when your setting up your cars fuel delivery system, you'll obviously need to know the physically requirements of the engine your about to feed,

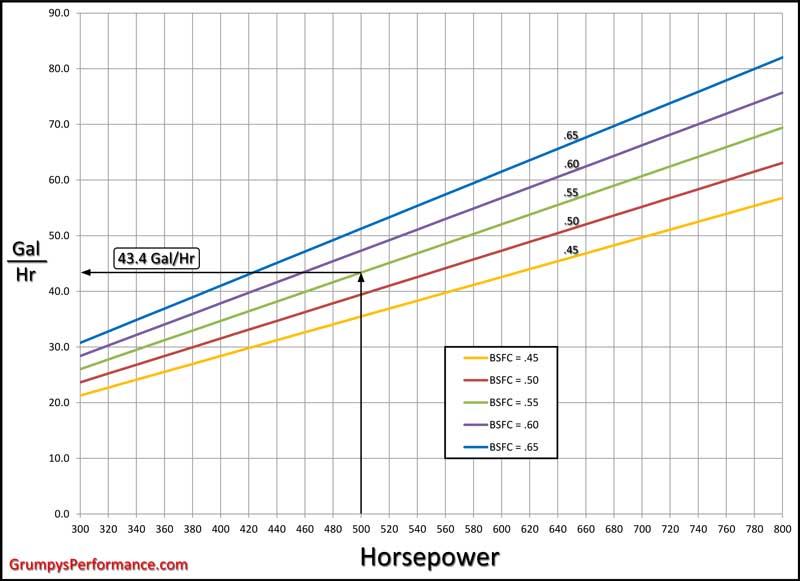

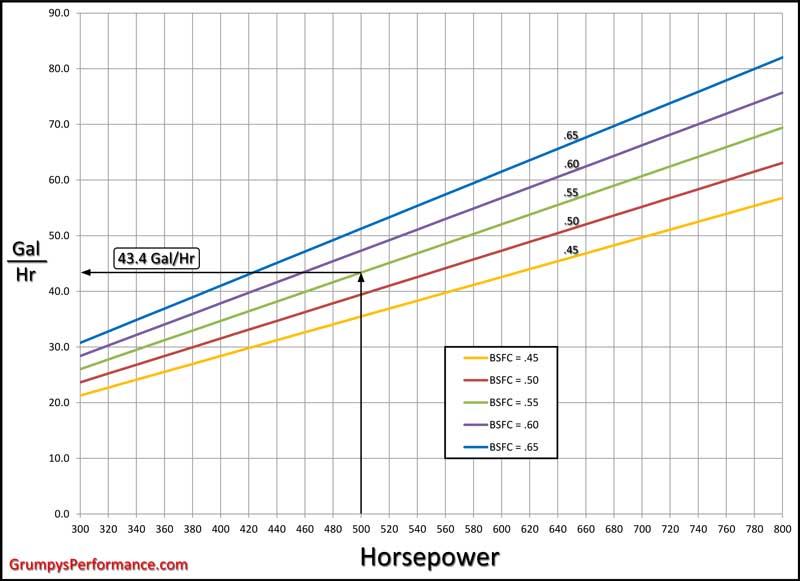

For your older carburetor, equiped muscle car, this will generally be for most performance cars 5-6 psi of fuel pressure at the carb inlet port, a fuel pump should supply about 130%-to-150% of the minimum flow rates the charts posted lower in the thread , so a manual fuel pump rated at 90-130 gph is generally a good idea if your intent on making 400-550 hp, and taking the time and effort to accurately check your carbs float levels when you set it up!

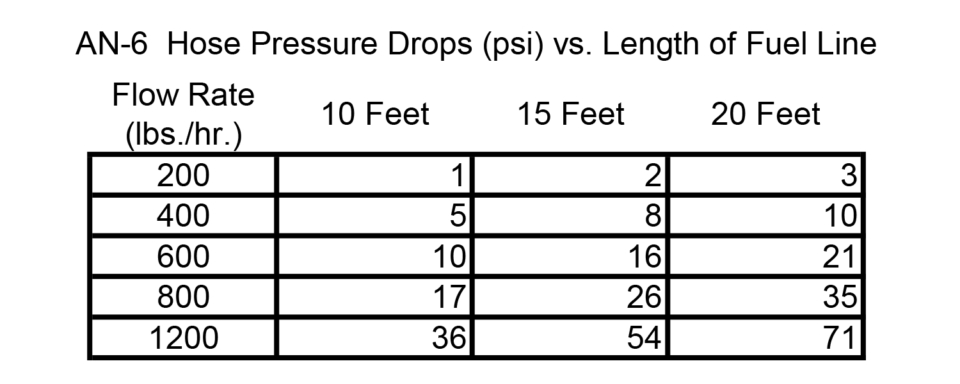

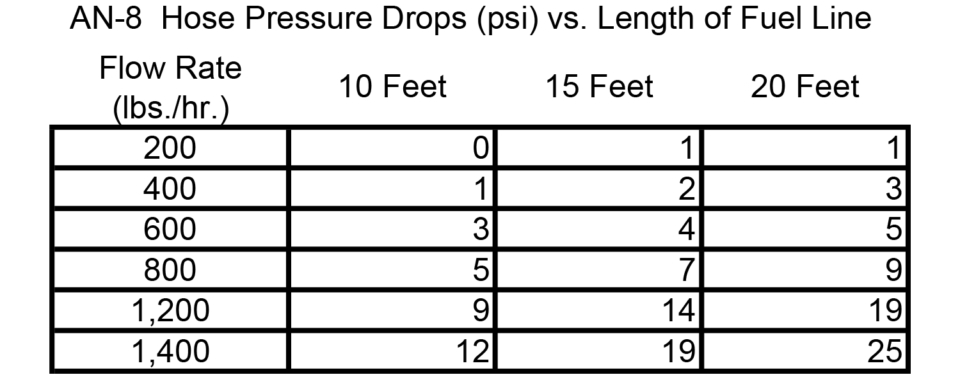

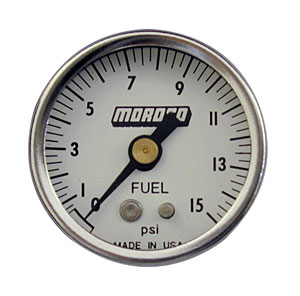

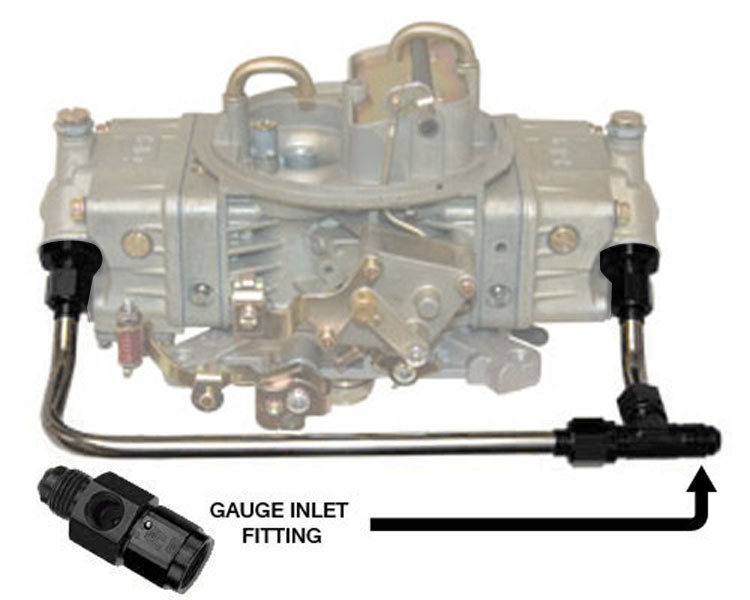

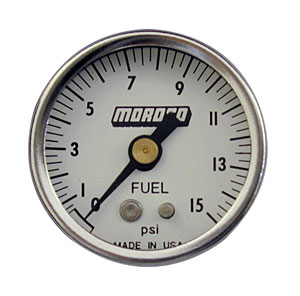

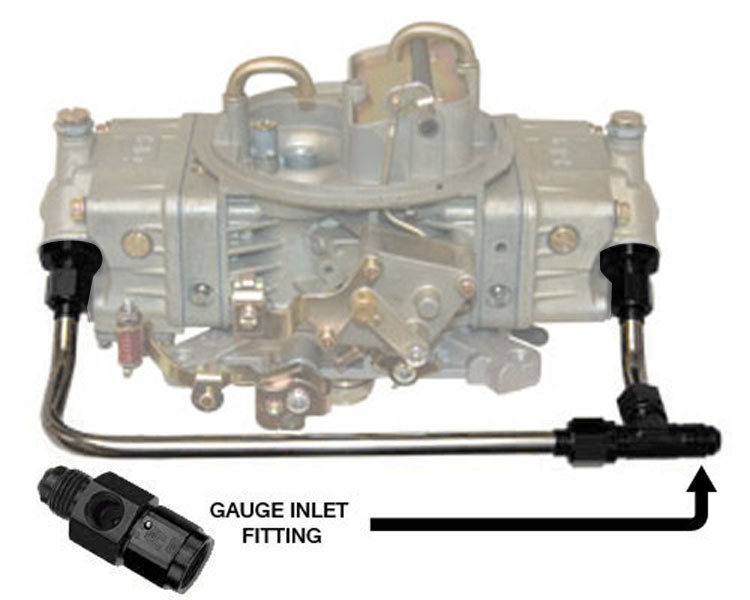

and youll need to know not guess or assume that the limitations of the current fuel pump, pressure, and volume , so its able to supply your engine, having a small fuel pressure gauge mounted on the fuel rail helps and know the limitations on the current fuel lines, fuel filter and any restrictions to flow imposed by the fittings and connections to the filters and fuel tank, the fittings , lines internal cross sectional area,and the restrictions to flow that they potentially represent.

heat, inertial loads and distance all reduce flow rates.

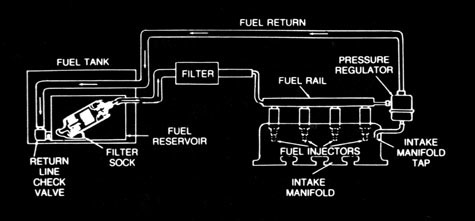

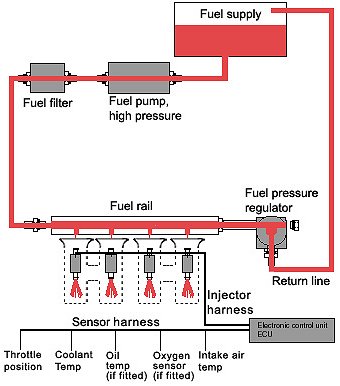

as a basic rule carburetor engines will need about 6 psi at the carburetor inlet port, fuel rails or lines for fuel injection systems that feed , fuel injectors generally need between 40-60 psi at the fuel rail.

http://www.prpracingproducts.com/products-page/fuel-system-accessories/fuel-pressure-regulators/it makes no logical sense to run 1/2" or AN#8 lines to and from a fuel cell, or fuel tank, too a pressure regulator , or fuel pump or fuel filter,with restrictive AN#6 or 3/8" lines, if your intention is to make much over 500 hp so use a regulator , fuel filter and lines and fittings that all match, and allow max flow levels with little restriction, remember a chain is as strong as its weakest link, and a fuel delivery system will be limited by its most restrictive flow points..

one very common symptom, of a fuel system thats not keeping up with demand is a car that pulls hard through first gear and maybe second then power noses over as you go further, or a bad miss that develops in 2nd or third gear thats not there in first gear at the same rpm level.

http://www.eastwood.com/professiona...e=&network=g&gclid=CIe-y9b938cCFUhhfgodBkQCDg

heres a bunch of good info

http://www.aeromotiveinc.com/stealthdiagrams/

you DO understand that theres a very visable and meassurable difference between a O.E.M. style replacement fuel pump, designed as a replacement part that can be swapped in, that might provide a bit higher flow, and a true performance aftermarket electric fuel pump. right?

any serious fuel delivery system will require a fuel cell, or major changes to an existing fuel tank, and larger diameter fuel lines and a better fuel filter aling with a matched return style fuel pressure regulator and return lines, you can,t simply swap in a few components the whole system, (end to end) will need to be upgraded if you expect reliable fuel delivery by the time your exceeding about 550-600 hp.

Everyone initially, thinks they can simply put a larger fuel pump on the existing fuel lines the car came with,

inevitably they will be forced to accept the reality of the physics involved,

even if they don,t yet see the need yet

and those that don,t make the required upgrades,

will look far less knowledgeable if that issue is not resolved before damage occurs,

this is simply a watch them read links ,accept advice, and make suggested ,

changes or watch them gain knowledge, the hard & expensive way after replacing damaged parts that resulted

DON'T SKIP OVER/IGNORE THIS LINKED INFO

low pressure electrical fuel pumps are available for carb applications

https://www.holley.com/products/fue...ed_fuel_pumps/carbureted_electric_fuel_pumps/

http://www.jegs.com/c/Fuel-Carbs-Intakes_Electric-Fuel-Pumps/10307/10002/-1

http://www.edelbrock.com/automotive/mc/fuel-pumps/

http://www.mechanicalcaveman.com/best-electric-pump-for-carburetor-fuel-pump-review/

http://www.weldonracing.com/store/!/Pumps/c/14136041/offset=0&sort=normal

http://www.jegs.com/p/Aeromotive/Aeromotive-A3000-Drag-Race-Fuel-Pump/2944771/10002/-1

http://www.superchevy.com/how-to/en...ou-need-to-know-about-aftermarket-fuel-pumps/

http://gottafishcarburetors.com/CFM Formula.html

http://wallaceracing.com/intakecfm.php

http://realstreetperformance.com/Fuel-Pump-Comparison-Test.html

As usual it helps to do some detailed research on the internet and if your racing on a local track there will generally be a rule book that clearly lays out whats required and whats prohibited to read through, and if you take the time to look, you may find some older and experience successful racers willing to give you a few details and tips

YOULL FIND THESE CLOSELY RELATED THREADS VERY USEFUL

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.com/index.php?threads/fuel-line-sizing-return-vs-feed.3067/

http://garage.grumpysperformance.co...lectric-fuel-pump-selection.10664/#post-46121

http://garage.grumpysperformance.co...-sizing-return-vs-feed.3067/page-2#post-44820

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/#post-42213

http://garage.grumpysperformance.co...bit-of-intank-fuel-pump-info.7848/#post-27077

http://garage.grumpysperformance.co...selection-design-for-500-hp-fuel-system.7787/

http://garage.grumpysperformance.com/index.php?threads/flex-fuel-lines.4381/#post-16285

http://garage.grumpysperformance.com/index.php?threads/installing-a-fuel-cell.733/#post-6470

viewtopic.php?f=55&t=635

http://www.superchevy.com/how-to/0606ch-carbureted-motor-fuel-system/

http://www.chevyhardcore.com/tech-s...ning-building-street-performance-fuel-system/

viewtopic.php?f=55&t=624

http://www.atlinc.com/racing.html

http://www.magnafuel.com/support/

VERY INTERESTING ADDITION TO THE POTENTIAL FUEL SYSTEM DESIGN

http://www.motoiq.com/MagazineArticles/ ... rvoir.aspx

the problem with all decent quality fuel line supply component parts is they cost more money, than the cheap low quality parts and generally take up more room and take a bit more time and thought to instal correctly

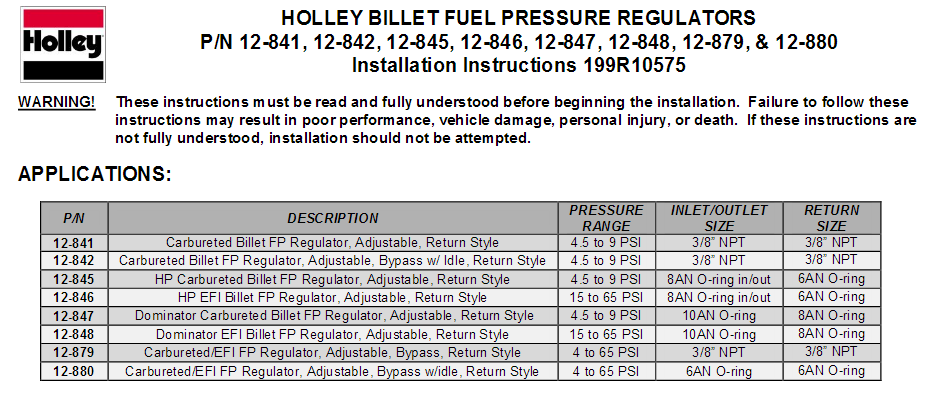

http://www.summitracing.com/parts/hly-12-841/overview/

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

http://www.summitracing.com/parts/edl-1792/overview/

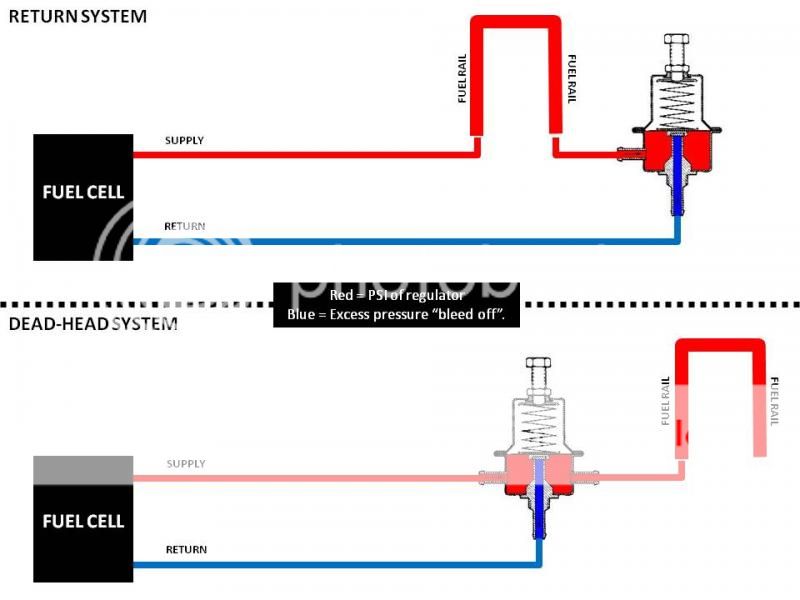

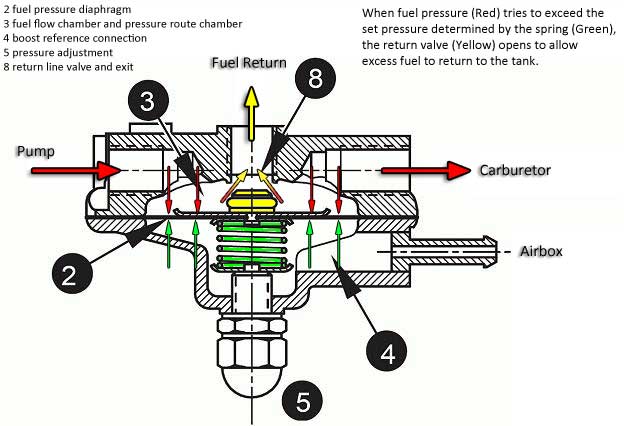

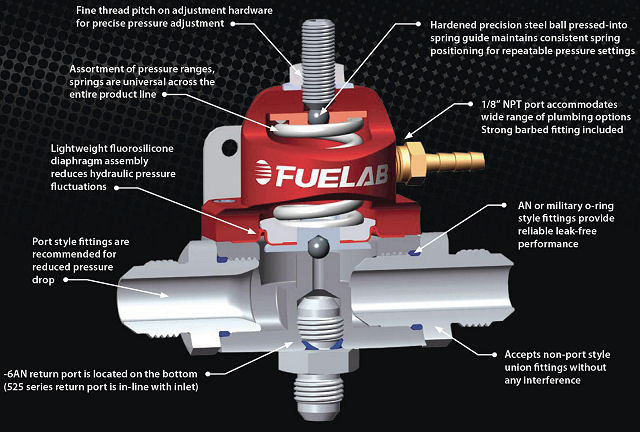

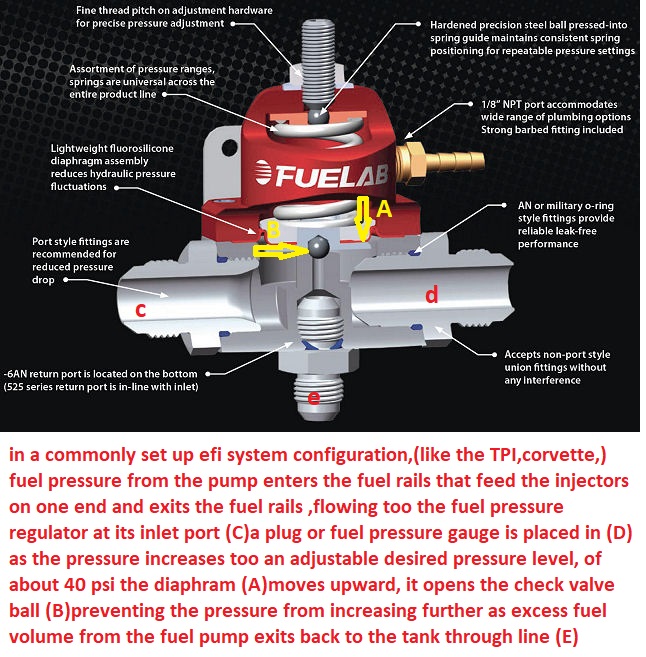

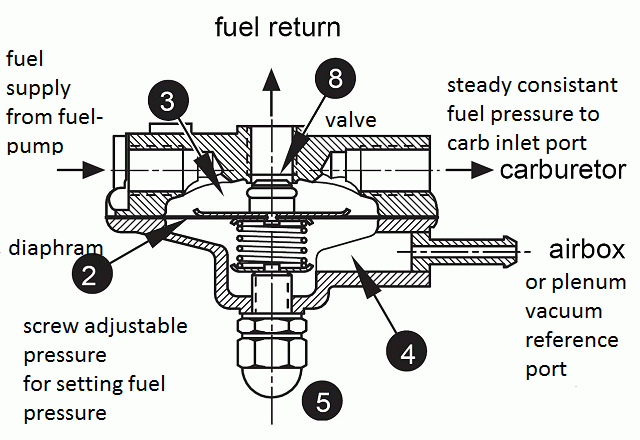

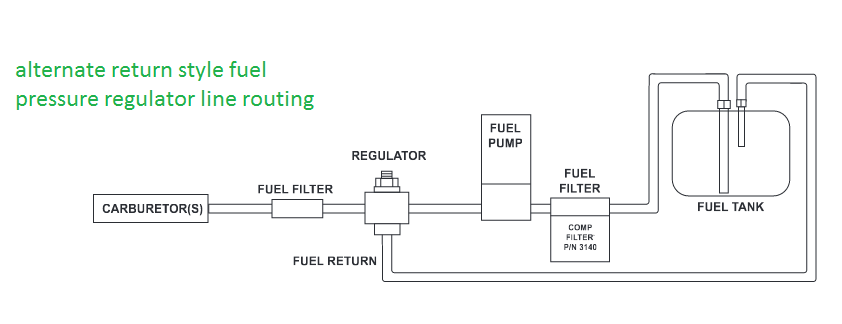

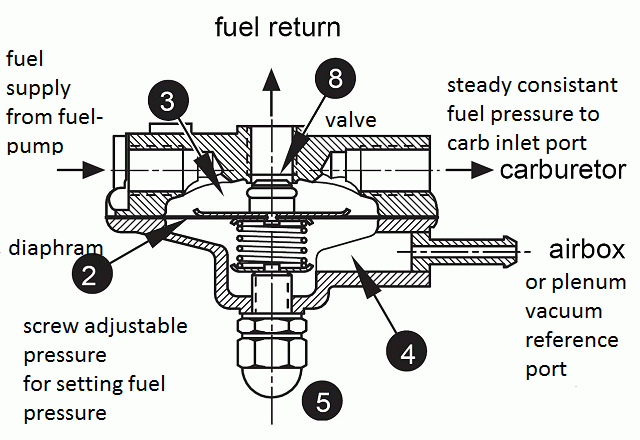

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

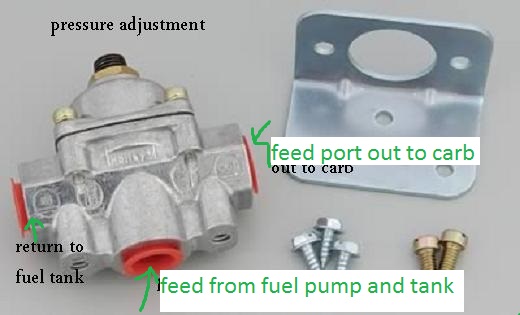

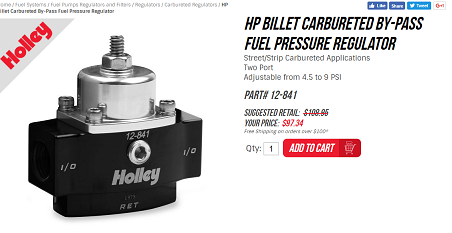

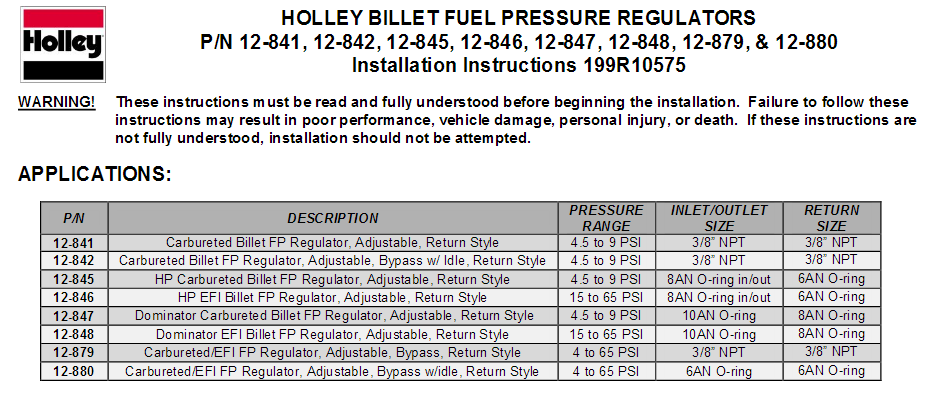

I can easily see where the diagram may be confusing ,, and while that cheap holley return style fuel pressure regulator works

at maintaining fuel pressure on the inlet port and can be used its far from the better choice

this is the type of FP regulator you want in most cases,

and it comes in AN#8 and AN#10 sizes

its simply a strait through fuel flow with a pressure release that leads to the return line that opens if the fuel pressure exceeds a set level, thus it maintains that max pressure

https://www.holley.com/products/fuel_systems/fuel_pumps_regulators_and_filters/regulators/carbureted_regulators/parts/12-841

http://documents.holley.com/199r10575rev3.pdf

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

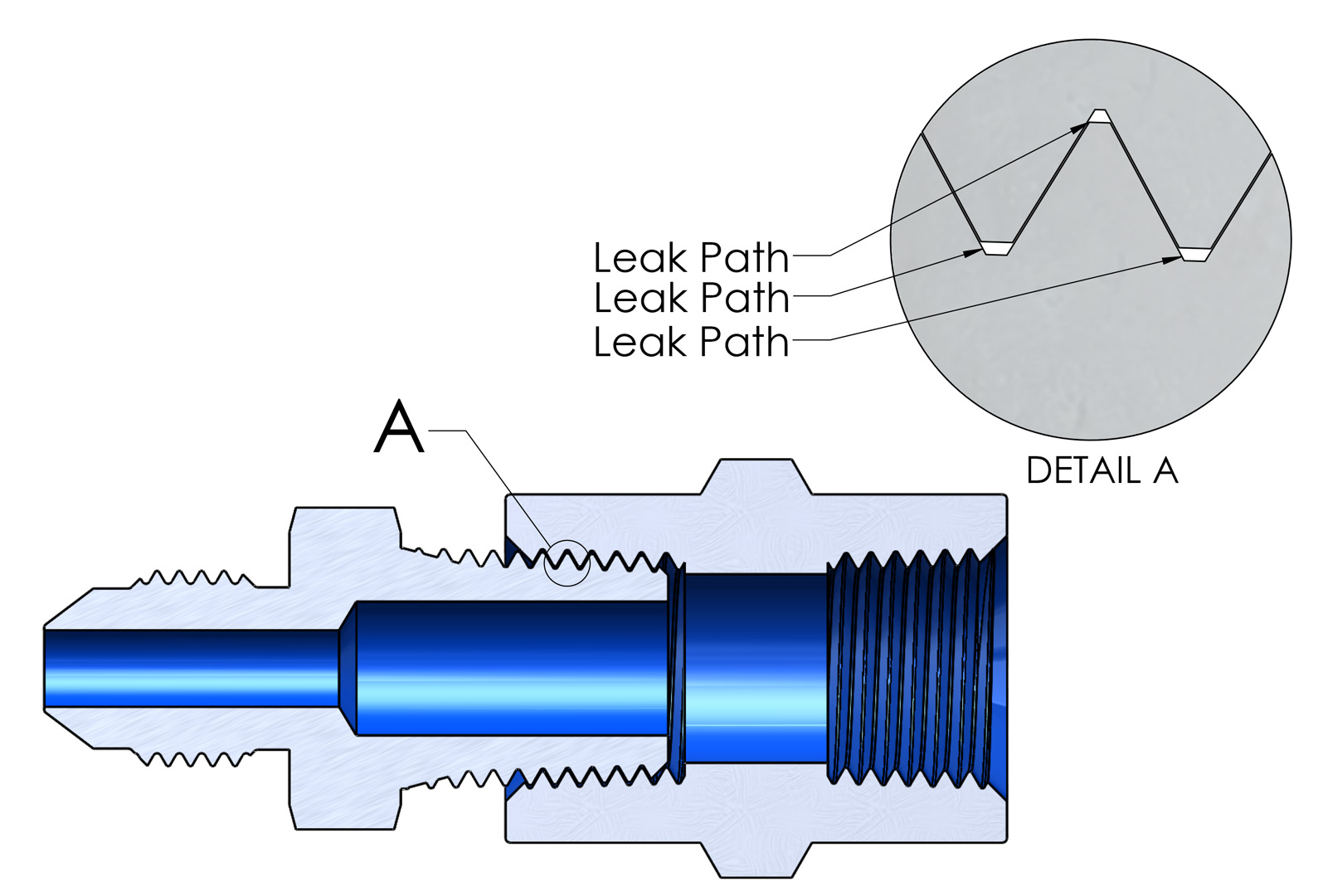

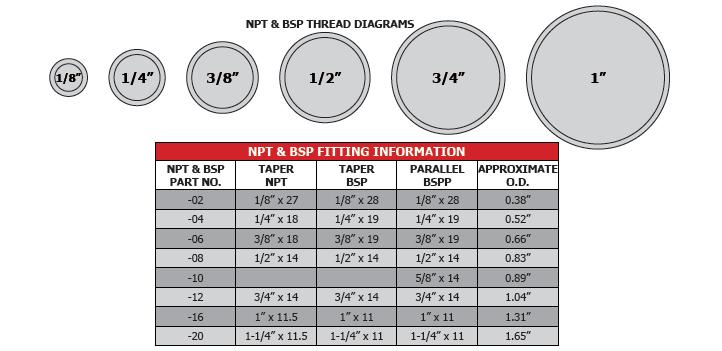

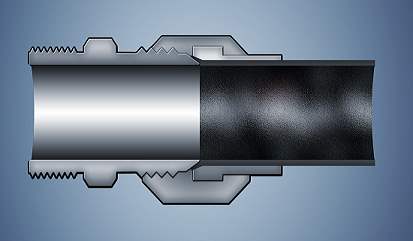

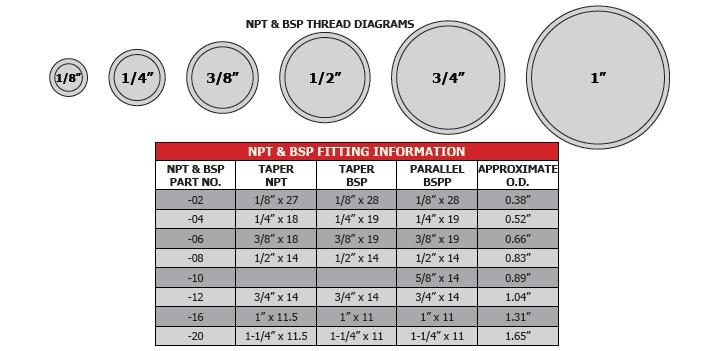

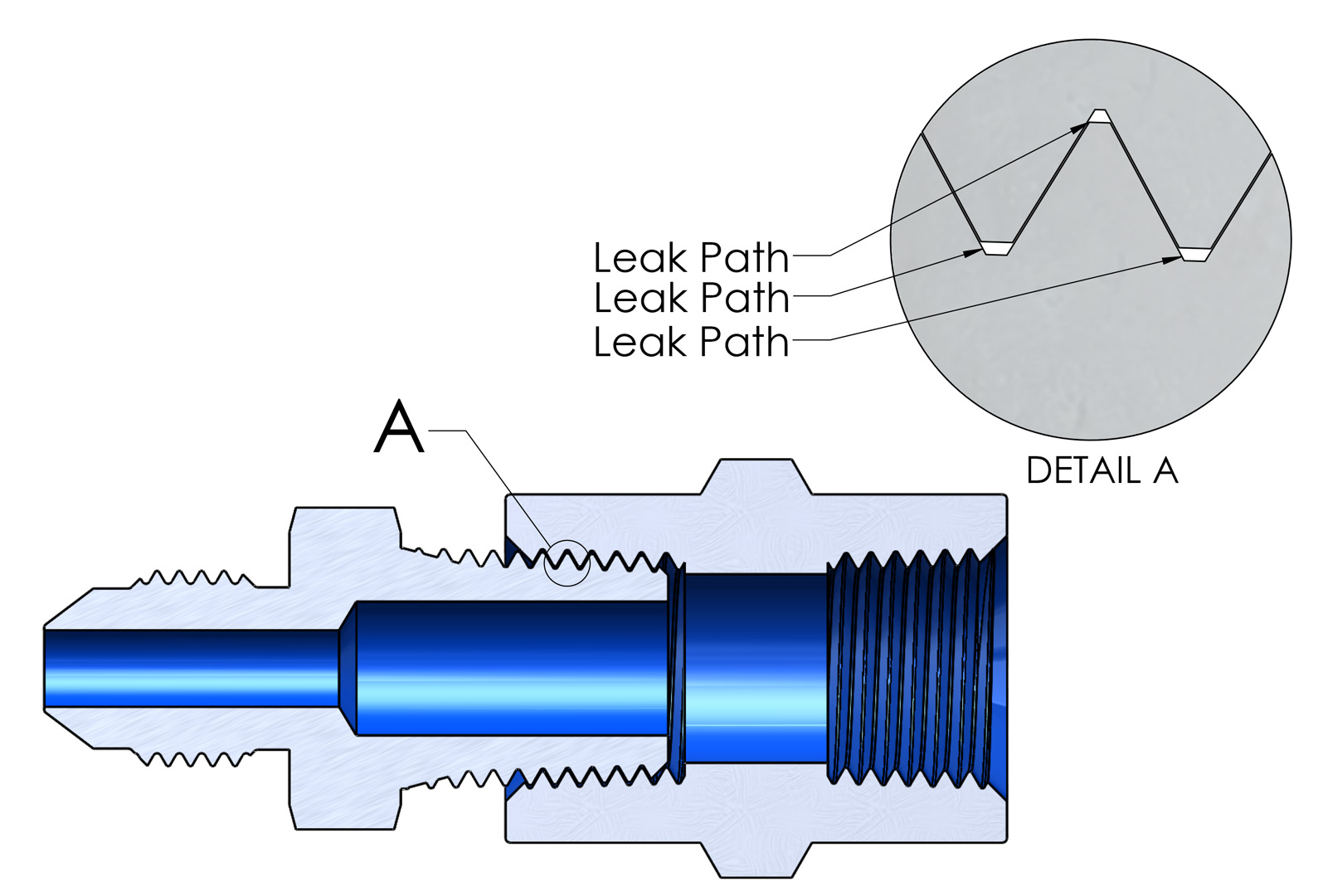

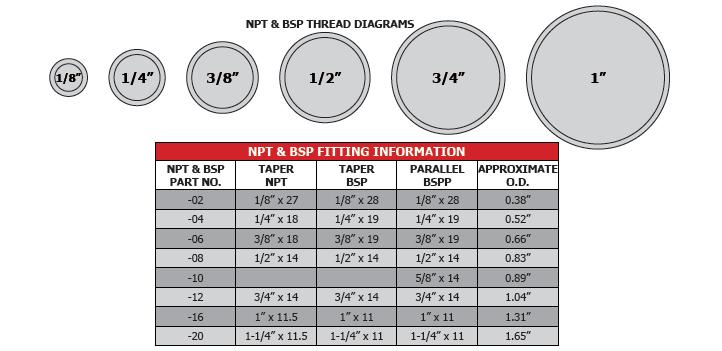

one of the most common mistakes less than experienced performance enthusiasts, face and very commonly over-look, is the fact that the internal cross sectional area on many hydraulic and fuel line fittings are considerably more restrictive to flow that the fuel limes or hydraulic lines inside diameter they were designed to be used with, and it varies a great deal between different manufacturers, now ideally the fittings internal passage cross sectional area is both consistent and the same or greater that the tube or hydraulic line size, it listed to match, , so a 1/2" inside diameter fuel line, or hydraulic lines?hoses, for example should have components for the connections and fittings that have significantly smaller internal cross sectional areas, it does you very little good to use lets say, AN#8 or half inch fuel lines if the internal cross sectional area of the connections and fitting used with those lines is only 3/8" or smaller in cross sectional area,this is an area where dealing with a local hydraulic supply shop that has the correct tools and fittings to custom fabricate your fuel lines, coolant or lubrication lines is a very good idea!

talk to a local professional at your local hydraulic supply, measure accurately, take the time to explain what your trying to accomplish and take several pictures to show them what your doing, and get them too fabricate any high pressure fuel or coolant lines and related fittings

*

Up to 45 GPH= 3/4 GPM = 5/16" or -04 AN

*

Up to 90 GPH = 1.5 GPM= 3/8" or -06 AN

*

Up to 250 GPH =4.2 GPM= 1/2" or -08 AN

nearly ideal for transmission and oil coolers

*

Up to 450 GPH =7.5 GPM= 5/8" or -10 AN

*

Up to 900 GPH = 15GPM 3/4"or -12 AN

keep in mind that thats the minimum required, a fuel system has restrictions to flow rates like filters ,fitting and internal line flow restrictions requiring you to have a slightly higher actual supply volume and pressure

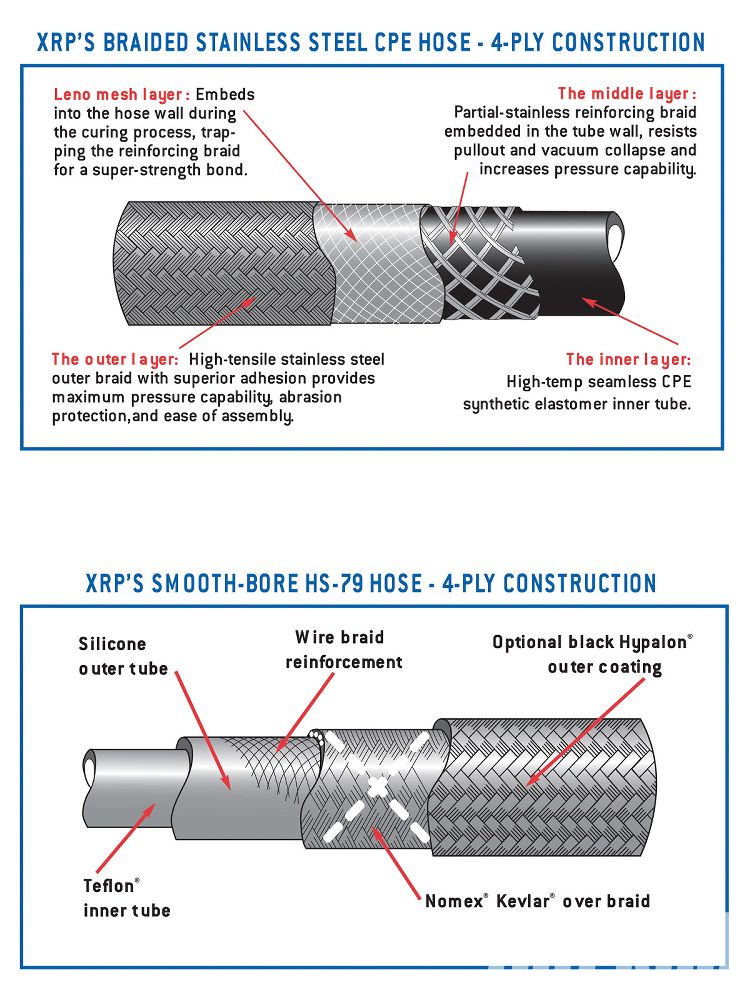

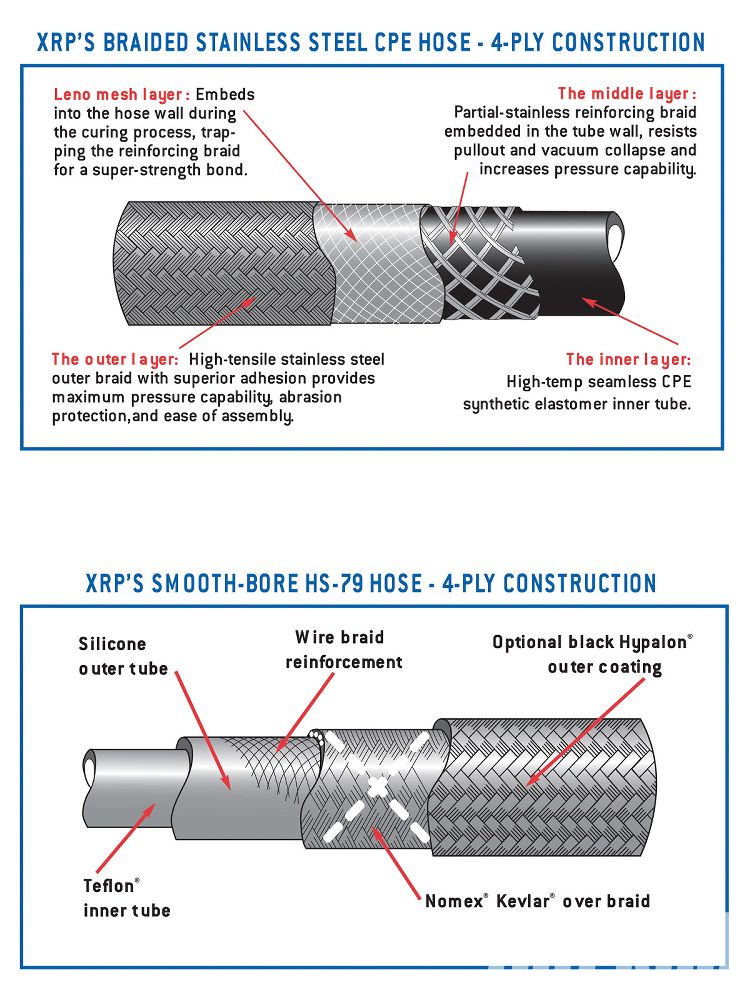

I don,t use aluminum, fuel line, because it fatigues quickly and it frequently rated under 40 psi., the best line is stainless steel hydraulic line you can usually get from a local hydraulic hose supply manufacturer or repair shop, its generally rated at 1000 psi or higher in 1/2" size I GENERALLY RUN ON PERFORMANCE CAR APPLICATIONS, shop carefully some places price that line like its made of gold, most are far more reasonable.

remember pressure and volume are two different measurements and youll need to supply both at a certain level to maintain a dependable power level, what works just fine in a fuel supply system idling in your drive way on a typical 350-400 cubic inch engine thats common in most cars ,built for performance,to feed the needs of an engine running at 1500rpm-3000rpm is a far cry from whats required at 6500rpm under 3/4 G acceleration loads.

that brass fitting you picked up cheaply some place that feeds the 3/8" inside diam. hose that has the 1/4" passage thru it , that allows a fuel pump rated at lets say 130gph to pump 70gph, won,t seem restrictive until the cars under full acceleration in top gear.

these links and sub links below should help, keep in mind in the tank electric fuel pumps tend to be cooled by sloshing fuel , so maintaining at least a 1/4 tank volume tends to prolong pump life span and pumps work far better with a return style fuel pressure regulator as that style tends to allow a consistent minimal fuel flow thru the pump to absorb and transfer heat out of the pump. the less expensive frame mount external electric fuel pumps tend to have heat related durability issues and tend to be louder as they operate. don,t forget a decent quality fuel filter that has the flow capacity to not be restrictive, a restrictive fuel filter can significantly reduce fuel flow rates.

http://www.amazon.com/Ti-Industries--Ca ... aulic+line

http://www.hydraulic-supply.com/html/pr ... tubing.htm

http://store.fedhillusa.com/cnf6.aspx

http://www.discounthydraulichose.com/Hy ... tm?Click=3

http://shop.hoseandfittings.com/catalog ... S-304.html

IF you decide you want a fuel cut off valve to make fuel filter changes less messy,

http://www.harborfreight.com/38-Full-Po ... 68255.html

while not ideal Ive seen these valves above used

http://www.brewershardware.com/1-2-Full ... Valve.html

I generally use AN#8 lines and stainless valves like this

viewtopic.php?f=55&t=7787&hilit=shut+off+fuel

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=4381

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=6105&p=18854#p18854

viewtopic.php?f=55&t=211&p=275&hilit=fuel+filter+drain#p275

http://www.copper.org/applications/auto ... brake.html

use steel hydraulic/fuel line its rated well over 1000 psi, it comes in 25 ft lengths in either 3/8" (AN#6) or 1/2" (AN#8)

READ THESE LINKS POSTED IN THE THREAD BELOW ALSO[/color]

https://www.centuryperformance.com/fuelish-tendencies.html

viewtopic.php?f=55&t=1378&p=3035#p3035

http://web.archive.org/web/200701062316 ... 1.htm#FPHP

http://www.duccutters.com/ConvertionCha ... bzyv5ytbP1

viewtopic.php?f=55&t=231

http://www.youtube.com/watch?feature=pl ... uIoAa5RRBs

http://www.stealth316.com/2-air-fuel-flow.htm

http://www.circletrack.com/enginetech/c ... _pressure/

http://www.smartfireinjectors.com/fuelflowchart.html

http://www.designatedengineer.com/FuelLineSizing.html

viewtopic.php?f=44&t=4912&p=14365#p14365

viewtopic.php?f=55&t=1939&p=5137#p5137

viewtopic.php?f=55&t=10664

e.com/viewtopic.php?f=55&t=231

For Dead-Head type regulators:

Multiply maximum horsepower by .23 to calculate minimum pump size in "free flow" GPH.

Example: 400 HP x .23 = 91 GPH "free flow"

For Return-Style regulators:

Multiply maximum horsepower by .17 to calculate minimum pump size in "free flow" GPH.

Example: 400 HP x .17 = 68 GPH "free flow"

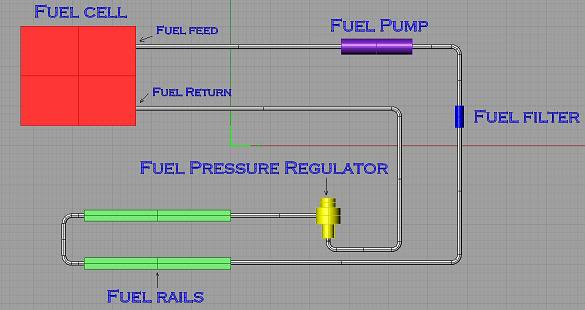

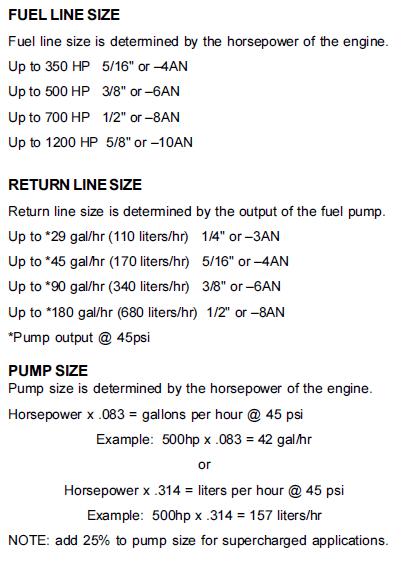

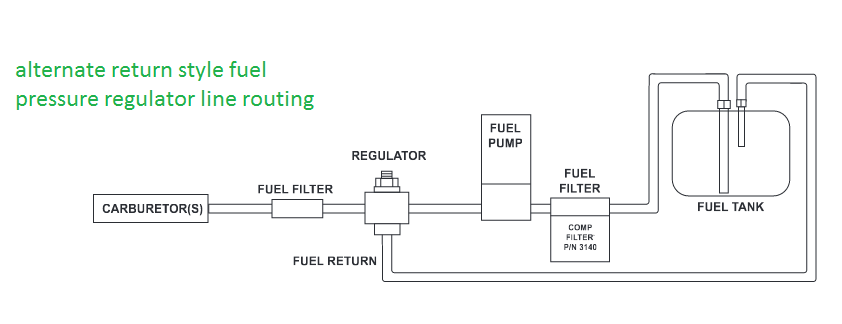

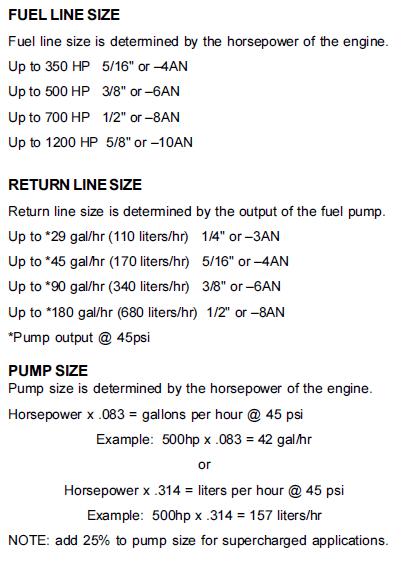

The minimum fuel line size (from the pump to the regulator) is dependent on the horsepower output of the engine (and/or Nitrous system) regardless of the size of the pump. fuel pressure regulators are normally placed as close to the fuel rail or carburetor feed inlet port as possible to maintain most of the fuel feed lines under higher pressure to reduce vapor-lock, high g -force fuel starvation and to reduce the chance of air entering the carburetor ,or injectors and keep a constant flow of cool fuel reaching the injector's or carburetor, because theres a constant flow of new fresh fuel being forced up to and some bye-passed thru the system, and fed to the engine

keep in mind TPI fuel pressure regulators maintain about 40-45 psi while carburetors require about 4.5-6.5 psi MAX, but in most cases the fuel pressure at the carb inlet port NEEDS to read 4.5-5 psi MAX and you NEED to set the float levels per the carburetor manufacturers instructions, having the pressure at 6.5 psi will in many cases cause the needle & seat valve to constantly leak excess fuel, into the carburetor while the engine runs.

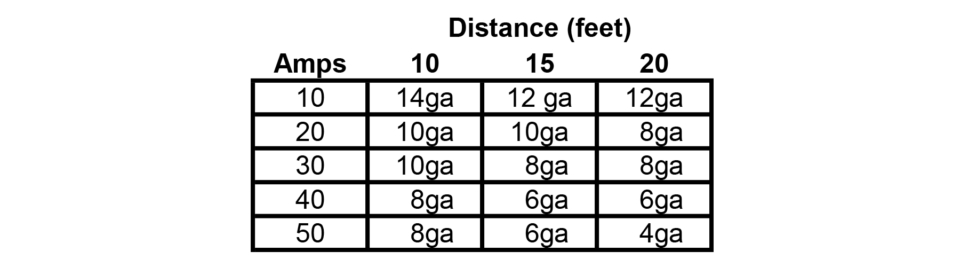

BTW any time you start having fuel delivery issue's check the electrical connections, fuzes, relays, and replace the fuel filter as those are frequently major factors in causing problems

Use these figures as a fuel line sizing standard: if your feeding a carburetor with the typical 8-10 psi fuel pump feeding to the fuel pressure regulator

* Up to 250 HP = 5/16" or -04 AN

* Up to 500 HP = 3/8" or -06 AN

* Up to 700 HP = 1/2" or -08 AN

* Up to 1000 HP = 5/8" or -10 AN

* Up to 1500 HP = 3/4" or -12 AN

many guys fail to keep the line size consistent, it does no good to feed a 1/2" or AN8 line from a 3/8" or AN6 fitting in your fuel filter or fuel pump are to try to suck fuel from the tank thru the stock lines and then feed larger lines, you'll need a fuel tank or fuel cell,and matching line adapters and fittings with the correct matched internal dimensions

fuel flow is restricted to the limitations imposed by the smallest cross sectional area of the smallest and most restrictive line or fitting, if a fuel filter restricts you to lets say 70 gph at 7psi hooking it to a fuel line that potentially flows 120gph at 7psi won,t increase the flow

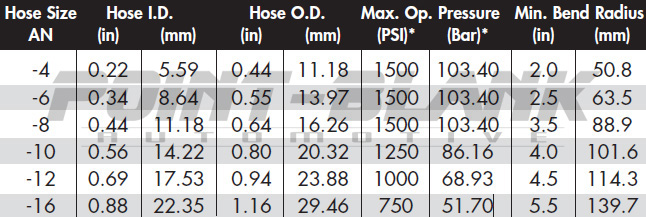

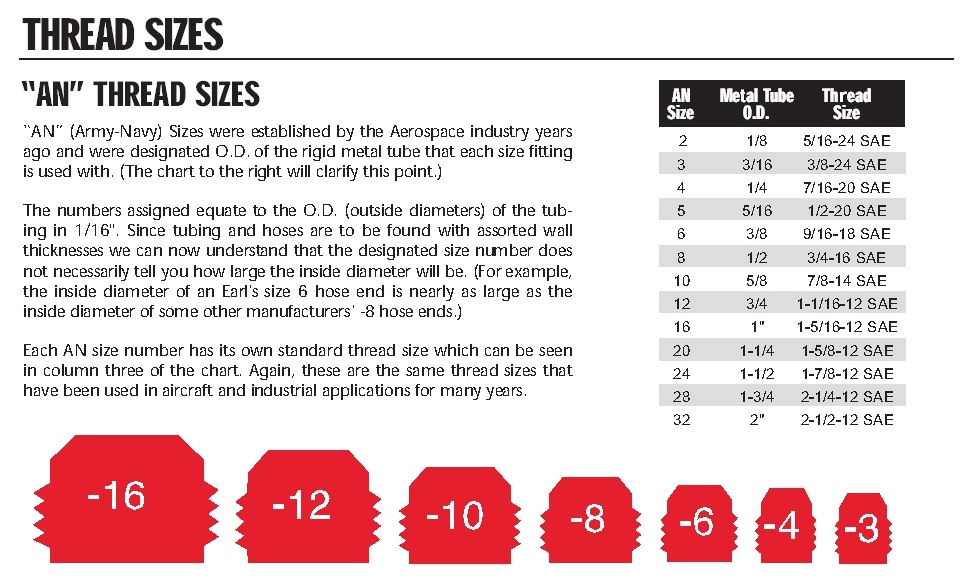

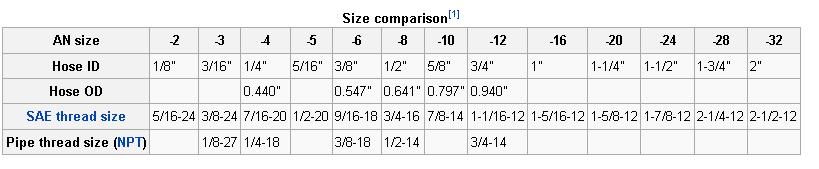

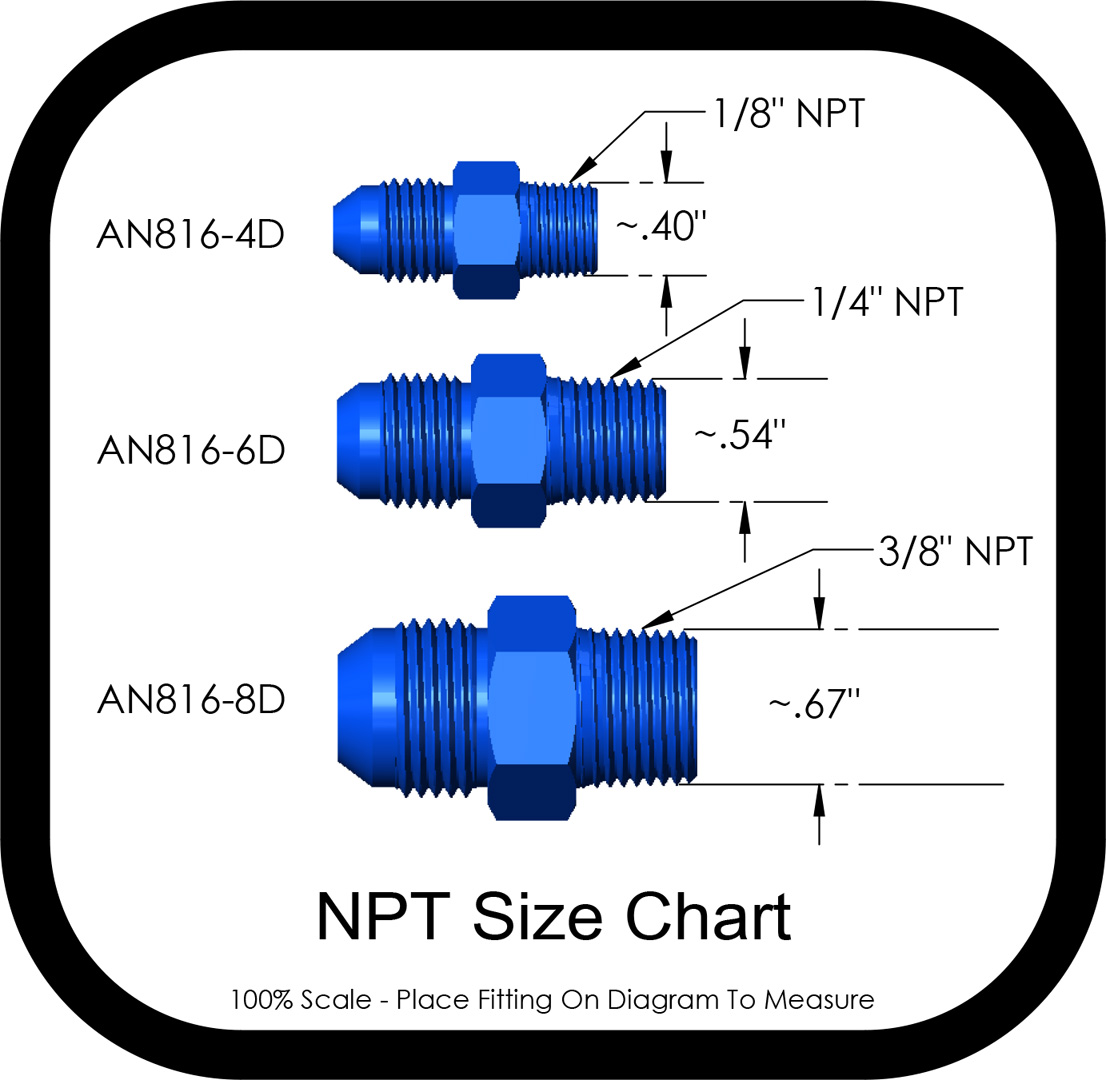

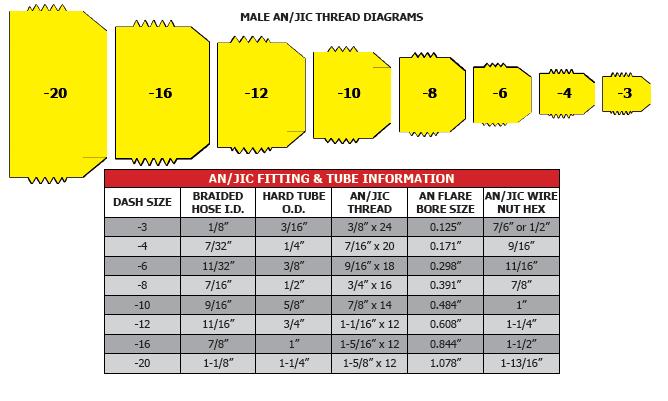

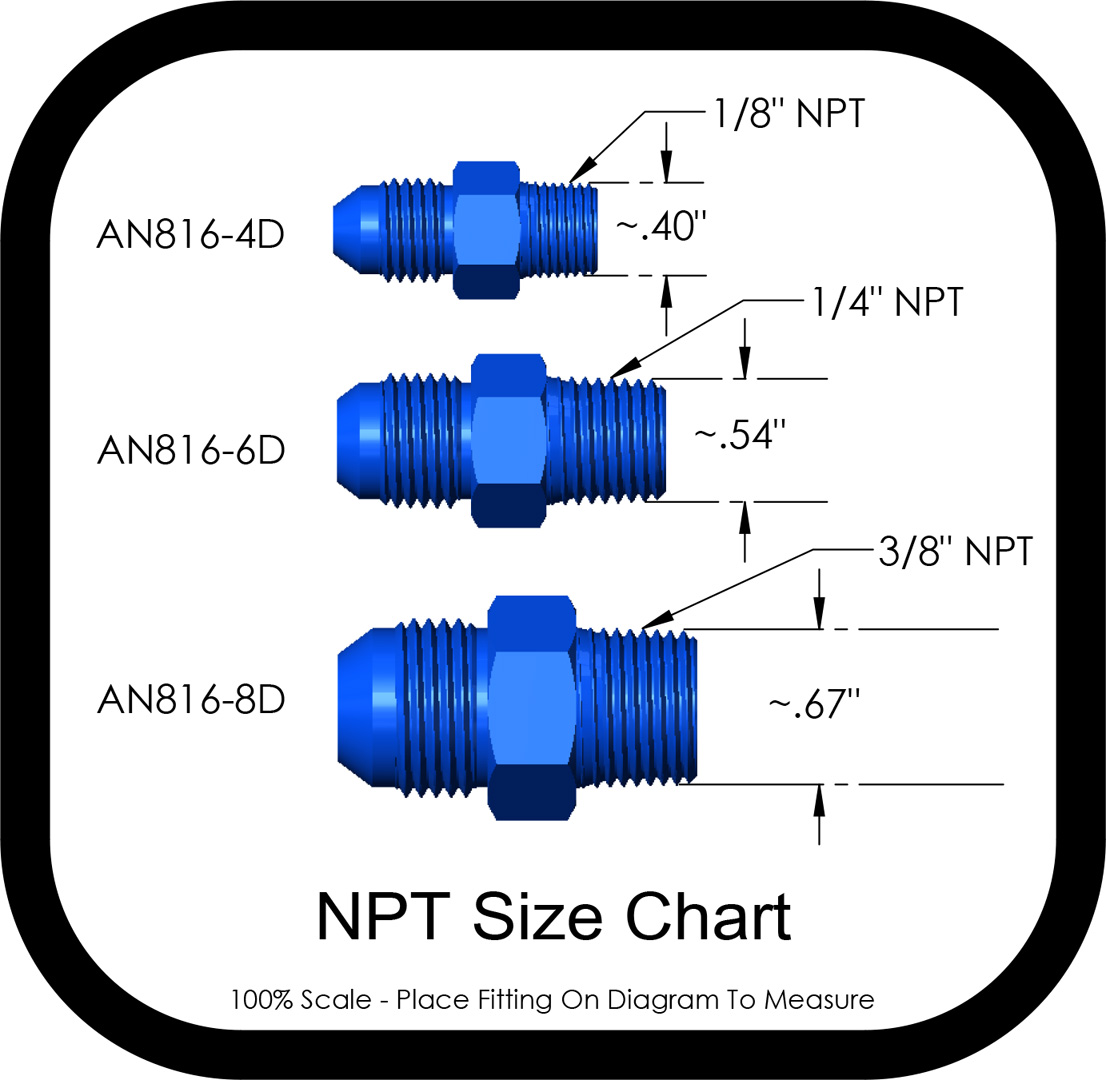

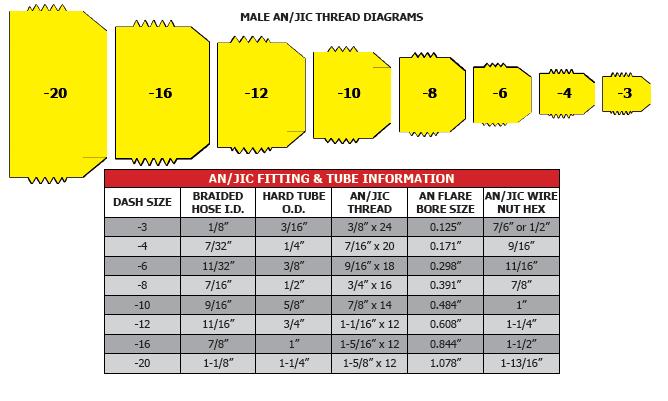

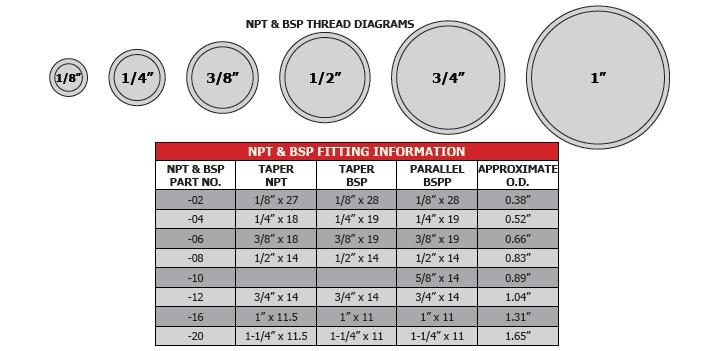

In the automotive world, hose size is expressed by inside diameter. For example, a 3/8 inch has has a nominal (approximate) inside diameter (ID) of 3/8 inch. Not so with aircraft hose. Aircraft hose uses dash numbers to designate the hose size.

Dash size is in 1/16 of an inch. So

-2 (2/16) 1/8 inch,

-6 (6/16) 3/8 inch,

-8 (8/16) 1/2 inch and so on.

But be careful, this does not mean that a -6 hose has an inside diameter of 3/8 inch. In fact, it can be anywhere from .298 to .359 inch, depending upon the hose type.

Common aircraft hose dash sizes are:

-2 Smallest hose size. Used as an instrument gage line

-3 Also used as an instrument gauge line

-4 Common hydraulic line. Some smaller fuel line

-6 Common size for fuel delivery lines

-8 Fuel delivery and oil cooler lines

-10 Larger aircraft, oil and fuel

-12 Larger aircraft, oil and fuel

-16 Larger aircraft, oil and fuel

The inside diameter of each hose and fitting dash size is found in size charts. A common mistake is to think all hose of the same dash size has the same inside diameter. There not

A common mistake is to think that all fittings of the same dash size have the same inside diameter. They do not.

http://www.jegs.com/i/Russell/799/670353/10002/-1

and yes, use of a small handy and accurate fuel pressure gauge, mounted on the fuel injector fuel rail (0-100 psi for FUEL INJECTION)

or carb inlet port (0-15 psi for carburetors)is almost mandatory, they generally cost under $30

http://www.grumpysperformance.com/braidhose.jpg[/im

http://www.jegs.com/i/Moroso/710/65374/10002/-1

http://www.grumpysperformance.com/efisystem.jpg

having a gauge helps

A common mistake is to think that a straight -6 fitting and a 90 -6 fitting of used on the same hose should both have the same inside diameter. They do not. A hose with a straight fitting on one end and an angle fitting on the other end will have different inside diameters.

http://www.grumpysperformance.com/sizing-fittingthread.gif

http://www.grumpysperformance.com/sizing-anthread.gif

READ THESE THREADS ALSO

viewtopic.php?f=55&t=733&p=6470&hilit=fuel+cell#p6470

viewtopic.php?f=55&t=4381&p=11507&hilit=fuel+cell#p11507

If you use a return-style regulator, you will also need a return line from the regulator back to the tank. The size of the return line is dependent on the size of the pump you are using, regardless of the engine's horsepower output. The return line must have limited or NO pressure in it. In most cases, the minimum return line size will match that of the supply line, but a larger return line is sometimes preferred.

Use these ratings to decide your return line sizing based upon fuel pump output:

*

Up to 45 GPH = 5/16" or -04 AN

*

Up to 90 GPH = 3/8" or -06 AN

*

Up to 250 GPH = 1/2" or -08 AN

*

Up to 450 GPH = 5/8" or -10 AN

*

Up to 900 GPH = 3/4"or -12 AN

http://www.grumpysperformance.com/fuelsysxz1.png

E85 fuel requires larger lines and a bigger fuel pump

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=10202']viewtopic.php?f=44&t=10202

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635']viewtopic.php?f=55&t=635

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=3172']viewtopic.php?f=55&t=3172

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=109']viewtopic.php?f=55&t=109

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1961']viewtopic.php?f=55&t=1961

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1442']viewtopic.php?f=55&t=1442

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=7787&p=26658#p26658']viewtopic.php?f=55&t=7787&p=26658#p26658

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1790']viewtopic.php?f=55&t=1790

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1030&p=1912&hilit=fittings#p1912']viewtopic.php?f=55&t=1030&p=1912&hilit=fittings#p1912

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=1469&p=3303&hilit=+gauges#p3303']viewtopic.php?f=62&t=1469&p=3303&hilit=+gauges#p3303

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635&p=12710#p12710']viewtopic.php?f=55&t=635&p=12710#p12710

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=733&p=1030#p1030']viewtopic.php?f=55&t=733&p=1030#p1030

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635']viewtopic.php?f=55&t=635

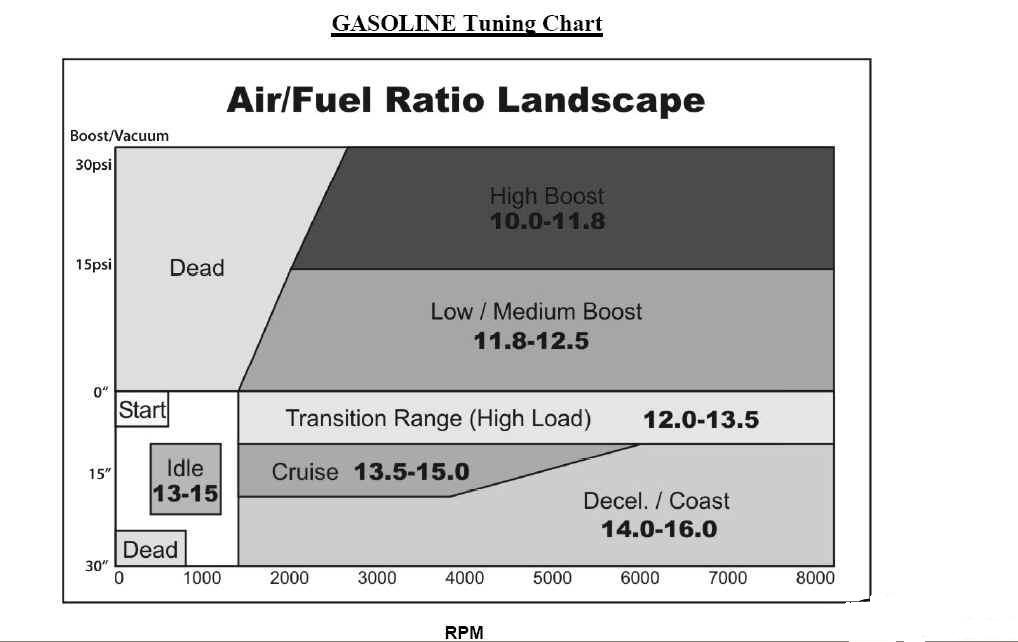

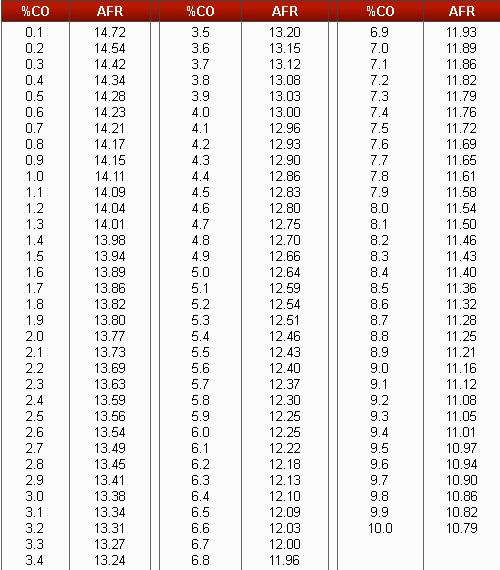

http://garage.grumpysperformance.co...ir-ratios-that-gets-ignored.15506/#post-92064

http://www.chevyhiperformance.com/techarticles/0606ch_carbureted_motor_fuel_system/index.html']http://www.chevyhiperformance.com/techa ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1939']viewtopic.php?f=55&t=1939

http://www.corvettefever.com/techarticles/corp_0908_corvette_fuel_systems/index.html']http://www.corvettefever.com/techarticl ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635&p=849#p849']viewtopic.php?f=55&t=635&p=849#p849

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587']viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587

most of the under hood gauges screw directly into fuel rails or fuel line fittings and read direct pressure, they are used for tuning and trouble shooting, direct pressure while accurate does pose safety issues inside the cars cab so they use remote electric sensors and wiring to in cab dash gauges for safety reasons, (you don,t want fuel leaks inside the cars cab, especially during a traffic accident, so get the remote dash gauges if its in the cab)

you should own a DEALER SHOP MANUAL for your car,that will provide the ideal fuel pressure info, but generally you'll want about 4.5-5.5 psi feed on carbs and about 40 psi on Chevy tpi or lT1 injection systems

read this first

https://www.centuryperformance.com/fuelish-tendencies.html

http://www.grumpysperformance.com/powra1.gif

http://www.grumpysperformance.com/AFR_Torque.gif

http://www.grumpysperformance.com/FuelFlowDiagram02a1.jpg

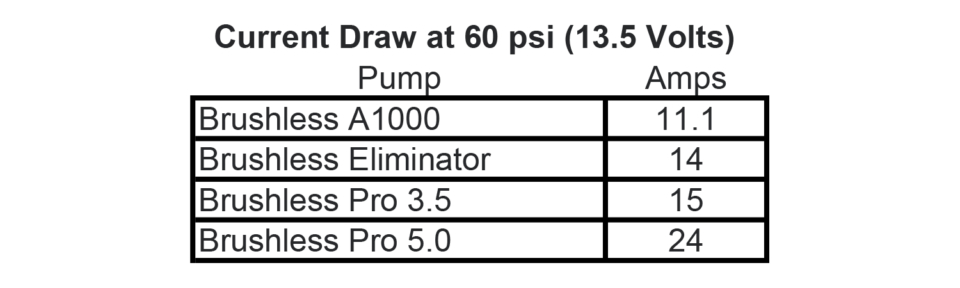

most electric fuel pumps last much longer if you follow three simple rules,

IF ITS INTERNAL TO THE FUEL TANK

(1)keep the fuel tank at least 1/4 full, so sloshing fuel cools the pump

(2) use a return style FUEL PRESSURE regulator, that allows a constant flow of fuel to cool the pump

IF ITS EXTERNALLY MOUNTED

(3) mount the pump low enough under the tanks fuel level so it self primes

BASIC CAR FUEL SYSTEM DESIGN

http://www.grumpysperformance.com/FuelFlowDiagram01.jpg

THIS WILL WORK

http://www.grumpysperformance.com/FuelFlowDiagramEdit copy123.gif

if your, looking at the diagram,and asking what pressure the fuel rail feeding the carburetor is pressurized too its obviously controlled by the fuel pressure regulator just beyond it in the diagram, which is usually located near the carburetor and fuel rail, to maintain the indicated 5psi, beyond that is the return line feeding back to the fuel tank and that should be close to zero, the main feed line from pump to the first fuel pressure regulator which ideally is located on the inner front fender or firewall maintains the 8psi-12psi the fuel pump provides , keep in mind a fuel pressure regulator can only control the pressure between it and its pressurized feed source, by bleeding off pressure above the peak its set for, it has zero control past it, it only controls pressure between it and its pressure feed source

OR

http://www.grumpysperformance.com/FuelFlowDiagram02.jpg

PERSONALLY, THE SIMPLER THE BETTER ,ID go THIS ROUTE

http://www.grumpysperformance.com/fpr123.jpg

http://www.grumpysperformance.com/EDL-1792.jpg

http://www.grumpysperformance.com/665-MP-6208.jpg

http://www.jegs.com/i/Magnafuel/665/MP-6208/10002/-1

http://www.summitracing.com/parts/EDL-1792/?rtype=10

ID be more likely to put something together that looked more like this but with a single fuel filter, and single fuel pump and two separate fuel pressure regulators all feed with two separate feed and return AN8 lines so you could have about 12 psi feed each fuel pressure regulator with 1/2" ID lines and run AN8 lines to the nitrous and carb fuel log and return lines

Ive had 750hp cars with a single 1/2" inside diam. fuel line loop from tank sump too pump too regulator and back as a return line that worked just fine BTW 1/2" inside diam. fuel line measures about 5/8"-3/4" outside, I buy mine from the local hydraulic supply house, SPECIFICALLY ask for HIGH TEMP,MID PRESSURE FUEL LINE with the metallic braided shield, 250-300F and 150PSI MINIMUM rated, measure VERY CAREFULLY then have them install the AN fittings with their hydraulic press that's designed to do the job correctly, and don,t get it near, or install it near hot engine or exhaust parts

ELECTRIC FUEL PUMPS PUSH FUEL FAR MORE EFFICIENTLY THAN THEY PULL FUEL, so place the pump low and close to the fuel tank, but inside the frame for impact protection in accidents

looks like this....

viewtopic.php?f=55&t=4381&p=11507&hilit=fuel+cell#p11507

http://www.discounthydraulichose.com/SAE_100R5_General_Purpose_Truck_Hose_p/r5-hose.htm

http://horsepowerperformance.com/c-7774 ... l-die.html

viewtopic.php?f=55&t=1030

AN4 or 5/16 id line will support up to about 420hp,

AN6 or 3/8 ID fuel line will support about 550-600hp if its correctly set up, youll want to jump to AN8 or 1/2" id line if your in the 550-800hp power zone

BTW THEY ALSO MAKE A SIMILAR FUEL LINE WITH STAINLESS BRAID on the outside

http://www.jegs.com/images/photos/500/555/555-100914.jpg

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_752578_-1_10019

look thru this link I provided

http://www.robbmcperformance.com/produc ... msend.html

http://www.centuryperformance.com/f...tanding-fuel-pressure-and-volume-spg-140.html

and just because you've installed a bigger diam. line and a better pump that's not the end of the deal, you can still have problems if the fittings and routing are less than ideal or the filters restrictive, the fitting most guys use cause a problem because the passages thru those fittings are to small and restrict flow ,that may or may not be the source of your problem, you REALLY SHOULD install a return style fuel pressure regulator and a return line or the fuel flow rates won,t cool the electric fuel pump,but ID point out that fittings and routing effect results, most guys don,t understand that the return line is designed too have and supposed too have nearly zero resistance too flow back to the tank, the factory line is marginal,and restrictive at best. and of to small a diam. on even the stock engine in my opinion, a 1/2" feed and a 3/8" minimum,or better yet a 1/2" return line would be a far more realistic match in a performance application, and be aware that the cheaper fittings have smaller internal passages, adding a 3/8" return like does little good if a fitting in that line has a 1/4" or 3/16" internal passage like some do!

IF your getting inconsistent fuel pressure in most cases,

IF you’re not using a RETURN LINE and a bye-pass style fuel pressure regulator that problems fairly common, it’s NOT common with a decent 3/8" or larger fuel lines, (BOTH feed AND return lines) matched with a bye-pass style fuel pressure regulator.

dead head style fuel pressure regulators are famous for that crappy control.

naturally you'll need to verify the carbs set up correctly with the correct jets,power valves, float levels etc, also, but the problem of fuel pressure jumping around inconsistently and seemingly for no reason is far more common to the dead head fuel pressure regulator designs with carbs..

http://www.centuryperformance.com/f...tanding-fuel-pressure-and-volume-spg-140.html

http://www.centuryperformance.com/fuel-system-troubleshooting-spg-142.html

it does very little good to run a 1/2" fuel feed and return line and hook it up to the factory 3/8" or 1/4" fittings at the factory tank , if the flow gets restricted at any point you'll see problems

HERES ONE SOURCE OF FITTINGS

http://www.holley.com/division/Earls.asp#21

http://www.russellperformance.com/misc/ ... pdf/26.pdf

http://www.holley.com/types/Ultra-Flex Hose Ends (standard length nut).asp

generally when Ive added a sump to a tank Ive used a steady flush of CO2 shield welding gas to fill the tank and make it totally inert if I had doubts, or several pounds of dry ice stuffed in the tank to evaporate, will help make it totally safe to weld on, but several flushes with hot water with some dish washing soap mix generally removes the vapors/residue. then after your done welding, just let it dry out in the hot sun with the air compressor flushing the interior.

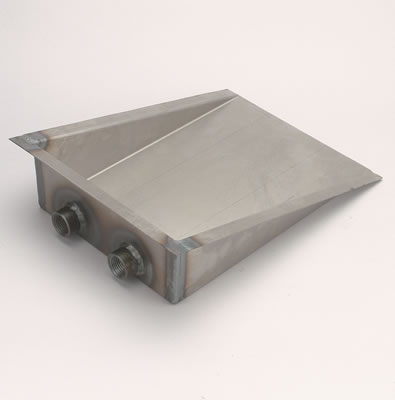

keep in mind you'll be drilling 4-6 holes in the tank and welding the sump over the holes so fuel dropping thru the holes is trapped in the sump under high G loads, you DON,T want to cut one huge hole it weakens the tank and makes it far more flexible, BTW if your not 100% sure all the pin holes in the weld seam are filled you can silver solder over the welds, or get cheap and dirty and use J&B epoxy as an exterior sealer, use something like this

http://www.kbs-coatings.com/KBS-Aut...UserID=1045409&SessionID=PoOgOUlfTTIo3wZCT7yV

to seal crud inside the tank

naturally if your bucks up, you avoid the work buy purchasing a aluminum fuel cell, http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-293220-S&N=700+115&autoview=sku

http://www.russellperformance.com/misc/ ... pdf/26.pdf

keep in mind its does little good to run larger 1/2" lines in a high hp application and then install fittings or filters ETC. with internal passages significantly smaller than the 1/2" lines feeding them. Ive seen many installs where decent line size was rendered nearly useless with fittings or filters of significantly smaller internal diam. rendering the line size almost immaterial to the flow restriction the fitting presented to the flow of fuel

a 1/2" fittings with 5/16" internal passages effectively make a 1/2" like flow at a 5/16" line rate

THE AN FITTINGS (like the two lower examples) WILL GENERALLY HAVE MUCH MORE CONSISTENT INTERNAL DIAM. AND HIGHER FLOW RATES THAN CHEAPER PLUMBING STYLE ADAPTER FITTINGS, MANY GUYS PICK UP AND USE FROM LOCAL HARDWARE STORES

I can assure you fittings like these restrict flow rates more than CORRECTLY SELECTED and SIZED /MATCHED FITTINGS LIKE THESE

if you ask the supplier of any fuel lines, you buy at any hydraulic supply house, in most cases they will know if the hose, lines they supply are compatible with current fuel, and at what pressures,but keep in mind current fuels have a bit of alcohol in many of the blends and hose that handles gas may not handle an alcohol blend /gas fuel long term...I see guys experience leaks from degraded rubber/synthetic fuel lines that held up fine with just gas, far more frequently with today's fuel lines than in the past

For your older carburetor, equiped muscle car, this will generally be for most performance cars 5-6 psi of fuel pressure at the carb inlet port, a fuel pump should supply about 130%-to-150% of the minimum flow rates the charts posted lower in the thread , so a manual fuel pump rated at 90-130 gph is generally a good idea if your intent on making 400-550 hp, and taking the time and effort to accurately check your carbs float levels when you set it up!

and youll need to know not guess or assume that the limitations of the current fuel pump, pressure, and volume , so its able to supply your engine, having a small fuel pressure gauge mounted on the fuel rail helps and know the limitations on the current fuel lines, fuel filter and any restrictions to flow imposed by the fittings and connections to the filters and fuel tank, the fittings , lines internal cross sectional area,and the restrictions to flow that they potentially represent.

heat, inertial loads and distance all reduce flow rates.

as a basic rule carburetor engines will need about 6 psi at the carburetor inlet port, fuel rails or lines for fuel injection systems that feed , fuel injectors generally need between 40-60 psi at the fuel rail.

http://www.prpracingproducts.com/products-page/fuel-system-accessories/fuel-pressure-regulators/it makes no logical sense to run 1/2" or AN#8 lines to and from a fuel cell, or fuel tank, too a pressure regulator , or fuel pump or fuel filter,with restrictive AN#6 or 3/8" lines, if your intention is to make much over 500 hp so use a regulator , fuel filter and lines and fittings that all match, and allow max flow levels with little restriction, remember a chain is as strong as its weakest link, and a fuel delivery system will be limited by its most restrictive flow points..

one very common symptom, of a fuel system thats not keeping up with demand is a car that pulls hard through first gear and maybe second then power noses over as you go further, or a bad miss that develops in 2nd or third gear thats not there in first gear at the same rpm level.

http://www.eastwood.com/professiona...e=&network=g&gclid=CIe-y9b938cCFUhhfgodBkQCDg

heres a bunch of good info

http://www.aeromotiveinc.com/stealthdiagrams/

loss of third gear fuel pressure?

Hi all, I have a fairly healthy (~460hp) 406 SBC with a 800cfm DP Holley, a Carter M4891 (120gph) mechanical fuel pump and 3/8" hard line front to back with a 3/8" pickup. This fuel system has worked great for me the last three seasons of driving and ~30 passes down the quarter mile. But when...

garage.grumpysperformance.com

any serious fuel delivery system will require a fuel cell, or major changes to an existing fuel tank, and larger diameter fuel lines and a better fuel filter aling with a matched return style fuel pressure regulator and return lines, you can,t simply swap in a few components the whole system, (end to end) will need to be upgraded if you expect reliable fuel delivery by the time your exceeding about 550-600 hp.

Everyone initially, thinks they can simply put a larger fuel pump on the existing fuel lines the car came with,

inevitably they will be forced to accept the reality of the physics involved,

even if they don,t yet see the need yet

and those that don,t make the required upgrades,

will look far less knowledgeable if that issue is not resolved before damage occurs,

this is simply a watch them read links ,accept advice, and make suggested ,

changes or watch them gain knowledge, the hard & expensive way after replacing damaged parts that resulted

DON'T SKIP OVER/IGNORE THIS LINKED INFO

low pressure electrical fuel pumps are available for carb applications

https://www.holley.com/products/fue...ed_fuel_pumps/carbureted_electric_fuel_pumps/

http://www.jegs.com/c/Fuel-Carbs-Intakes_Electric-Fuel-Pumps/10307/10002/-1

http://www.edelbrock.com/automotive/mc/fuel-pumps/

http://www.mechanicalcaveman.com/best-electric-pump-for-carburetor-fuel-pump-review/

http://www.weldonracing.com/store/!/Pumps/c/14136041/offset=0&sort=normal

http://www.jegs.com/p/Aeromotive/Aeromotive-A3000-Drag-Race-Fuel-Pump/2944771/10002/-1

http://www.superchevy.com/how-to/en...ou-need-to-know-about-aftermarket-fuel-pumps/

http://gottafishcarburetors.com/CFM Formula.html

http://wallaceracing.com/intakecfm.php

http://realstreetperformance.com/Fuel-Pump-Comparison-Test.html

As usual it helps to do some detailed research on the internet and if your racing on a local track there will generally be a rule book that clearly lays out whats required and whats prohibited to read through, and if you take the time to look, you may find some older and experience successful racers willing to give you a few details and tips

YOULL FIND THESE CLOSELY RELATED THREADS VERY USEFUL

http://garage.grumpysperformance.com/index.php?threads/how-big-a-fuel-pump-do-you-need.1939/

http://garage.grumpysperformance.com/index.php?threads/fuel-line-sizing-return-vs-feed.3067/

http://garage.grumpysperformance.co...lectric-fuel-pump-selection.10664/#post-46121

http://garage.grumpysperformance.co...-sizing-return-vs-feed.3067/page-2#post-44820

http://garage.grumpysperformance.com/index.php?threads/replacing-a-c-4-fuel-pump.33/#post-42213

http://garage.grumpysperformance.co...bit-of-intank-fuel-pump-info.7848/#post-27077

http://garage.grumpysperformance.co...selection-design-for-500-hp-fuel-system.7787/

http://garage.grumpysperformance.com/index.php?threads/flex-fuel-lines.4381/#post-16285

http://garage.grumpysperformance.com/index.php?threads/installing-a-fuel-cell.733/#post-6470

viewtopic.php?f=55&t=635

http://www.superchevy.com/how-to/0606ch-carbureted-motor-fuel-system/

http://www.chevyhardcore.com/tech-s...ning-building-street-performance-fuel-system/

viewtopic.php?f=55&t=624

http://www.atlinc.com/racing.html

too much or too little fuel pressure?

Need advice. I have a 1956 Chevy truck. The problem I'm having is every time I put the gas pedal to the floor the truck gets up and takes off. After I let off the gas the truck sputters and dies. I open the hood and look at the fuel pressure regulator it reads zero and won't pressure up. I have...

garage.grumpysperformance.com

http://www.magnafuel.com/support/

VERY INTERESTING ADDITION TO THE POTENTIAL FUEL SYSTEM DESIGN

http://www.motoiq.com/MagazineArticles/ ... rvoir.aspx

the problem with all decent quality fuel line supply component parts is they cost more money, than the cheap low quality parts and generally take up more room and take a bit more time and thought to instal correctly

http://www.summitracing.com/parts/hly-12-841/overview/

http://www.amazon.com/Moeller-Separatin ... d_sbs_sg_1

http://www.summitracing.com/parts/edl-1792/overview/

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

I can easily see where the diagram may be confusing ,, and while that cheap holley return style fuel pressure regulator works

at maintaining fuel pressure on the inlet port and can be used its far from the better choice

this is the type of FP regulator you want in most cases,

and it comes in AN#8 and AN#10 sizes

its simply a strait through fuel flow with a pressure release that leads to the return line that opens if the fuel pressure exceeds a set level, thus it maintains that max pressure

https://www.holley.com/products/fuel_systems/fuel_pumps_regulators_and_filters/regulators/carbureted_regulators/parts/12-841

http://documents.holley.com/199r10575rev3.pdf

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

one of the most common mistakes less than experienced performance enthusiasts, face and very commonly over-look, is the fact that the internal cross sectional area on many hydraulic and fuel line fittings are considerably more restrictive to flow that the fuel limes or hydraulic lines inside diameter they were designed to be used with, and it varies a great deal between different manufacturers, now ideally the fittings internal passage cross sectional area is both consistent and the same or greater that the tube or hydraulic line size, it listed to match, , so a 1/2" inside diameter fuel line, or hydraulic lines?hoses, for example should have components for the connections and fittings that have significantly smaller internal cross sectional areas, it does you very little good to use lets say, AN#8 or half inch fuel lines if the internal cross sectional area of the connections and fitting used with those lines is only 3/8" or smaller in cross sectional area,this is an area where dealing with a local hydraulic supply shop that has the correct tools and fittings to custom fabricate your fuel lines, coolant or lubrication lines is a very good idea!

talk to a local professional at your local hydraulic supply, measure accurately, take the time to explain what your trying to accomplish and take several pictures to show them what your doing, and get them too fabricate any high pressure fuel or coolant lines and related fittings

*

Up to 45 GPH= 3/4 GPM = 5/16" or -04 AN

*

Up to 90 GPH = 1.5 GPM= 3/8" or -06 AN

*

Up to 250 GPH =4.2 GPM= 1/2" or -08 AN

nearly ideal for transmission and oil coolers

*

Up to 450 GPH =7.5 GPM= 5/8" or -10 AN

*

Up to 900 GPH = 15GPM 3/4"or -12 AN

keep in mind that thats the minimum required, a fuel system has restrictions to flow rates like filters ,fitting and internal line flow restrictions requiring you to have a slightly higher actual supply volume and pressure

I don,t use aluminum, fuel line, because it fatigues quickly and it frequently rated under 40 psi., the best line is stainless steel hydraulic line you can usually get from a local hydraulic hose supply manufacturer or repair shop, its generally rated at 1000 psi or higher in 1/2" size I GENERALLY RUN ON PERFORMANCE CAR APPLICATIONS, shop carefully some places price that line like its made of gold, most are far more reasonable.

remember pressure and volume are two different measurements and youll need to supply both at a certain level to maintain a dependable power level, what works just fine in a fuel supply system idling in your drive way on a typical 350-400 cubic inch engine thats common in most cars ,built for performance,to feed the needs of an engine running at 1500rpm-3000rpm is a far cry from whats required at 6500rpm under 3/4 G acceleration loads.

that brass fitting you picked up cheaply some place that feeds the 3/8" inside diam. hose that has the 1/4" passage thru it , that allows a fuel pump rated at lets say 130gph to pump 70gph, won,t seem restrictive until the cars under full acceleration in top gear.

these links and sub links below should help, keep in mind in the tank electric fuel pumps tend to be cooled by sloshing fuel , so maintaining at least a 1/4 tank volume tends to prolong pump life span and pumps work far better with a return style fuel pressure regulator as that style tends to allow a consistent minimal fuel flow thru the pump to absorb and transfer heat out of the pump. the less expensive frame mount external electric fuel pumps tend to have heat related durability issues and tend to be louder as they operate. don,t forget a decent quality fuel filter that has the flow capacity to not be restrictive, a restrictive fuel filter can significantly reduce fuel flow rates.

adding a fuel pressure gauge.

I wanted to install a mechanical fuel pressure gauge on my 91 L98 TPI. Sometimes the car don't start (driven infrequently) and I want to know at a glance if I got fuel pressure. I wanted the gauge to be visible from the drivers side, and not interfere with removing the valve covers. ended up...

garage.grumpysperformance.com

http://www.hydraulic-supply.com/html/pr ... tubing.htm

http://store.fedhillusa.com/cnf6.aspx

http://www.discounthydraulichose.com/Hy ... tm?Click=3

http://shop.hoseandfittings.com/catalog ... S-304.html

IF you decide you want a fuel cut off valve to make fuel filter changes less messy,

http://www.harborfreight.com/38-Full-Po ... 68255.html

while not ideal Ive seen these valves above used

http://www.brewershardware.com/1-2-Full ... Valve.html

I generally use AN#8 lines and stainless valves like this

viewtopic.php?f=55&t=7787&hilit=shut+off+fuel

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1939

viewtopic.php?f=55&t=4381

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=6105&p=18854#p18854

viewtopic.php?f=55&t=211&p=275&hilit=fuel+filter+drain#p275

http://www.copper.org/applications/auto ... brake.html

use steel hydraulic/fuel line its rated well over 1000 psi, it comes in 25 ft lengths in either 3/8" (AN#6) or 1/2" (AN#8)

READ THESE LINKS POSTED IN THE THREAD BELOW ALSO[/color]

https://www.centuryperformance.com/fuelish-tendencies.html

viewtopic.php?f=55&t=1378&p=3035#p3035

http://web.archive.org/web/200701062316 ... 1.htm#FPHP

http://www.duccutters.com/ConvertionCha ... bzyv5ytbP1

viewtopic.php?f=55&t=231

http://www.youtube.com/watch?feature=pl ... uIoAa5RRBs

http://www.stealth316.com/2-air-fuel-flow.htm

http://www.circletrack.com/enginetech/c ... _pressure/

http://www.smartfireinjectors.com/fuelflowchart.html

http://www.designatedengineer.com/FuelLineSizing.html

viewtopic.php?f=44&t=4912&p=14365#p14365

viewtopic.php?f=55&t=1939&p=5137#p5137

viewtopic.php?f=55&t=10664

e.com/viewtopic.php?f=55&t=231

For Dead-Head type regulators:

Multiply maximum horsepower by .23 to calculate minimum pump size in "free flow" GPH.

Example: 400 HP x .23 = 91 GPH "free flow"

For Return-Style regulators:

Multiply maximum horsepower by .17 to calculate minimum pump size in "free flow" GPH.

Example: 400 HP x .17 = 68 GPH "free flow"

The minimum fuel line size (from the pump to the regulator) is dependent on the horsepower output of the engine (and/or Nitrous system) regardless of the size of the pump. fuel pressure regulators are normally placed as close to the fuel rail or carburetor feed inlet port as possible to maintain most of the fuel feed lines under higher pressure to reduce vapor-lock, high g -force fuel starvation and to reduce the chance of air entering the carburetor ,or injectors and keep a constant flow of cool fuel reaching the injector's or carburetor, because theres a constant flow of new fresh fuel being forced up to and some bye-passed thru the system, and fed to the engine

keep in mind TPI fuel pressure regulators maintain about 40-45 psi while carburetors require about 4.5-6.5 psi MAX, but in most cases the fuel pressure at the carb inlet port NEEDS to read 4.5-5 psi MAX and you NEED to set the float levels per the carburetor manufacturers instructions, having the pressure at 6.5 psi will in many cases cause the needle & seat valve to constantly leak excess fuel, into the carburetor while the engine runs.

BTW any time you start having fuel delivery issue's check the electrical connections, fuzes, relays, and replace the fuel filter as those are frequently major factors in causing problems

Use these figures as a fuel line sizing standard: if your feeding a carburetor with the typical 8-10 psi fuel pump feeding to the fuel pressure regulator

* Up to 250 HP = 5/16" or -04 AN

* Up to 500 HP = 3/8" or -06 AN

* Up to 700 HP = 1/2" or -08 AN

* Up to 1000 HP = 5/8" or -10 AN

* Up to 1500 HP = 3/4" or -12 AN

many guys fail to keep the line size consistent, it does no good to feed a 1/2" or AN8 line from a 3/8" or AN6 fitting in your fuel filter or fuel pump are to try to suck fuel from the tank thru the stock lines and then feed larger lines, you'll need a fuel tank or fuel cell,and matching line adapters and fittings with the correct matched internal dimensions

fuel flow is restricted to the limitations imposed by the smallest cross sectional area of the smallest and most restrictive line or fitting, if a fuel filter restricts you to lets say 70 gph at 7psi hooking it to a fuel line that potentially flows 120gph at 7psi won,t increase the flow

In the automotive world, hose size is expressed by inside diameter. For example, a 3/8 inch has has a nominal (approximate) inside diameter (ID) of 3/8 inch. Not so with aircraft hose. Aircraft hose uses dash numbers to designate the hose size.

Dash size is in 1/16 of an inch. So

-2 (2/16) 1/8 inch,

-6 (6/16) 3/8 inch,

-8 (8/16) 1/2 inch and so on.

But be careful, this does not mean that a -6 hose has an inside diameter of 3/8 inch. In fact, it can be anywhere from .298 to .359 inch, depending upon the hose type.

Common aircraft hose dash sizes are:

-2 Smallest hose size. Used as an instrument gage line

-3 Also used as an instrument gauge line

-4 Common hydraulic line. Some smaller fuel line

-6 Common size for fuel delivery lines

-8 Fuel delivery and oil cooler lines

-10 Larger aircraft, oil and fuel

-12 Larger aircraft, oil and fuel

-16 Larger aircraft, oil and fuel

The inside diameter of each hose and fitting dash size is found in size charts. A common mistake is to think all hose of the same dash size has the same inside diameter. There not

A common mistake is to think that all fittings of the same dash size have the same inside diameter. They do not.

http://www.jegs.com/i/Russell/799/670353/10002/-1

and yes, use of a small handy and accurate fuel pressure gauge, mounted on the fuel injector fuel rail (0-100 psi for FUEL INJECTION)

or carb inlet port (0-15 psi for carburetors)is almost mandatory, they generally cost under $30

http://www.grumpysperformance.com/braidhose.jpg[/im

http://www.jegs.com/i/Moroso/710/65374/10002/-1

http://www.grumpysperformance.com/efisystem.jpg

having a gauge helps

A common mistake is to think that a straight -6 fitting and a 90 -6 fitting of used on the same hose should both have the same inside diameter. They do not. A hose with a straight fitting on one end and an angle fitting on the other end will have different inside diameters.

http://www.grumpysperformance.com/sizing-fittingthread.gif

http://www.grumpysperformance.com/sizing-anthread.gif

READ THESE THREADS ALSO

viewtopic.php?f=55&t=733&p=6470&hilit=fuel+cell#p6470

viewtopic.php?f=55&t=4381&p=11507&hilit=fuel+cell#p11507

If you use a return-style regulator, you will also need a return line from the regulator back to the tank. The size of the return line is dependent on the size of the pump you are using, regardless of the engine's horsepower output. The return line must have limited or NO pressure in it. In most cases, the minimum return line size will match that of the supply line, but a larger return line is sometimes preferred.

Use these ratings to decide your return line sizing based upon fuel pump output:

*

Up to 45 GPH = 5/16" or -04 AN

*

Up to 90 GPH = 3/8" or -06 AN

*

Up to 250 GPH = 1/2" or -08 AN

*

Up to 450 GPH = 5/8" or -10 AN

*

Up to 900 GPH = 3/4"or -12 AN

http://www.grumpysperformance.com/fuelsysxz1.png

E85 fuel requires larger lines and a bigger fuel pump

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=10202']viewtopic.php?f=44&t=10202

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635']viewtopic.php?f=55&t=635

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=3172']viewtopic.php?f=55&t=3172

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=109']viewtopic.php?f=55&t=109

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1961']viewtopic.php?f=55&t=1961

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1442']viewtopic.php?f=55&t=1442

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=7787&p=26658#p26658']viewtopic.php?f=55&t=7787&p=26658#p26658

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1790']viewtopic.php?f=55&t=1790

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1030&p=1912&hilit=fittings#p1912']viewtopic.php?f=55&t=1030&p=1912&hilit=fittings#p1912

http://forum.grumpysperformance.com/viewtopic.php?f=62&t=1469&p=3303&hilit=+gauges#p3303']viewtopic.php?f=62&t=1469&p=3303&hilit=+gauges#p3303

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635&p=12710#p12710']viewtopic.php?f=55&t=635&p=12710#p12710

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=733&p=1030#p1030']viewtopic.php?f=55&t=733&p=1030#p1030

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635']viewtopic.php?f=55&t=635

http://garage.grumpysperformance.co...ir-ratios-that-gets-ignored.15506/#post-92064

http://www.chevyhiperformance.com/techarticles/0606ch_carbureted_motor_fuel_system/index.html']http://www.chevyhiperformance.com/techa ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1939']viewtopic.php?f=55&t=1939

http://www.corvettefever.com/techarticles/corp_0908_corvette_fuel_systems/index.html']http://www.corvettefever.com/techarticl ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=635&p=849#p849']viewtopic.php?f=55&t=635&p=849#p849

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587']viewtopic.php?f=55&t=733&p=3587&hilit=cell#p3587

most of the under hood gauges screw directly into fuel rails or fuel line fittings and read direct pressure, they are used for tuning and trouble shooting, direct pressure while accurate does pose safety issues inside the cars cab so they use remote electric sensors and wiring to in cab dash gauges for safety reasons, (you don,t want fuel leaks inside the cars cab, especially during a traffic accident, so get the remote dash gauges if its in the cab)

you should own a DEALER SHOP MANUAL for your car,that will provide the ideal fuel pressure info, but generally you'll want about 4.5-5.5 psi feed on carbs and about 40 psi on Chevy tpi or lT1 injection systems

read this first

https://www.centuryperformance.com/fuelish-tendencies.html

http://www.grumpysperformance.com/powra1.gif

http://www.grumpysperformance.com/AFR_Torque.gif

http://www.grumpysperformance.com/FuelFlowDiagram02a1.jpg

most electric fuel pumps last much longer if you follow three simple rules,

IF ITS INTERNAL TO THE FUEL TANK

(1)keep the fuel tank at least 1/4 full, so sloshing fuel cools the pump

(2) use a return style FUEL PRESSURE regulator, that allows a constant flow of fuel to cool the pump

IF ITS EXTERNALLY MOUNTED

(3) mount the pump low enough under the tanks fuel level so it self primes

BASIC CAR FUEL SYSTEM DESIGN

http://www.grumpysperformance.com/FuelFlowDiagram01.jpg

THIS WILL WORK

http://www.grumpysperformance.com/FuelFlowDiagramEdit copy123.gif

if your, looking at the diagram,and asking what pressure the fuel rail feeding the carburetor is pressurized too its obviously controlled by the fuel pressure regulator just beyond it in the diagram, which is usually located near the carburetor and fuel rail, to maintain the indicated 5psi, beyond that is the return line feeding back to the fuel tank and that should be close to zero, the main feed line from pump to the first fuel pressure regulator which ideally is located on the inner front fender or firewall maintains the 8psi-12psi the fuel pump provides , keep in mind a fuel pressure regulator can only control the pressure between it and its pressurized feed source, by bleeding off pressure above the peak its set for, it has zero control past it, it only controls pressure between it and its pressure feed source

OR

http://www.grumpysperformance.com/FuelFlowDiagram02.jpg

PERSONALLY, THE SIMPLER THE BETTER ,ID go THIS ROUTE

http://www.grumpysperformance.com/fpr123.jpg

http://www.grumpysperformance.com/EDL-1792.jpg

http://www.grumpysperformance.com/665-MP-6208.jpg

http://www.jegs.com/i/Magnafuel/665/MP-6208/10002/-1

http://www.summitracing.com/parts/EDL-1792/?rtype=10

ID be more likely to put something together that looked more like this but with a single fuel filter, and single fuel pump and two separate fuel pressure regulators all feed with two separate feed and return AN8 lines so you could have about 12 psi feed each fuel pressure regulator with 1/2" ID lines and run AN8 lines to the nitrous and carb fuel log and return lines

Ive had 750hp cars with a single 1/2" inside diam. fuel line loop from tank sump too pump too regulator and back as a return line that worked just fine BTW 1/2" inside diam. fuel line measures about 5/8"-3/4" outside, I buy mine from the local hydraulic supply house, SPECIFICALLY ask for HIGH TEMP,MID PRESSURE FUEL LINE with the metallic braided shield, 250-300F and 150PSI MINIMUM rated, measure VERY CAREFULLY then have them install the AN fittings with their hydraulic press that's designed to do the job correctly, and don,t get it near, or install it near hot engine or exhaust parts

ELECTRIC FUEL PUMPS PUSH FUEL FAR MORE EFFICIENTLY THAN THEY PULL FUEL, so place the pump low and close to the fuel tank, but inside the frame for impact protection in accidents

looks like this....

viewtopic.php?f=55&t=4381&p=11507&hilit=fuel+cell#p11507

http://www.discounthydraulichose.com/SAE_100R5_General_Purpose_Truck_Hose_p/r5-hose.htm

http://horsepowerperformance.com/c-7774 ... l-die.html

viewtopic.php?f=55&t=1030

AN4 or 5/16 id line will support up to about 420hp,

AN6 or 3/8 ID fuel line will support about 550-600hp if its correctly set up, youll want to jump to AN8 or 1/2" id line if your in the 550-800hp power zone

BTW THEY ALSO MAKE A SIMILAR FUEL LINE WITH STAINLESS BRAID on the outside

http://www.jegs.com/images/photos/500/555/555-100914.jpg

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_752578_-1_10019

look thru this link I provided

http://www.robbmcperformance.com/produc ... msend.html

http://www.centuryperformance.com/f...tanding-fuel-pressure-and-volume-spg-140.html

and just because you've installed a bigger diam. line and a better pump that's not the end of the deal, you can still have problems if the fittings and routing are less than ideal or the filters restrictive, the fitting most guys use cause a problem because the passages thru those fittings are to small and restrict flow ,that may or may not be the source of your problem, you REALLY SHOULD install a return style fuel pressure regulator and a return line or the fuel flow rates won,t cool the electric fuel pump,but ID point out that fittings and routing effect results, most guys don,t understand that the return line is designed too have and supposed too have nearly zero resistance too flow back to the tank, the factory line is marginal,and restrictive at best. and of to small a diam. on even the stock engine in my opinion, a 1/2" feed and a 3/8" minimum,or better yet a 1/2" return line would be a far more realistic match in a performance application, and be aware that the cheaper fittings have smaller internal passages, adding a 3/8" return like does little good if a fitting in that line has a 1/4" or 3/16" internal passage like some do!

IF your getting inconsistent fuel pressure in most cases,

IF you’re not using a RETURN LINE and a bye-pass style fuel pressure regulator that problems fairly common, it’s NOT common with a decent 3/8" or larger fuel lines, (BOTH feed AND return lines) matched with a bye-pass style fuel pressure regulator.

dead head style fuel pressure regulators are famous for that crappy control.

naturally you'll need to verify the carbs set up correctly with the correct jets,power valves, float levels etc, also, but the problem of fuel pressure jumping around inconsistently and seemingly for no reason is far more common to the dead head fuel pressure regulator designs with carbs..

http://www.centuryperformance.com/f...tanding-fuel-pressure-and-volume-spg-140.html

http://www.centuryperformance.com/fuel-system-troubleshooting-spg-142.html

it does very little good to run a 1/2" fuel feed and return line and hook it up to the factory 3/8" or 1/4" fittings at the factory tank , if the flow gets restricted at any point you'll see problems

HERES ONE SOURCE OF FITTINGS

http://www.holley.com/division/Earls.asp#21

http://www.russellperformance.com/misc/ ... pdf/26.pdf

http://www.holley.com/types/Ultra-Flex Hose Ends (standard length nut).asp

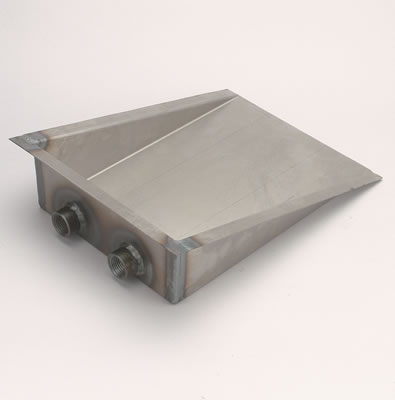

generally when Ive added a sump to a tank Ive used a steady flush of CO2 shield welding gas to fill the tank and make it totally inert if I had doubts, or several pounds of dry ice stuffed in the tank to evaporate, will help make it totally safe to weld on, but several flushes with hot water with some dish washing soap mix generally removes the vapors/residue. then after your done welding, just let it dry out in the hot sun with the air compressor flushing the interior.

keep in mind you'll be drilling 4-6 holes in the tank and welding the sump over the holes so fuel dropping thru the holes is trapped in the sump under high G loads, you DON,T want to cut one huge hole it weakens the tank and makes it far more flexible, BTW if your not 100% sure all the pin holes in the weld seam are filled you can silver solder over the welds, or get cheap and dirty and use J&B epoxy as an exterior sealer, use something like this

http://www.kbs-coatings.com/KBS-Aut...UserID=1045409&SessionID=PoOgOUlfTTIo3wZCT7yV

to seal crud inside the tank

naturally if your bucks up, you avoid the work buy purchasing a aluminum fuel cell, http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-293220-S&N=700+115&autoview=sku

http://www.russellperformance.com/misc/ ... pdf/26.pdf

keep in mind its does little good to run larger 1/2" lines in a high hp application and then install fittings or filters ETC. with internal passages significantly smaller than the 1/2" lines feeding them. Ive seen many installs where decent line size was rendered nearly useless with fittings or filters of significantly smaller internal diam. rendering the line size almost immaterial to the flow restriction the fitting presented to the flow of fuel

a 1/2" fittings with 5/16" internal passages effectively make a 1/2" like flow at a 5/16" line rate

THE AN FITTINGS (like the two lower examples) WILL GENERALLY HAVE MUCH MORE CONSISTENT INTERNAL DIAM. AND HIGHER FLOW RATES THAN CHEAPER PLUMBING STYLE ADAPTER FITTINGS, MANY GUYS PICK UP AND USE FROM LOCAL HARDWARE STORES

I can assure you fittings like these restrict flow rates more than CORRECTLY SELECTED and SIZED /MATCHED FITTINGS LIKE THESE

if you ask the supplier of any fuel lines, you buy at any hydraulic supply house, in most cases they will know if the hose, lines they supply are compatible with current fuel, and at what pressures,but keep in mind current fuels have a bit of alcohol in many of the blends and hose that handles gas may not handle an alcohol blend /gas fuel long term...I see guys experience leaks from degraded rubber/synthetic fuel lines that held up fine with just gas, far more frequently with today's fuel lines than in the past

Last edited by a moderator: