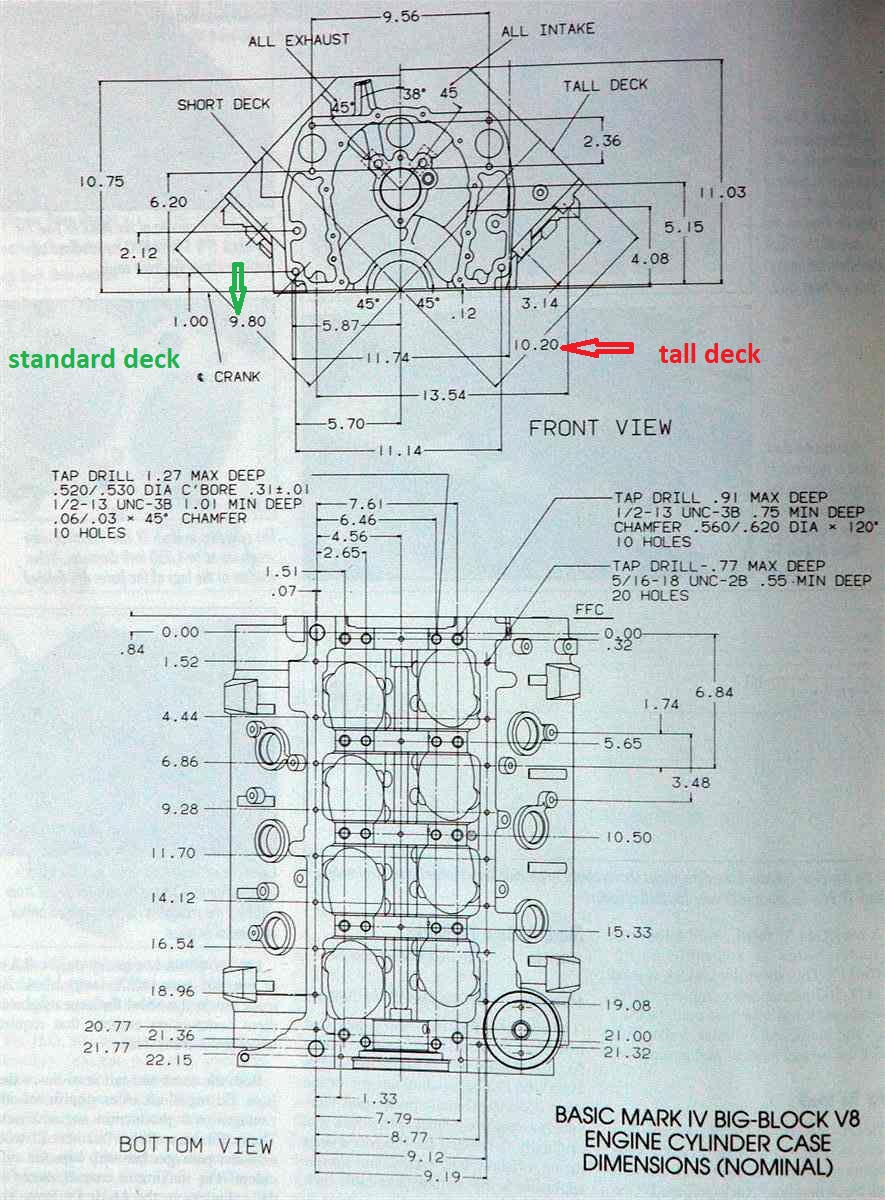

I recently had a discussion with one of the local guys concerning what heads and rotating assembly he should buy now that he recently purchased a tall deck (10.2") big block chevy block.

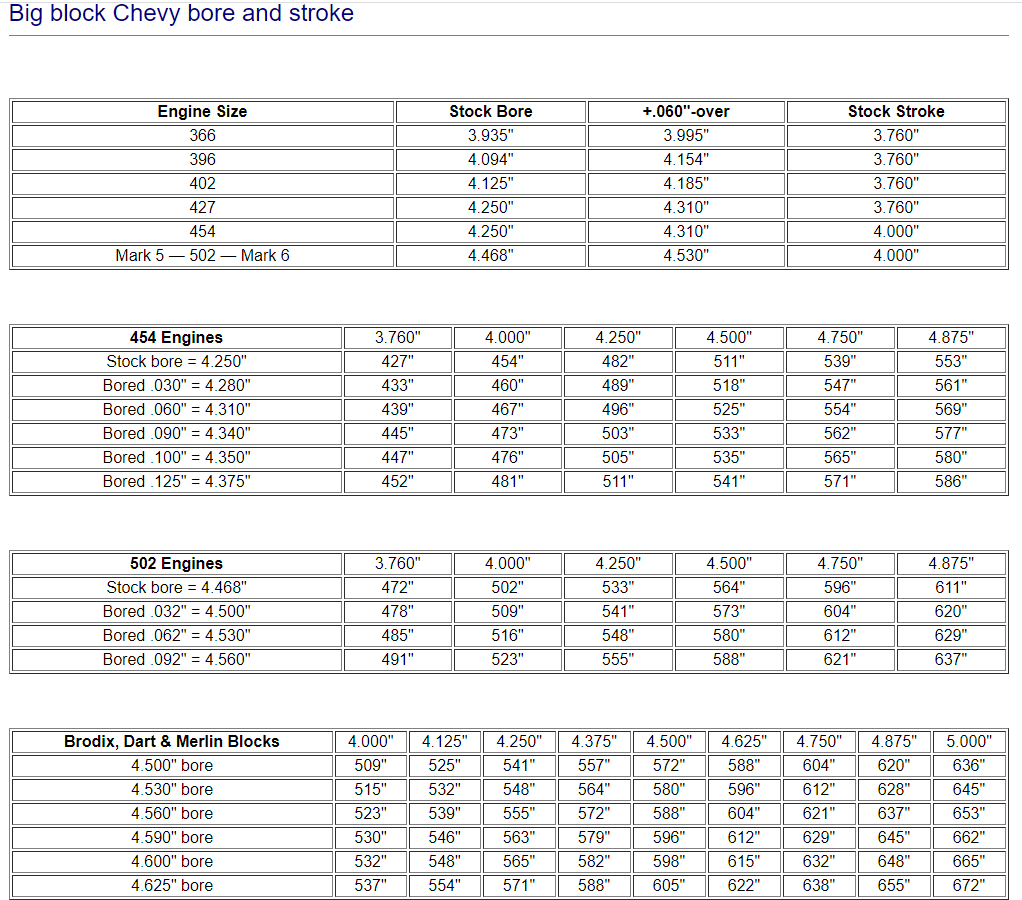

he has a perfectly good 427 forged crank (3.76" stroke) but hes seriously thinking of buying a (4.25" stroke) forged crank.

the DART blocks available have got a 4.6" bore.

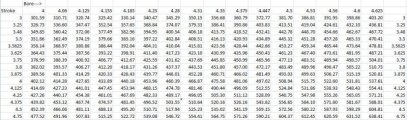

ok simple math, displacement= bore diam. x bore diam. x 8(cylinders)x stroke x .7854

lets assume these are max effort race engines built with 13:1 compression requiring E85 or race octane fuel, and yeah if your going to use e85 Id suggest you slightly increase the intake port cross sectional area as you'll need more air flow for alcohol based fuel.

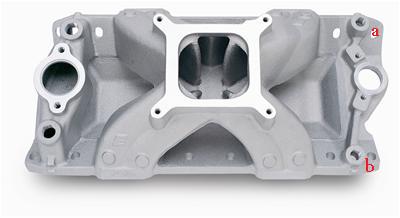

BBC cylinder head designs vary a great deal, so shop carefully

users.erols.com

3.76" stroke x 4.6 bore = 500 inches of displacement

users.erols.com

3.76" stroke x 4.6 bore = 500 inches of displacement

4.25" stroke x 4.6 bore = 565 cubic inches of displacement

www.magneticlynx.com

www.magneticlynx.com

www.scatcrankshafts.com

www.scatcrankshafts.com

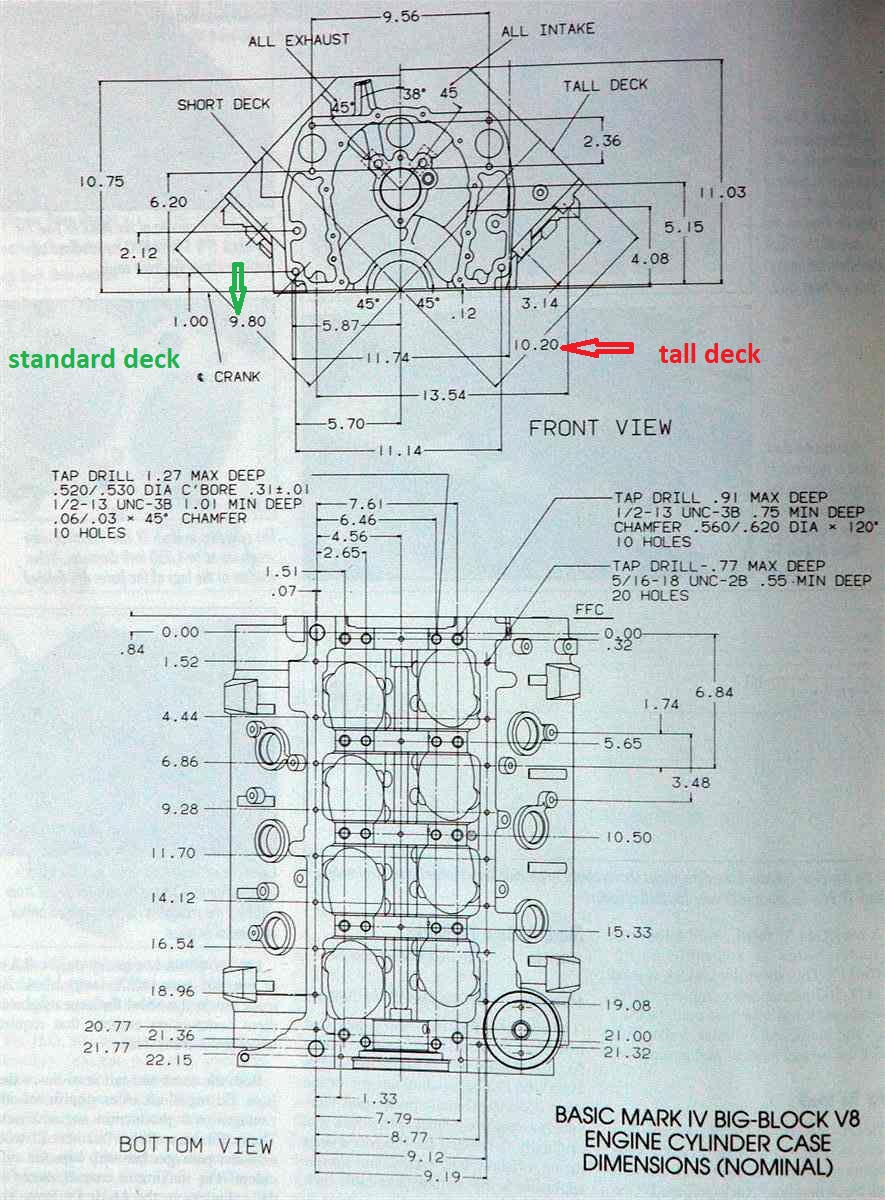

9.8 Short deck

Aftermarket block

Bore. Stroke. Rod. Displacement

4.5. 4. 6.385/6.535. 509

4.5. 4.25. 6.135/6.535 540

4.5. 4.5. 6.135. 572

4.56. 4.25. 6.385 555

4.6. 4.25. 6.385. 565

Tall deck 10.2

4.5. 4.25. 6.535. 540

4.5. 4.5. 6.535. 572

4.5. 4.75. 6.7. 604

4.56. 4.25. 6.535. 555

4.6. 4.5. 6.535. 598

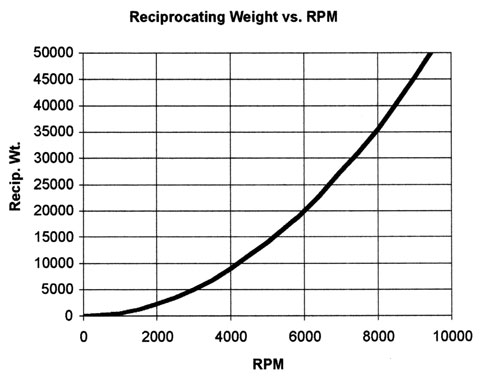

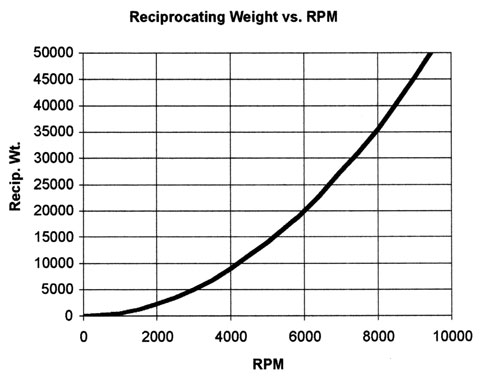

max piston speed should not exceed about 48,000 inches per minute and that requires high quality forged parts

3.76" stroke=6380 rpm redline

4.25" stroke- =5647 rpm redline

assuming either engine makes about 1.25 ft lbs of torque at close to peak rpm, lets say 500 rpm less

your looking at about 625 ft lbs on the 500 cubic inch engine.

close to 725 hp

it is likely your likely going to want heads with a 4.25 cross sectional area

Int. Duration is 276 degrees

Exh Duration is 290 degrees

LSA is 109 degrees

http://garage.grumpysperformance.co...onnecting-rod-rod-length-too-stroke-info.510/

www.jegs.com

www.jegs.com

your looking at about 706 ft lbs on the 565 cubic inch engine.

close to 737 hp is likely

it is likely your likely going to want heads with a 4.5 cross sectional area

Int. Duration is 286 degrees

Exh Duration is 303 degrees

LSA is 111 degrees

yes Im fully aware most people don,t bother to read the links and sub-links

UNTIL they have expensive parts fail.

but for the few people on the web site that might prefer spending less time and cash replacing expensive failed parts,

and financing the machine shop owners vacations and paying his mortgage... I post them anyway

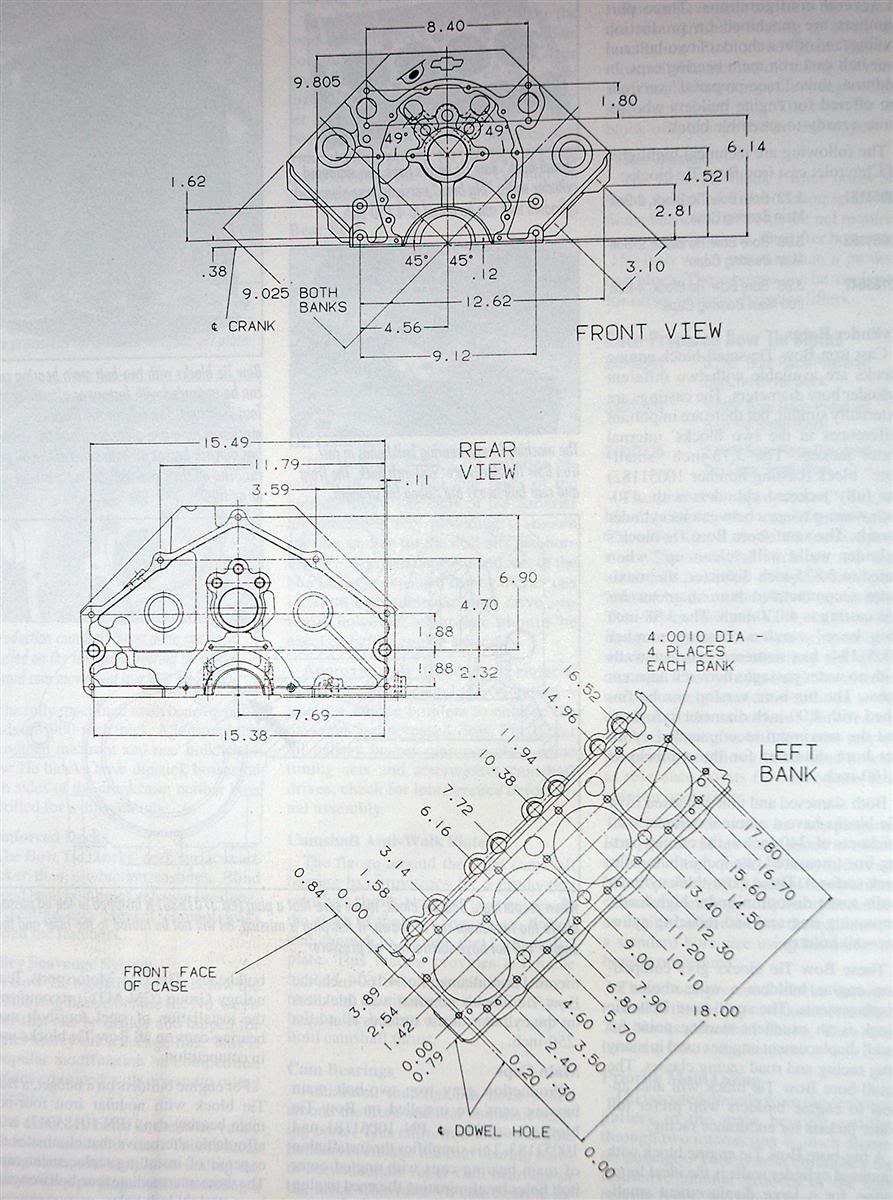

what length connecting rod and what piston pin height are you using, building the 496 BBC?

yes Im assuming its a tall deck 10.2" block and a 4.25" stroke

a 4.25" stroke,6.8" rod and 1.270 pin height, for that 10.2 deck height block

6.8" rod divided by a 4.25" stroke=1.6 ratio

displacement = bore x bore x stroke x 8 x .7854

1/2 stroke + rod length+piston pin compression height,

should roughly equal block deck height ,

www.scatcrankshafts.com

www.scatcrankshafts.com

9.8 Short deck

Aftermarket block

Bore. Stroke. Rod. Displacement

4.5. 4. 6.385/6.535. 509

4.5. 4.25. 6.135/6.535 540

4.5. 4.5. 6.135. 572

4.56. 4.25. 6.385 555

4.6. 4.25. 6.385. 565

Tall deck 10.2

4.5. 4.25. 6.535. 540

4.5. 4.5. 6.535. 572

4.5. 4.75. 6.7. 604

4.56. 4.25. 6.535. 555

4.6. 4.5. 6.535. 598

plus or minus a few thousandths,

minor adjustments in compression,

due to head gasket thickness and what the piston deck height is are common

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

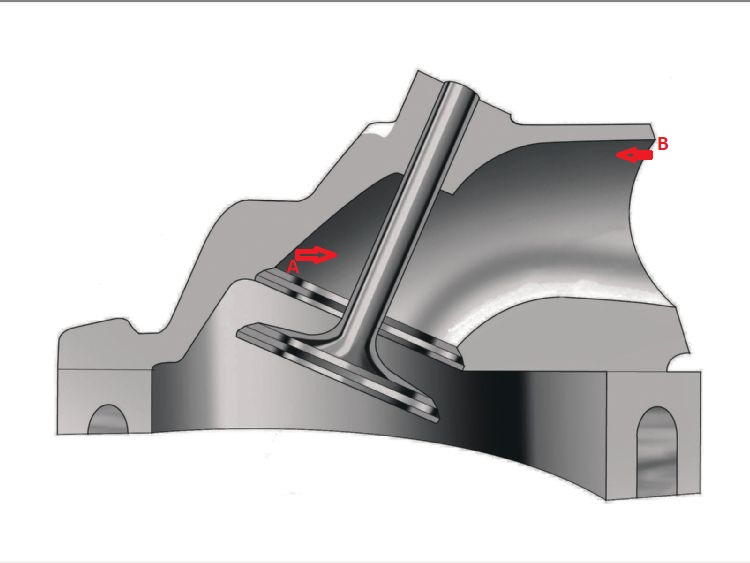

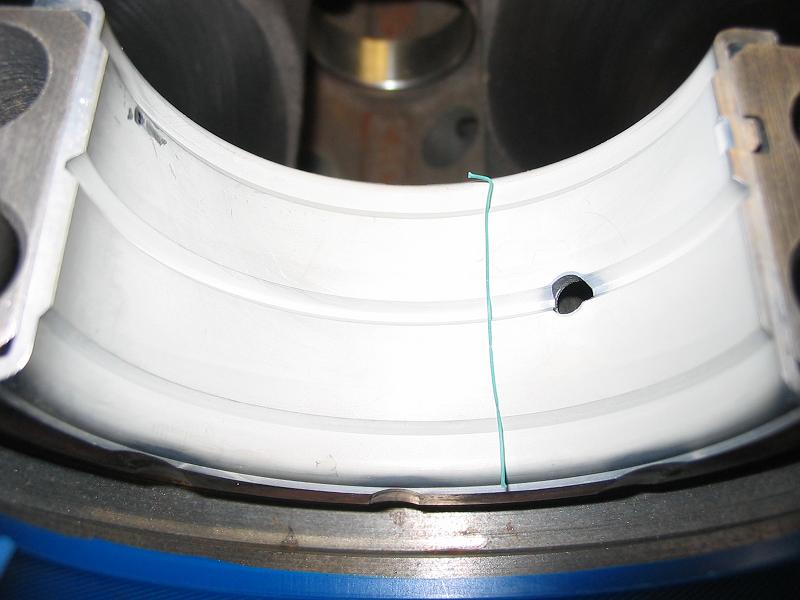

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

After market performance ,big block connecting rods come in several common lengths

6.7-6.8"

https://www.summitracing.com/parts/esp-67003dl19/overview/make/chevrolet

https://www.summitracing.com/parts/cpi-u16230/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6670022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022/overview/make/chevrolet

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

http://garage.grumpysperformance.co...-about-your-potential-dream-bbc-combos.14607/

http://garage.grumpysperformance.co...od-rod-length-too-stroke-info.510/#post-10311

http://garage.grumpysperformance.co...onnecting-rod-rod-length-too-stroke-info.510/

http://garage.grumpysperformance.com/index.php?threads/measuring-rod-and-pin-heights.3760/#post-9968

blueprint engine blocks

https://www.jegs.com/v/Blueprint-En...brand&storeId=10001&catalogId=10002&langId=-1

DART BLOCKS

http://dartheads.com/product-category/big-block-chevy/blocks/

world products blocks

https://www.billmitchellproducts.com/engine-blocks/

G.M. performance

https://www.gmperformancemotor.com/category/LS196.html

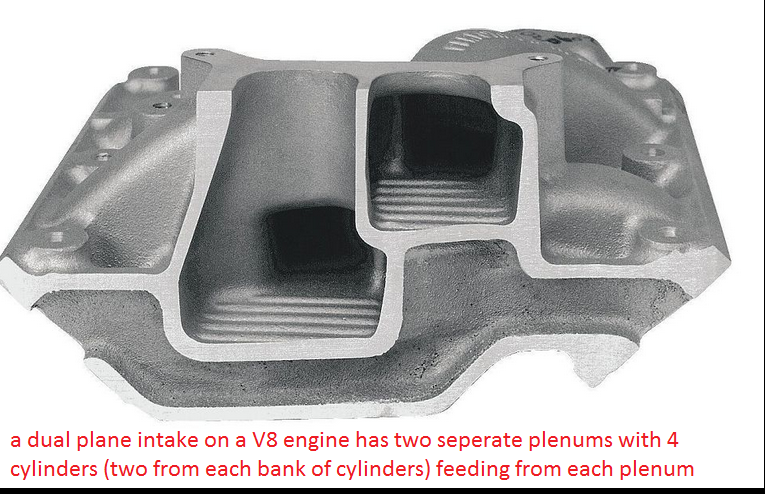

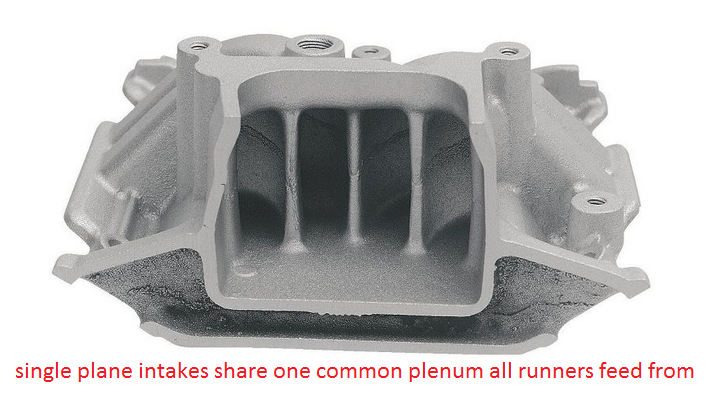

either engine will require a roller lifter cam with a fairly tight 109-111 lsa and about a .700 lift too breath to its potential, both engines would benefit from a tunnel ram intake and dual quads or a stack injection style intake

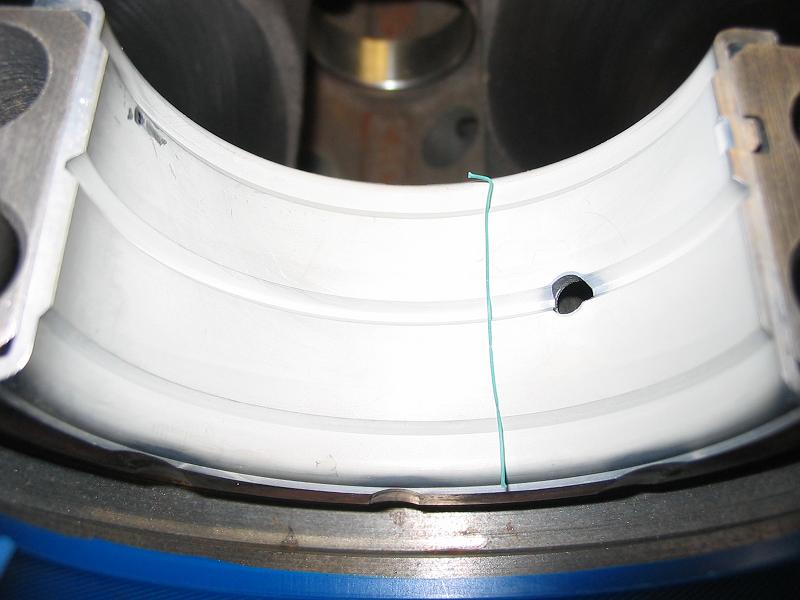

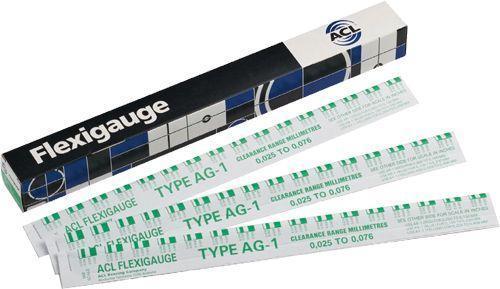

Catalog info on P bearings:

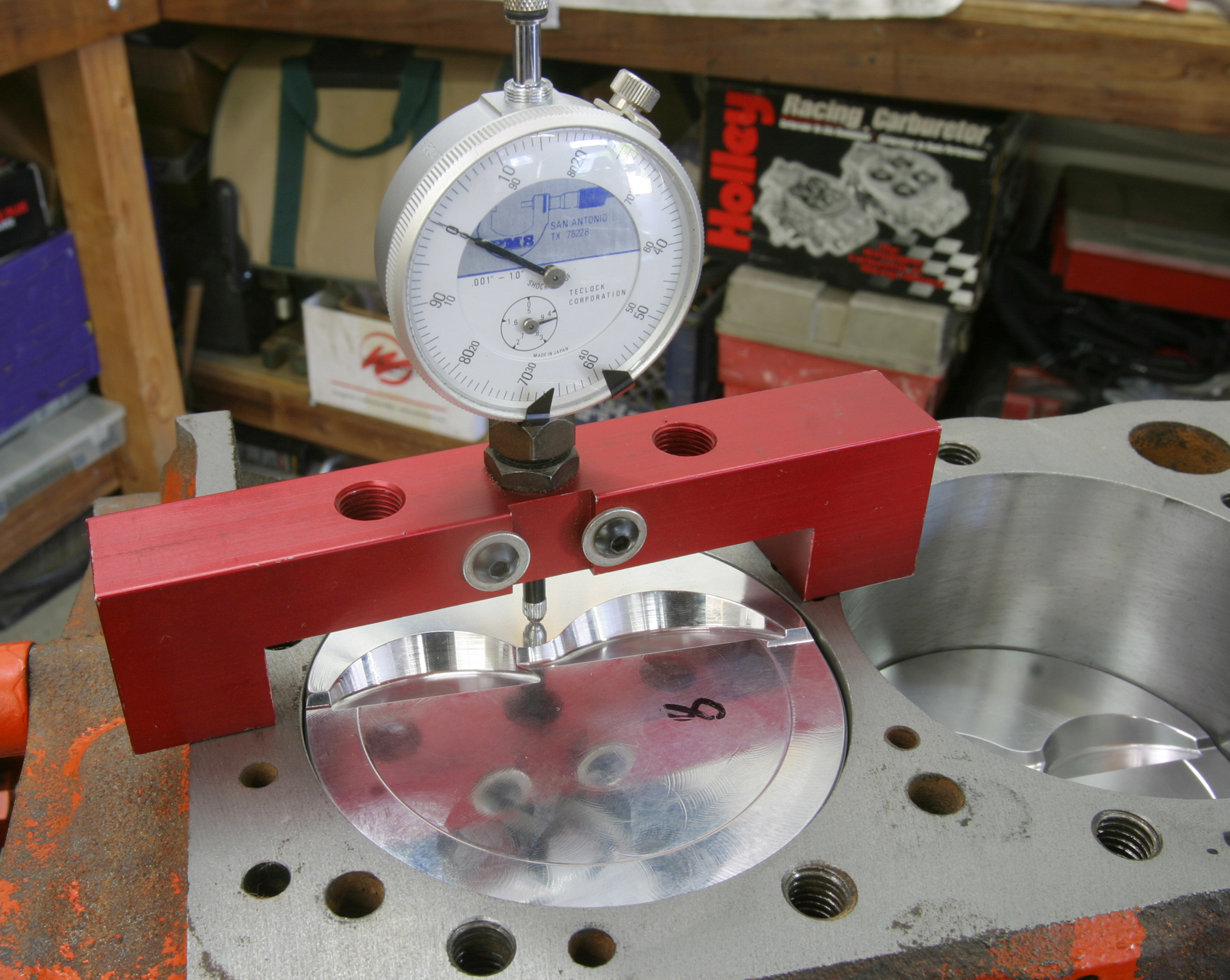

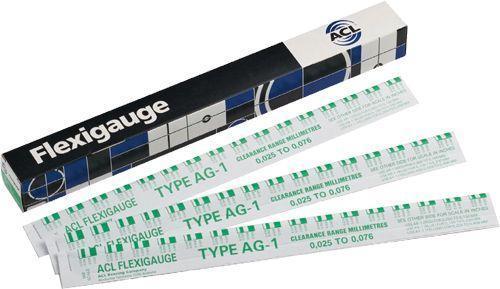

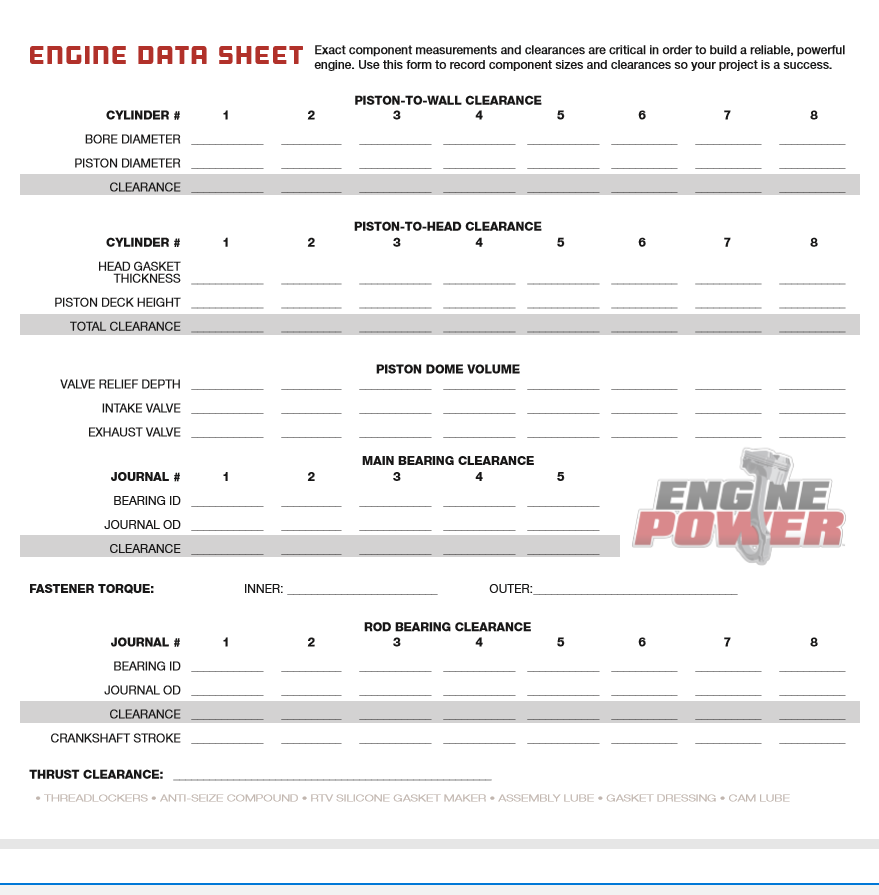

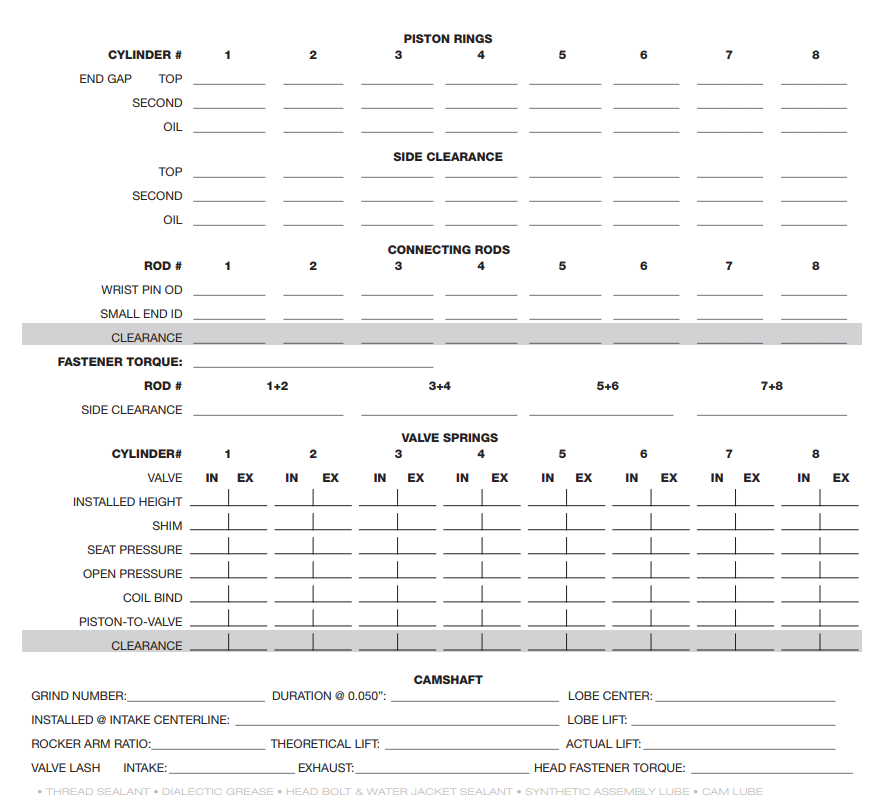

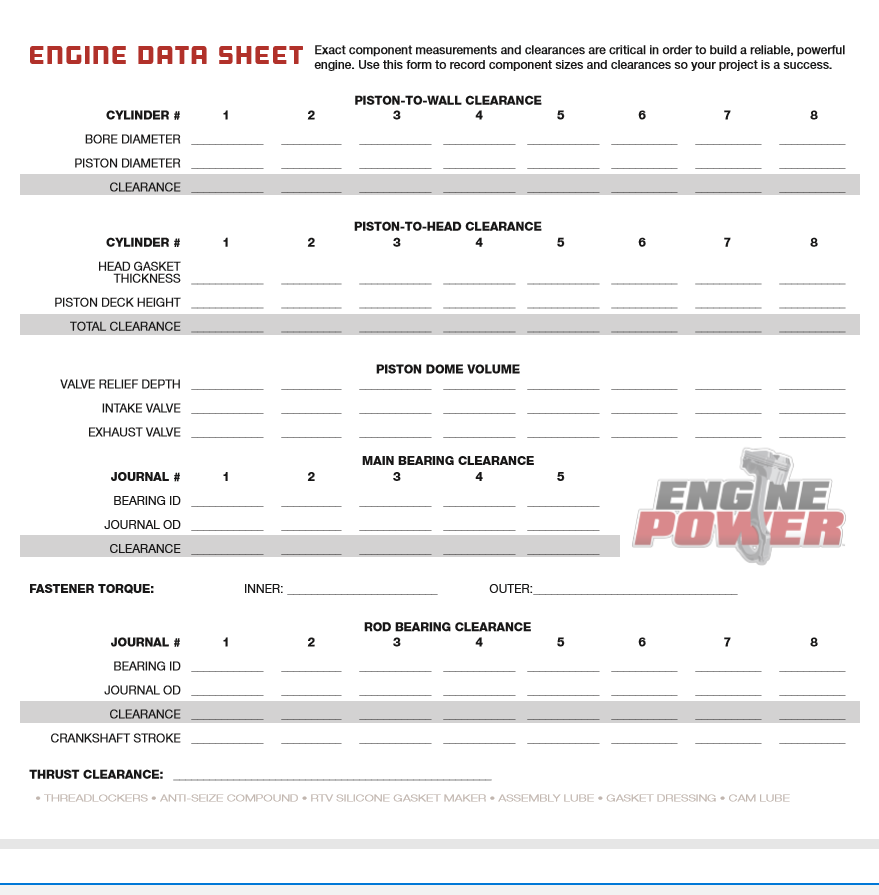

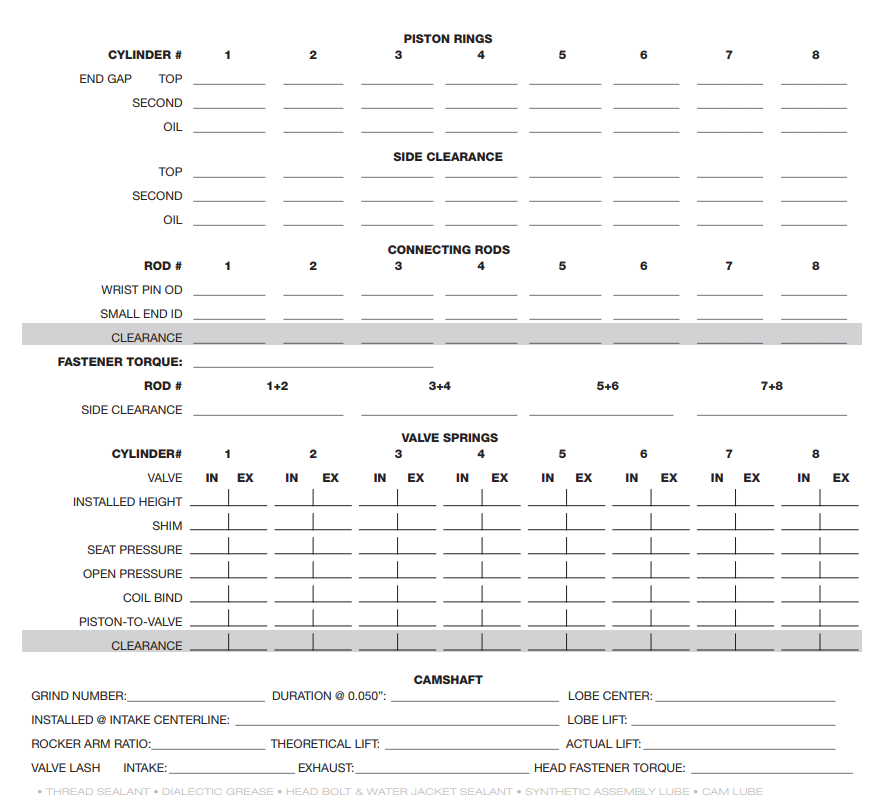

its the attention to details and checking clearance etc. and time and care taken,

that makes the difference between a barely or average functional ,

and a rather exceptional engine build, yes the urge to get it running is strong,

but getting it done correctly is the goal

your fpm is found by multiplying the engine rpms x the stroke x 2

example

on a 383 sbc the stroke is 3.75", so 4000fpm on a 383 is reached at 4000rpm x 12"(inches)= 48,000 inches per minute of piston travel

so 48,000/7.5" of stroke =6400rpm, (7.5" is twice the engines 3.75" stroke) exceeding that is a reasonably sure way to over stress the engine or (get into valve control issues ( which is a different can of worms)

this is a good place to point out that ARP makes much stronger rod bolts and main cap studs,and that the better aftermarket forged 4340 forged connecting rods are far stronger than most OEM connecting rods and that a 7/16" arp rod bolt is on average 200%-250% stronger than a stock 3/8" OEM rod bolt.

balanced components tend to put significantly lower stress on the engine components

theres lots of guys that don,t comprehend the stress levels involved in spinning a longer stroke engine up over 7000 rpm,

as a result theres a lot of guys who as a result get an expensive personal education in that area,of engineering stress management ,

after their engine "EXPLODED FOR NO REASON" and 90% plus will blame the machine shop ,

not realizing or refusing to accept, its their own lack of grasping the concepts involved.

ideal port cross section

IVE talked to several engineers, all strongly suggested the vertical stack injection manifold pictured below will significantly out flow the horizontal stack version above

the first few rule's of GRUMPY'S engine assembly

(1) THINK THINGS THROUGH CAREFULLY ,

WRITE DOWN A LIST OF COMPONENTS ,

MAKE DARN SURE THE LIST IS COMPATIBLE WITH,

and AT LEAST SEMI-REASONABLY PRICED WITHIN YOUR BUDGET.

FOR WHAT YOU INTEND TO BUILD AND RESEARCH THE RELATED MACHINE WORK,

RESEARCH CAREFULLY THE COMPONENT INSTALLATION AND INTENDED USE ,

AND POWER BAND THE PARTS WILL REQUIRE

AND FIND AN EXPERIENCED MENTOR.

(2) if in doubt, about how to do anything, on an engine, do some detailed research,

find and compare at least 3-5 valid trust worthy sources info,

read the instructions over again, several time's very carefully

and if available watch several related videos.

(3) if any component will not easily function as designed or requires a good bit of physical force to install ,

or your not 100% sure your doing something CORRECTLY

STOP, FIND OUT EXACTLY HOW THE PARTS SUPPOSED TO FIT AND FUNCTION,& WHY! YOUR HAVING PROBLEMS

theres a reason, and you better verify your clearances are correct , and your following the instructions before you proceed.

(4) never assume the parts you purchased can be used without carefully , cleaning them prior too,

checking the physical condition, verifying clearances and using the correct sealant, lubricants etc.

(5) the quality of a component is generally at least loosely related to the cost to produce it,

and the amount of detailed research and quality machine work that went into its production.

if you got a significant reduced price, theres typically a reason.

it might simply be because a new improved part superseded the one you purchased,

but it might be a far lower quality imported clone with lower quality materials and machine work.

its the purchasers responsibility to research quality.

(6) if you did not do the work personally or at least take the effort to verify it was done correctly and personally verify clearances

ITS almost a sure thing that it was NOT done , correctly, and yes that mandates you fully understand what your looking at,

and how the components are supposed to function and have high quality precision measuring tools.

(7) ITS ALMOST ALWAYS FASTER AND LESS EXPENSIVE , AND PRODUCES BETTER RESULTS IF YOU,

BUY FEWER HIGH QUALITY PARTS & DO THINGS CORRECTLY THE FIRST TIME

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

before you buy components talk to both the vendors and your machine shop of choice , you damn sure don,t want mis-matched components and clearances.

you need to measure accurately, know what your current block will function correctly with and pay attention to clearances and other details that make or break the engines potential durability and power potential.

related info

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-8692

http://garage.grumpysperformance.co...od-rod-length-too-stroke-info.510/#post-10311

http://garage.grumpysperformance.com/index.php?threads/redline.343/#post-15729

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.com/index.php?threads/connecting-rod-strength-h-vs-i-beam.1168/

http://garage.grumpysperformance.com/index.php?threads/bits-of-427-bbc-build-related-info.15543/

http://garage.grumpysperformance.com/index.php?threads/427-tall-deck.15267/

http://garage.grumpysperformance.co...-the-oil-used-and-oil-level-does-mater.15592/

http://www.wallaceracing.com/cam-spec-calc.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/runnertorquecalc.php

he has a perfectly good 427 forged crank (3.76" stroke) but hes seriously thinking of buying a (4.25" stroke) forged crank.

the DART blocks available have got a 4.6" bore.

ok simple math, displacement= bore diam. x bore diam. x 8(cylinders)x stroke x .7854

lets assume these are max effort race engines built with 13:1 compression requiring E85 or race octane fuel, and yeah if your going to use e85 Id suggest you slightly increase the intake port cross sectional area as you'll need more air flow for alcohol based fuel.

BBC cylinder head designs vary a great deal, so shop carefully

Stan Weiss' - Engine Bore, Stroke, Rod Length, Ratio Table

Bore, Stroke, Rod Length, Ratio Table

users.erols.com

users.erols.com

4.25" stroke x 4.6 bore = 565 cubic inches of displacement

David Vizard and Stan Weiss'' - Programs designed to Help Cylinder Head Optimization and Cam Selection

Programs designed to Help Cylinder Head Optimization and Cam Selection

www.magneticlynx.com

www.magneticlynx.com

Connecting Rods

Connecting Rods sold by SCAT Crankshafts, the leader in high-performance engine components for over 50 years.

BBC Rods | 396 427 454 502 | Molnar Big Block Chevy Rods

Molnar BBC rods. Big selection of H beam big block Chevy connecting rods. Standard, stroker, turbo, power adder, power adder plus and small journal.

molnarrods.com

9.8 Short deck

Aftermarket block

Bore. Stroke. Rod. Displacement

4.5. 4. 6.385/6.535. 509

4.5. 4.25. 6.135/6.535 540

4.5. 4.5. 6.135. 572

4.56. 4.25. 6.385 555

4.6. 4.25. 6.385. 565

Tall deck 10.2

4.5. 4.25. 6.535. 540

4.5. 4.5. 6.535. 572

4.5. 4.75. 6.7. 604

4.56. 4.25. 6.535. 555

4.6. 4.5. 6.535. 598

max piston speed should not exceed about 48,000 inches per minute and that requires high quality forged parts

3.76" stroke=6380 rpm redline

4.25" stroke- =5647 rpm redline

assuming either engine makes about 1.25 ft lbs of torque at close to peak rpm, lets say 500 rpm less

your looking at about 625 ft lbs on the 500 cubic inch engine.

close to 725 hp

it is likely your likely going to want heads with a 4.25 cross sectional area

Int. Duration is 276 degrees

Exh Duration is 290 degrees

LSA is 109 degrees

Bbc Related & Links And Useful Info

a few useful links, and sub links videos, and tips to look over yeah, increased displacement helps and building a killer BBC old school, for your car can be both cost effective and produce impressive results some of the most effective, cost per hp and efficient combo's , will be the 496...

garage.grumpysperformance.com

big block chevy info

the real basics, (off ebays site)------------------------------------------------------------------------------- " This guide is intended to help you sort out the more major differences among Big Block Chevrolet engines produced since 1958. Chevrolet has designed and produced several different...

garage.grumpysperformance.com

Another 427 Tall Deck Truck/Marine

I am building this engine and I know you have a lot of links and post but (no offense) its like an unorganized library. I dont know where to look. So here goes: I am planning on using stock block 473478, stock tall deck intake 364462, Holley 850 cfm doublepump manual choke carb 4150, stock...

garage.grumpysperformance.com

Big-Block Chevy OE And Aftermarket Block Variants

Generation Gap: Big-Block Chevy OE And Aftermarket Block Variants By GREG ACOSTA AUGUST 07, 2018 https://garage.grumpysperformance.com/index.php?threads/some-basic-bbc-math-to-get-you-thinking-about-your-potential-dream-bbc-combos.14607/#post-96895 When it comes to big-block engines, there...

garage.grumpysperformance.com

SRP 297250: Forged Flat Top Pistons Big Block Chevy 572 ci [4.560 in. Bore] - JEGS

Get the Best Performance with SRP Forged Flat Top Pistons Big Block Chevy 572 ci [4.560 in. Bore] 297250 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

your looking at about 706 ft lbs on the 565 cubic inch engine.

close to 737 hp is likely

it is likely your likely going to want heads with a 4.5 cross sectional area

Int. Duration is 286 degrees

Exh Duration is 303 degrees

LSA is 111 degrees

yes Im fully aware most people don,t bother to read the links and sub-links

UNTIL they have expensive parts fail.

but for the few people on the web site that might prefer spending less time and cash replacing expensive failed parts,

and financing the machine shop owners vacations and paying his mortgage... I post them anyway

what length connecting rod and what piston pin height are you using, building the 496 BBC?

yes Im assuming its a tall deck 10.2" block and a 4.25" stroke

a 4.25" stroke,6.8" rod and 1.270 pin height, for that 10.2 deck height block

6.8" rod divided by a 4.25" stroke=1.6 ratio

displacement = bore x bore x stroke x 8 x .7854

1/2 stroke + rod length+piston pin compression height,

should roughly equal block deck height ,

Connecting Rods

Connecting Rods sold by SCAT Crankshafts, the leader in high-performance engine components for over 50 years.

BBC Rods | 396 427 454 502 | Molnar Big Block Chevy Rods

Molnar BBC rods. Big selection of H beam big block Chevy connecting rods. Standard, stroker, turbo, power adder, power adder plus and small journal.

molnarrods.com

9.8 Short deck

Aftermarket block

Bore. Stroke. Rod. Displacement

4.5. 4. 6.385/6.535. 509

4.5. 4.25. 6.135/6.535 540

4.5. 4.5. 6.135. 572

4.56. 4.25. 6.385 555

4.6. 4.25. 6.385. 565

Tall deck 10.2

4.5. 4.25. 6.535. 540

4.5. 4.5. 6.535. 572

4.5. 4.75. 6.7. 604

4.56. 4.25. 6.535. 555

4.6. 4.5. 6.535. 598

plus or minus a few thousandths,

minor adjustments in compression,

due to head gasket thickness and what the piston deck height is are common

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

After market performance ,big block connecting rods come in several common lengths

6.7-6.8"

https://www.summitracing.com/parts/esp-67003dl19/overview/make/chevrolet

https://www.summitracing.com/parts/cpi-u16230/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6670022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022/overview/make/chevrolet

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

http://garage.grumpysperformance.co...-about-your-potential-dream-bbc-combos.14607/

http://garage.grumpysperformance.co...od-rod-length-too-stroke-info.510/#post-10311

http://garage.grumpysperformance.co...onnecting-rod-rod-length-too-stroke-info.510/

http://garage.grumpysperformance.com/index.php?threads/measuring-rod-and-pin-heights.3760/#post-9968

blueprint engine blocks

https://www.jegs.com/v/Blueprint-En...brand&storeId=10001&catalogId=10002&langId=-1

DART BLOCKS

http://dartheads.com/product-category/big-block-chevy/blocks/

world products blocks

https://www.billmitchellproducts.com/engine-blocks/

G.M. performance

https://www.gmperformancemotor.com/category/LS196.html

either engine will require a roller lifter cam with a fairly tight 109-111 lsa and about a .700 lift too breath to its potential, both engines would benefit from a tunnel ram intake and dual quads or a stack injection style intake

Catalog info on P bearings:

its the attention to details and checking clearance etc. and time and care taken,

that makes the difference between a barely or average functional ,

and a rather exceptional engine build, yes the urge to get it running is strong,

but getting it done correctly is the goal

your fpm is found by multiplying the engine rpms x the stroke x 2

example

on a 383 sbc the stroke is 3.75", so 4000fpm on a 383 is reached at 4000rpm x 12"(inches)= 48,000 inches per minute of piston travel

so 48,000/7.5" of stroke =6400rpm, (7.5" is twice the engines 3.75" stroke) exceeding that is a reasonably sure way to over stress the engine or (get into valve control issues ( which is a different can of worms)

this is a good place to point out that ARP makes much stronger rod bolts and main cap studs,and that the better aftermarket forged 4340 forged connecting rods are far stronger than most OEM connecting rods and that a 7/16" arp rod bolt is on average 200%-250% stronger than a stock 3/8" OEM rod bolt.

balanced components tend to put significantly lower stress on the engine components

theres lots of guys that don,t comprehend the stress levels involved in spinning a longer stroke engine up over 7000 rpm,

as a result theres a lot of guys who as a result get an expensive personal education in that area,of engineering stress management ,

after their engine "EXPLODED FOR NO REASON" and 90% plus will blame the machine shop ,

not realizing or refusing to accept, its their own lack of grasping the concepts involved.

ideal port cross section

IVE talked to several engineers, all strongly suggested the vertical stack injection manifold pictured below will significantly out flow the horizontal stack version above

the first few rule's of GRUMPY'S engine assembly

(1) THINK THINGS THROUGH CAREFULLY ,

WRITE DOWN A LIST OF COMPONENTS ,

MAKE DARN SURE THE LIST IS COMPATIBLE WITH,

and AT LEAST SEMI-REASONABLY PRICED WITHIN YOUR BUDGET.

FOR WHAT YOU INTEND TO BUILD AND RESEARCH THE RELATED MACHINE WORK,

RESEARCH CAREFULLY THE COMPONENT INSTALLATION AND INTENDED USE ,

AND POWER BAND THE PARTS WILL REQUIRE

AND FIND AN EXPERIENCED MENTOR.

(2) if in doubt, about how to do anything, on an engine, do some detailed research,

find and compare at least 3-5 valid trust worthy sources info,

read the instructions over again, several time's very carefully

and if available watch several related videos.

(3) if any component will not easily function as designed or requires a good bit of physical force to install ,

or your not 100% sure your doing something CORRECTLY

STOP, FIND OUT EXACTLY HOW THE PARTS SUPPOSED TO FIT AND FUNCTION,& WHY! YOUR HAVING PROBLEMS

theres a reason, and you better verify your clearances are correct , and your following the instructions before you proceed.

(4) never assume the parts you purchased can be used without carefully , cleaning them prior too,

checking the physical condition, verifying clearances and using the correct sealant, lubricants etc.

(5) the quality of a component is generally at least loosely related to the cost to produce it,

and the amount of detailed research and quality machine work that went into its production.

if you got a significant reduced price, theres typically a reason.

it might simply be because a new improved part superseded the one you purchased,

but it might be a far lower quality imported clone with lower quality materials and machine work.

its the purchasers responsibility to research quality.

(6) if you did not do the work personally or at least take the effort to verify it was done correctly and personally verify clearances

ITS almost a sure thing that it was NOT done , correctly, and yes that mandates you fully understand what your looking at,

and how the components are supposed to function and have high quality precision measuring tools.

(7) ITS ALMOST ALWAYS FASTER AND LESS EXPENSIVE , AND PRODUCES BETTER RESULTS IF YOU,

BUY FEWER HIGH QUALITY PARTS & DO THINGS CORRECTLY THE FIRST TIME

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

before you buy components talk to both the vendors and your machine shop of choice , you damn sure don,t want mis-matched components and clearances.

you need to measure accurately, know what your current block will function correctly with and pay attention to clearances and other details that make or break the engines potential durability and power potential.

related info

http://garage.grumpysperformance.com/index.php?threads/calculating-ideal-port-size.624/#post-8692

http://garage.grumpysperformance.co...od-rod-length-too-stroke-info.510/#post-10311

http://garage.grumpysperformance.com/index.php?threads/redline.343/#post-15729

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.com/index.php?threads/connecting-rod-strength-h-vs-i-beam.1168/

(X) or (H) PIPE

Would be interesting to see some dyno testing to see how much BSFC changes with the typical injection mode and then change to End-of-Injection mode. Agreed. A few scientific studies found that, with the engines that they tested (Zhai and Lai 1995 and Berkmuller 1997), that an open valve...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/bits-of-427-bbc-build-related-info.15543/

http://garage.grumpysperformance.com/index.php?threads/427-tall-deck.15267/

http://garage.grumpysperformance.co...-the-oil-used-and-oil-level-does-mater.15592/

http://www.wallaceracing.com/cam-spec-calc.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/runnertorquecalc.php

Last edited: