you might want to CAREFULLY,

read thru these links and sub links,

it will help you avoid costly mistakes,

a half hour reading the links,

could save you hundreds of dollars and hours of work

theres at least a few hours of very worth while , and quite useful reading in this thread and links that will prevent you wasting time and money, keep in mind the sub links contain a huge wealth of additional info youll need

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

https://www.youtube.com/watch?v=o5is9BsH5OU

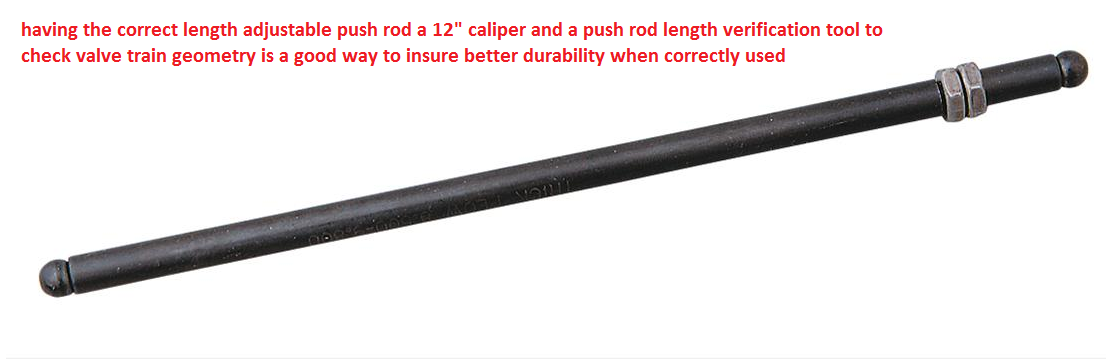

the last few sets of push rods I purchased were from TRICKFLOW

https://www.trickflow.com/search/product-line/trick-flow-chromoly-pushrods

you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal, Its a good idea TOO ALWAYS ask detailed questions as to the best , and most durable parts combination they have available, for your intended application, from your cam suppliers tech department

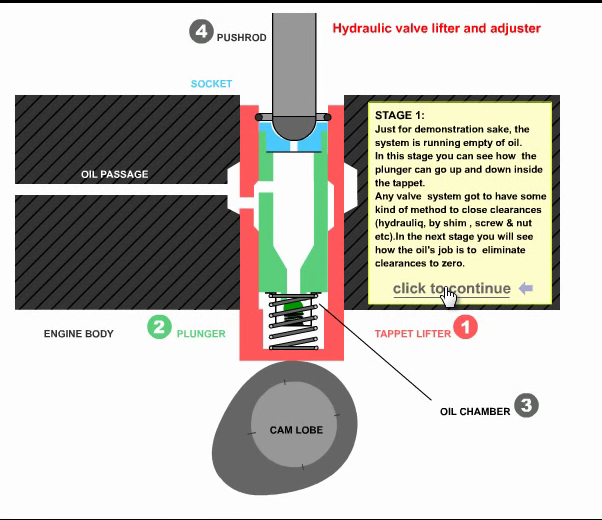

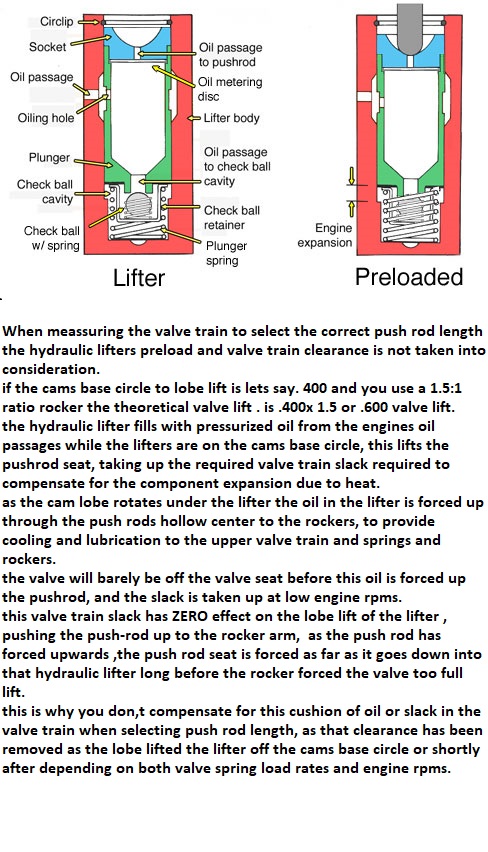

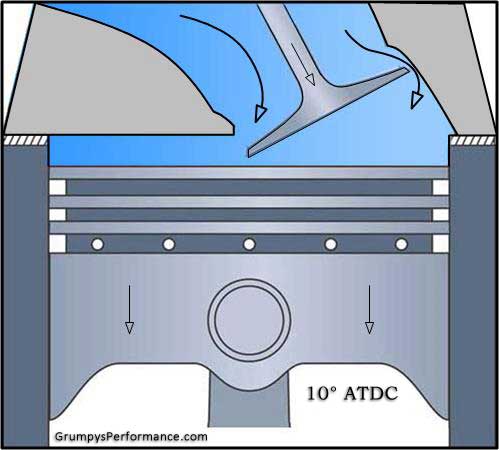

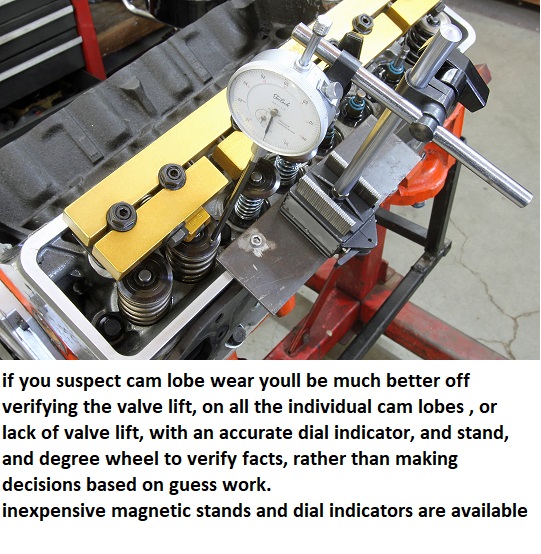

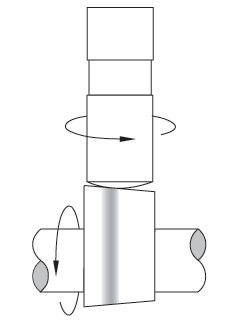

if you plan on graphing the lift vs cam lobe rotation per degree of rotation, you can safely ignore, totally the lifter seat being held up on a running engine, when your using a lifter and push rod too move, and verify a dial indicator reading, (keep in mind the cam rotates at 1/2 the crank rotation speed.)

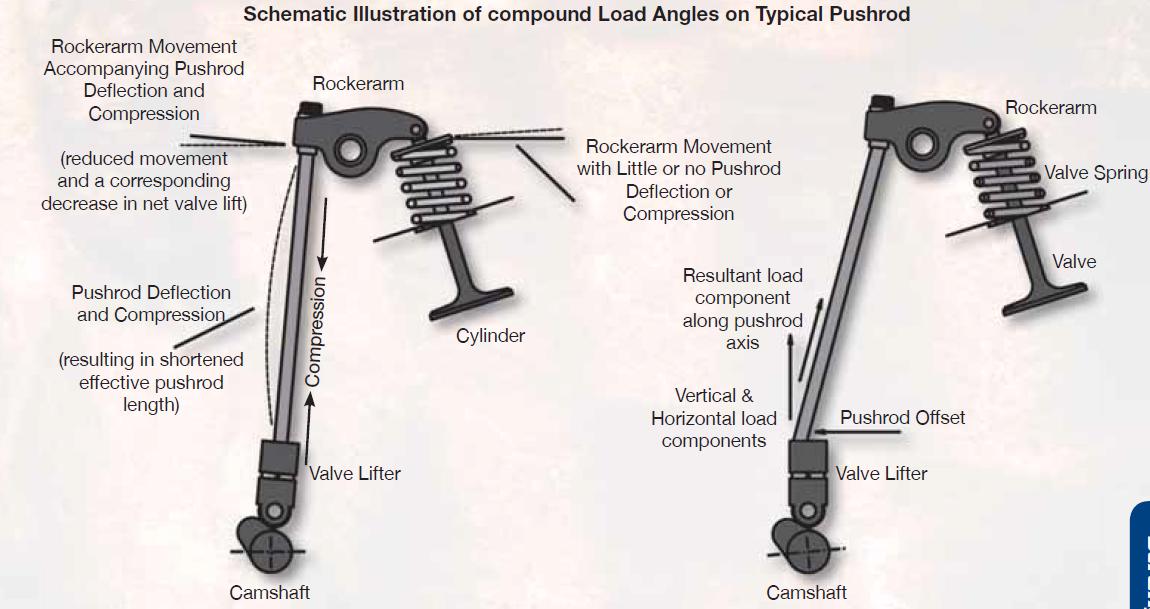

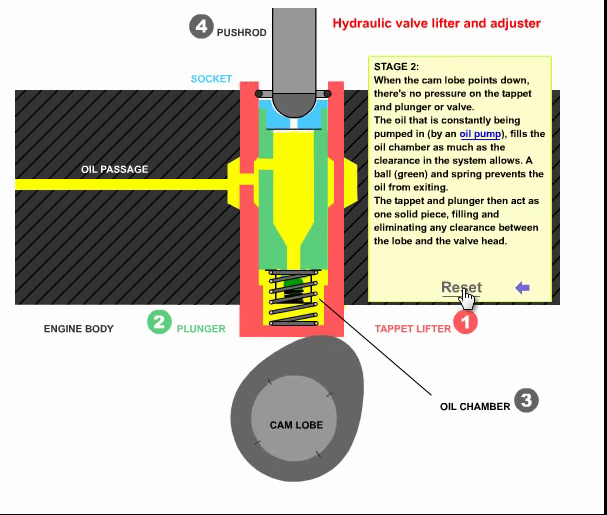

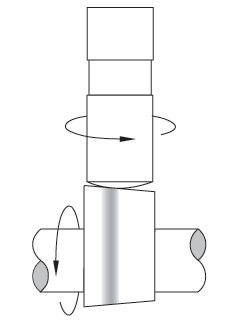

when checking the cam lobe lift and duration.as the cam rotates it compresses the lifter seat as the lobe acceleration ramp, or start of the lifter movement upwards in its lifter bore occurs.

this is how the oil is forced up the push rod to cool the rocker and valve springs and at low rotational rpm's the push-rod lifter seat bottoms out in the lifter well before max lift on the push-rod even gets close,

thus theres a minor delay in the lifter movement as the engine oil is forced up the push rod as the cam lobe rotates under the lifter base but this has very little effect on duration and almost zero on total lift.

watch this video, it depicts the lifters movement as the cam lobe rotates under its base forcing it up as the lobes ramp, rotates under the lifter base,removing the clearance slack,

as it compresses the valve spring and forces the trapped oil, up the push rod and lifts the valve

so you can order the correct length push rods...

I don,t think you have the correct idea as to how hydraulic lifters work,

yes it is possible for an engine with hydraulic lifters to be pushed too operate at a high enough rpm that the time required for the lifter seat to fully depress and all the oil too be forced up to the push rod/rockers , to be so short that the lifter pumps up and the valves will have less seat time, ( sometimes one of several factors, like the lifter leaving the cam lobes surface as the inertial loads exceed the valve springs ability to maintain lifter too lobe contact, referred too or contributing to what is commonly referred too as valve float) but that has ZERO to do with selecting push rod length or proper valve train geometry, (remember at 6000 rpm the valve is lifted off its seat 50 times PER SECOND)

viewtopic.php?f=52&t=1376&p=3033#p3033

http://www.hotrod.com/how-to/engine/1501-how-to-measure-for-correct-length-pushrods/

http://www.hotrod.com/how-to/engine/116-0401-setting-pushrod-length/

http://mantonpushrods.com/pushrod-info/determine-length/

http://www.enginebuildermag.com/2007/09/push-rods-lifters/

http://www.lunatipower.com/Tech/Valvetr ... metry.aspx

file:///C:/Users/Marge/Downloads/Jim%20Miller%20Mid%20Lift%20VTG.pdf

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...ck-chevy-gen-v-vi-to-adjustable-rockers.4564/

http://www.lunatipower.com/Tech/Valvetrain/HowToVerifyValvetrainGeometry.aspx

READ THIS THREAD AND RELATED LINKED INFO

http://garage.grumpysperformance.co...rdering-correct-custom-length-pushrods.14241/

http://garage.grumpysperformance.co...rect-custom-length-pushrods.14241/#post-72353

http://garage.grumpysperformance.com/index.php?threads/pushrod-length-tolerance.15189/#post-86918

http://garage.grumpysperformance.co...nd-check-info-you-might-need.5931/#post-18267

http://mantonpushrods.com/pushrod-info/determine-length/

https://www.enginelabs.com/engine-t...ing-valvetrain-geometry-and-getting-it-right/

https://www.hotrod.com/articles/how-to-measure-for-correct-length-pushrods/

https://www.hotrod.com/articles/setting-pushrod-length/

https://www.summitracing.com/parts/pro-66789

Parts List for Ask Away: Big Block Chevy 454 Pushrod Length

| Part Number | Description |

|---|---|

| CCA-7702-1 | COMP Cams Hi-Tech Pushrod Length Checking Tool, 6.80" - 7.80" (Intake) |

| CCA-7703-1 | COMP Cams Hi-Tech Pushrod Length Checking Tool, 7.80" - 8.80" (Intake) |

| CCA-7704-1 | COMP Cams Hi-Tech Pushrod Length Checking Tool, 8.80" - 9.80" (Exhaust) |

| CCA-7900 | COMP Cams Magnum Checking Pushrod Set* |

| *Master Kit: five separate adjustable pushrods from 6.125" to 11.50". |

https://www.summitracing.com/parts/tfs-9501

you can,t guess or assume, a stock push rod length will work,

especially if you used an aftermarket, cam, lifters or rockers or changed cylinder heads, or valve springs!

If you want durability,you,ve got to measure correctly and get the correct length,

http://www.summitracing.com/parts/tfs-9001 (7.5-to-8.7")

http://www.summitracing.com/parts/tfs-9000 (6.125-to-07.5")

heres a bit of useful related push rod length info

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

failure to take the time and effort required usually results in valve train durability issues or engine damage,

yeah you can ignore the info provided, but taking the time to do it correctly will save you a whole lot of potential problems & grief later on.

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=9687&p=48105#p48105

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

http://garage.grumpysperformance.co...swap-in-1-6-1-ratio-rockers.10671/#post-46039

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

DON"T FORGET TO VERIFY SPRING BIND CLEARANCE AND PISTON TO VALVE CLEARANCE ETC>

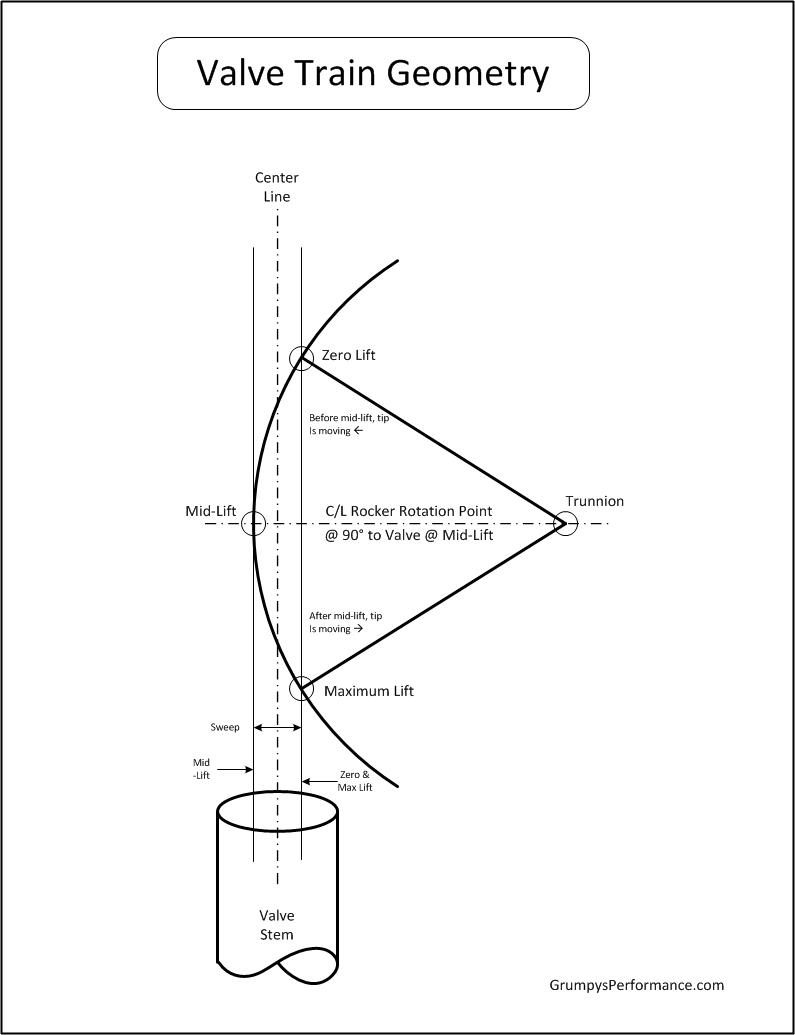

idealy the roller rocker, contact on the valve stem, would be centered but any place in the center 1/3rd of the valve stem diameter is acceptable ,if the contact wear bar is very narrow and you can change the location with both longer push rods and valve stem caps and longer valves and valve spring shims

The answer, too when or if you need longer valves, depends on the engine valve train geometry and the cylinder head design,

it differs from intake to exhaust on most engines also.

I've usually found longer valves are required if the valve lift exceeds about .630, but theres no rock solid rule, you need to do some research and call your machine shop and the cylinder head manufacture. the load rate also plays a significant part in that decision, thinner valve spring seats require thicker castings for structural rigidity.

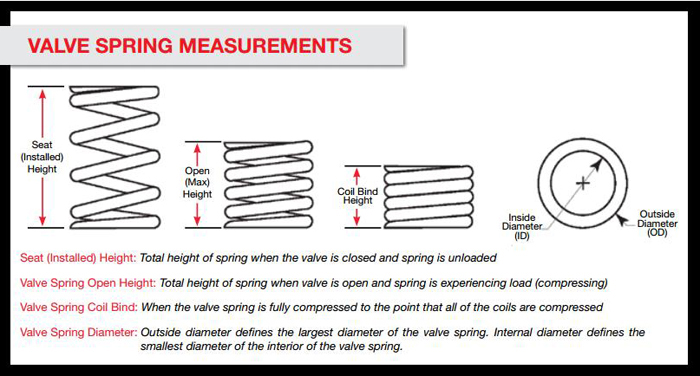

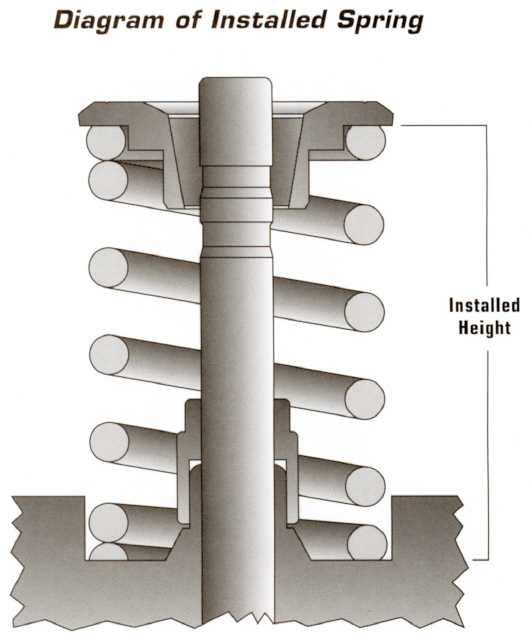

valve lift alone withing reasonable limits, has little to do with the need for longer valves, but as the lift increases the difference between the spring installed height and its spring bind or coil stack obviously changes.

if your standard valve spring has lets say a 1.70 installed height and a 1.20 coil bind or stack height you would generally be looking at .500 difference, subtract the .060 minimum clearance,

added to prevent binding issues for coil bind, that only leaves you .440 useful valve clearance.

now you can machine the heads in the valve spring seat area only minimally as the valve spring seats are over the coolant passages and generally ,

the manufacturers will tell you you can only machine the valve seat so far from the O.E.M. original location,

and in many cylinder heads you can't machine deeper without reducing the heads functional strength or causing problems.

if you can,t increase the installed height, of the valve spring by machining extra clearance downward, into the spring seat, the other answer is found in longer valve stem length and longer push rods too keep the rocker geometry correct.

before as cast

http://www.hotrod.com/articles/ctrp-0611-rocker-arm-valvetrain-geometry/

http://www.enginelabs.com/engine-te...ing-valvetrain-geometry-and-getting-it-right/

http://garage.grumpysperformance.com/index.php?threads/finding-matched-valve-spring-required.13774/

http://www.lunatipower.com/Tech/Valvetrain/HowToVerifyValvetrainGeometry.aspx

http://www.sbintl.com/tech_library/articles/rocker_arm_geometry.pdf

http://garage.grumpysperformance.com/index.php?threads/timing-chains-stretch.5734/#post-17492

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-67562

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.co...nter-1-for-timing-ignition-cam.966/#post-1682

http://garage.grumpysperformance.co...e-train-clearances-and-problems.528/#post-668

http://garage.grumpysperformance.co...king-piston-to-valve-clearances.399/#post-488

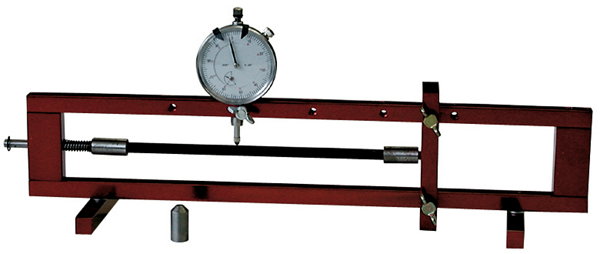

http://www.competitionproducts.com/Camshaft-Degreeing-and-Cam-Measuring-Tools/products/1387/

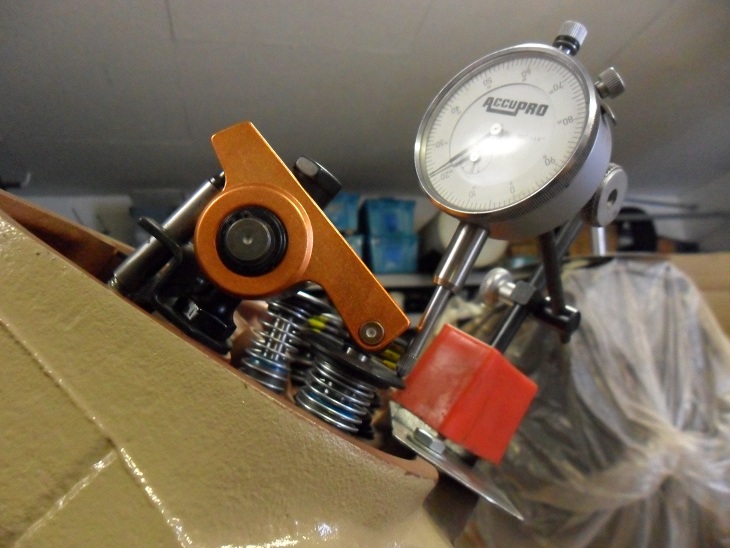

youll need these also

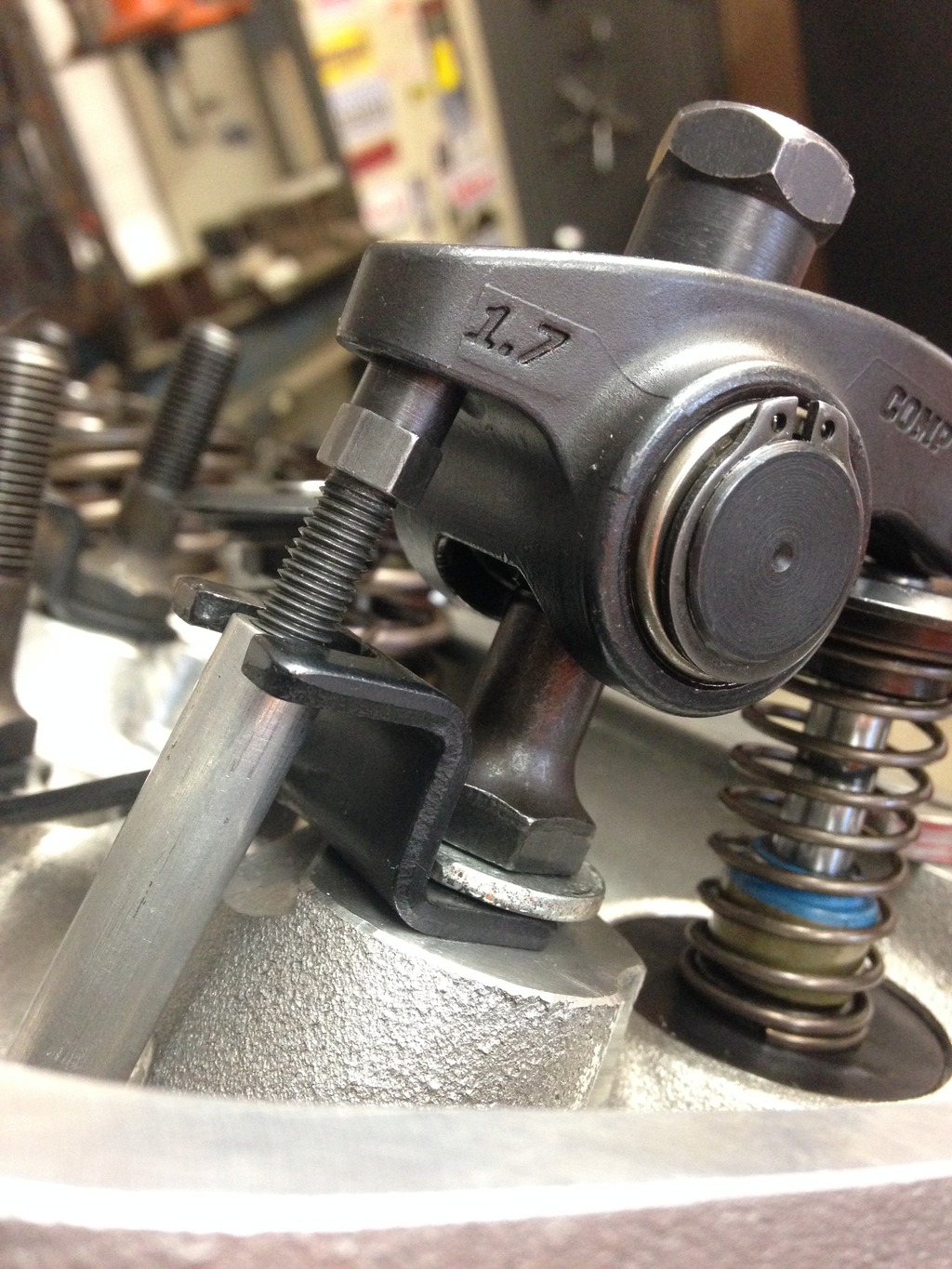

in an ideal valve train geometry set-up the sweep mark on the valve tip will be very narrow and close to the valve center-line , but having the sweep mark narrow is more important than keeping it centered on the valve stem tip, the valve train does not like lateral or side ways loads on the valves and the wider sweep is an indicator of that issue, while a correctly set up valve train may have components that result in the valve tip sweep mark being slightly off the valve center-line this is not a major concern.

Its checking and verifying the valve train clearances and basic geometry that should be your major concern

the clearances and rocker geometry (push rod length,spring bind rocker to rocker stud clearance, etc.) must be checked carefully prior to starting the engine

http://www.summitracing.com/parts/pro-66830/overview/

https://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html

https://www.harborfreight.com/catalogsearch/result/index/?dir=asc&order=EAScore,f,EAFeatured+Weight,f,Sale+Rank,f&q=indicator+stand

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

"THAT PLASTIC THING" is a PUSH ROD LENGTH CHECKER, THE PUSH ROD LENGTH CHECKING, AND ROCKER GEOMETRY TOOL, ARE ENGINE SPECIFIC, so you MUST USE ONE DESIGNED FOR THE SAME STUD DIAM. SPECIFICALLY FOR YOUR SPECIFIC ENGINE, to find the correct rocker geometry and push rod length. If you for example use one designed for 7/16" studs on a SBC and used it on a BBC with 7/16" rocker studs the result would not be close to correct, if the tool designed for one engine is used on the wrong engine, so be damn sure you use the correct tool.

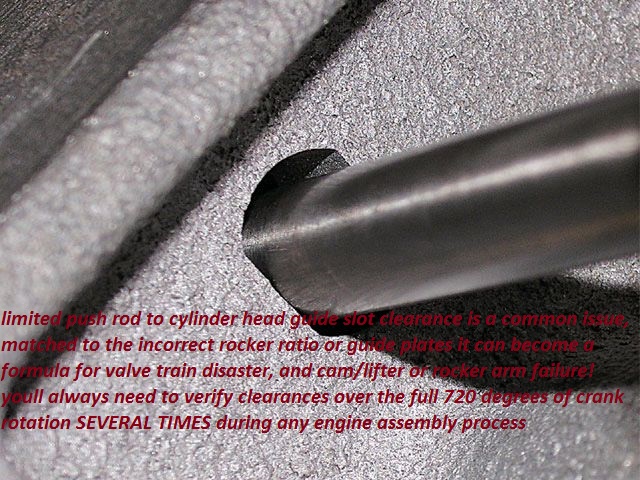

valve train components RARELY just break for no reason

Fact

it takes hundreds of pounds of force to bend push-rods

Fact

IMPROPER CLEARANCES can destroy a valve train or cam in under 30 seconds

Fact

the most common REASON is INCORRECT CLEARANCE OR ROCKER GEOMETRY, or failure to adjust valves properly

FACT

reading links and sub-links helps you isolate the cause, of a failure,... carefully reading through will allow you to avoid having the problem

Fact

In most cases its operator error , or failure to correctly set-up and clearance the valve train that causes problems

Fact

20 minutes -to a couple hours well spent asking questions, and being damn sure you understand the answers, can save you weeks of repairs and machine shop bills

Fact

NO ONE does this the first few times without making SOME mistakes

Fact

having an experienced mentor help guide you through the process tends to reduce the chances of failure

Fact

joining several local corvette or muscle car clubs and helping the older more experienced members work on their cars, and letting them help you on yours, speeds the learning curve

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-52017

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

http://garage.grumpysperformance.co...caused-hydraulic-lifters-to-come-apart.10482/

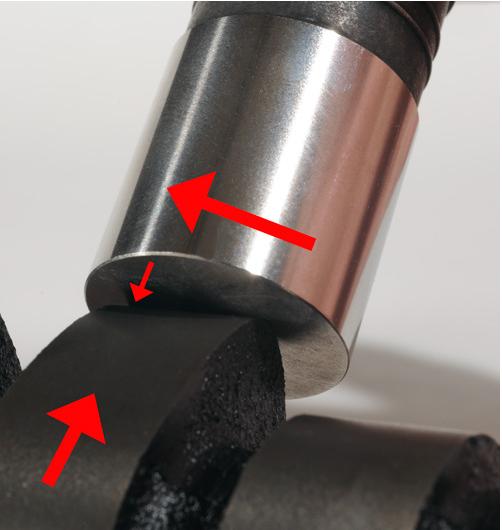

any time you have used push rods you can do a quick visual inspection, by rolling them on a glass mirror with a bit of oil on the push rod surface

if you see skips in the center or ends in the oil pattern, on the mirror surface they are seriously bent , rolling them as a group of 8 at a time won,t allow the oil smear test but frequently will visually identify and bent push rod

if you have the correct tool with a dial indicator you can obviously measure precisely

see anything over about .005" run-out measuring with a dial indicator and v blocks and I would suggest replacement if the engines got higher than about 350 ft lbs of valve spring load rates, see over about .020 on any stock engines push rods and they go in the trash, keep in mind this is very important on flat tappet engines because the lifters are designed to spin with little resistance as the cam lobe passes under the lifter base, a bent push rod slows or retards the lifter spin increasing wear rates significantly.

flat tappet lifters are designed to spin as they pass over the rotating cam lobe to reduce friction, they are not centered over a slightly beveled cam lobe center line

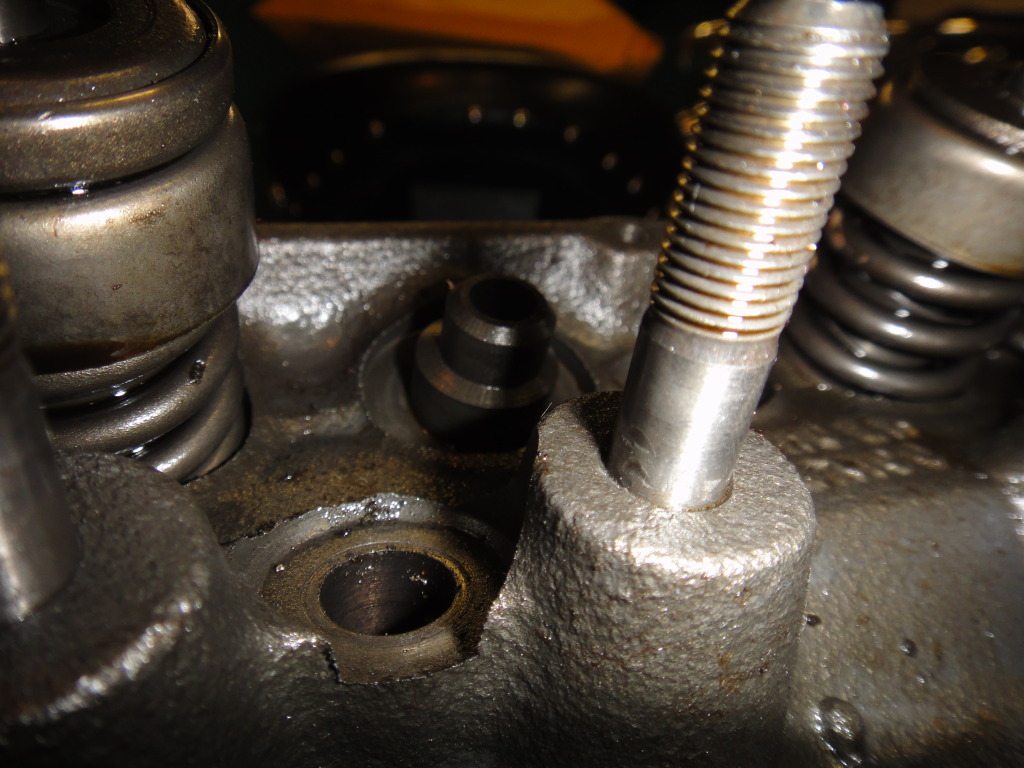

you need EITHER PUSH ROD GUIDE PLATES

BELOW NOTICE SCREW IN ROCKER STUDS

OR SELF ALIGNING ROCKERS (BELOW)

USED WITH PRESS IN ROCKER STUDS

used with press in rocker studs

yes they DO MAKE ROLLER ROCKERS IN BOTH STANDARD AND SELF ALIGNING VERSIONS

any time you find the valve train producing a noise its generally a clearance issue or a worn part,

to help locate the source of the noise, take off the valve cover and, have a buddy start the engine,

press down on the rockers individually at idle with the palm of your hand,

,if the lifter, rocker or other valvetrain component is worn or mal-adjusted,

the sound on each valve assembly will change as pressures applied to the rocker with the heel of your hand on the rocker testing individually at idle,

obviously done before oil temps rise too far and

visually check for cracked valve springs,

bent or loose rocker studs and

rocker slots that contact the rocker stud

and

missing valve lock keys in the valve spring retainer

Id also suggest you swap rockers if you find one causing the noise,

burn or worn rocker balls in the rocker can cause this,

and that helps you isolate the defective component

https://www.chevydiy.com/small-block-chevy-rocker-arms-studs-pushrods-lifters-guide/

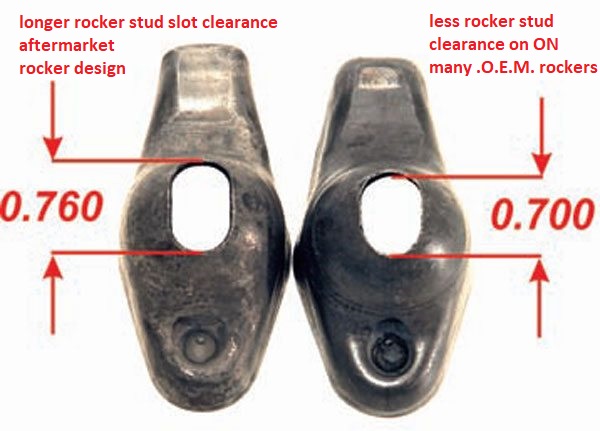

Stamped rockers use a slot cut in the base of the rocker that allows the rocker to move relative to the stud. With higher lift cams,

make sure there is a minimum of 0.050 inches clearance between the end of the rocker slot and the rocker stud at max lift.

a burn rocker ball can result from lack of volume of pushrod oil flow,

this tends to temporarily result in galling and a rough surface,

rocker balls with grooves tend to allow more oil flow to the rocker ball bearing surfaces thus a marginally lower failure rate due to galling

check all valve train geometry and clearance on any engine you assemble or modify the valve train on.

In the mid 1980s, all production small blocks began using “guided” rocker arms that use two small guides that straddle the valve tip to locate the rocker arm tip. Guided or “rail” rockers should not be used with guideplates since this could create a binding situation that would break parts.

its not unusual to find mixed sets on older engines

let us know what you find

if your heads have push rod guide plates you are not supposed to use self aligning rockers as yes they will frequently bind the push rods up and keep them from spinning, if you have guide plates you want the NON-self aligning rockers

as I've pointed out dozens of times a day spent reading links will save you a week of work and a wheelbarrow full of wasted cash.

http://garage.grumpysperformance.co...s-in-vs-threaded-rocker-studs.2746/#post-7475

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...-in-vs-threaded-rocker-studs.2746/#post-43539

http://garage.grumpysperformance.com/index.php?threads/push-rods-rub.13031/#post-67779

http://garage.grumpysperformance.co...-rockers-and-the-pushrods-rub.198/#post-56571

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...-pushrods-and-check-info-you-might-need.5931/

http://garage.grumpysperformance.com/index.php?threads/stock-gm-push-rod-length.3844/

http://garage.grumpysperformance.co...ve-spring-iinstalled-height.12790/#post-66037

http://garage.grumpysperformance.com/index.php?threads/more-bent-push-rods.12401/#post-61890

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/#post-54088

long slot rockers are far less likely to bind on rocker studs

TAKE THE TIME TO CLEAN THE INTERIOR PASSAGES

while your inspecting push-rods soak them in solvent and blow out the inside oil passage with high pressure air as you don,t need clogged push rods reducing oil flow rates or crud in lifters[/color]

the slight bevel on the cam lobe and the slight convex surface on the lifter base in combination with the lobe center-line being slightly offset from the blocks lifter bore results in the lifter rotating in its bores as the lobe rotates under the lifter base

http://www.summitracing.com/parts/PRO-66979/?rtype=10

both offset retainers and offset valve locks exist that will each allow .050 added height,or clearance, but be aware added space reduces the valve spring pressure , yes its very common for a cam with increased lift to require both the valve guide and spring seats to be machined and new valve seals and valve springs and retainers to be installed

http://garage.grumpysperformance.co...ng-height-load-on-a-l98-383.14592/#post-77688

http://garage.grumpysperformance.co...tched-valve-spring-required.13774/#post-77425

http://garage.grumpysperformance.com/index.php?threads/what-springs.11352/#post-51835

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46658

http://garage.grumpysperformance.com/index.php?threads/valve-guide-cutting.8382/#post-29239

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...d-high-spring-pressures-don-t-work-well.1489/

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-79273

related useful info

http://www.trickflow.com/egnsearch.asp? ... toview=sku

http://www.mantonpushrods.com/Images/Manton_Catalog.pdf

http://www.manleyperformance.com/dl/2012/pushrods.pdf

http://www.compcams.com/Products/CC-%27 ... %27-0.aspx

http://www.cvproducts.com/Products/Engi ... sh%20Rods/

http://www.cpgnation.com/forum/pushrod- ... -3084.html

viewtopic.php?f=52&t=181&hilit=measuring+pushrods

viewtopic.php?f=52&t=1489

viewtopic.php?f=52&t=3802

viewtopic.php?f=52&t=90

Last edited by a moderator: