I get asked if guys should you build a 350 or a 383 SBC COMBO, in my opinion a great deal depends on your goals and what your starting with in parts and your budget and mechanical skills. these engines have been worked on, and tested for decades, theres lots of parts available and with the correct heads and roller cams well over 600 hp is potentially possible, even without a turbo, or super charger.

soft ware dynos can be rather useful at predicting potential power ranges but obviously the better the soft ware and the more exact the input data the more likely your results will reflect reality.

I will point out a few facts

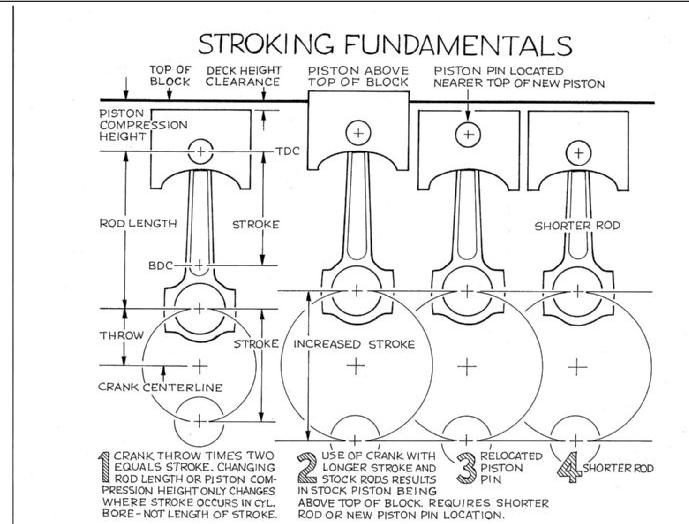

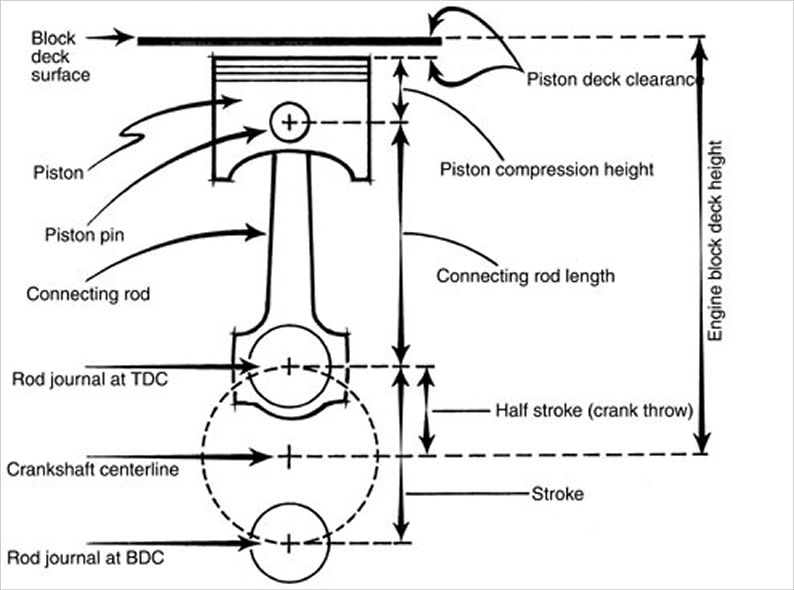

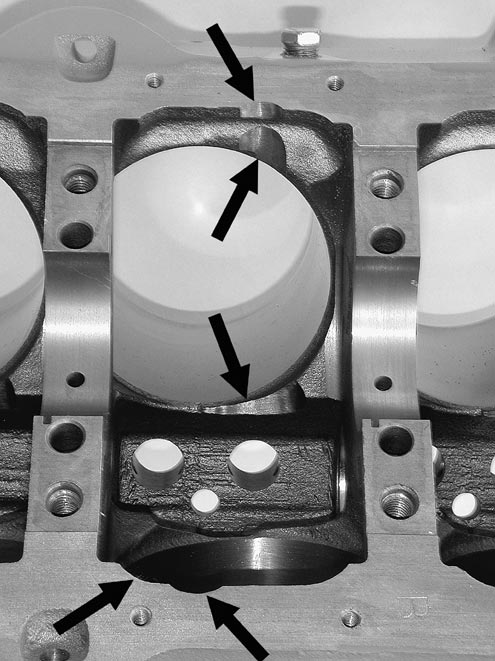

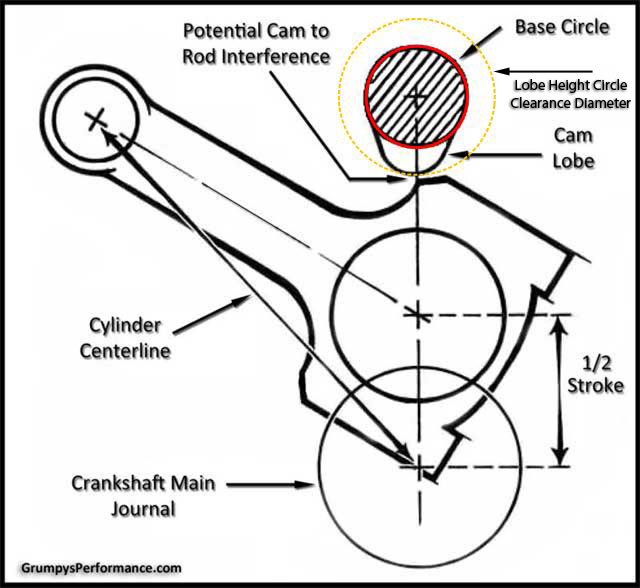

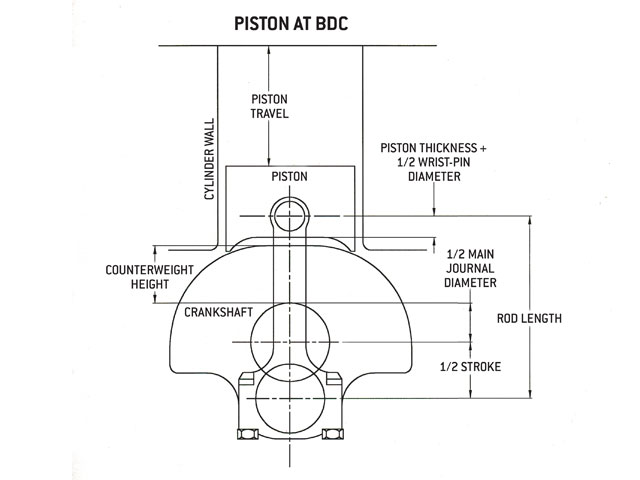

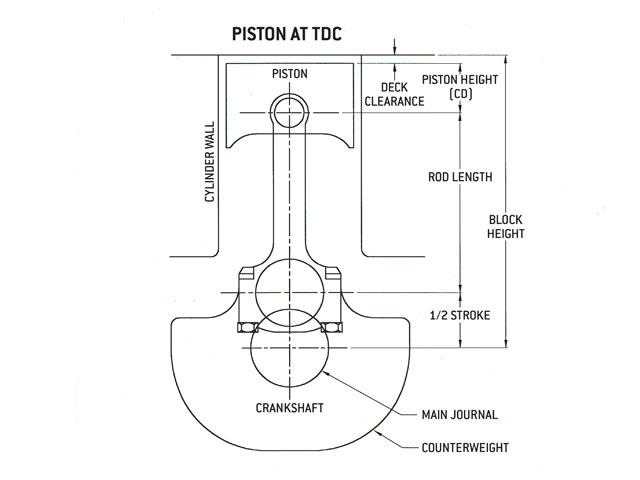

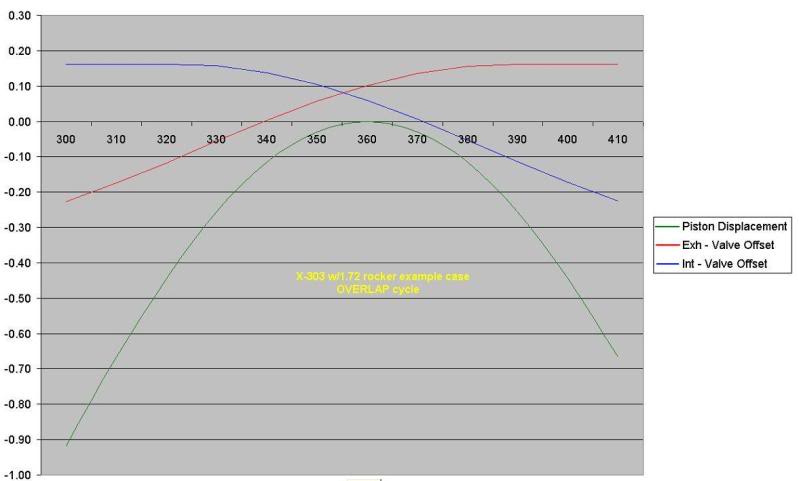

notice how the longer crank stroke effects the piston stroke distance in the bore, both at the lower and upper end of the cylinder

first critical piston speed is about 4300feet per minute with very good quality components and most hydraulic lifter valve trains will dramatically loose power at or above about 6300rpm, so you should think seriously about researching your options and perhaps using solid lifters if you intend to exceed that rpm level.

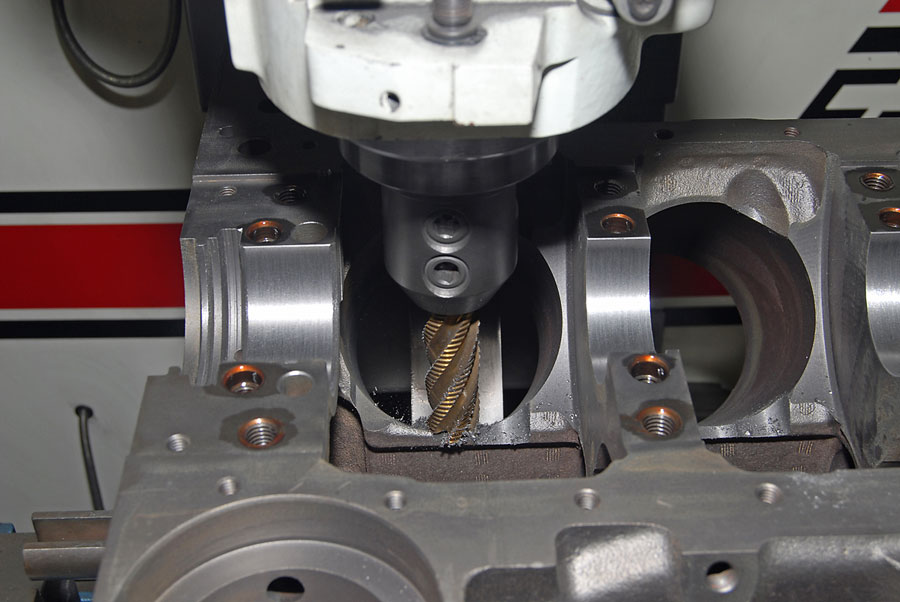

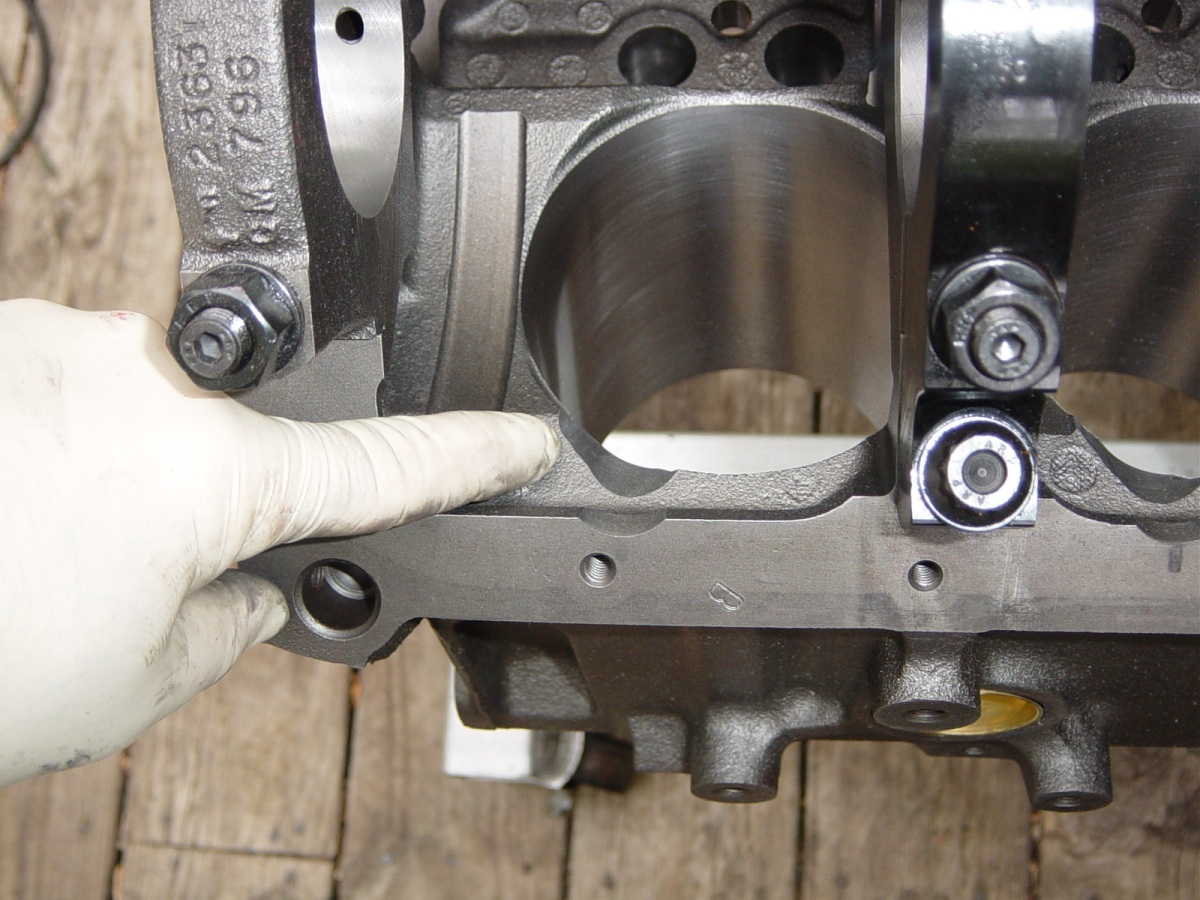

it helps a great deal if you take the time and effort to find a trust worthy and reasonably priced local machine shop , and trust me when I say this is critical, and yes, the machinist will seem to point out endless things that should be done to increase durability, or just allow proper component function,and a good machinist will try to guide you in component selection to help avoid mis-matched parts and low quality parts being used, yes quality parts and machine work, ALWAYS COST more than you may expect them too!

a 350 has a 3.48" stroke so your looking at about 7350 rpm as a max peak rpm.

a 383 has a 3.75" stroke so your looking at about 6800 rpm as a max peak rpm.

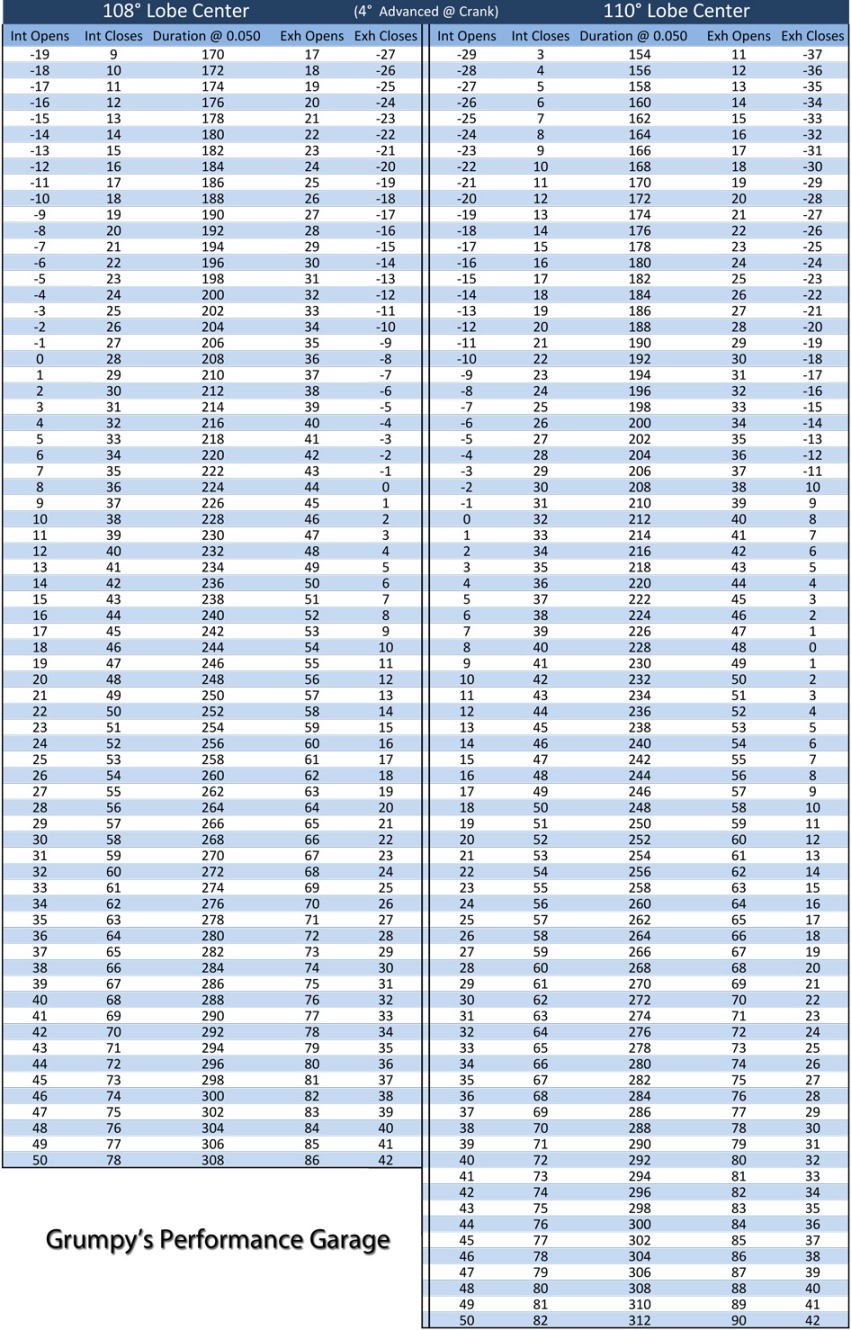

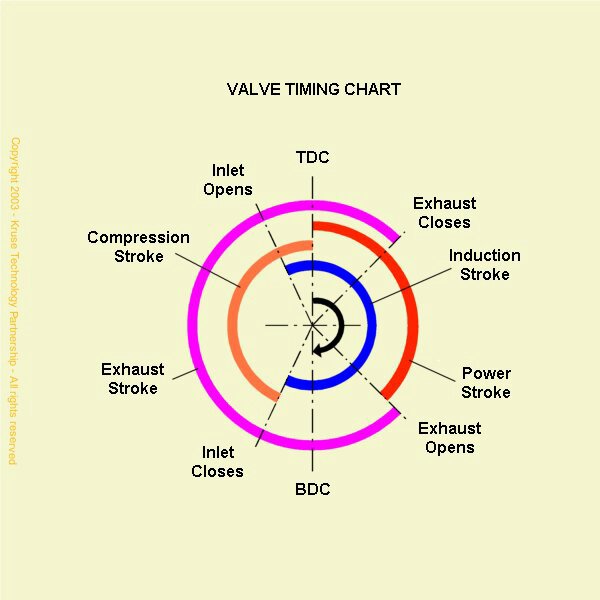

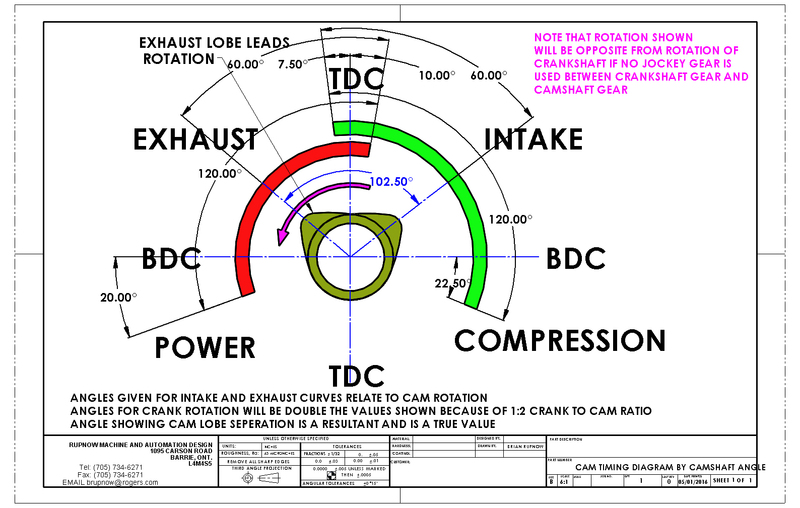

with either engine size youll need to match the compression ratio, cam duration and port sizes to match the intended power curve.

if your starting from scratch, Id strongly suggest the 383 is the better option.

but remember the cars rear gear ratio and transmission gearing, ETC. must match the intended power band.

the extra displacement of the 383 will almost always result in an extra 35-40 extra foot labs of torque in the most effective part of the power band and at least 20-35 foot lbs more than a similar 350 over most of the lower and mid range rpm band.

carefully read thru the links then do more research, if you do the research youll save a good deal of time and money.

heres a few general tips, and related linked info, to read thru

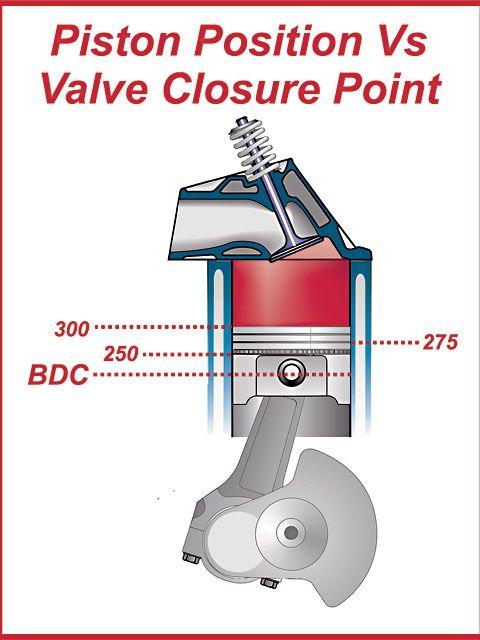

youll need too, calculate the required static compression to match the required cam duration matching your intended power band so the dynamic compression falls close to 8:1 , the more duration in the cam, the higher the static compression required to keep the engine torque fairly reasonable, remember the piston compresses nothing until both valves are seated

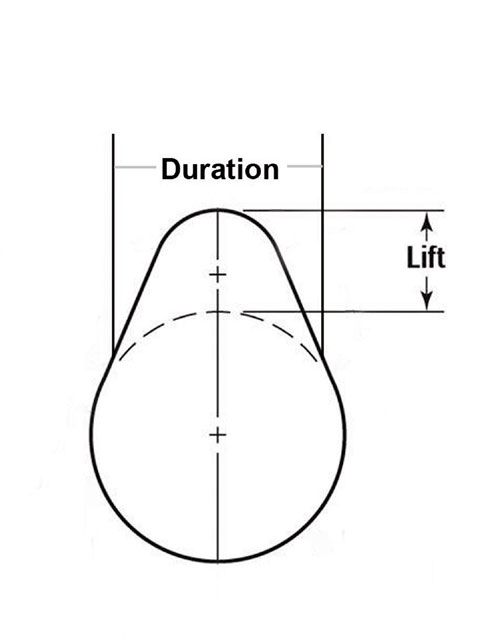

if the cams duration at .050 lift is under 235 degrees youll almost always do better with a dual plane intake manifold, and as both lift and duration increase your need to check valve train geometry and piston to valve and valve train clearances and spring load rates also becomes mandatory

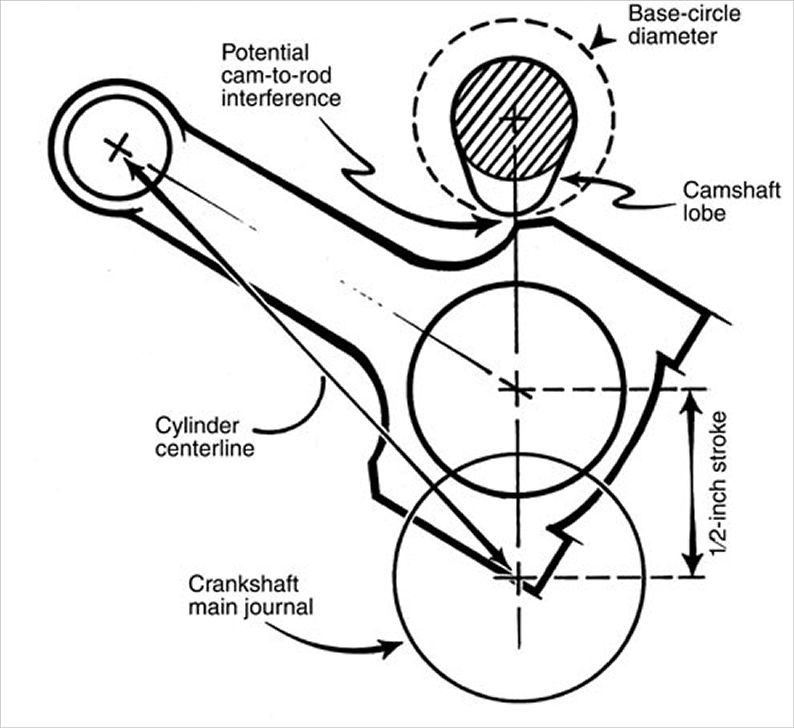

Longer rod ratios have a longer dwell at TDC ,

In theory thats more high rpm tq for the 6" rods due to more efficient use of cylinder pressure at those high rpms but cam timing, scavenging and compression ratio must match to get the benefits, and detonation could be slightly more common

MATCHED ,CAM TIMING, PORT CROSS SECTION AND LENGTH< <COMPRESSION< AND EXHAUST HEADER CONSTRUCTION, DESIGNED TO MATCH THE LONGER ROD DWELL TIME IS REQUIRED TO ACCESS THE POTENTIAL BENEFITS, FAIL TO DO THAT CORRECTLY AND YOU LOOSE THE SLIGHT POTENTIAL GAINS

calculate the intake port size in your intake and in your cylinder heads to match the engine intended power band and operational rpm range

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/lpv.php

http://www.chevyhiperformance.com/tech/ ... ewall.html

match the drive train gearing and converter stall to the engines intended power band

http://www.hotrod.com/articles/1206phr-383ci-small-block-chevy/

http://www.superchevy.com/how-to/76178-chevrolet-ht-383-engine/

http://www.enginelabs.com/news/dyno-video-qmp-builds-500-horse-383-stroker/

http://www.chevyhardcore.com/tech-stories/engine/building-the-little-383-small-block-that-could/

http://royalpurpleconsumer.com/wp-c...-block-in-six-easy-steps-hot-rod-magazine.pdf

RELATED THREADS, it might take you several hours to read thru these but you'll save a lot of time and money doing so! rather that just buying parts first

rebuilt or new chevy 350 crank

https://www.speedwaymotors.com/Speedway-Chevy-350-Crankshaft-Two-Piece-Main,8682.html

https://www.amazon.com/Scat-Crankshafts-9-10442-Crankshaft-Chevrolet/dp/B003N2RRTY

http://www.northernautoparts.com/Pr...=20&product_ecat_engine=1386&btnSubmit=Search

rebuilt or new chevy 383 crank

http://www.superchevy.com/how-to/project-cars/sucp-0706-small-block-chevy-stroker-kit/

soft ware dynos can be rather useful at predicting potential power ranges but obviously the better the soft ware and the more exact the input data the more likely your results will reflect reality.

I will point out a few facts

notice how the longer crank stroke effects the piston stroke distance in the bore, both at the lower and upper end of the cylinder

first critical piston speed is about 4300feet per minute with very good quality components and most hydraulic lifter valve trains will dramatically loose power at or above about 6300rpm, so you should think seriously about researching your options and perhaps using solid lifters if you intend to exceed that rpm level.

it helps a great deal if you take the time and effort to find a trust worthy and reasonably priced local machine shop , and trust me when I say this is critical, and yes, the machinist will seem to point out endless things that should be done to increase durability, or just allow proper component function,and a good machinist will try to guide you in component selection to help avoid mis-matched parts and low quality parts being used, yes quality parts and machine work, ALWAYS COST more than you may expect them too!

a 350 has a 3.48" stroke so your looking at about 7350 rpm as a max peak rpm.

a 383 has a 3.75" stroke so your looking at about 6800 rpm as a max peak rpm.

with either engine size youll need to match the compression ratio, cam duration and port sizes to match the intended power curve.

if your starting from scratch, Id strongly suggest the 383 is the better option.

but remember the cars rear gear ratio and transmission gearing, ETC. must match the intended power band.

the extra displacement of the 383 will almost always result in an extra 35-40 extra foot labs of torque in the most effective part of the power band and at least 20-35 foot lbs more than a similar 350 over most of the lower and mid range rpm band.

carefully read thru the links then do more research, if you do the research youll save a good deal of time and money.

heres a few general tips, and related linked info, to read thru

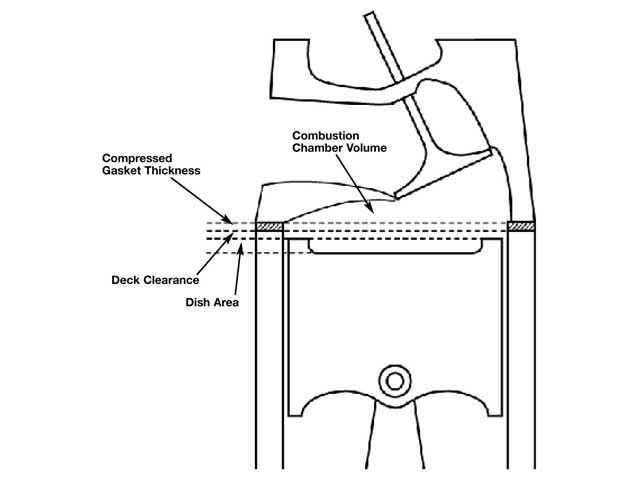

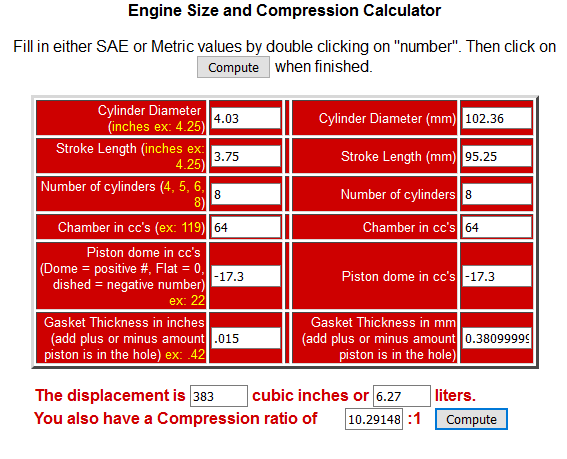

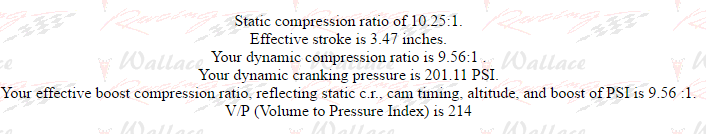

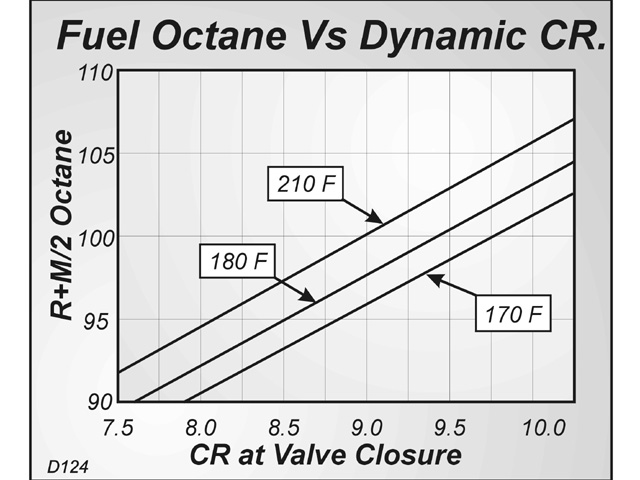

youll need too, calculate the required static compression to match the required cam duration matching your intended power band so the dynamic compression falls close to 8:1 , the more duration in the cam, the higher the static compression required to keep the engine torque fairly reasonable, remember the piston compresses nothing until both valves are seated

upgrading SBC crate engine heads

Will L 98 ,58cc, 160-165,cc port alum heads (14101128)help performance on a 290hp small block thank you pete. you may find info in links you can use else-ware in many threads https://garage.grumpysperformance.com/index.php?threads/bbc-related-links-and-useful-info.17140/ as compared to...

garage.grumpysperformance.com

if the cams duration at .050 lift is under 235 degrees youll almost always do better with a dual plane intake manifold, and as both lift and duration increase your need to check valve train geometry and piston to valve and valve train clearances and spring load rates also becomes mandatory

Longer rod ratios have a longer dwell at TDC ,

In theory thats more high rpm tq for the 6" rods due to more efficient use of cylinder pressure at those high rpms but cam timing, scavenging and compression ratio must match to get the benefits, and detonation could be slightly more common

MATCHED ,CAM TIMING, PORT CROSS SECTION AND LENGTH< <COMPRESSION< AND EXHAUST HEADER CONSTRUCTION, DESIGNED TO MATCH THE LONGER ROD DWELL TIME IS REQUIRED TO ACCESS THE POTENTIAL BENEFITS, FAIL TO DO THAT CORRECTLY AND YOU LOOSE THE SLIGHT POTENTIAL GAINS

calculate the intake port size in your intake and in your cylinder heads to match the engine intended power band and operational rpm range

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/lpv.php

http://www.chevyhiperformance.com/tech/ ... ewall.html

match the drive train gearing and converter stall to the engines intended power band

http://www.hotrod.com/articles/1206phr-383ci-small-block-chevy/

http://www.superchevy.com/how-to/76178-chevrolet-ht-383-engine/

http://www.enginelabs.com/news/dyno-video-qmp-builds-500-horse-383-stroker/

http://www.chevyhardcore.com/tech-stories/engine/building-the-little-383-small-block-that-could/

http://royalpurpleconsumer.com/wp-c...-block-in-six-easy-steps-hot-rod-magazine.pdf

RELATED THREADS, it might take you several hours to read thru these but you'll save a lot of time and money doing so! rather that just buying parts first

rebuilt or new chevy 350 crank

https://www.speedwaymotors.com/Speedway-Chevy-350-Crankshaft-Two-Piece-Main,8682.html

https://www.amazon.com/Scat-Crankshafts-9-10442-Crankshaft-Chevrolet/dp/B003N2RRTY

http://www.northernautoparts.com/Pr...=20&product_ecat_engine=1386&btnSubmit=Search

rebuilt or new chevy 383 crank

http://www.superchevy.com/how-to/project-cars/sucp-0706-small-block-chevy-stroker-kit/

Last edited by a moderator: