always call the cylinder head manufacturer for their input on rocker stud girdles,BEFORE PURCHASING THEM< because rocker stud spacing, and stud angles can vary, between head designs and models

READ THRU THIS THREAD ALSO

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

shaft rockers add rigidity , to the valve train,by eliminating the rocker stud flex issues,

but keep in mind that a rocker stud girdle can be added to the stock type of valve train,

and when used with quality roller rockers they add a good bit of rigidity to the stock style valve train.

shaft rockers add rigidity , to the valve train,by eliminating the rocker stud flex issues,

but keep in mind that a rocker stud girdle can be added to the stock type of valve train,

and when used with quality roller rockers they add a good bit of rigidity to the stock style valve train.

short answer, as a rule of thumb,shaft rockers are advisable

(1) any time your valve open loads exceed 400 lbs and/or you want to exceed 6500 rpm regularly.

(2) any time you intend to exceed 7000 rpm regularly and valve open loads exceed 500 lbs they would be considered almost mandatory..

yes you can in most cases use a stud girdle, with quality roller rockers,

but the shaft rocker design tends to be more rigid, and tends to aid durability

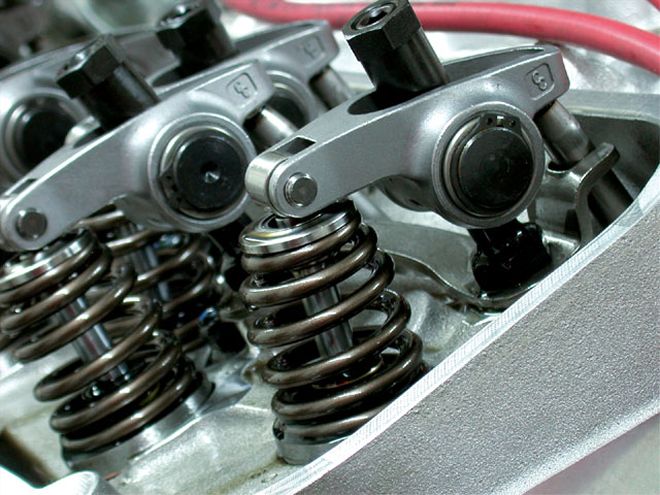

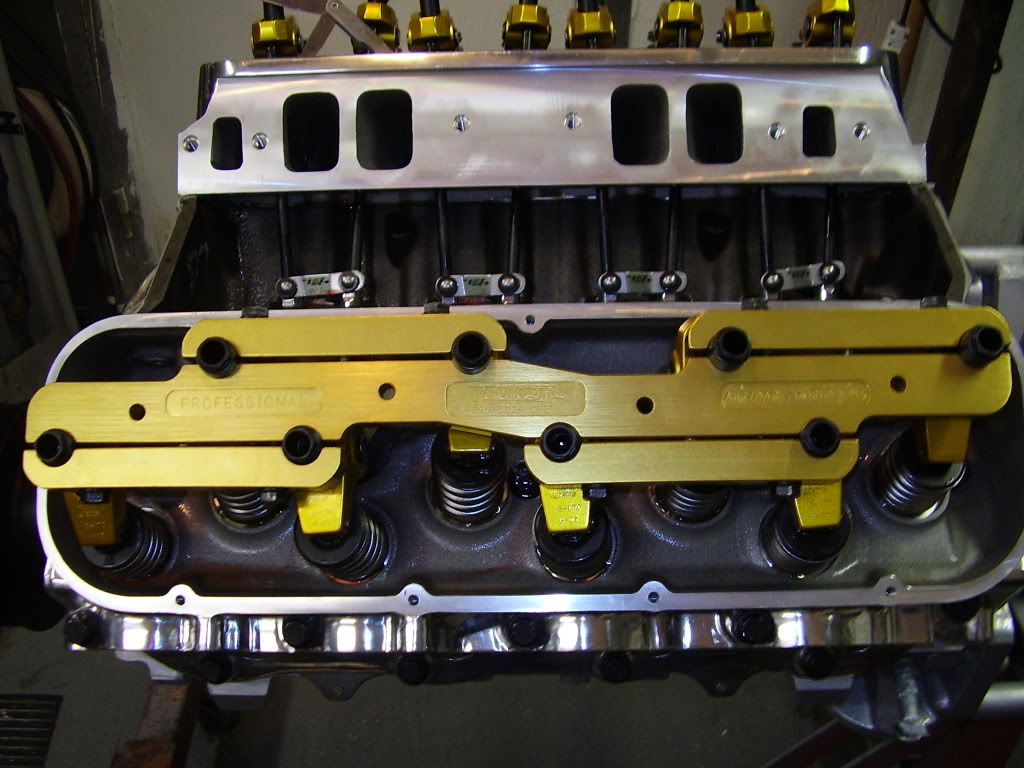

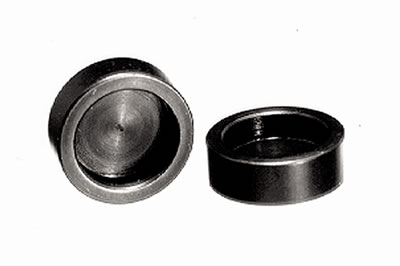

cranes gold roller rockers are decent quality rockers for a small or big block chevy,Ive used those, ERSON, CROWER and COMP CAMS ROLLER ROCKERS, many of them come with jam nuts that require a 3/16" allen key

and look a great deal like these posted here below

but these are NOT locking jam nuts designed to work with a rocker stud girdle

http://www.summitracing.com/parts/tfs-3 ... /overview/

BTW.IF YOUR BUILDING A SBC

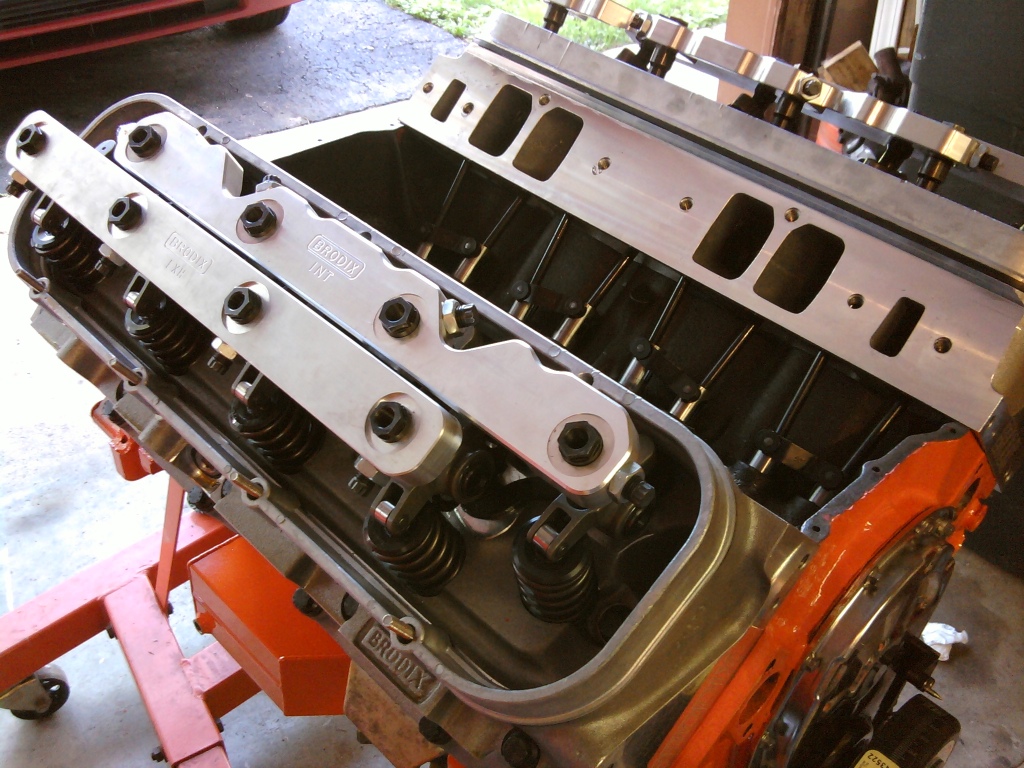

http://brodix.com/heads-2/small-block-chevrolet-compatible-heads/ik-series

http://www.jegs.com/i/Brodix/158/1021001/10002/-1

brodix ph# 1-479-394-1075 (ALWAYS VERIFY PART NUMBERS SEVERAL,

TIMES FROM AT LEAST TWO SOURCES, BEFORE ORDERING PARTS)

the brodix rock stud girdle is part # BR-6435 and LIST price is about $230 you can get it for less if you shop carefully

BE AWARE that the I.K. 200 heads were shipped with BOTH 3/8" and 7/16" rocker studs ,

and the poly locks for the 7/16" rocker studs ONLY fit that rocker stud girdle

obviously you need to verify what your heads have before you order the matching rocker stud girdle

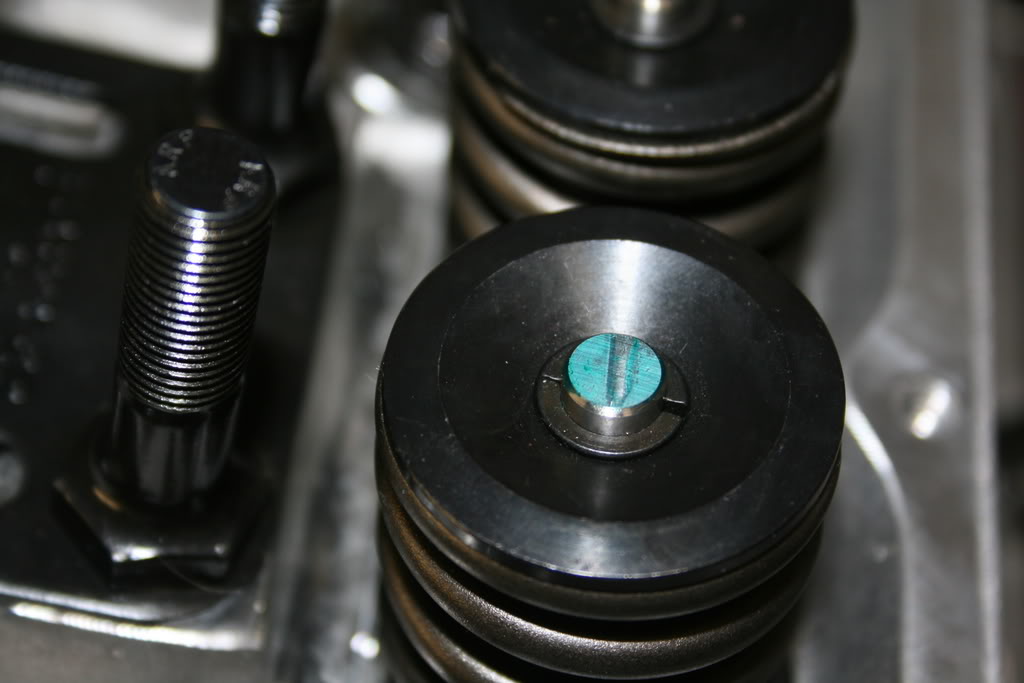

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

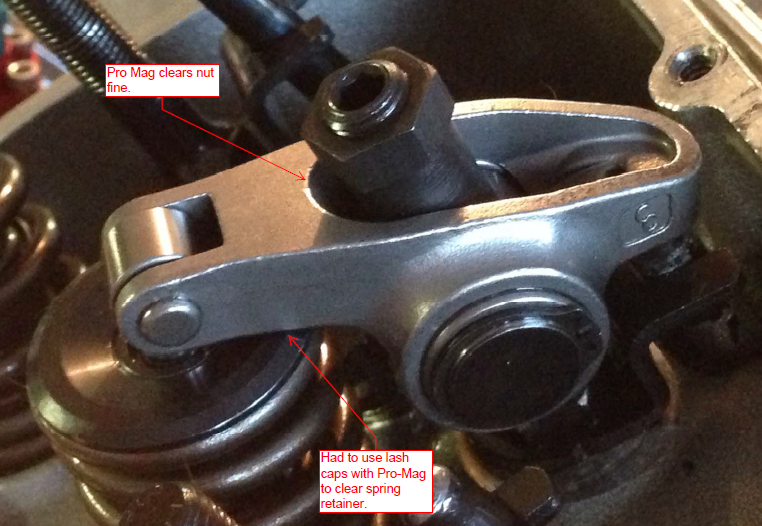

rocker stud girdles require significantly longer shank jam nuts , but you need to mount the rocker stud girdle up out of the way so the upper surface of the rockers can,t touch the lower surface of the stud girdle at full lift

RELATED THREADS

http://garage.grumpysperformance.co...-rockers-vs-rocker-stud-girdles.663/#post-911

http://garage.grumpysperformance.co...-in-vs-threaded-rocker-studs.2746/#post-43539

http://garage.grumpysperformance.co...ich-is-best-steel-or-aluminum.3124/#post-9141

http://garage.grumpysperformance.com/index.php?threads/roller-rockers.3009/#post-8361

http://garage.grumpysperformance.com/index.php?threads/cam-lobe-aceleration-rates.2627/#post-8341

http://garage.grumpysperformance.co...and-setting-up-the-valve-train.181/#post-1192

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...er-tip-vs-full-roller-rockers.2875/#post-7458

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://garage.grumpysperformance.co...n-v-vi-to-adjustable-rockers.4564/#post-12170

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

viewtopic.php?f=52&t=181&p=215#p215

Ive used them several times,BECAUSE the guys paying the bills insisted on them,or had them on the heads they supplied.

http://store.summitracing.com/partdetai ... toview=sku

http://www.enginebuildermag.com/Article ... itch_.aspx

the net result IN MY opinion is that a set of roller rockers and a rocker stud girdle come very close to duplicating the results,of the shaft rocker systems on most engines that are spinning at under 7000rpm but keep in mind most of the engines I built are designed to run UNDER 6700RPM MAXIMUM rpms and most are either 383 or larger sbc or 496 and larger BBC engines, theres not much reason to spend mega buck$ on an engine designed to spin up in the 7500rpm plus power band on the street when its usually cheaper to just add displacement, when your not limited by class rules limiting you to a set displacement for a given weight

on many hydraulic roller lifter applications a REV KIT on hydraulic roller lifters adds several hundred RPM to the power band before valve control issues develop

the idea is that normally stud mount rockers relies on a single studs rigidity to stabilize the valve train for each single rocker, but adding a stud girdle or shaft mounted rockers adds a good deal of stability due to several studs and their combined stability & rigidity stabilize the rockers,with spring load rates and lifts commonly used on flat tappet cams its probably no big deal, with roller rockers and their increased spring load rates and lifts the stud girdle or shaft rockers might be a good idea but roller rockers with roller bearings become almost mandatory add enough spring pressure, lift and rpms and the individual rocker stud flexes enough so that either the stud or the cylinder head its mounted in will eventually fail

the one area where they make sense is when you've got offset push rods due to huge ports, so the valve train geometry won,t be correct with the standard rocker stud location

READ THRU THIS THREAD ALSO

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

shaft rockers add rigidity , to the valve train,by eliminating the rocker stud flex issues,

but keep in mind that a rocker stud girdle can be added to the stock type of valve train,

and when used with quality roller rockers they add a good bit of rigidity to the stock style valve train.

shaft rockers add rigidity , to the valve train,by eliminating the rocker stud flex issues,

but keep in mind that a rocker stud girdle can be added to the stock type of valve train,

and when used with quality roller rockers they add a good bit of rigidity to the stock style valve train.

short answer, as a rule of thumb,shaft rockers are advisable

(1) any time your valve open loads exceed 400 lbs and/or you want to exceed 6500 rpm regularly.

(2) any time you intend to exceed 7000 rpm regularly and valve open loads exceed 500 lbs they would be considered almost mandatory..

yes you can in most cases use a stud girdle, with quality roller rockers,

but the shaft rocker design tends to be more rigid, and tends to aid durability

cranes gold roller rockers are decent quality rockers for a small or big block chevy,Ive used those, ERSON, CROWER and COMP CAMS ROLLER ROCKERS, many of them come with jam nuts that require a 3/16" allen key

and look a great deal like these posted here below

but these are NOT locking jam nuts designed to work with a rocker stud girdle

http://www.summitracing.com/parts/tfs-3 ... /overview/

BTW.IF YOUR BUILDING A SBC

http://brodix.com/heads-2/small-block-chevrolet-compatible-heads/ik-series

http://www.jegs.com/i/Brodix/158/1021001/10002/-1

brodix ph# 1-479-394-1075 (ALWAYS VERIFY PART NUMBERS SEVERAL,

TIMES FROM AT LEAST TWO SOURCES, BEFORE ORDERING PARTS)

the brodix rock stud girdle is part # BR-6435 and LIST price is about $230 you can get it for less if you shop carefully

BE AWARE that the I.K. 200 heads were shipped with BOTH 3/8" and 7/16" rocker studs ,

and the poly locks for the 7/16" rocker studs ONLY fit that rocker stud girdle

obviously you need to verify what your heads have before you order the matching rocker stud girdle

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

rocker stud girdles require significantly longer shank jam nuts , but you need to mount the rocker stud girdle up out of the way so the upper surface of the rockers can,t touch the lower surface of the stud girdle at full lift

RELATED THREADS

http://garage.grumpysperformance.co...-rockers-vs-rocker-stud-girdles.663/#post-911

http://garage.grumpysperformance.co...-in-vs-threaded-rocker-studs.2746/#post-43539

http://garage.grumpysperformance.co...ich-is-best-steel-or-aluminum.3124/#post-9141

http://garage.grumpysperformance.com/index.php?threads/roller-rockers.3009/#post-8361

http://garage.grumpysperformance.com/index.php?threads/cam-lobe-aceleration-rates.2627/#post-8341

http://garage.grumpysperformance.co...and-setting-up-the-valve-train.181/#post-1192

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...er-tip-vs-full-roller-rockers.2875/#post-7458

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://garage.grumpysperformance.co...n-v-vi-to-adjustable-rockers.4564/#post-12170

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

viewtopic.php?f=52&t=181&p=215#p215

Ive used them several times,BECAUSE the guys paying the bills insisted on them,or had them on the heads they supplied.

http://store.summitracing.com/partdetai ... toview=sku

http://www.enginebuildermag.com/Article ... itch_.aspx

the net result IN MY opinion is that a set of roller rockers and a rocker stud girdle come very close to duplicating the results,of the shaft rocker systems on most engines that are spinning at under 7000rpm but keep in mind most of the engines I built are designed to run UNDER 6700RPM MAXIMUM rpms and most are either 383 or larger sbc or 496 and larger BBC engines, theres not much reason to spend mega buck$ on an engine designed to spin up in the 7500rpm plus power band on the street when its usually cheaper to just add displacement, when your not limited by class rules limiting you to a set displacement for a given weight

on many hydraulic roller lifter applications a REV KIT on hydraulic roller lifters adds several hundred RPM to the power band before valve control issues develop

the idea is that normally stud mount rockers relies on a single studs rigidity to stabilize the valve train for each single rocker, but adding a stud girdle or shaft mounted rockers adds a good deal of stability due to several studs and their combined stability & rigidity stabilize the rockers,with spring load rates and lifts commonly used on flat tappet cams its probably no big deal, with roller rockers and their increased spring load rates and lifts the stud girdle or shaft rockers might be a good idea but roller rockers with roller bearings become almost mandatory add enough spring pressure, lift and rpms and the individual rocker stud flexes enough so that either the stud or the cylinder head its mounted in will eventually fail

the one area where they make sense is when you've got offset push rods due to huge ports, so the valve train geometry won,t be correct with the standard rocker stud location

Last edited by a moderator: