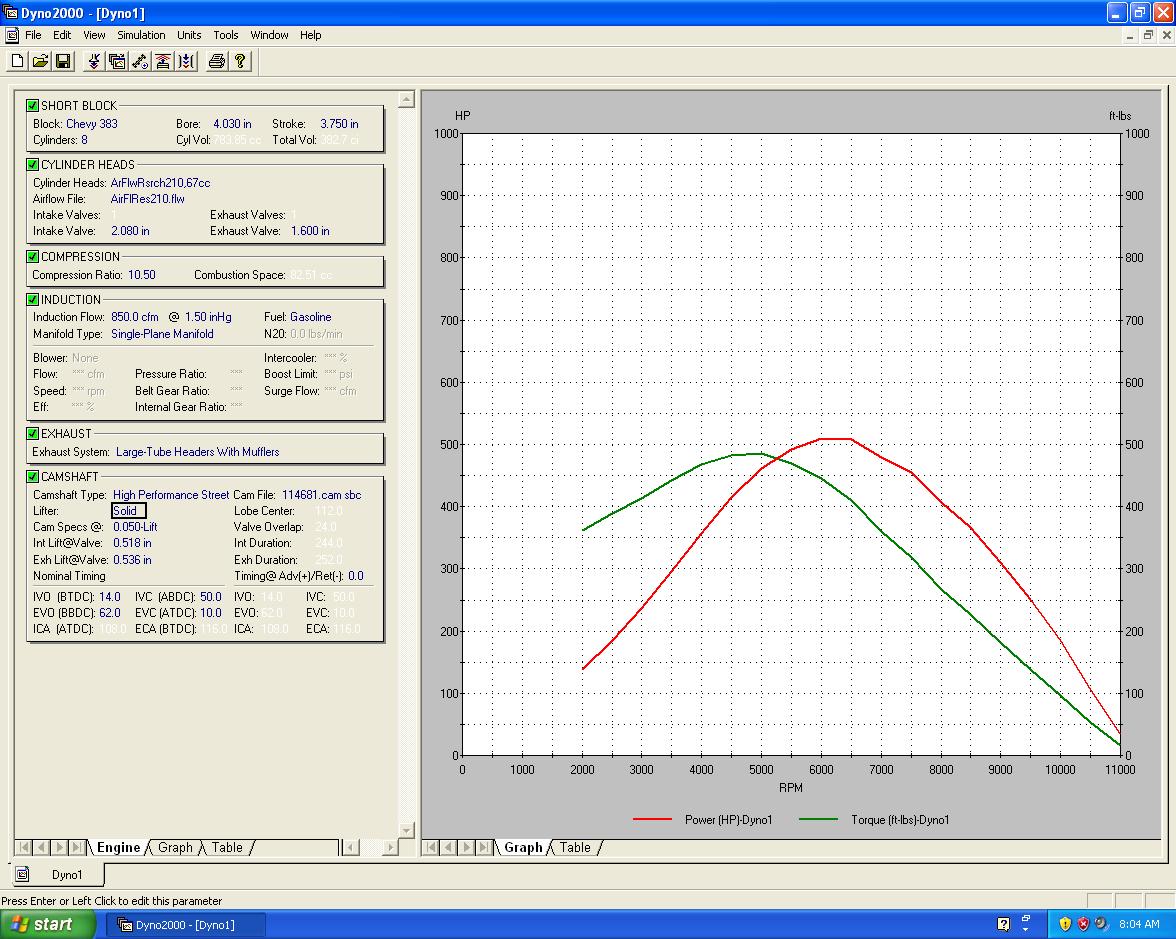

you can start with this, the SIX cam manufacturers POSTED OR LINKED BELOW that have proven to be dependable, the soft ware below might prove useful, so use it to get a base line

INFO YOU NEED IF YOUR selecting the correct cam for YOUR combo

FIRST!!>>>>>>ANY AND ALL CAM MANUFACTURERS WILL need more info than the common, request for....

"I want a LUMPY IDLE SOUND and a FASTER CAR, whats the best cam... so it sure helps if you have as much valid info about your car handy as you can "

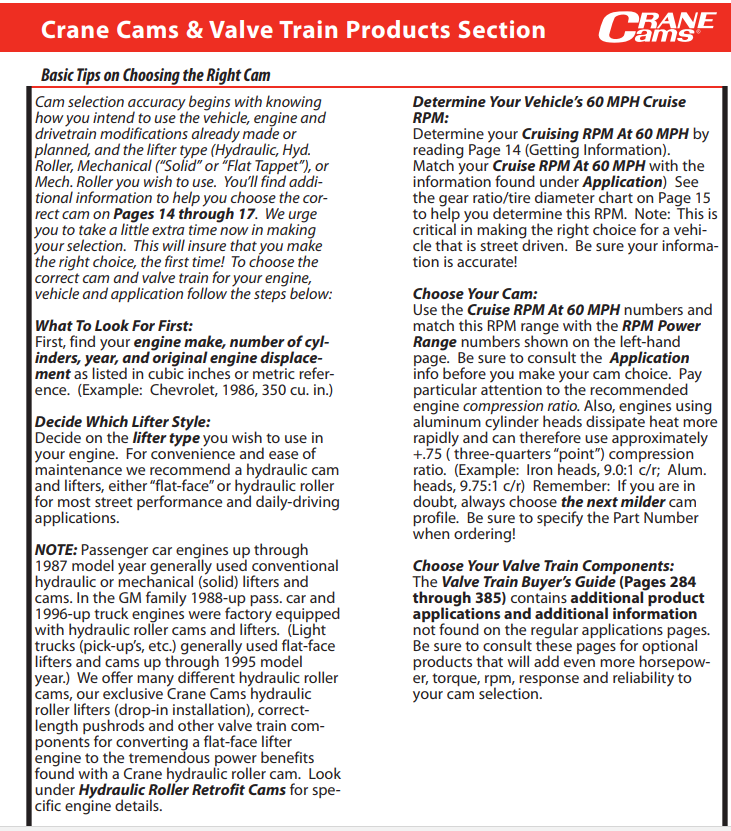

crane (386)310-4875

crower 619.661.6477

https://www.crower.com/camshafts.html?cat=854

erson 800-641-7920

http://www.pbm-erson.com/UserFiles/Documents/Catalogs/2013 erson catalog.pdf

lunati..662-892-1500

http://www.lunatipower.com/Performance-Cams.aspx

ISKY 323.770.0930

clay smith 714-523-0530

herbert cams 714-491 -2267

mgispeedware.com

mgispeedware.com

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator1.htm

FREE cam selection software

(while it may get you roughly in the ball park as far as duration, its not especially accurate in my opinion)

http://www.camquest.com/

http://www.popularhotrodding.com/tech/0 ... ewall.html

http://garage.grumpysperformance.co...ing-camshaft-for-specific-applications.10162/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

there are quite useful ,cam selection soft ware programs that get you in the ball park, but the final selection is based on far more factors than most of those software programs address, so I would not trust these cheap software programs to be fairly accurate in most cases

http://www.camquest.com/

write a list of all factors that will influence the cam selection choice, CALL AT LEAST 6-9 DIFFERENT CAM MANUFACTURERS, 7-9 WILL BE EVEN BETTER!, ask about warrantee, and billet quality and options like extra hardened, or polished billets or better quality lifters, youll tend to get the quality level you pay for, so don,t expect supper bargains on top quality components, and it makes little sense to save $100 on the total cost if youll have to pull the engine apart later and replace a worn or broken component

DON,T LIE tell them EXACTLY what you expect and what you have currently ,installed,

and that the cam must work with NOW, NOT what you intend to install later.

DO NOT DISCUSS IN ANY WAY WHAT ANY OTHER MANUFACTURER SUGGESTED,

OR THAT YOU'VE EVEN TALKED TO ANY OTHER MANUFACTURER

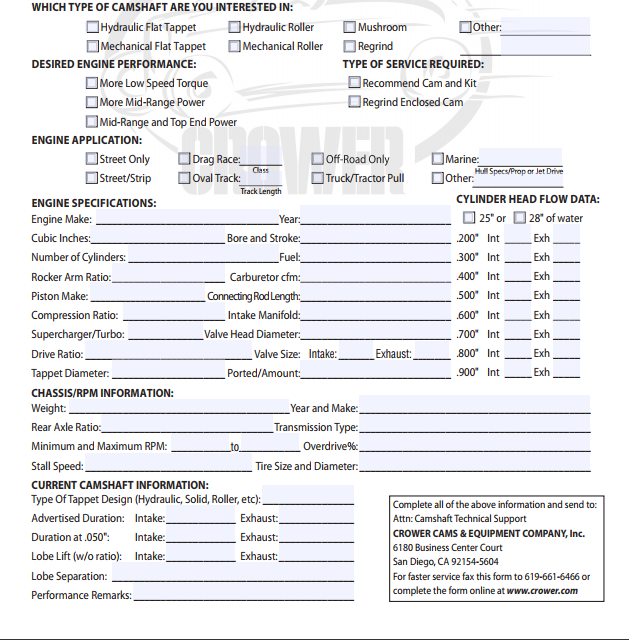

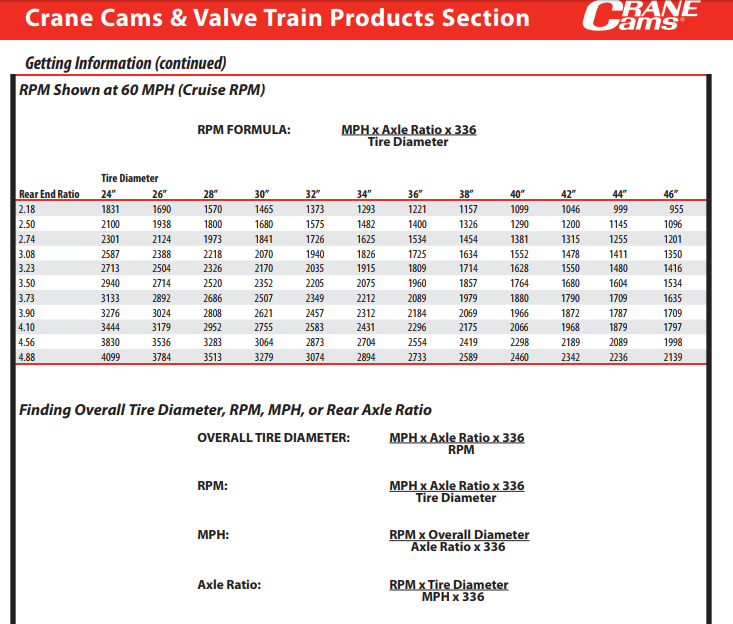

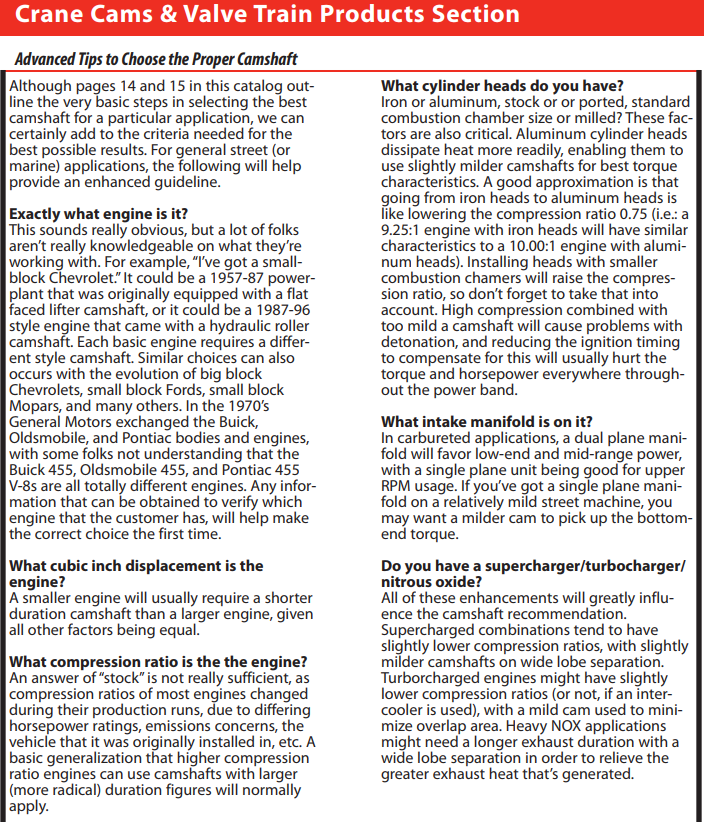

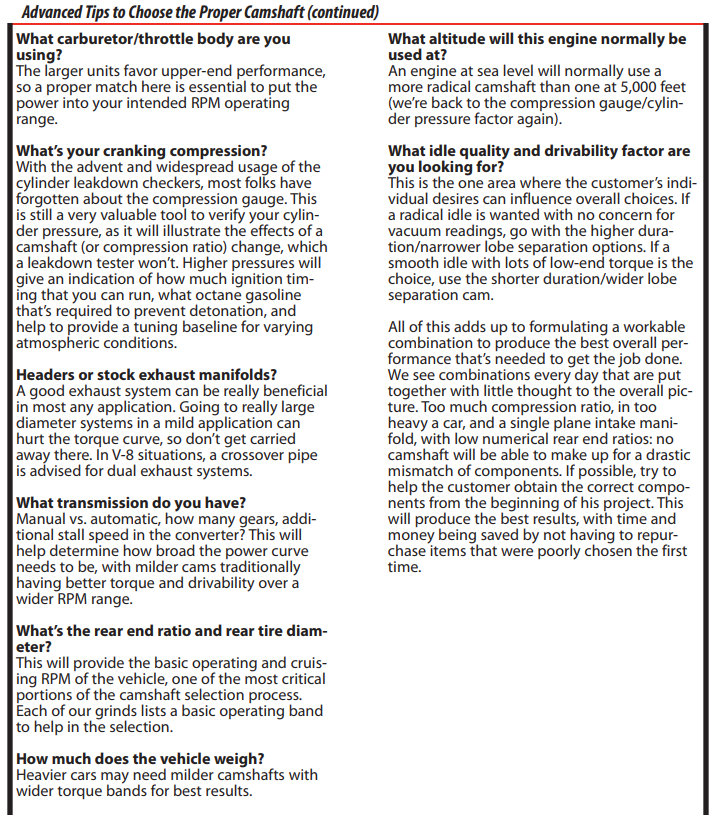

YES you NEED too KNOW your COMPRESSION RATIO, and all the other answers to the questions below BEFORE calling....knowing a few more things, than your want a lope in the engines idle and you want a fast car when your done, about your combo , like your static compression ratio, displacement, cylinder heads used, rocker ratio, max valve spring clearance, or coil bind, height, spring load rates, carb,size, if its a vacuum or manual secondary carb, intake manifold,(single or dual plane,) headers, dimensions, your car weight, tire diam., do you need to pass emission testing? are you racing the car or is it daily transportation,etc would sure help, in the cam selection process??

on the street youll almost always find that the lower duration cam in the choice between two similar cams will in the long term be a slightly more useful choice.

(the simple reason why is that most street cars spend the vast majority of the time operating well below 4500-5000 rpm, and lower and mid rpm torque not peak hp is used far more often) it hardly makes sense to build any engine to produce its peak power in the rpm range you,ll rarely use. and the extra duration will generally reduce the low and mid rpm torque you use the vast majority of the time, in exchange for a bit more peak power you'll rarely access.

selecting a cam without knowing those factors, is rather like marrying a girl based only on the color of her hair brush, you might make a good match but the odds say your dreaming

tell them your

car weigh?

rear gear ratio?

tire diam.

trans and gear ratios?

stall speed if its an auto?

displacement?

quench distance, head gasket thickness

COMPRESSION RATIO

HEADS (flow numbers)(lift restrictions)

intake type

tire size

intended use

max rpms

launch rpms

MIMIMUM IDLE

fuel octane

carbs,mpfi? CFM

ETC.

knowing a few more things, than your want a lope in the engines idle and you want a fast car when your done, about your combo , like your static compression ratio, displacement, cylinder heads used, rocker ratio, max valve spring clearance, or coil bind, height, spring load rates, carb,size, if its a vacuum or manual secondary carb, intake manifold,(single or dual plane,) headers, dimensions, your car weight, tire diam., do you need to pass emission testing? are you racing the car or is it daily transportation,etc would sure help??

selecting a cam without knowing those factors is rather like marrying a girl based on the color of her hair brush, you might make a good match but the odds say your dreaming

don,t be afraid to ask for suggestions on how to improve the combo and ask if in their opinion your ignoring some factor, that cold help improve the engine, or doing something wrong

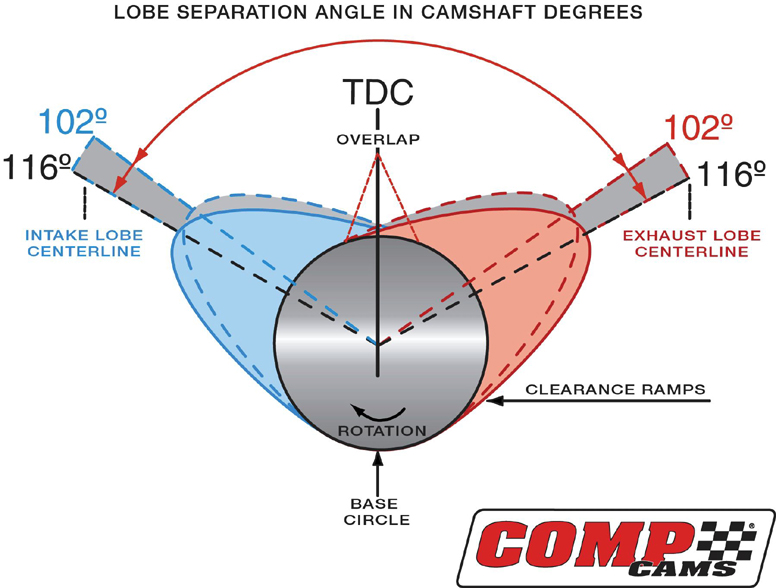

AVERAGE the RESULTS FROM EACH manufacturers suggestion,as to lift, duration and LCA and buy the cam thats the closest match to that average

www.motortrend.com

after talking to each tech from each company

www.motortrend.com

after talking to each tech from each company

write down EACH CAM MANUFACTURERS , recommended cam type,

its lift, and duration at .050 and LCA.

REMEMBER!

if you have a problem with a component or need info on how to test or install a part or want to purchase a part and need details or choices explained in detail..

have you ever called some company and talked to some sales guy that was rather obviously reading the info off the catalog page about the part you wanted info on,

theres going to be 99 times out of 100 some guy answering the phone that is not an engineer or some guy that fully understands the way the product is made,

potentially being used or has any concept about its stress dimensions or operational conditions.

that does not necessarily mean the guys in the tech department , sales department or manufacturing departments are all totally clueless,

there are generally a few people in any company that really know all the details and are fully experienced,

those peoples time is worth far more to the company than the typical minimum wage zombie answering the incoming call traffic.

if you have a question,

start the call by asking the guy answering the call for his first and last name, always be polite, never waste the guys time

write it down

now you may or may not ever want to talk to this guy again, but its will at least tend to make them think hard about treating you like an idiot, or slamming the phone down,

or disconnecting you if they don,t want to answer questions.

\address the guy by his NAME several times, during the conversation, and ask his function in the company.

if he can,t answer your question ask if they have an engineer or more tech savvy guy you can talk too...

start the call by asking the guy answering the call for his first and last name,

and direct phone extension number if you can.always be polite, never waste the guys time

write it down address the guy by his NAME several times, during the conversation,

that way you can in the future bye-pass the answering desk zombies if you can build a friendly conversation,

but don,t waste the guys time and be sure you thank him by name at the conclusion of any conversation if he helps you.

keep a note book with company names phone numbers and the skilled tech guys as a future reference,

and remember the guys answering the incoming calls are rarely knowledgeable or even give a crap about the company..

that does not indicate the guys in engineering that know how things actually are made and function are anywhere near as useless as the phone desk guys.

its simply a fact that, a company can produce quality parts but have hired some real clowns to answer phones

read the data and average it off the list to each manufactures tech guys,once you have 6-7 to average

but DON,T DISCUSS IN ANY WAY WHAT OTHER MANUFACTURERS SUGGESTED

with the other tech guys or even hint you talked with anyone else simply give them the basic info and let them talk, don,t interrupt or ask questions that indicate you talked to other companys as thats sure to sway the average end result.

AVERAGE THE RESULTING LIFT DURATION and LCA info from each cam, and buy the cam that's CLOSEST TOO THAT AVERAGE, (ALL the MAJOR MANUFACTURERS HAVE DECENT CAMS) this tends to give consistently good results

http://www.cranecams.com/userfiles/PP08 ... ePages.pdf

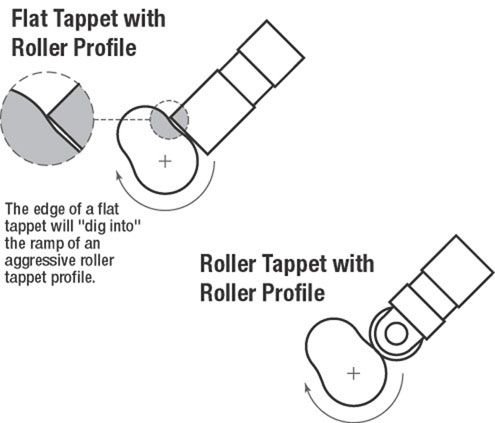

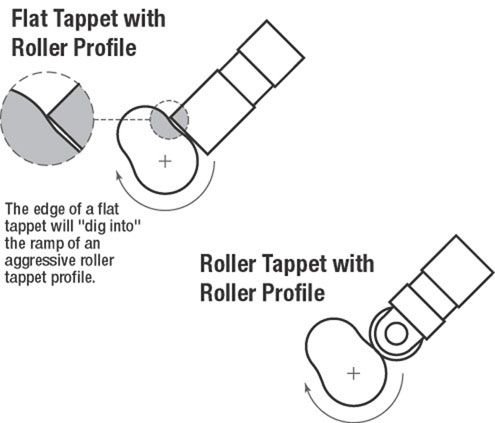

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

and the linked chart info, use both as a base line, but remember to call at least 5-7 cam company's and 7-9 would be even better as it virtually eliminates the chances of some moron giving you bad info, that will screw up your cam selection

generally its best to purchase all the listed components in a cam installation kit (cam, lifters,valve springs, etc. ) from a single manufacturer as mixing parts, sources or brands,

allows the cam manufacturer to void the warranty, even if the parts in the kit they sell are either identical or inferior to,

the individually purchased components you individually sourced. keep in mind most manufacturers will have tested parts compatibility ,

so they are reasonably sure the components they sell in the kit will work, that can,t be always assumed,

with randomly matched parts even if those parts are good quality.

and if you call many cam companies the tech guy you'll talk to will simply asked questions so he can fill in blanks on software programs, because he may not know squat about the type of engine your building, and they darn sure have no way to check your engines clearances or valve train geometry, so thats up to YOU to get THAT correctly done!

keep in mind a cams main function is control of valve timing and lift, valve timing and lift control airflow thru the cylinder head ports,intake, and exhaust system and the displacement and compression ratio,,needs to be a factor in your calculations, then theres clearance issues ,in the valve train,that need to be addressed, and compression and the restrictions to flow in BOTH the intake tract and exhaust system need to be used in your cam selection calculations, one very common mistake, is over camming a combo, or not verifying clearances, this almost always reduces potential power and frequently results in parts breakage

DO NOT UNDER ANY CIRCUMSTANCES DISCUSS ANYTHING A DIFFERENT CAM COMPANYS TECH GUYS SAID WITH EACH OTHER CAM MANUFACTURERS TECH GUYS IT WILL ONLY SCREW UP YOUR RESULTS

heres free cam selection software to narrow your choices

just for grins put your info into this program, and don,t lie, and see what cam it suggests

http://www.camquest.com/

http://www.compcams.com/Pages/409/camquest-6.aspx

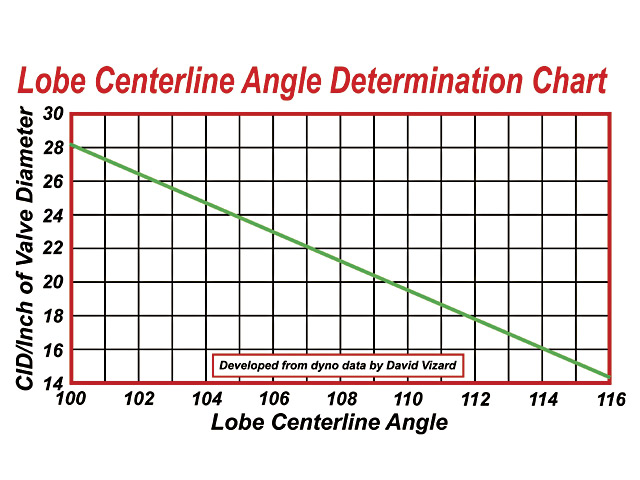

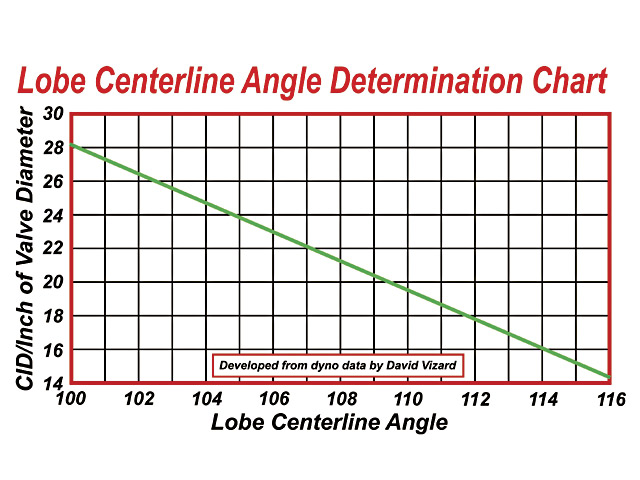

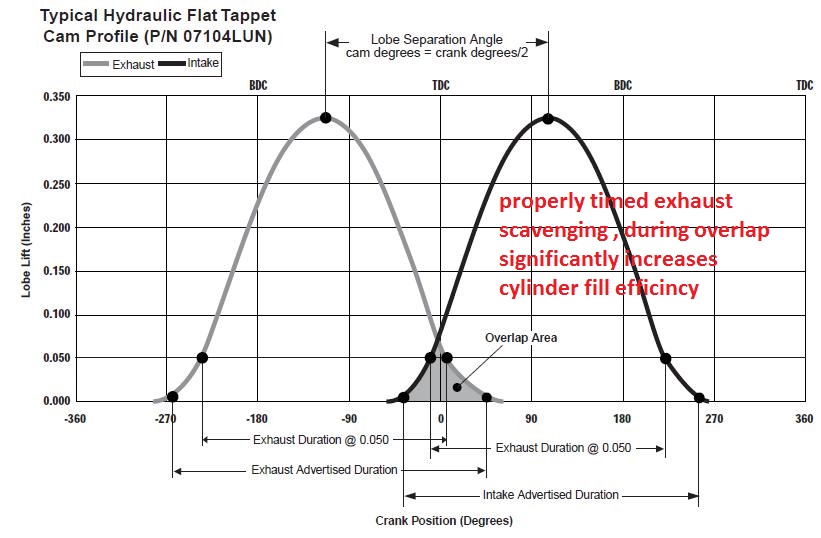

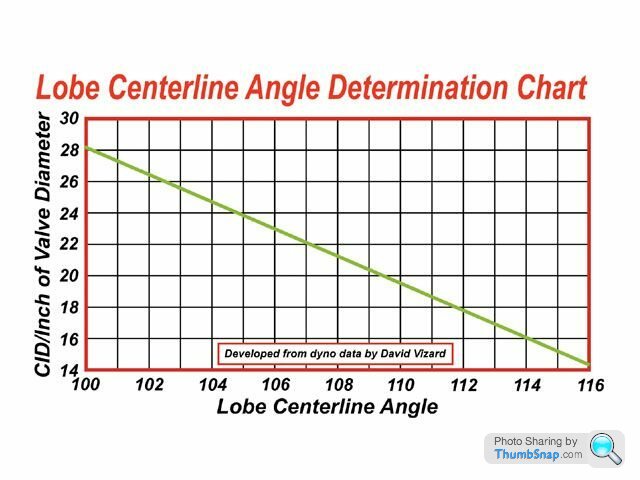

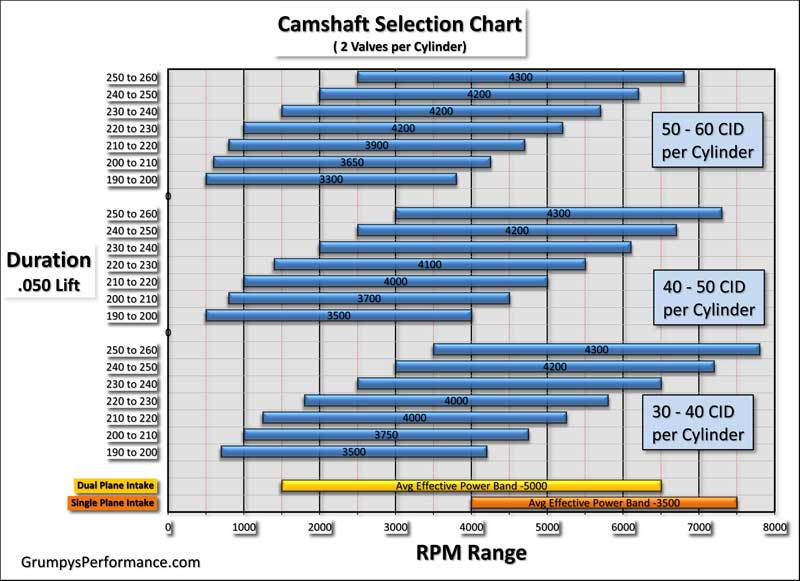

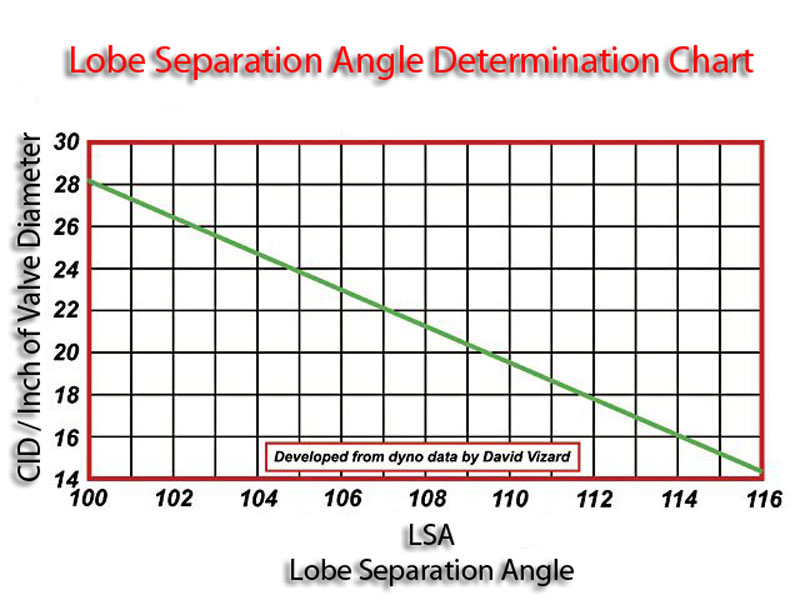

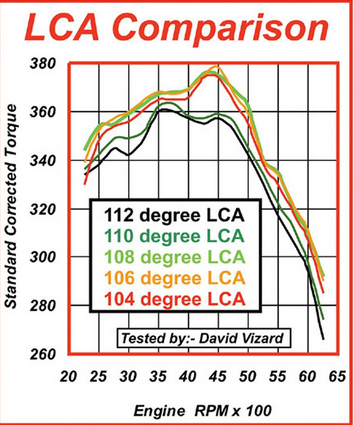

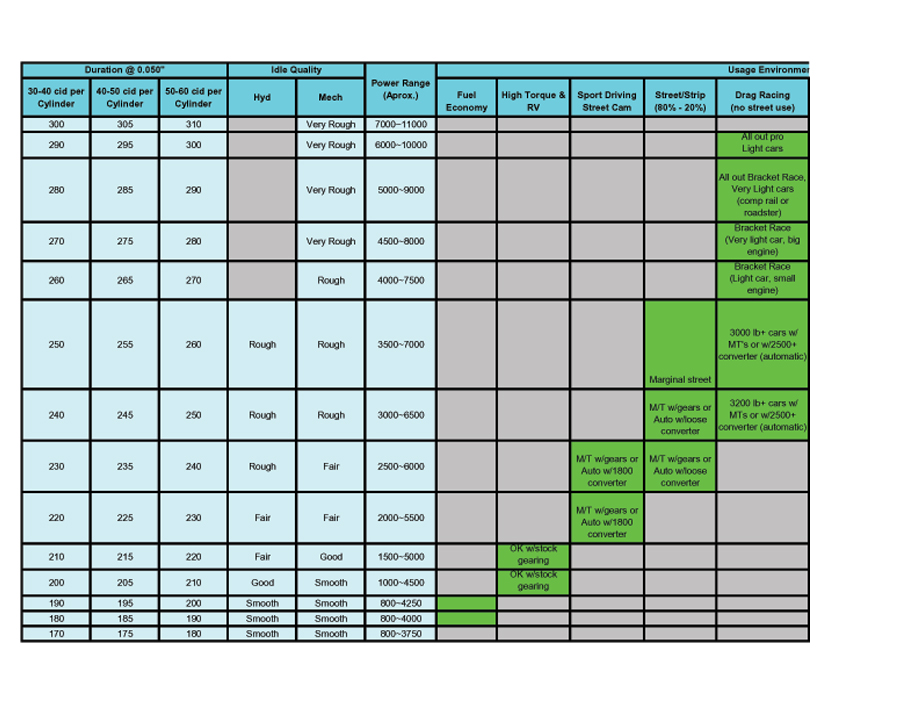

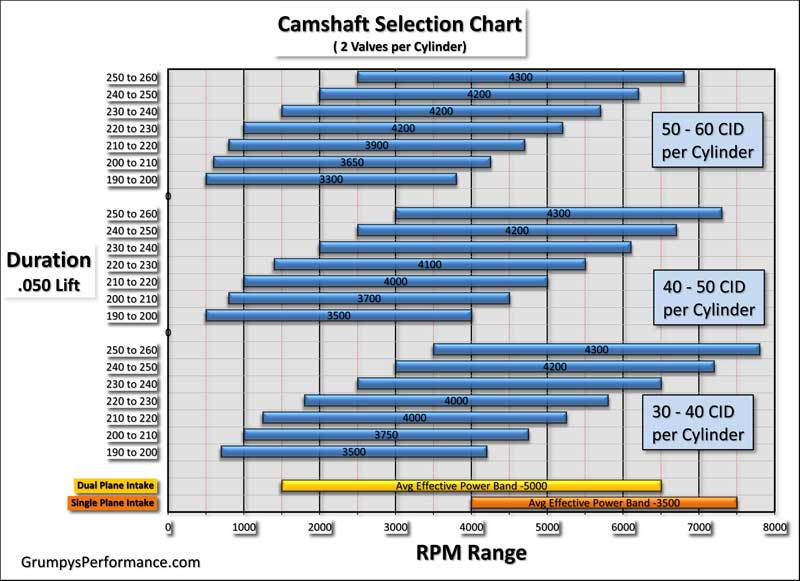

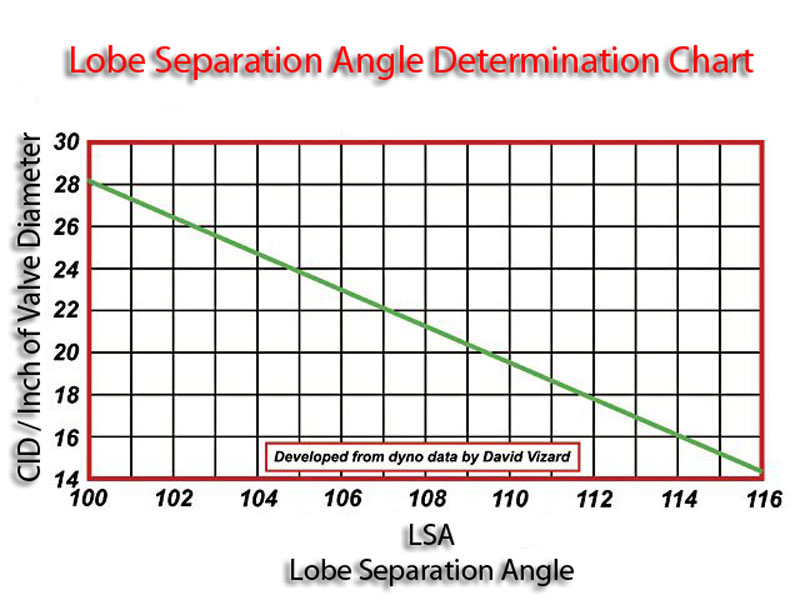

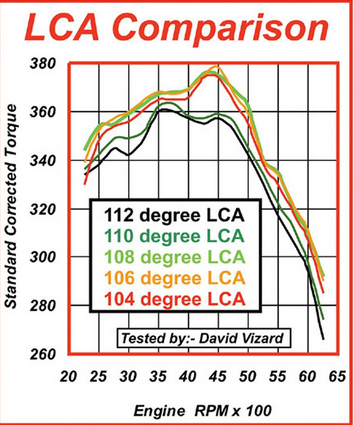

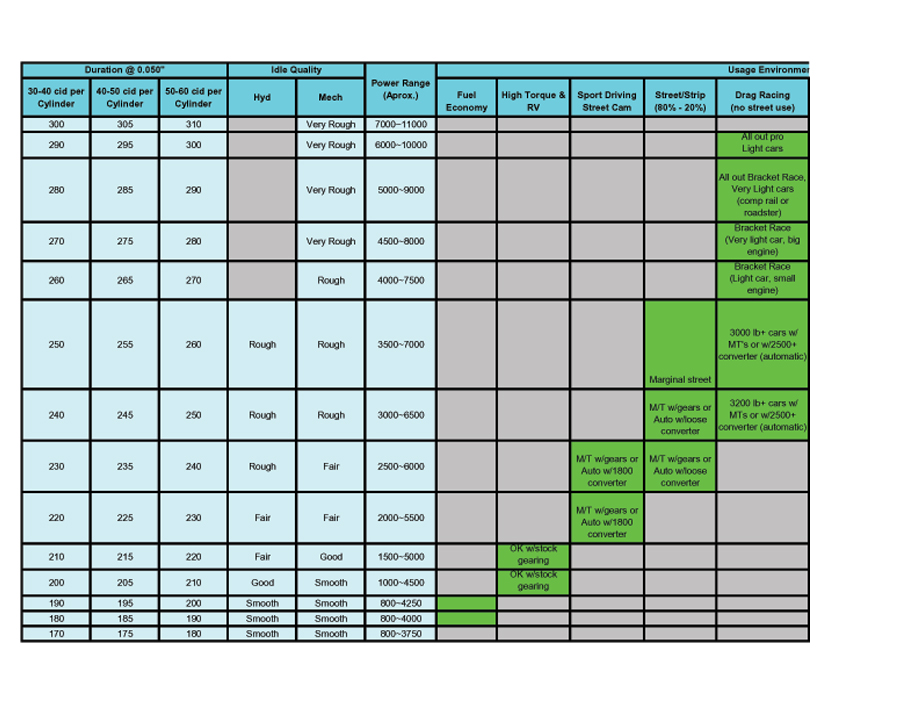

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

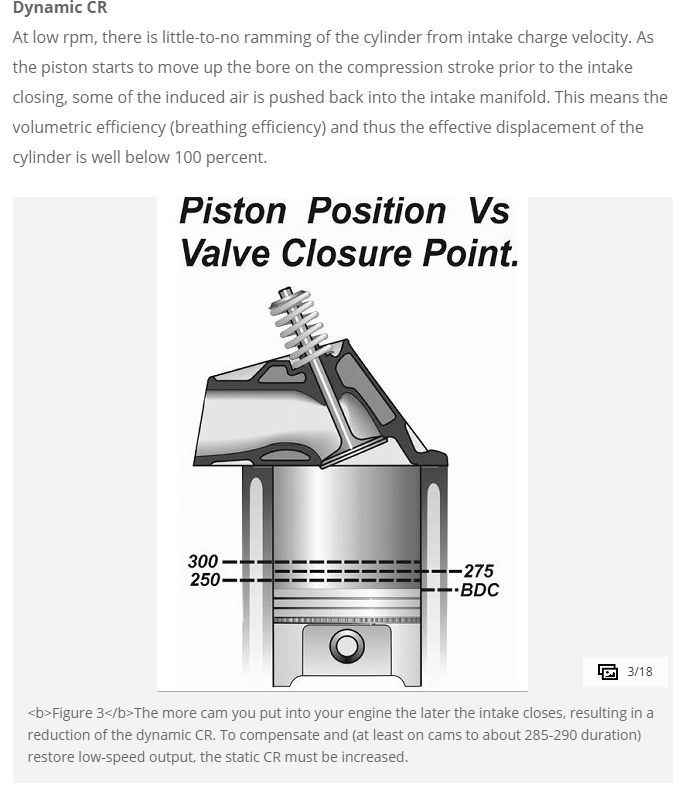

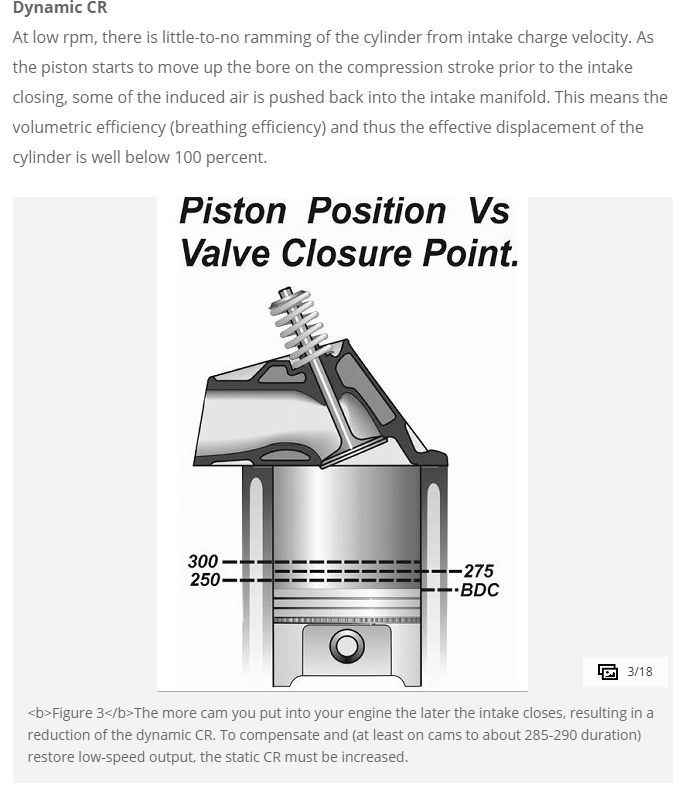

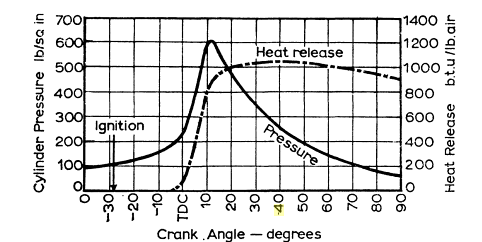

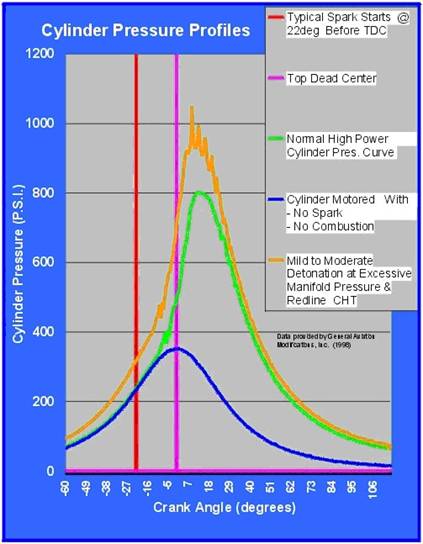

Ive built enough engines that I think I can post a bit of info regarding the effect of the need to consider dynamic compression, in the engine planing

fact

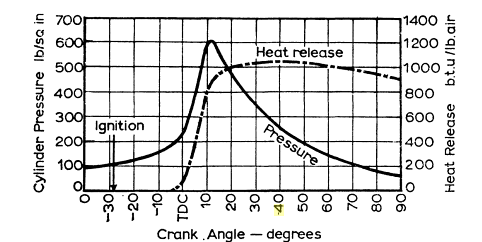

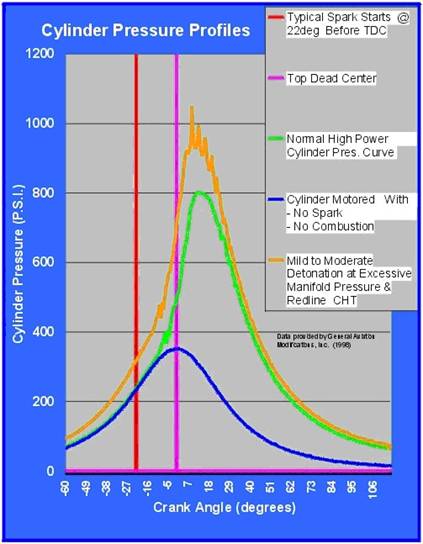

usable torque the engine produces tends to go up as cylinder pressure increases

fact

your fuels OCTANE LEVEL LIMITATIONS, or tolerance, to heat & rapid compression before you tend to get into potential detonation,from the fuel igniting from rapidly induced heat and compression, issues limits the effective useful compression.

fact

uncontrolled detonation will rather quickly damage pistons and rings

fact

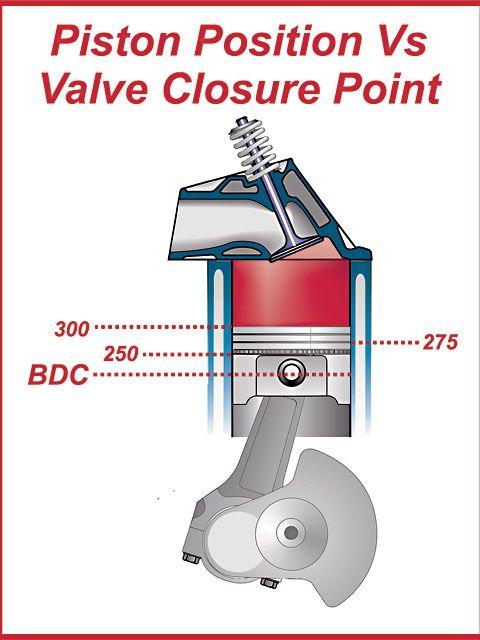

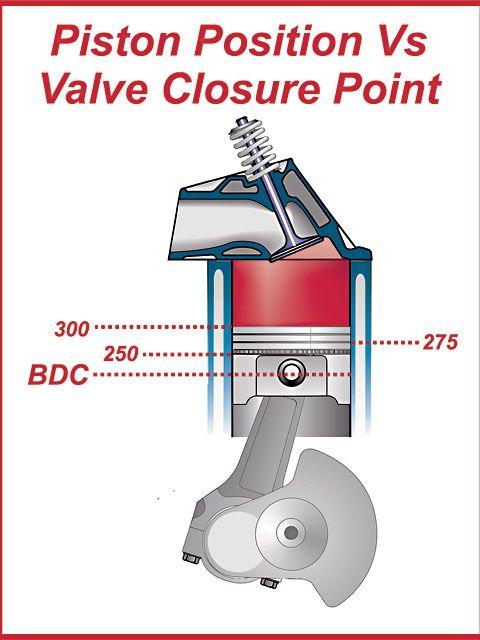

cylinder pressure is greatly influenced by the cylinders,displacement, and valve timing as well as the static compression ratio

fact

on a N/A engine you'll rarely if ever exceed the static compression, with the effective dynamic compression, but you can markedly reduce it with cam timing changes, that delay the valves closing as the piston compresses the cylinder volume.

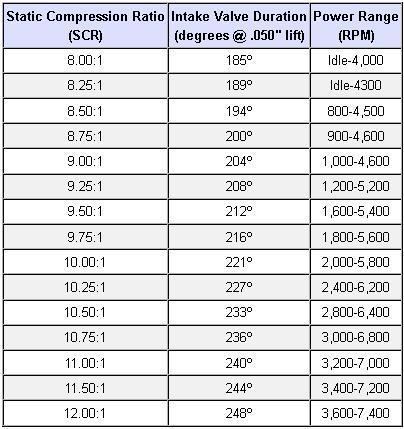

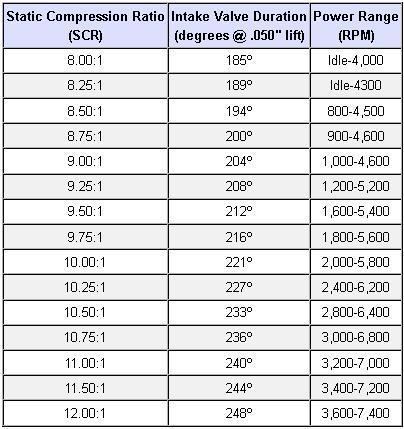

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

software like the free comp cams software below[/color]

[/size]

http://garage.grumpysperformance.co...mbers-or-a-good-street-combo-your-after.5078/

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.hotrod.com/how-to/engine/113 ... -camshaft/

http://www.superchevy.com/how-to/49224- ... gine-cams/

http://www.superchevy.com/how-to/148-04 ... m#cxrecs_s

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://garage.grumpysperformance.co...s-and-a-few-similar-aftermarket.133/#post-163

http://www.superchevy.com/how-to/engine ... t#cxrecs_s

http://www.superchevy.com/how-to/148-03 ... t#cxrecs_s

http://www.compcams.com/Camquest/default.asp

but its almost always a good idea to get info from at least 6-7 sources, because you need to compensate for the occasional bad bits of info,

its not all that hard to calculate ,approximately the most efficient cam lift, duration, and LSA of a cam in an engine, if you know the cars tire diam. car weight, drive train gear ratios, engine compression displacement, head flow numbers,port cross sectional area, valve size, and a dozen other factors, its just that very few people that even understand what they need to look at and how each factor effects the combo,take the time and effort to do so , even the cam company Techs rarely bother, to factor in all the related components, but if you were to call lets say 7 cam companies and lets just as an example say that these were the suggested cams,

READ THESE LINK s

USE THIS SOFTWARE TOOL

http://www.compcams.com/Camquest/default.asp

lets just say you got THESE HYPOTHETICAL EXAMPLES as suggested cams

(1) 245 /245 dur 106 lsa

(2) 255/260 dur 108 LSA

(3)252/258 dur 110 lsa

(4) 260/267 dur 112 lsa

(5) 246/249 dur 112 lsa

(6)250./250 dur 110 lsa

(7) 260/270 dur 106 lsa

your average would be

253/257 dur 109 .618/.630 , so you could reasonably assume that you would be very close to correct if you selected a cam with close to those specs, cam #(3) IN THIS CASE COMES CLOSE but look at the range, suggested 245 all the way to 260 , intake duration and 106-112 LSA ,thats fully 15 degrees spread in intake duration and 6 degrees in LSA, is it any wonder that most guys have a problem selecting cams when theres that much latitude in even what the cam tech guys suggest, let alone the guys on the internet who may be far less knowledgeable and just suggesting what they read worked in some magazine article on an engine that was only slightly similar designed for a car and drive train that bore little resemblance to your current application, thats why I always suggest getting a few cam company tech guys input, and by averaging the results you can effectively find and easily see , the OFF THE WALL SUGGESTIONS, and YES , RARELY SOME TECH SUPPORT GUYS SEEM TO BE CLUELESS MORONS

IVE had best results sticking with CRANE,CROWER, and ERSON generally

given a choice between two similar cams for a street car, selecting the lower duration, wider LSA and LOWER lift generally produces a better more durable combo for a daily driver car engine, or put a different way trading increased durability and lower stress over a bit more peak horsepower is rarely a bad idea if your dependent on the car for transportation

read the links below as they hold a great deal more important info [/color]

http://www.compcams.com/Community/Artic ... 2026144213

http://www.aa1car.com/library/camshafts.htm

http://www.aera.org/ep/downloads/ep1/EP012008_34-40.pdf

http://www.hotrod.com/techarticles/113_ ... index.html

read thru these linked threads, as they will prove very useful

posting.php?mode=edit&f=52&p=189

http://www.crankshaftcoalition.com/wiki ... patibility

http://www.crankshaftcoalition.com/wiki ... ationships

look you may not want too hear this but...IF YOU FOLLOW the advice BELOW EXACTLY, you'll have a decent cam, ignore it and your very likely to find you've selected a cam that won,t run correctly in YOUR APPLICATION

heres a semi-fool proof method

THERE'S A GOOD DEAL MORE INFO, and several sources for cams IN THE Links BELOW

http://www.aa1car.com/library/camshafts.htm

http://www.compcams.com/Technical/FAQ/C ... stions.asp

http://www.camcraft-cams.com/index.php? ... ting-a-cam

http://www.chevyhiperformance.com/techa ... index.html

http://www.cranecams.com/?show=faq&id=2

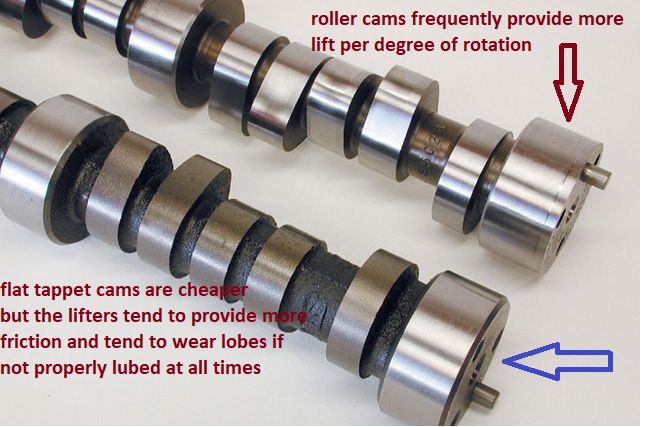

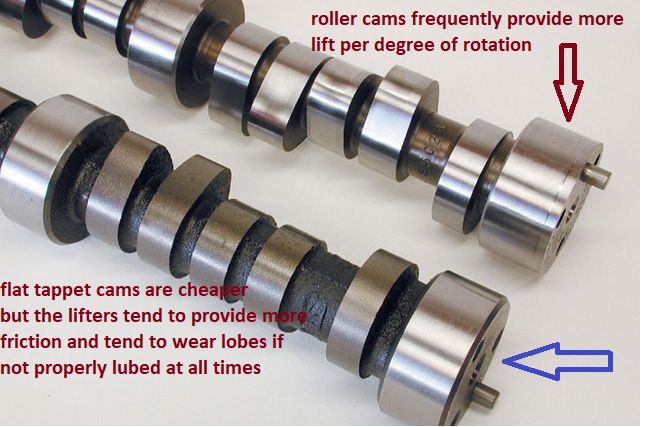

keep in mind solid lifters generally have an rpm advantage and roller cams generally out perform flat tappet designs but cost more

http://www.crower.com/

http://www.cranecams.com/

http://www.pbm-erson.com/UserFiles/Documents/Erson_Tech/Erson-custom-cams-tech.pdf

http://www.mr-gasket.com/pdf/Chevrolet.pdf

http://www.lunaticams.com/

http://www.chetherbert.com/newchet.html

http://www.howardscams.com/index-2.html

http://www.iskycams.com/

http://www.reedcams.com/

http://www.schneidercams.com/cams/20.htm

http://www.lazercams.com/CamTables.html

http://www.bulletcams.com/BulletCatalog.htm

http://www.englecams.com/

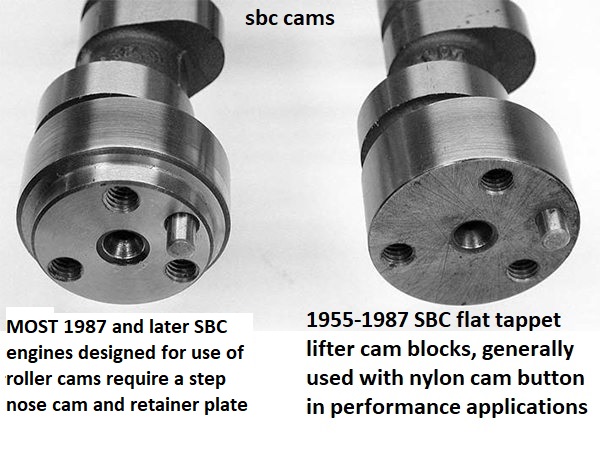

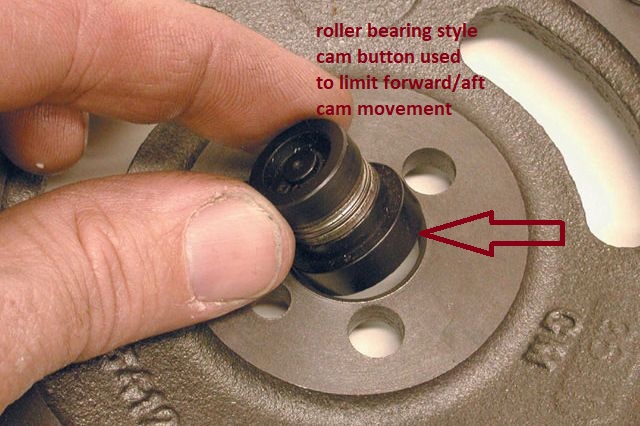

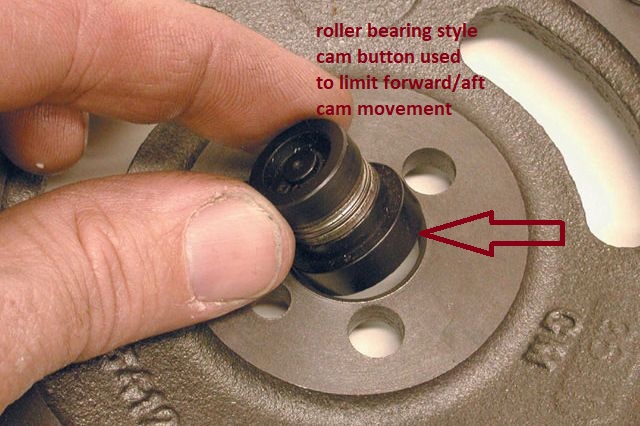

you should also keep in mind that a roller cam valve train with the same lift and duration can provide a good deal more port flow and resulting power.

but even roller cams can wipe out lobes if the valve train components or valve train lubrication,and geometry is not set up correctly

READ THE LINKED INFO CAREFULLY

http://garage.grumpysperformance.co...ped-nose-cam-in-early-block.14182/#post-71937

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-street-roller-cam-selection.5709/#post-46850

http://garage.grumpysperformance.co...a-better-cam-to-a-zz3-350-sbc.182/#post-26013

NO! ONE SIZE LARGER WON,T GENERALLY WORK BETTER, IN FACT ITS FAR MORE LIKELY TO BE A HUGE P.I.T.A to DRIVE AND HURT PERFORMANCE .

If your re-building a known combo,the questions that really should be asked here......

were you completely happy with the old cam or did you feel you wanted more upper or lower rpm band torque, did you like the way the engine ran, or did you feel it needed some tweaking?.....

what would you have liked to be changed about the power band when the old grind was in use?

BTW are you aware that reducing cams lift and valve spring load rates /pressures, and the degree of the aggressive cam ramp acceleration tends to increase durability in valve train components? yes it may cost you some hp, but it may be a good trade for increased durability

its critical that the converter stall speed and rear gear ratio match the cam timing and compression ratio if its an AUTO TRANSMISSION,......

MORE than if you have a manual trans, which is far more flexible as to what it will function with.

but having the rear gear ratio and compression ratio match the cam is mandatory for good results

and the larger the displacement and the better the heads flow the more likely it is that you'll find both good low rpm tq and mid to upper rpm hp you'll want in a street/strip combo, Ive seen many bad combos put together due to selecting a cam based on, the flawed logic

(well my buddies running cam (X) his car runs good...and I want to beat him so ILL buy the NEXT more aggressive cam with just a bit more duration and outrun him)

in most cases you'll be far better off, researching and selecting a combo with better cylinder heads, intake flow rates and larger displacement, rather than trying to go with a wilder cam.

remember your rarely going to make a huge improvement in hp per cubic inch with cam upgrades once you've reached about 1.25 hp per cubic inch displacement, but increasing the displacement, compression ratio and DISPLACEMENT tends to give a good boost over similar combos with lower displacement/cpr and head flow rates

if a 350 with 9.5:1 cpr that makes 1.25 hp per cubic inch that's 437 hp

build a similar stroker combo that has 401 cubic inches and 10.5:1 cpr and your far more likely to have about 520hp based on similar components

(the same 1.25 hp per cubic inch plus .04 increased tq due to the higher cpr and increased stroke ) plus all that at a slightly LOWER rpm that's easier on the valve train stress.

you might want to remember that a restrictive exhaust will kill much of the power potential, so decent TUNED headers and a low restriction exhaust is a necessary part of any build, and unless you can maintain the correct fuel/air ratio you can,t make good hp, so matching the fuel delivery and injector size to the applications mandatory.

keep in mind a" LAZY " cam, might be far better for low wear and increased durability,

engineers that design a cam and valve train, need to know whats expected,

any cam may be significantly easier on the valve train and durability may be greatly enhanced or extended or peak power might be the goal,

minor changes can have very significant effects on durability without changing power very much,

both CRANE AND CROWER are rather well known of tending too design cams that might sacrifice a couple peak horsepower,

if it required to significantly boost long term durability and reducer the chances of valve train stress levels,

some other company's have a few cam lobe designs that are right at or even at times in some rpm ranges a bit past the limits,

of what most builders might see as reasonable for longer term durability,

they seem more concerned with being able to produce the best possible peak power,

even if doing so might reduce the engines longer term life expectancy.

a cam designed for drag racing that might be expected to make peak power for less than 15 seconds at a time will be a great deal different than one in an engine designed to run the 24 hour race at le-mans even if both cars ran in a car with a similar engine family, and certainly both would be designed far differently than a cam designed to run issue free for 100K miles

a difference in philosophy ,

one group thinks you have to finish the race to win,

most guys don,t have unlimited cash so lets design something that will last a long time without issues!

the other group thinks, youll never win unless your making the most power available,

and race engines get torn down , inspected and re-built regularly so push the limits

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

http://www.digitalcorvettes.com/forums/showthread.php?t=39010

http://www.compcams.com/Camquest/default.asp

comp cams is now offering a free cam selection software,THIS IS A USEFUL TOOL, this is useful in seeing the lift/duration/LCA they suggest for your application, in most cases they get fairly close so its a tool thats useful, now you don,t necessarily need to buy a COMP CAM but a cam with a similar lift/duration/LCA from your favorite manufacturer probably should be fairly close to whats recommended

willing to spend a few bucks ,want far more detailed results and a program requireing FAR more detailed input??

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.wallaceracing.com/dynamic-cr.php

http://www.rbracing-rsr.com/comprAdvHD.htm

http://performancetrends.com/Compression_Ratio_Calculator_V2.3.htm

http://www.wallaceracing.com/cr_test2.php

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

http://www.csgnetwork.com/compcalc.html

http://www.diamondracing.net/tools/

https://www.uempistons.com/index.php?main_page=calculators&type=comp

https://www.rbracing-rsr.com/compstaticcalc.html

http://www.auto-ware.com/software/eap/eap.htm

INFO YOU NEED IF YOUR selecting the correct cam for YOUR combo

FIRST!!>>>>>>ANY AND ALL CAM MANUFACTURERS WILL need more info than the common, request for....

"I want a LUMPY IDLE SOUND and a FASTER CAR, whats the best cam... so it sure helps if you have as much valid info about your car handy as you can "

crane (386)310-4875

crower 619.661.6477

https://www.crower.com/camshafts.html?cat=854

erson 800-641-7920

http://www.pbm-erson.com/UserFiles/Documents/Catalogs/2013 erson catalog.pdf

lunati..662-892-1500

http://www.lunatipower.com/Performance-Cams.aspx

ISKY 323.770.0930

clay smith 714-523-0530

herbert cams 714-491 -2267

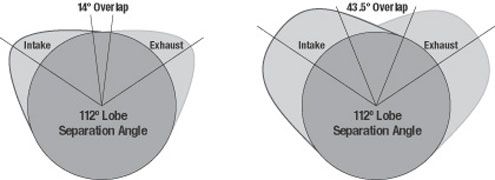

Camshaft Calculator & Valve Overlap Profiles | MGI SpeedWare

An interactive camshaft calculator where engine builders can see how valve overlap (and boost efficiency) is affected by a camshaft’s physical design.

mgispeedware.com

mgispeedware.com

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator1.htm

FREE cam selection software

(while it may get you roughly in the ball park as far as duration, its not especially accurate in my opinion)

http://www.camquest.com/

http://www.popularhotrodding.com/tech/0 ... ewall.html

http://garage.grumpysperformance.co...ing-camshaft-for-specific-applications.10162/

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

there are quite useful ,cam selection soft ware programs that get you in the ball park, but the final selection is based on far more factors than most of those software programs address, so I would not trust these cheap software programs to be fairly accurate in most cases

http://www.camquest.com/

DON,T LIE tell them EXACTLY what you expect and what you have currently ,installed,

and that the cam must work with NOW, NOT what you intend to install later.

DO NOT DISCUSS IN ANY WAY WHAT ANY OTHER MANUFACTURER SUGGESTED,

OR THAT YOU'VE EVEN TALKED TO ANY OTHER MANUFACTURER

YES you NEED too KNOW your COMPRESSION RATIO, and all the other answers to the questions below BEFORE calling....knowing a few more things, than your want a lope in the engines idle and you want a fast car when your done, about your combo , like your static compression ratio, displacement, cylinder heads used, rocker ratio, max valve spring clearance, or coil bind, height, spring load rates, carb,size, if its a vacuum or manual secondary carb, intake manifold,(single or dual plane,) headers, dimensions, your car weight, tire diam., do you need to pass emission testing? are you racing the car or is it daily transportation,etc would sure help, in the cam selection process??

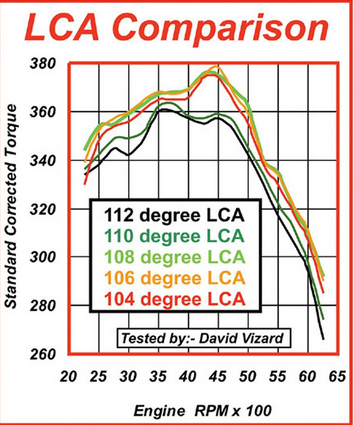

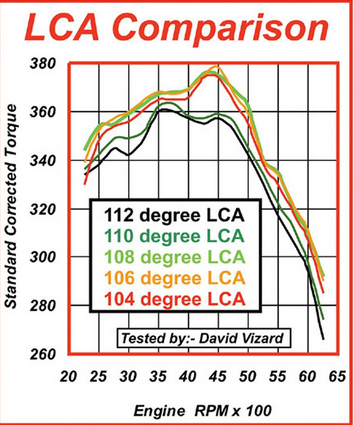

on the street youll almost always find that the lower duration cam in the choice between two similar cams will in the long term be a slightly more useful choice.

(the simple reason why is that most street cars spend the vast majority of the time operating well below 4500-5000 rpm, and lower and mid rpm torque not peak hp is used far more often) it hardly makes sense to build any engine to produce its peak power in the rpm range you,ll rarely use. and the extra duration will generally reduce the low and mid rpm torque you use the vast majority of the time, in exchange for a bit more peak power you'll rarely access.

selecting a cam without knowing those factors, is rather like marrying a girl based only on the color of her hair brush, you might make a good match but the odds say your dreaming

tell them your

car weigh?

rear gear ratio?

tire diam.

trans and gear ratios?

stall speed if its an auto?

displacement?

quench distance, head gasket thickness

COMPRESSION RATIO

HEADS (flow numbers)(lift restrictions)

intake type

tire size

intended use

max rpms

launch rpms

MIMIMUM IDLE

fuel octane

carbs,mpfi? CFM

ETC.

knowing a few more things, than your want a lope in the engines idle and you want a fast car when your done, about your combo , like your static compression ratio, displacement, cylinder heads used, rocker ratio, max valve spring clearance, or coil bind, height, spring load rates, carb,size, if its a vacuum or manual secondary carb, intake manifold,(single or dual plane,) headers, dimensions, your car weight, tire diam., do you need to pass emission testing? are you racing the car or is it daily transportation,etc would sure help??

selecting a cam without knowing those factors is rather like marrying a girl based on the color of her hair brush, you might make a good match but the odds say your dreaming

don,t be afraid to ask for suggestions on how to improve the combo and ask if in their opinion your ignoring some factor, that cold help improve the engine, or doing something wrong

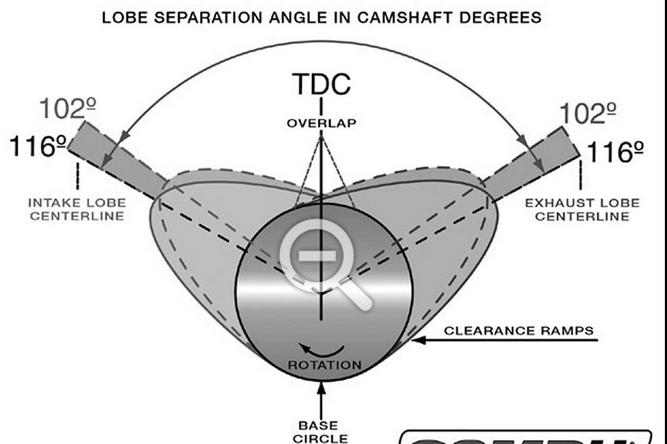

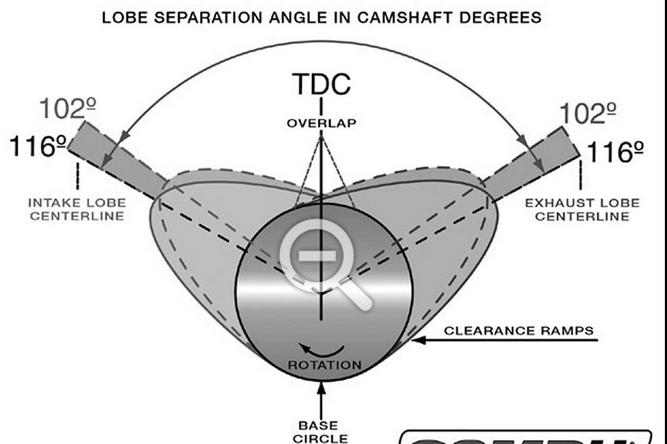

AVERAGE the RESULTS FROM EACH manufacturers suggestion,as to lift, duration and LCA and buy the cam thats the closest match to that average

Camshaft Shootout: Lobe-Separation Angle Tested and Explained

If the cylinder heads are the lungs of an engine, the camshaft is the brain. Lobe-Separation Angle Tested and Explained.

write down EACH CAM MANUFACTURERS , recommended cam type,

its lift, and duration at .050 and LCA.

REMEMBER!

if you have a problem with a component or need info on how to test or install a part or want to purchase a part and need details or choices explained in detail..

have you ever called some company and talked to some sales guy that was rather obviously reading the info off the catalog page about the part you wanted info on,

theres going to be 99 times out of 100 some guy answering the phone that is not an engineer or some guy that fully understands the way the product is made,

potentially being used or has any concept about its stress dimensions or operational conditions.

that does not necessarily mean the guys in the tech department , sales department or manufacturing departments are all totally clueless,

there are generally a few people in any company that really know all the details and are fully experienced,

those peoples time is worth far more to the company than the typical minimum wage zombie answering the incoming call traffic.

if you have a question,

start the call by asking the guy answering the call for his first and last name, always be polite, never waste the guys time

write it down

now you may or may not ever want to talk to this guy again, but its will at least tend to make them think hard about treating you like an idiot, or slamming the phone down,

or disconnecting you if they don,t want to answer questions.

\address the guy by his NAME several times, during the conversation, and ask his function in the company.

if he can,t answer your question ask if they have an engineer or more tech savvy guy you can talk too...

start the call by asking the guy answering the call for his first and last name,

and direct phone extension number if you can.always be polite, never waste the guys time

write it down address the guy by his NAME several times, during the conversation,

that way you can in the future bye-pass the answering desk zombies if you can build a friendly conversation,

but don,t waste the guys time and be sure you thank him by name at the conclusion of any conversation if he helps you.

keep a note book with company names phone numbers and the skilled tech guys as a future reference,

and remember the guys answering the incoming calls are rarely knowledgeable or even give a crap about the company..

that does not indicate the guys in engineering that know how things actually are made and function are anywhere near as useless as the phone desk guys.

its simply a fact that, a company can produce quality parts but have hired some real clowns to answer phones

read the data and average it off the list to each manufactures tech guys,once you have 6-7 to average

but DON,T DISCUSS IN ANY WAY WHAT OTHER MANUFACTURERS SUGGESTED

with the other tech guys or even hint you talked with anyone else simply give them the basic info and let them talk, don,t interrupt or ask questions that indicate you talked to other companys as thats sure to sway the average end result.

AVERAGE THE RESULTING LIFT DURATION and LCA info from each cam, and buy the cam that's CLOSEST TOO THAT AVERAGE, (ALL the MAJOR MANUFACTURERS HAVE DECENT CAMS) this tends to give consistently good results

http://www.cranecams.com/userfiles/PP08 ... ePages.pdf

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

and the linked chart info, use both as a base line, but remember to call at least 5-7 cam company's and 7-9 would be even better as it virtually eliminates the chances of some moron giving you bad info, that will screw up your cam selection

generally its best to purchase all the listed components in a cam installation kit (cam, lifters,valve springs, etc. ) from a single manufacturer as mixing parts, sources or brands,

allows the cam manufacturer to void the warranty, even if the parts in the kit they sell are either identical or inferior to,

the individually purchased components you individually sourced. keep in mind most manufacturers will have tested parts compatibility ,

so they are reasonably sure the components they sell in the kit will work, that can,t be always assumed,

with randomly matched parts even if those parts are good quality.

and if you call many cam companies the tech guy you'll talk to will simply asked questions so he can fill in blanks on software programs, because he may not know squat about the type of engine your building, and they darn sure have no way to check your engines clearances or valve train geometry, so thats up to YOU to get THAT correctly done!

keep in mind a cams main function is control of valve timing and lift, valve timing and lift control airflow thru the cylinder head ports,intake, and exhaust system and the displacement and compression ratio,,needs to be a factor in your calculations, then theres clearance issues ,in the valve train,that need to be addressed, and compression and the restrictions to flow in BOTH the intake tract and exhaust system need to be used in your cam selection calculations, one very common mistake, is over camming a combo, or not verifying clearances, this almost always reduces potential power and frequently results in parts breakage

DO NOT UNDER ANY CIRCUMSTANCES DISCUSS ANYTHING A DIFFERENT CAM COMPANYS TECH GUYS SAID WITH EACH OTHER CAM MANUFACTURERS TECH GUYS IT WILL ONLY SCREW UP YOUR RESULTS

heres free cam selection software to narrow your choices

just for grins put your info into this program, and don,t lie, and see what cam it suggests

http://www.camquest.com/

http://www.compcams.com/Pages/409/camquest-6.aspx

cast roller cams and high spring pressures don't generally work well

running a cast core roller cam on the street with significantly more than MINIMAL spring pressures for the intended application, IS JUST asking for valve train problems, but a balance must be maintained, if the valve spring is too weak and allows the cam lobe to throw or loft the lifter at...

garage.grumpysperformance.com

AS your displacement per cylinder increases the effective valve size per cubic inch decreases so you need a slightly tighter LSA and these charts should help.

Ive built enough engines that I think I can post a bit of info regarding the effect of the need to consider dynamic compression, in the engine planing

fact

usable torque the engine produces tends to go up as cylinder pressure increases

fact

your fuels OCTANE LEVEL LIMITATIONS, or tolerance, to heat & rapid compression before you tend to get into potential detonation,from the fuel igniting from rapidly induced heat and compression, issues limits the effective useful compression.

fact

uncontrolled detonation will rather quickly damage pistons and rings

fact

cylinder pressure is greatly influenced by the cylinders,displacement, and valve timing as well as the static compression ratio

fact

on a N/A engine you'll rarely if ever exceed the static compression, with the effective dynamic compression, but you can markedly reduce it with cam timing changes, that delay the valves closing as the piston compresses the cylinder volume.

heres a chart I found that I don,t fully agree with, I think its a bit conservative, by about 3%-5% on the required cam duration ,required to avoid detonation with todays crappy octane fuel, but it at least gives you a base to work from, but Id suggest selecting a bit more duration

software like the free comp cams software below[/color]

[/size]

http://garage.grumpysperformance.co...mbers-or-a-good-street-combo-your-after.5078/

http://www.projectpontiac.com/ppsite15/ ... calculator

http://www.hotrod.com/how-to/engine/113 ... -camshaft/

http://www.superchevy.com/how-to/49224- ... gine-cams/

http://www.superchevy.com/how-to/148-04 ... m#cxrecs_s

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://garage.grumpysperformance.co...s-and-a-few-similar-aftermarket.133/#post-163

http://www.superchevy.com/how-to/engine ... t#cxrecs_s

http://www.superchevy.com/how-to/148-03 ... t#cxrecs_s

http://www.compcams.com/Camquest/default.asp

but its almost always a good idea to get info from at least 6-7 sources, because you need to compensate for the occasional bad bits of info,

its not all that hard to calculate ,approximately the most efficient cam lift, duration, and LSA of a cam in an engine, if you know the cars tire diam. car weight, drive train gear ratios, engine compression displacement, head flow numbers,port cross sectional area, valve size, and a dozen other factors, its just that very few people that even understand what they need to look at and how each factor effects the combo,take the time and effort to do so , even the cam company Techs rarely bother, to factor in all the related components, but if you were to call lets say 7 cam companies and lets just as an example say that these were the suggested cams,

READ THESE LINK s

USE THIS SOFTWARE TOOL

http://www.compcams.com/Camquest/default.asp

lets just say you got THESE HYPOTHETICAL EXAMPLES as suggested cams

(1) 245 /245 dur 106 lsa

(2) 255/260 dur 108 LSA

(3)252/258 dur 110 lsa

(4) 260/267 dur 112 lsa

(5) 246/249 dur 112 lsa

(6)250./250 dur 110 lsa

(7) 260/270 dur 106 lsa

your average would be

253/257 dur 109 .618/.630 , so you could reasonably assume that you would be very close to correct if you selected a cam with close to those specs, cam #(3) IN THIS CASE COMES CLOSE but look at the range, suggested 245 all the way to 260 , intake duration and 106-112 LSA ,thats fully 15 degrees spread in intake duration and 6 degrees in LSA, is it any wonder that most guys have a problem selecting cams when theres that much latitude in even what the cam tech guys suggest, let alone the guys on the internet who may be far less knowledgeable and just suggesting what they read worked in some magazine article on an engine that was only slightly similar designed for a car and drive train that bore little resemblance to your current application, thats why I always suggest getting a few cam company tech guys input, and by averaging the results you can effectively find and easily see , the OFF THE WALL SUGGESTIONS, and YES , RARELY SOME TECH SUPPORT GUYS SEEM TO BE CLUELESS MORONS

IVE had best results sticking with CRANE,CROWER, and ERSON generally

given a choice between two similar cams for a street car, selecting the lower duration, wider LSA and LOWER lift generally produces a better more durable combo for a daily driver car engine, or put a different way trading increased durability and lower stress over a bit more peak horsepower is rarely a bad idea if your dependent on the car for transportation

read the links below as they hold a great deal more important info [/color]

http://www.compcams.com/Community/Artic ... 2026144213

http://www.aa1car.com/library/camshafts.htm

http://www.aera.org/ep/downloads/ep1/EP012008_34-40.pdf

http://www.hotrod.com/techarticles/113_ ... index.html

read thru these linked threads, as they will prove very useful

posting.php?mode=edit&f=52&p=189

http://www.crankshaftcoalition.com/wiki ... patibility

http://www.crankshaftcoalition.com/wiki ... ationships

look you may not want too hear this but...IF YOU FOLLOW the advice BELOW EXACTLY, you'll have a decent cam, ignore it and your very likely to find you've selected a cam that won,t run correctly in YOUR APPLICATION

heres a semi-fool proof method

THERE'S A GOOD DEAL MORE INFO, and several sources for cams IN THE Links BELOW

http://www.aa1car.com/library/camshafts.htm

http://www.compcams.com/Technical/FAQ/C ... stions.asp

http://www.camcraft-cams.com/index.php? ... ting-a-cam

http://www.chevyhiperformance.com/techa ... index.html

http://www.cranecams.com/?show=faq&id=2

keep in mind solid lifters generally have an rpm advantage and roller cams generally out perform flat tappet designs but cost more

http://www.crower.com/

http://www.cranecams.com/

http://www.pbm-erson.com/UserFiles/Documents/Erson_Tech/Erson-custom-cams-tech.pdf

http://www.mr-gasket.com/pdf/Chevrolet.pdf

http://www.lunaticams.com/

http://www.chetherbert.com/newchet.html

http://www.howardscams.com/index-2.html

http://www.iskycams.com/

http://www.reedcams.com/

http://www.schneidercams.com/cams/20.htm

http://www.lazercams.com/CamTables.html

http://www.bulletcams.com/BulletCatalog.htm

http://www.englecams.com/

you should also keep in mind that a roller cam valve train with the same lift and duration can provide a good deal more port flow and resulting power.

but even roller cams can wipe out lobes if the valve train components or valve train lubrication,and geometry is not set up correctly

READ THE LINKED INFO CAREFULLY

http://garage.grumpysperformance.co...ped-nose-cam-in-early-block.14182/#post-71937

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...-street-roller-cam-selection.5709/#post-46850

http://garage.grumpysperformance.co...a-better-cam-to-a-zz3-350-sbc.182/#post-26013

NO! ONE SIZE LARGER WON,T GENERALLY WORK BETTER, IN FACT ITS FAR MORE LIKELY TO BE A HUGE P.I.T.A to DRIVE AND HURT PERFORMANCE .

If your re-building a known combo,the questions that really should be asked here......

were you completely happy with the old cam or did you feel you wanted more upper or lower rpm band torque, did you like the way the engine ran, or did you feel it needed some tweaking?.....

what would you have liked to be changed about the power band when the old grind was in use?

BTW are you aware that reducing cams lift and valve spring load rates /pressures, and the degree of the aggressive cam ramp acceleration tends to increase durability in valve train components? yes it may cost you some hp, but it may be a good trade for increased durability

its critical that the converter stall speed and rear gear ratio match the cam timing and compression ratio if its an AUTO TRANSMISSION,......

MORE than if you have a manual trans, which is far more flexible as to what it will function with.

but having the rear gear ratio and compression ratio match the cam is mandatory for good results

and the larger the displacement and the better the heads flow the more likely it is that you'll find both good low rpm tq and mid to upper rpm hp you'll want in a street/strip combo, Ive seen many bad combos put together due to selecting a cam based on, the flawed logic

(well my buddies running cam (X) his car runs good...and I want to beat him so ILL buy the NEXT more aggressive cam with just a bit more duration and outrun him)

in most cases you'll be far better off, researching and selecting a combo with better cylinder heads, intake flow rates and larger displacement, rather than trying to go with a wilder cam.

remember your rarely going to make a huge improvement in hp per cubic inch with cam upgrades once you've reached about 1.25 hp per cubic inch displacement, but increasing the displacement, compression ratio and DISPLACEMENT tends to give a good boost over similar combos with lower displacement/cpr and head flow rates

if a 350 with 9.5:1 cpr that makes 1.25 hp per cubic inch that's 437 hp

build a similar stroker combo that has 401 cubic inches and 10.5:1 cpr and your far more likely to have about 520hp based on similar components

(the same 1.25 hp per cubic inch plus .04 increased tq due to the higher cpr and increased stroke ) plus all that at a slightly LOWER rpm that's easier on the valve train stress.

you might want to remember that a restrictive exhaust will kill much of the power potential, so decent TUNED headers and a low restriction exhaust is a necessary part of any build, and unless you can maintain the correct fuel/air ratio you can,t make good hp, so matching the fuel delivery and injector size to the applications mandatory.

keep in mind a" LAZY " cam, might be far better for low wear and increased durability,

engineers that design a cam and valve train, need to know whats expected,

any cam may be significantly easier on the valve train and durability may be greatly enhanced or extended or peak power might be the goal,

minor changes can have very significant effects on durability without changing power very much,

both CRANE AND CROWER are rather well known of tending too design cams that might sacrifice a couple peak horsepower,

if it required to significantly boost long term durability and reducer the chances of valve train stress levels,

some other company's have a few cam lobe designs that are right at or even at times in some rpm ranges a bit past the limits,

of what most builders might see as reasonable for longer term durability,

they seem more concerned with being able to produce the best possible peak power,

even if doing so might reduce the engines longer term life expectancy.

a cam designed for drag racing that might be expected to make peak power for less than 15 seconds at a time will be a great deal different than one in an engine designed to run the 24 hour race at le-mans even if both cars ran in a car with a similar engine family, and certainly both would be designed far differently than a cam designed to run issue free for 100K miles

a difference in philosophy ,

one group thinks you have to finish the race to win,

most guys don,t have unlimited cash so lets design something that will last a long time without issues!

the other group thinks, youll never win unless your making the most power available,

and race engines get torn down , inspected and re-built regularly so push the limits

Isky claims that the Comp XE cams violate the 47.5% rule. The 47.5% rule applies to flat tappet cams for SBCs with 1.5 rockers but the concept is still the same for other configurations where the designs are "on the edge" or "over the edge" for lobe intensity. For 1.5 ratio SBCs, the duration at .050 must exceed 47.5% of the total valve lift or your asking valve train problems. For example, take a Comp Cams Magnum 280H, with 230 duration and, 480 lift...230/.480 = 47.9% which exceeds 47.5% therefore would not pose a threat to components. We do not regularly hear about the older, safer HE and Magnum designs rounding off lobes anywhere near as often as the XE cam designs. Unfortunately, some of the Comp Cams XE dual pattern lobes break this 47.5% rule on the intake side so they are likely to be problematic. The design has "steeper" ramps that are too quick for durability and reliability according to other cam manufacturers. They will wipe lobes in a heart beat especially if you have not followed the proper break-in procedure. Other designs are more forgiving during break-in and less likely to fail.

http://www.digitalcorvettes.com/forums/showthread.php?t=39010

http://www.compcams.com/Camquest/default.asp

comp cams is now offering a free cam selection software,THIS IS A USEFUL TOOL, this is useful in seeing the lift/duration/LCA they suggest for your application, in most cases they get fairly close so its a tool thats useful, now you don,t necessarily need to buy a COMP CAM but a cam with a similar lift/duration/LCA from your favorite manufacturer probably should be fairly close to whats recommended

willing to spend a few bucks ,want far more detailed results and a program requireing FAR more detailed input??

http://www.projectpontiac.com/ppsite15/compression-ratio-calculator

http://www.wallaceracing.com/dynamic-cr.php

http://www.rbracing-rsr.com/comprAdvHD.htm

http://performancetrends.com/Compression_Ratio_Calculator_V2.3.htm

http://www.wallaceracing.com/cr_test2.php

http://www.pcengines.com.au/calculators/Calculate dynamic Comp Ratio.htm

http://www.csgnetwork.com/compcalc.html

http://www.diamondracing.net/tools/

https://www.uempistons.com/index.php?main_page=calculators&type=comp

https://www.rbracing-rsr.com/compstaticcalc.html

http://www.auto-ware.com/software/eap/eap.htm

Last edited by a moderator: