I was recently asked HOW to shim an oil pump relief spring to gain added oil pressure!

SHORT ANSWER NEVER SHIM THE OIL PUMP SPRING!!

many pumps come with two springs , one standard and one high pressure

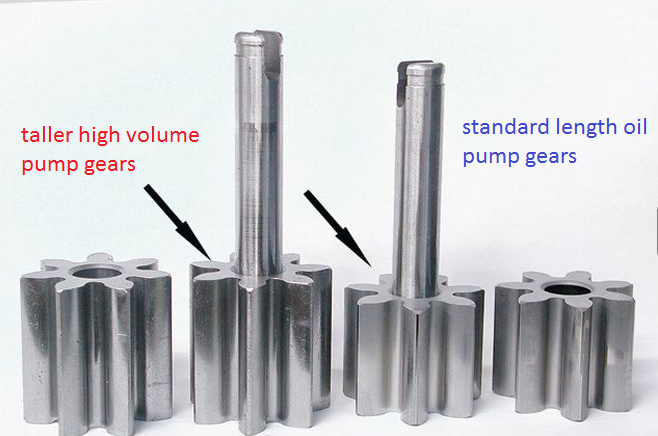

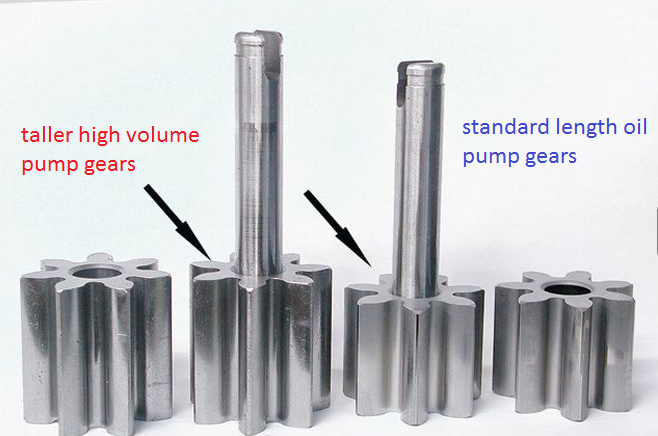

you should NEVER shim an oil pumps pressure relief spring

back in the 1950s-1960s it was common to pull the pressure relief spring retaining pin in the oil pump that retains the pressure relief spring and insert a washer , between the pin and spring to add pressure to the spring, this mod has zero effect on lower rpm oil pressure it simply delays the pressure relief valve from opening until a bit more, or higher peak oil pressure is reached

thus forcing the pump to build more pressure before the relief valve opened, this was before properly designed higher pressure springs were available, this could be done but it frequently caused problems,

but the problem is that it reduced the distance the control valve piston potentially moves and this can cause the system to malfunction.

as it reduces the clearances and may cause spring coil stacking before the pressure valve opens fully,it may prevent the piston that pressure relief spring holds from moving back down its bore far enough to allow it to open the by-pass passage, that shim behind the spring causes a reduction of distance it can travel to open the oil pressure release, valve or allow return oil flow through that passage allowing the pressure on the high pressure side of the oil pump from bleeding off back into the intakes low pressure intake side of the oil pump, the oil pump relief springs come in several resistance strength levels, but extensive testing has shown no increased bearing protection at pressure levels exceeding 65 psi, higher strength pressure relief springs,

just increase engine rotational resistance

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

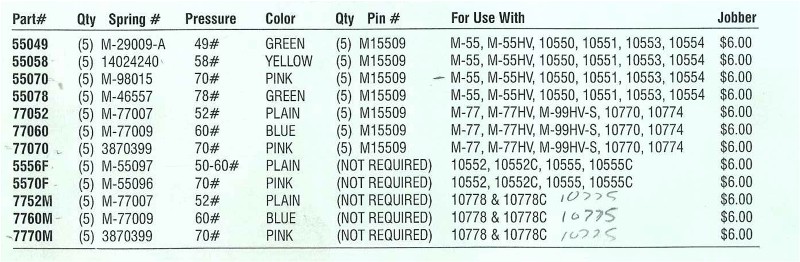

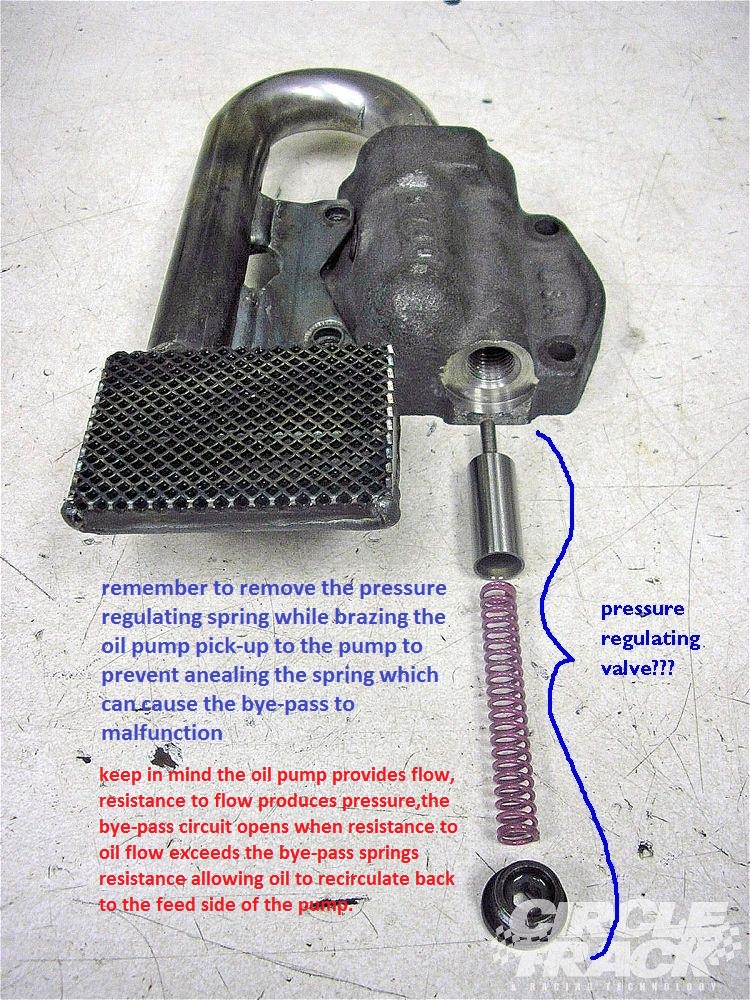

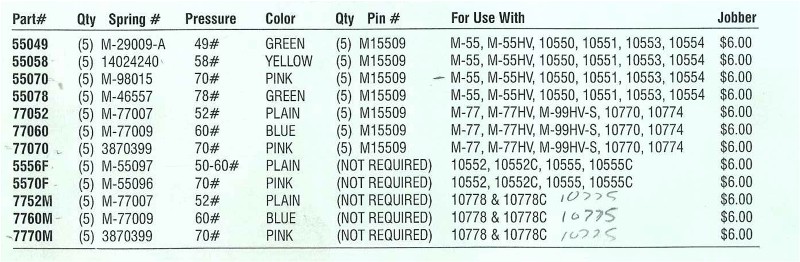

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

from what I've read pressure over 65 psi at W.O.T.

or over 20PSI at idle for a sbc or BBC adds no benefit.

some ford engines are designed to work with up to 100 psi of oil pressure at peak rpms

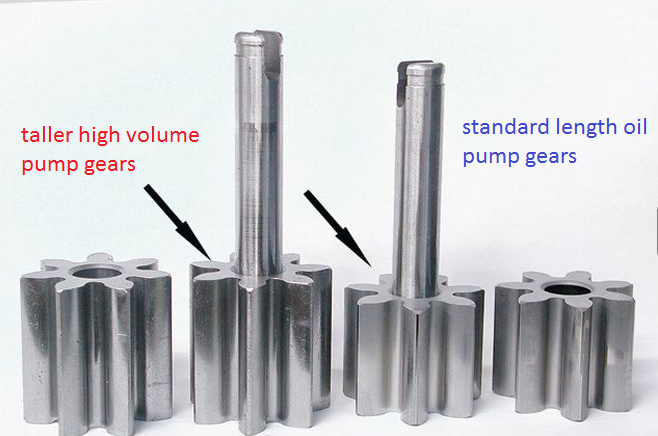

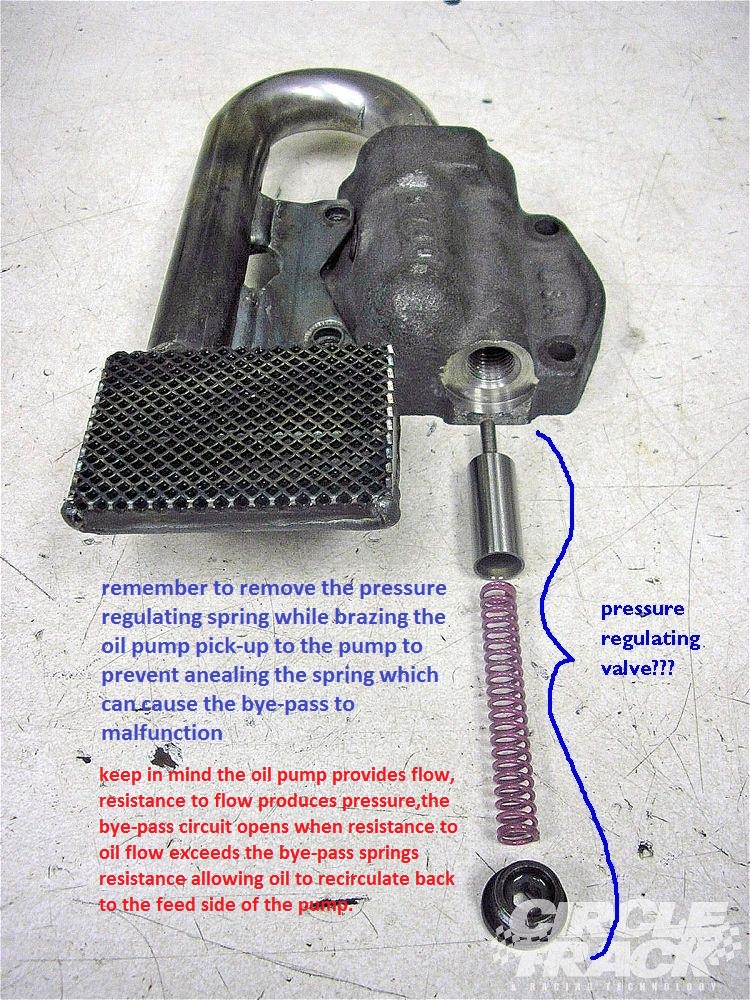

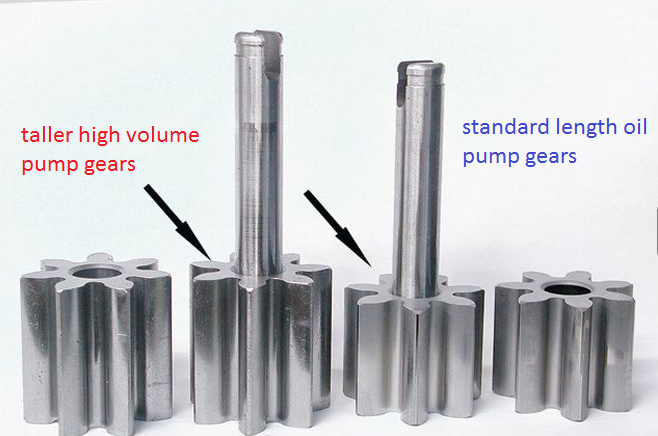

added oil flow rate volume helps cool and lubricate to a greater extent than added pressure

Some experts estimate that the wear on the rings of an internal combustion engine is as high as 0.001" per 1000 miles of operation when the oil temperature is below 170 degrees F. If the maximum allowable wear is 0.006", how long can you run your engine when the oil temperature is below 170 degrees before you wear it out?"

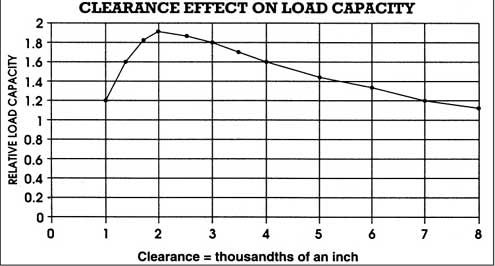

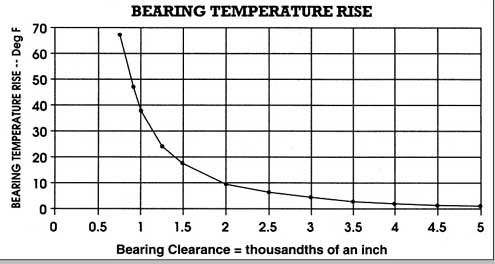

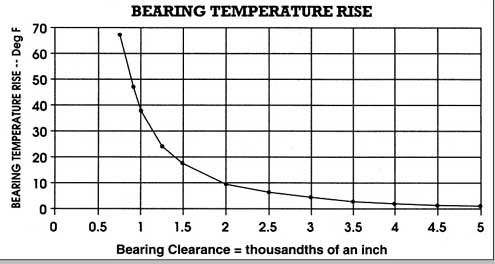

just a bit of info, I remember seeing a test on bearing wear and long term durability, where it was proven that at least on the BBC engines there was almost zero gains in long term durability once oil pressure reached 60 PSI, and almost no gains with 60 psi over what was seen at 50 psi, even at higher rpms (5000-7000 rpm under full loads) provided the volume of oil flow and bearing clearances and oil temps were reasonably close to ideal, consistently higher oil temps over about 235F are detrimental to long term bearing life,

but oil needs to exceed 215F intermittently to remove trapped moisture.

yeah the linked info holds a great deal more USEFUL RELATED info

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/#post-87726

related threads with info you might want

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

many pumps come with two springs , one standard and one high pressure you should NEVER shim an oil pumps pressure relief spring back in the 1950s-1960s it was common to pull the pressure...

many pumps come with two springs , one standard and one high pressure you should NEVER shim an oil pumps pressure relief spring back in the 1950s-1960s it was common to pull the pressure...

garage.grumpysperformance.com

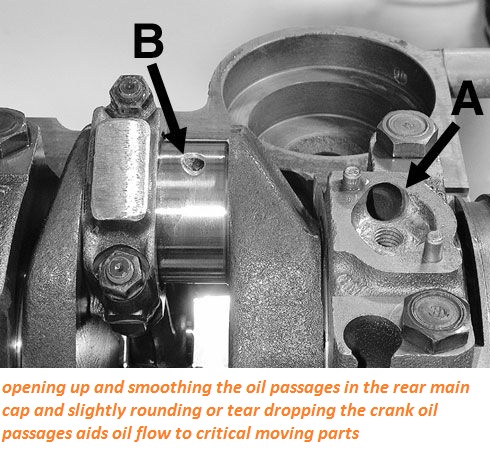

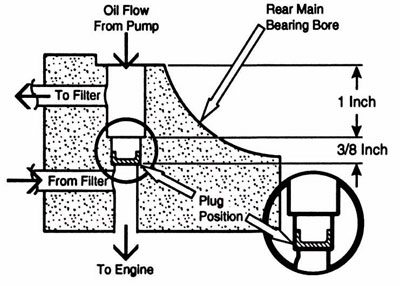

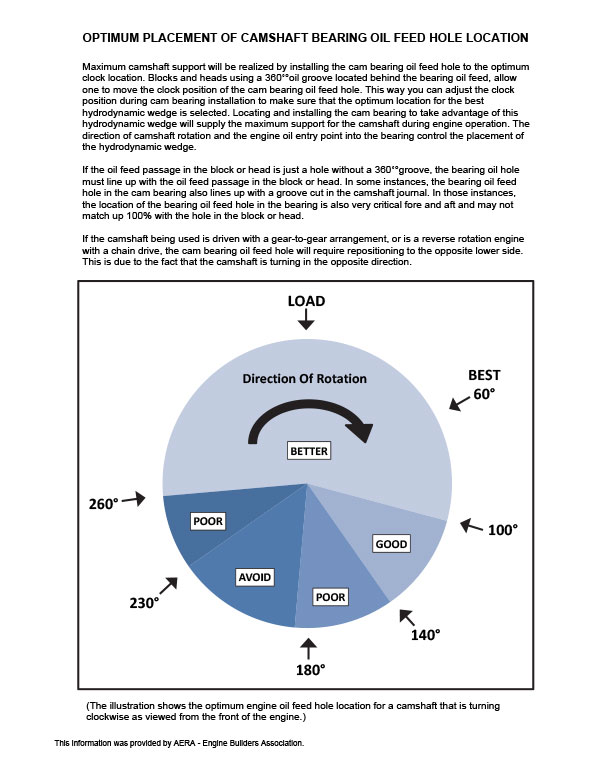

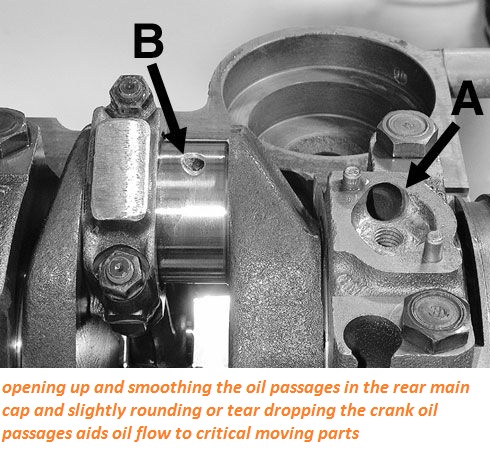

obviously the small groove is intended to flow extra oil volume to the rear vertical thrust bearing surfaces

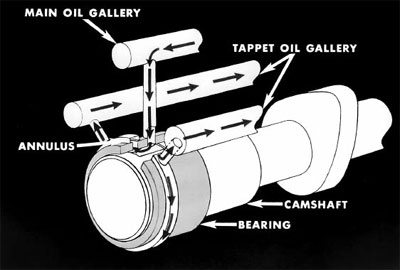

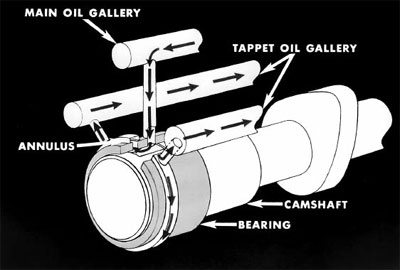

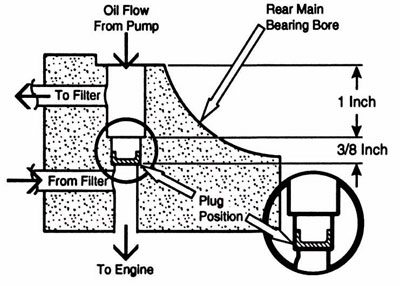

If your not getting oil to the rockers but have 65 psi as the engine idles,

Id suspect either the cam bearings (especially the rear cam bearing or the oil passage plugs under the timing chain are incorrectly installed

www.lethalperformance.com

www.lethalperformance.com

www.jegs.com

www.jegs.com

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

SHORT ANSWER NEVER SHIM THE OIL PUMP SPRING!!

many pumps come with two springs , one standard and one high pressure

you should NEVER shim an oil pumps pressure relief spring

back in the 1950s-1960s it was common to pull the pressure relief spring retaining pin in the oil pump that retains the pressure relief spring and insert a washer , between the pin and spring to add pressure to the spring, this mod has zero effect on lower rpm oil pressure it simply delays the pressure relief valve from opening until a bit more, or higher peak oil pressure is reached

thus forcing the pump to build more pressure before the relief valve opened, this was before properly designed higher pressure springs were available, this could be done but it frequently caused problems,

but the problem is that it reduced the distance the control valve piston potentially moves and this can cause the system to malfunction.

as it reduces the clearances and may cause spring coil stacking before the pressure valve opens fully,it may prevent the piston that pressure relief spring holds from moving back down its bore far enough to allow it to open the by-pass passage, that shim behind the spring causes a reduction of distance it can travel to open the oil pressure release, valve or allow return oil flow through that passage allowing the pressure on the high pressure side of the oil pump from bleeding off back into the intakes low pressure intake side of the oil pump, the oil pump relief springs come in several resistance strength levels, but extensive testing has shown no increased bearing protection at pressure levels exceeding 65 psi, higher strength pressure relief springs,

just increase engine rotational resistance

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

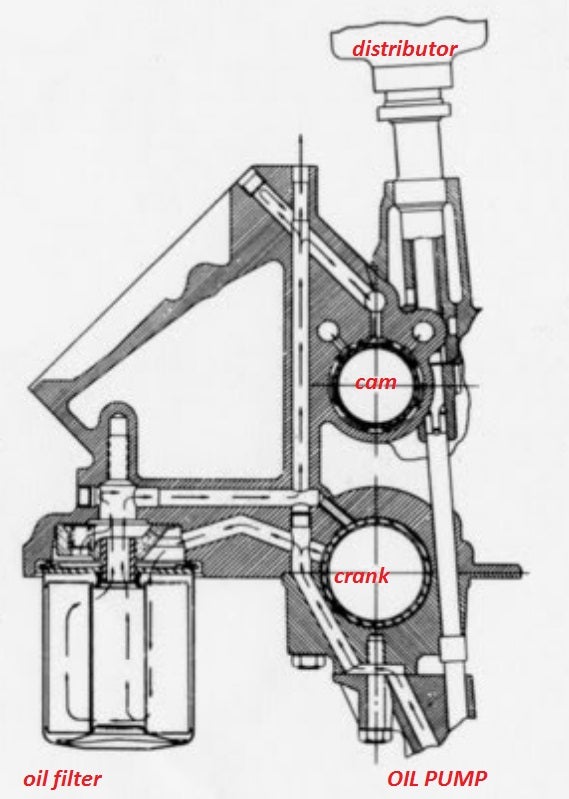

While reading several books on building performance engines I found one recurring message – stick with the stock big block oil pump! Apparently these pumps have a solid reputation for being bulletproof. Here’s what the stock oil pump looked like after a thorough cleaning.

Oftentimes people replace the stock oil pump with a high flow or high pressure aftermarket pump as a matter of course when completing an engine build. However, much of my research seriously questioned this practice and made a compelling case in the process. First, for street and street performance use the stock oil pump is perfectly capable of pushing more than enough of oil (provided the correct main bearings are used and that bearing clearances are not ridiculously large). Secondly, high pressure and high volume pumps certainly do push a lot of oil, but much of that oil is simply forced out of the pressure release valve and never makes it through the engine. Also, don’t forget that pushing all that extra oil takes more work and more horsepower. Lastly, although a high volume pump could easily have been provided by GM engineers, they didn’t feel it was necessary – even on the high performance L-88 and ZL-1 models. With that in mind I started checking my stock pump to see how it looked, overall it was in very good condition. Below is a photo of the pump with the cover removed.

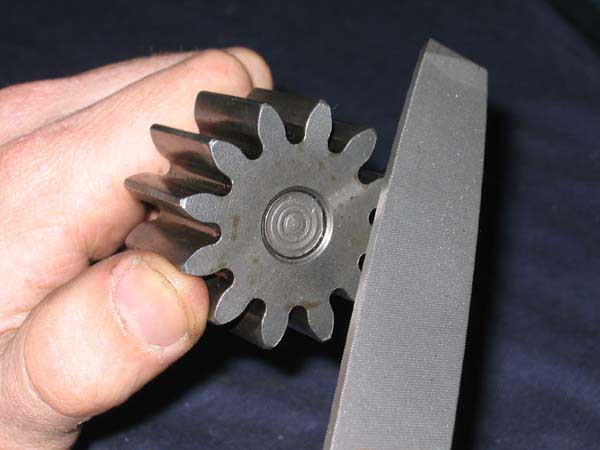

Disassembly of the pump is quite simple, the parts are all slip fit so they’re easily removed. Prior to removing the drive and idler gears I marked their relative position so that they could be reinstalled in the same orientation.

Despite the bullet-proof reputation of the stock big block oil pump several of my references recommended a few minor modifications when using them in a performance application. After giving this some consideration I opted to go ahead and make the modifications as they were explained and outlined in the book “How to Hotrod Big-Block Chevys”. The book is a good reference, although it’s a bit dated, but it provides some good info nonetheless. Considering used copies can be had for less than $10 it’s certainly a worthwhile investment.

I was asked recently, as to my best guess, as to why a recently installed oil pump was making noise,

oil pumps rarely make much noise, unless, the drive shaft driving the oil pump, is rubbing on the block which will happen if you install a standard drive shaft in a 400 type small block which requires the drive shaft with the smaller diameter midsection. (what was going on in this case) Or you forget to install that little metal or nylon collar that keeps it aligned, or if your drive shaft has one the little spring clip, and remember to install the shaft along with the oil pump from below because the collar is designed to be too large to pass thru the block passage above it to insure the drive shaft stays attached to the oil pump. remember if the clearances inside the oil pump are not checked, and is partly binding or in some cases of the oil pump has ingested, some small bits of metal or other foreign material. the pump might be damaged, the standard high-performance oil pump drive shaft looks like the one below ,it has a steel collar and is made from a stronger than normal steel

heres a standard volume BBC oil pump which can be used in a small block high performance application provided its matched to the correct oil pan and oil pump pick-up of course.

REMEMBER once the oil pumps installed on the main cap and the distributors test fitted on the intake manifold there should be about .050=.060 vertical clearance remaining on the oil pump drive shaft between the oil pump and distributor with the distributor firmly seated on the intake manifold and at least .060 in all directions around the oil pump drive shaft, "CHECK THE COLLAR" in rare cases it binds

http://m.summitracing.com/parts/mel-m77

http://m.summitracing.com/parts/mel-77060

chevy oil pump drive shafts come in several lengths and styles and some have metal or nylon collars, you should select the oil pump drive shaft that allows about a .050-.060 thousands clearance between the oil pump and distributor when the distributors seated on the intake manifold

its not uncommon for distributor gears and cam gears to not be perfectly lined up as to depth of the distributor or length of the oil pump drive, theres several different pump drive shaft lengths and spacer shims but in many cases a slip collar on the distributor or modifying the oil pump drive shaft will be required to get perfect alignment

your current distributor can usually be easily modified by a local machine shop with a lathe for an adjustable slip collar by carefully machining off the current one and adding a slip collar, if you need to make distributor gear to cam gear engagement or oil pump drive shaft length changes

http://www.summitracing.com/parts/MOR-26217/?rtype=10

First on the list of modifications was to lightly chamfer the edges of the gear teeth with a file.

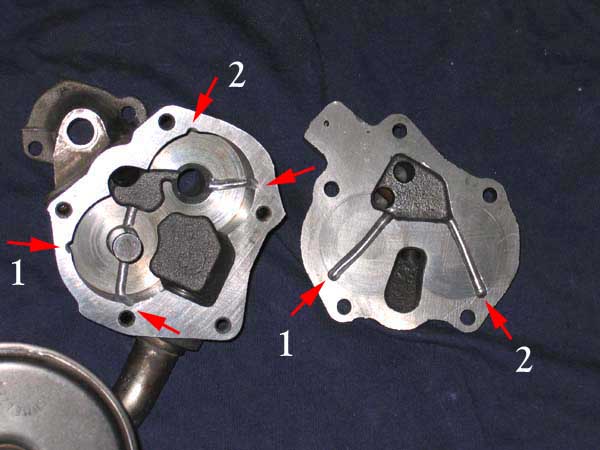

Next, and perhaps the scariest modification, was pressure balancing the oil pump. By creating small grooves in the pump housing the hydrostatic forces on the idler and drive gears can be more evenly distributed. This reduces the amount of pulsating forces that are transmitted up the oil pump drive shaft and ultimately into the distributor. Although not a major problem, this pulsating has been known to contribute to spark scatter (changes in timing) at high RPM. The pressure balancing also helps prevent cavitation and allows the pump to operate more efficiently and on less horsepower. GM engineers provided some of these pressure balancing grooves on their high performance pumps (used on L-88 Corvettes), but these modifications go a step further. Having said that, below I’ve laid out the locations of the pressure balancing grooves on the pump housing.

To make the grooves I used a Dremel tool with a bit intended for chain saw blade sharpening. The size of the bit (5/32″ diameter) was just about the perfect size and it worked very well.

After a few hours of careful work the grooves were complete. Below is a picture of the modified housing. Note that care needs to be taken to assure the grooves in the cover (#1 & #2) need to line up with the vertical grooves on the pump housing (#1 & #2). The other two red arrows are meant to point out vertical grooves in the pump housing (a bit hard to see in the photo).

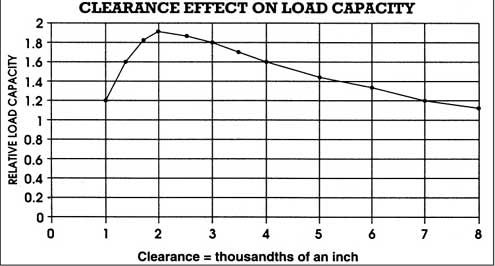

Lastly, and probably most importantly, the proper end clearance between the gears and pump housing cover needs to be established. Excessive clearance results in poor priming ability and inefficient pump operation. Ideally end clearance should be about 0.0025 inches. If excessive clearance is found the housing can be sanded down by using a piece of fine to medium grit sandpaper placed on a flat, hard surface. Be sure to apply even pressure and rotate the pump often during this process to ensure material is removed evenly. Conversely, if the clearance is too small the gear height can be reduced by using the same sanding procedure above.

After establishing the proper clearance and a very, very thorough cleaning I reinstalled the pump cover and screws using Loctite on the screw threads. That’s all for this update!

from what I've read pressure over 65 psi at W.O.T.

or over 20PSI at idle for a sbc or BBC adds no benefit.

some ford engines are designed to work with up to 100 psi of oil pressure at peak rpms

added oil flow rate volume helps cool and lubricate to a greater extent than added pressure

Some experts estimate that the wear on the rings of an internal combustion engine is as high as 0.001" per 1000 miles of operation when the oil temperature is below 170 degrees F. If the maximum allowable wear is 0.006", how long can you run your engine when the oil temperature is below 170 degrees before you wear it out?"

just a bit of info, I remember seeing a test on bearing wear and long term durability, where it was proven that at least on the BBC engines there was almost zero gains in long term durability once oil pressure reached 60 PSI, and almost no gains with 60 psi over what was seen at 50 psi, even at higher rpms (5000-7000 rpm under full loads) provided the volume of oil flow and bearing clearances and oil temps were reasonably close to ideal, consistently higher oil temps over about 235F are detrimental to long term bearing life,

but oil needs to exceed 215F intermittently to remove trapped moisture.

yeah the linked info holds a great deal more USEFUL RELATED info

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/#post-87726

related threads with info you might want

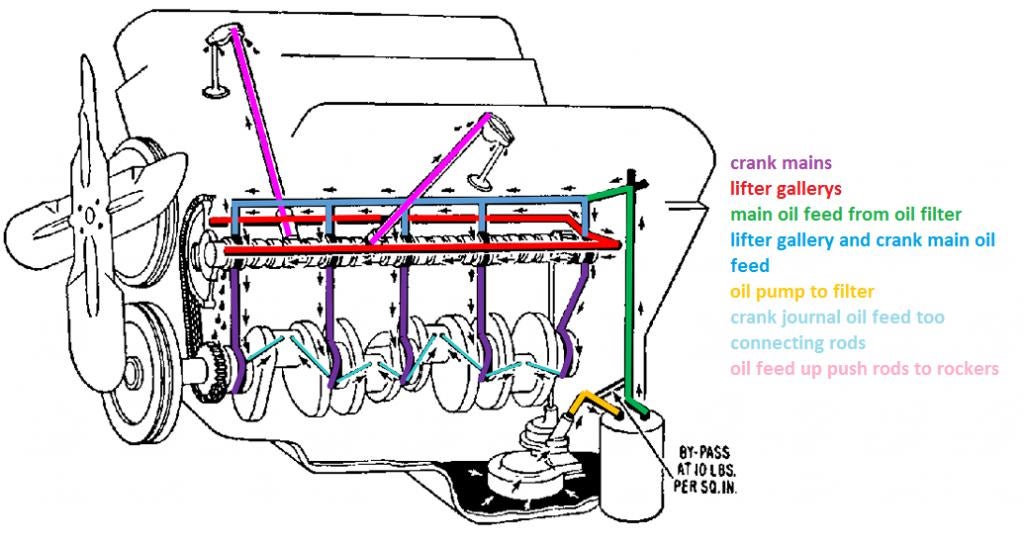

oil system mods that help

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers,valves etc. obviously use of a high quality synthetic oil that has a higher heat tolerance and that...garage.grumpysperformance.com

building a custom wet sump oil pan

The question comes up rather frequently when I suggest buying or modifying oil pans as to "WHY BOTHER?" well its simply the fact that most stock oil pans were designed simply to be the cheapest to manufacture component that would function on an engine that would rarely be spinning over 3500rpm...garage.grumpysperformance.com

Oil pump priming

I have attempted to prime and pre oil the system in my 355 build using the tool shown on Grumpy's stickys but am not sure if all is as it should be. The filter was filled pre installation and the balance of the 5 quarts of oil poured into the lifter valley. The tool in inserted and run with a...garage.grumpysperformance.com

whats a windage tray do?

"OK GRUMPYVETTE< I have dumb question? What is a windage tray and whats it for?" windage trays don,t provide a huge boost in horse power, the purpose is mostly in providing much improved oil control, faster oil return and less aeration and increased delivery efficiency, to the oil pump, the...garage.grumpysperformance.com

how your oil pumps pressure bye-pass circuit works,

theres seems to be a lot of mis-information about , how the oil pump regulates its pressure curve, and the related subject of shimming oil pump springs and how your oil pumps pressure bye-pass circuit works. PRESSURE, that you see displayed on the oil pressure gauge is a measure of the...garage.grumpysperformance.com

magnets

heres an old post "Any source for the magnets Grumpy? what do you use? " http://www.kjmagnetics.com/proddetail.a ... SH&cat=167 magnets are ceramic and glass hard, don,t try to drill or grind them, as they can shatter or http://www.magnet4sale.com/samarium-cobalt-discs/ proper magnets trap...garage.grumpysperformance.com

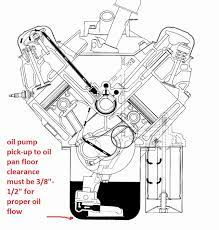

installing an oil pump pick-up tube

there's two ways ,...... you can use the correct tool, which is ADVISABLE! use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor...garage.grumpysperformance.com

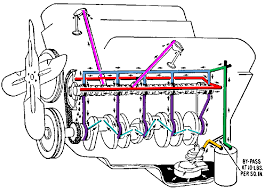

basic info on your v8 lube system

now think it thru, HERES SOME USEFUL INFO, that might help in this thread and the sub links http://garage.grumpysperformance.com/index.php?threads/crank-case-blow-bye-and-related-info.16790/ the first thing Id be doing here, if your not getting a strong oil flow at each rocker while your...garage.grumpysperformance.com

cam bearing install tools & install info

Youll need a cam bearing installation tool or your local machine shop can install the bearings for you, if your not doing this regularly, have them do it, as its cheaper and easier,on a one time install basis, but if you are doing it frequently GET a decent tool and learn how to use it, keep in...garage.grumpysperformance.com

Oil accumulator

an oil accumulator is basically an aux pressurized oil tank , that in most cases holds 1.5-4 quarts of oil in reserve, the engine oil pump pumps it full once the oil pressures in the engines oil passages is high enough, and feeds it back into the passages under pressure if the oil pump sucks air...garage.grumpysperformance.com

Valve Spring Cooling via Engine Oil

Grumpy: Read your post on the subject of Valve Spring Cooling with Engine Oil. Thanks VERY MUCH for bringing this to my attention. I have built a SBC 383 stroker going into a 1971 Datsun 240Z. Used a shaft rocker setup, but am uncertain that the trunion is being lubricated via Engine Oil...garage.grumpysperformance.com

bearings and oil flow

Bearings and oil flow viewtopic.php?f=53&t=88 http://www.babcox.com/editorial/us/us90126.htm http://www.insightservices.net/testoil/ ... cation.htm http://www.thirskauto.net/BearingPics.html http://micapeak.com/info/oiled.html http://www.unofficialbmw.com/all/misc/all_oilfaq.html...garage.grumpysperformance.com

Shimming An Oil Pump Relief Spring

I was recently asked HOW to shim an oil pump relief spring to gain added oil pressure!garage.grumpysperformance.com

obviously the small groove is intended to flow extra oil volume to the rear vertical thrust bearing surfaces

If your not getting oil to the rockers but have 65 psi as the engine idles,

Id suspect either the cam bearings (especially the rear cam bearing or the oil passage plugs under the timing chain are incorrectly installed

Canton Racing Oil Pump Spring For Big Block Chevy High Pressure 50-75 PSI - 22-180

Canton Racing Oil Pump Spring For Big Block Chevy High Pressure 50-75 PSI - 22-180 A higher pressure bypass spring in an oil pump forces more oil through the engine while a lower pressure spring allows for more oil to be recycled within the pump. This sp

Oil Pump Spring - JEGS High Performance

1 million+ parts, 800+ brands-all in-stock at guaranteed best prices. Buy by 11pm & your order ships same-day. Trust JEGS to get it right. Shop now!

http://www.summitracing.com/parts/mel-77070/overview/

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

http://www.summitracing.com/parts/mel-7760m/overview/

http://www.summitracing.com/parts/stf-35250/overview/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

Last edited: