spark plug info..SO!...read thru the links theres a ton of good info,

but its spread over all the links, if you can get that skill mastered your well ahead of most guys who fail to take the time and effort to learn that skill

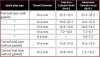

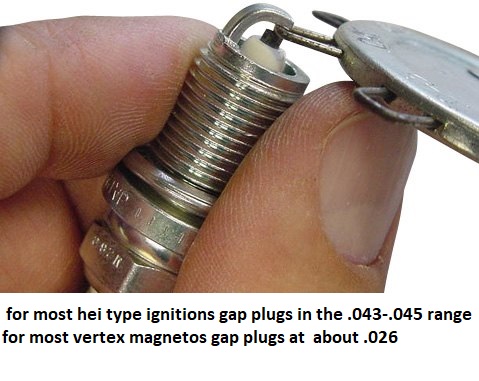

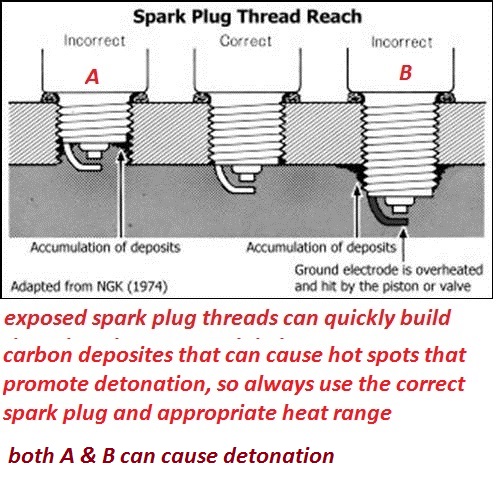

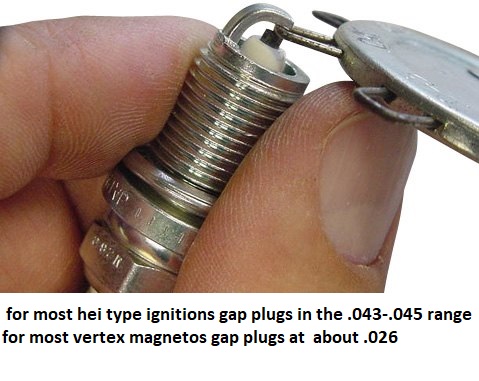

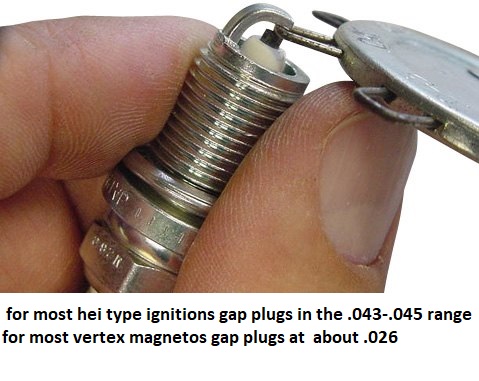

guys frequently ask me what plug gap to use, Provided your ignition functions correctly and your using the correct heat range plugs and a reasonably close fuel/air ratio and timing advance, Ive never seen any improvements in gaps tighter or wider than .045.

Ive never seen any advantage to gaps over .045 and Ive seen plug gaps as wide as .060 or under .035 cause misfires with some ignitions in a FEW applications so after years of testing and racing I generally set plug gaps at .045, if your having issues with misses at .045 its not the plug gap thats the cause,its some other problem with your ignition or fuel/air ratio or ignition timing advance,high resistance ignition wire, moisture,a bad coil,loose connections, firing order or arcing ignition etc..

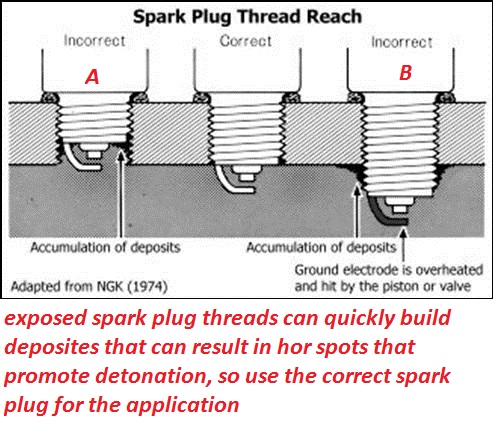

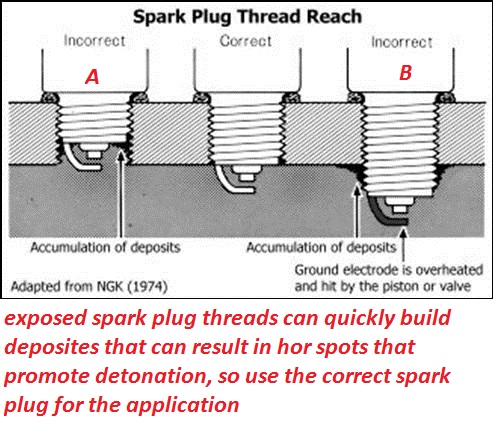

always use a bit of anti-seize paste on spark plugs, threads, being used in aluminum cylinder heads even if not required and its best to remove & install them when the engines not very hot, be very careful to start threading them into the heads by hand, and don,t over tighten them as its all too easy to strip soft aluminum plug threads in aluminum cylinder heads, if you have access to a 3/8" drive inch/la torque wrench 12-13 ft lbs is about correct torque

always use a bit of anti-seize paste on spark plugs, threads, being used in aluminum cylinder heads even if not required and its best to remove & install them when the engines not very hot, be very careful to start threading them into the heads by hand, and don,t over tighten them as its all too easy to strip soft aluminum plug threads in aluminum cylinder heads, if you have access to a 3/8" drive inch/la torque wrench 12-13 ft lbs is about correct torque

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

BTW some of the older guys will remember that the SBC used to have 13/16" spark plugs and they were changed to the smaller 5/8" style in the early 1970s, and if your wondering why they changed it was because they found that smaller diam. plug threads allowed slightly larger coolant passages and allowed moving the plug location slightly closer to the exhaust valve and also allowed a slightly changed angle all of which allowed lower emissions, better control on combustion and less chance of stripped or cross threading plugs.

post very clear pictures of your spark plugs, label the cylinder # they came from, and measure the fuel pressure you can tell a good deal if you know those factors and how to read plugs.

most engine misses are related to either fuel/air ratio changes or ignition, so the first step is isolate the problem, or the cause, it could be the timing, advance curve, fuel pressure , a vacuum leak,or a defective ignition etc, you need to do a few tests

they make adapter crush gaskets

The following examples detail the typical temperatures of various combustion-related engine parts during normal operation:

"The most commonly known flammable liquid is gasoline.

It has a flash point of about −50° F (−65° C). The ignition temperature is about 495° F (232(232° C) [sic], a comparatively low figure."

The temperature of the burning gases inside the combustion chamber is typically around 2,800° F. In a diesel engine, this temperature remains fairly steady. In a gasoline-powered engine, the temperature can climb to 4,500° F or more under certain circumstances. However, the vehicle's engine cooling system keeps the walls of the combustion chamber at a temperature of between 265° F and 475° F.

www.denso.com

www.denso.com

www.quora.com

www.quora.com

vehq.com

vehq.com

www.denso.com

www.denso.com

https://www.jegs.com/i/Moroso/710/71900/10002/-1

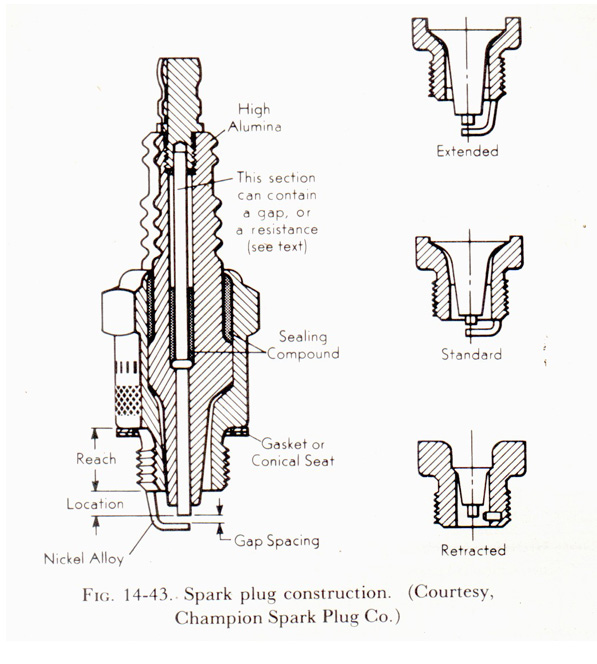

there are both 13/16" and 5/8" spark plug sockets, used on most chevy engines,

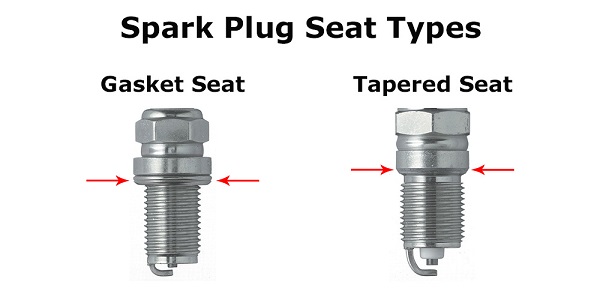

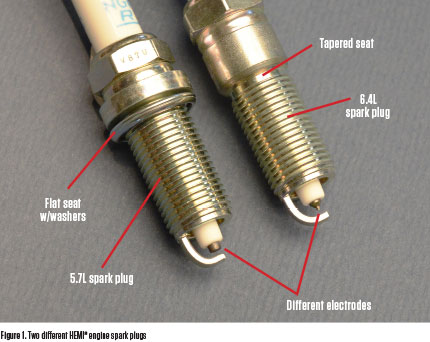

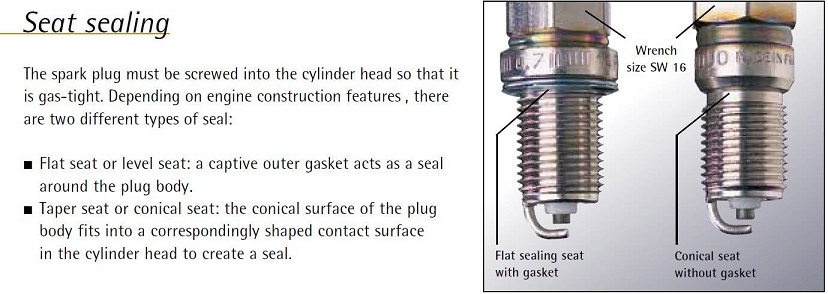

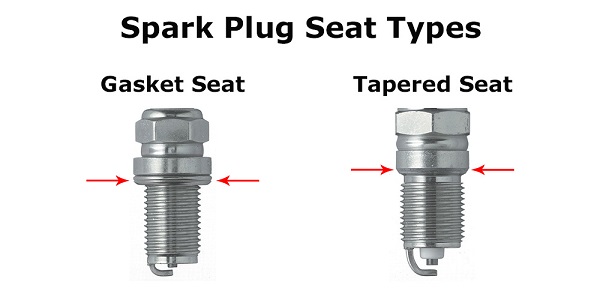

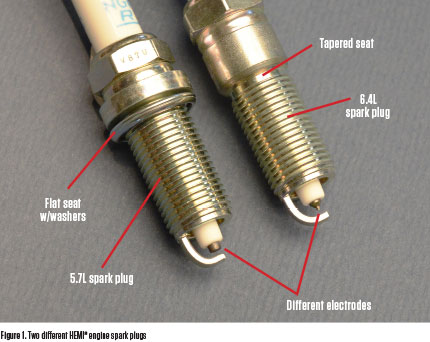

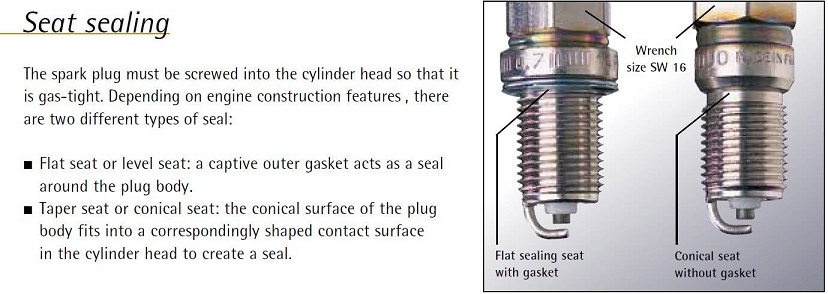

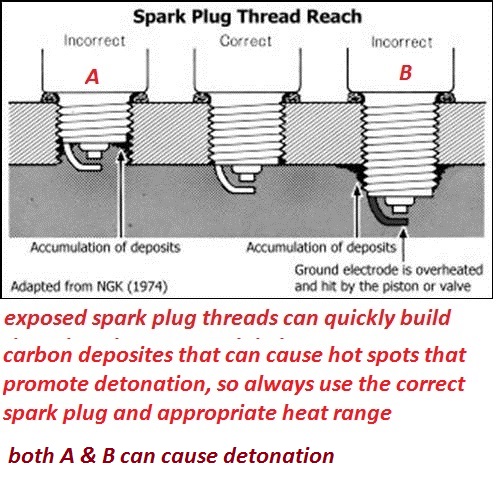

and both tapered and flat seats that use a crush washer seal design

www.harborfreight.com

www.harborfreight.com

www.summitracing.com

www.summitracing.com

THE >>> TS <<< STANDS FOR "TAPERED SEAT" PLUGS.

NO STEEL GASKET

http://www.harborfreight.com/3x-magnify ... 94367.html

having a spark plug holder with numbered holes and a good inspection tool helps

testing ignition coil

http://www.aa1car.com/library/ignition_coils.htm

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

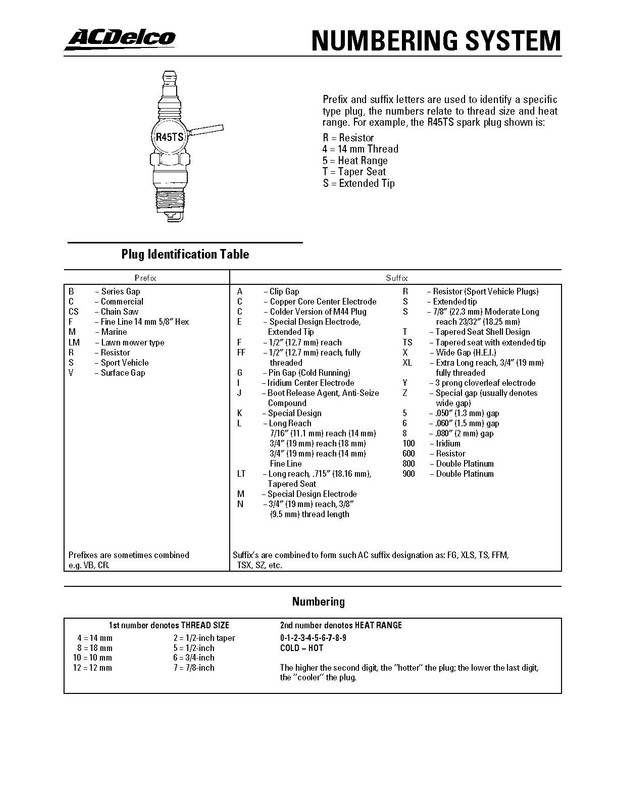

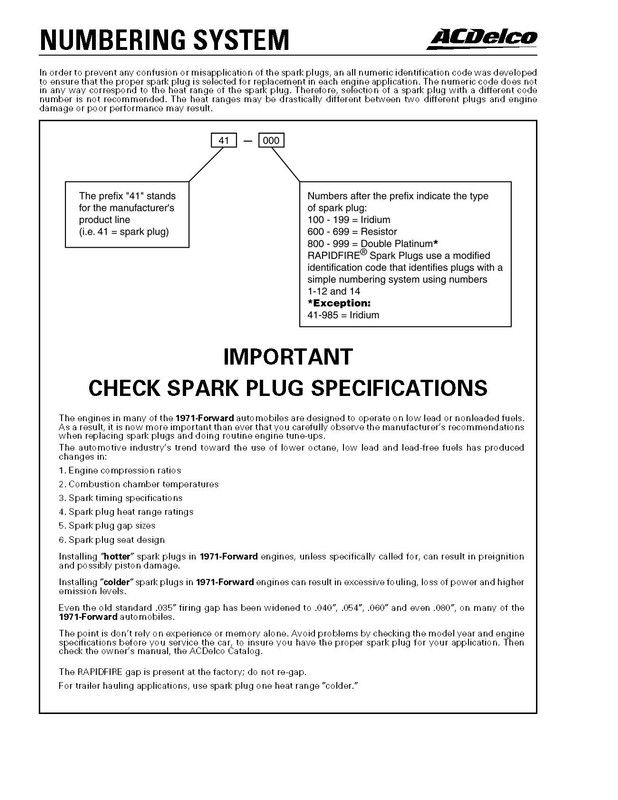

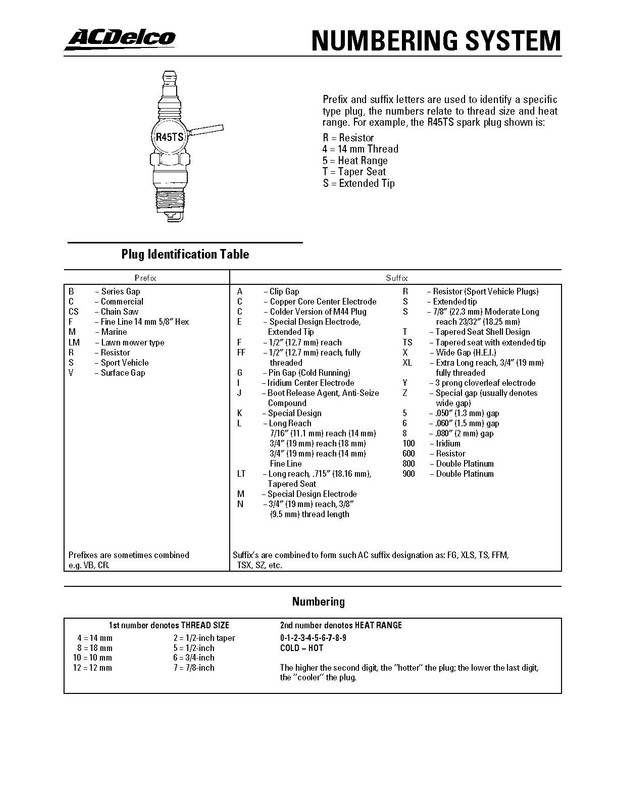

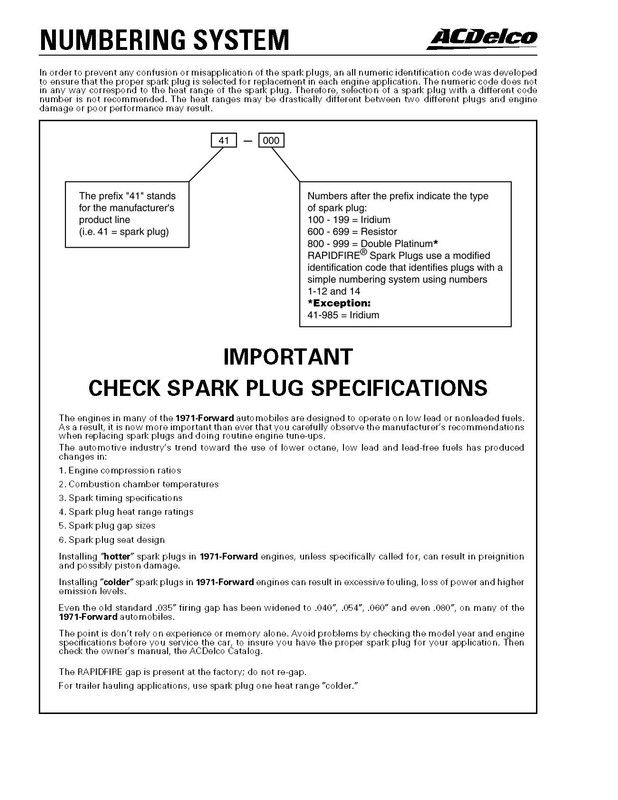

The images below are pages out of the ACDelco plug catalog and shows the old and new numbering system. The new system doesn't have as detailed "intelligence" built into it like the old system.

WATCH THE VIDEO

Recommended Spark Plugs for Vortec Heads

http://garage.grumpysperformance.com/index.php?threads/spark-plug-info.202/

http://garage.grumpysperformance.co...that-some-guys-don-t-look-at-the-clues.11176/

http://garage.grumpysperformance.com/index.php?threads/changing-long-over-due-spark-plugs.10404/

http://garage.grumpysperformance.com/index.php?threads/why-use-anti-seize-paste.9424/

http://garage.grumpysperformance.co...ition-wires-getting-the-header-clearance.840/

http://www.summitracing.com/parts/PIT-229/

Ive found its a whole lot faster to use a quality IR temp gun, to locate a individual cylinder that's mis-firing as it tends to run significantly cooler than adjacent cylinders, or hotter if its a vacuum leak at times, as lean F/A mixes tend to run hotter

(Ive used this one for years)

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

many temp guns don,t read high enough or accurately enough

http://www.professionalequipment.com/ex ... ermometer/

that you can use on the engine to check ALL 8 exhaust temps, individually, this quickly locates plugged injectors or vacuum leaks ETC

Wide temperature range from -58 to 1832°F

when selecting an IR gun for automotive use, you really want to be able to read from 0 F deg-about 1400F deg. to cover most conditions you'll test for

READ THRU LINKS AND SUB LINKS

http://www.4secondsflat.com/Spark_plug_reading.html

viewtopic.php?f=70&t=3949&p=25481#p25481

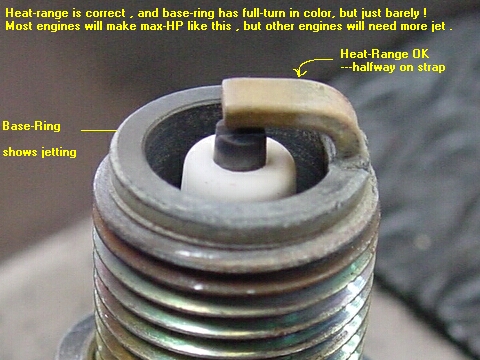

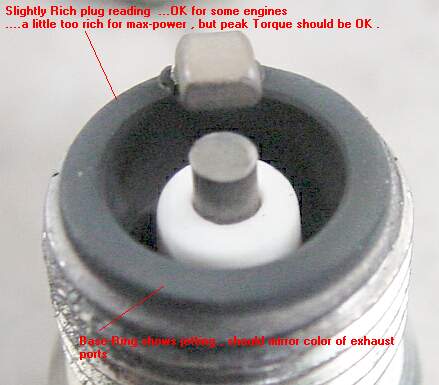

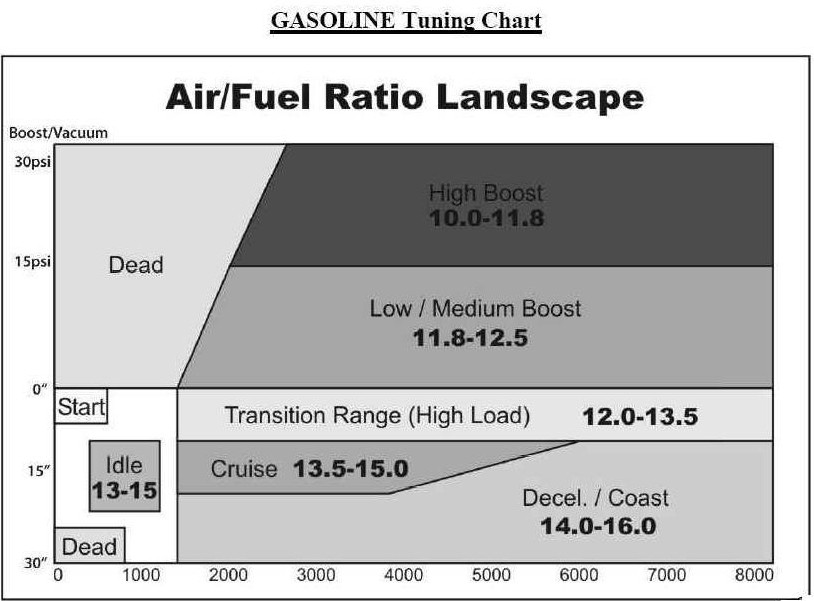

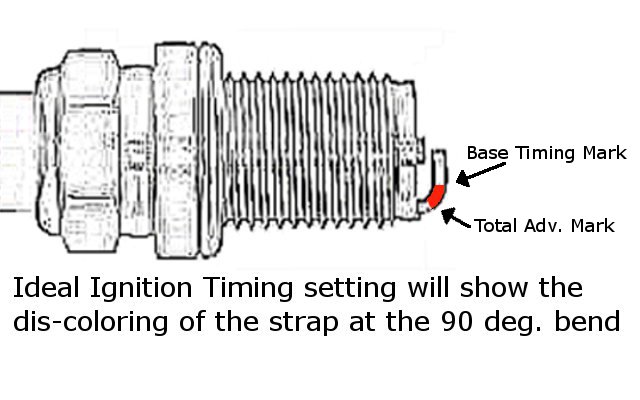

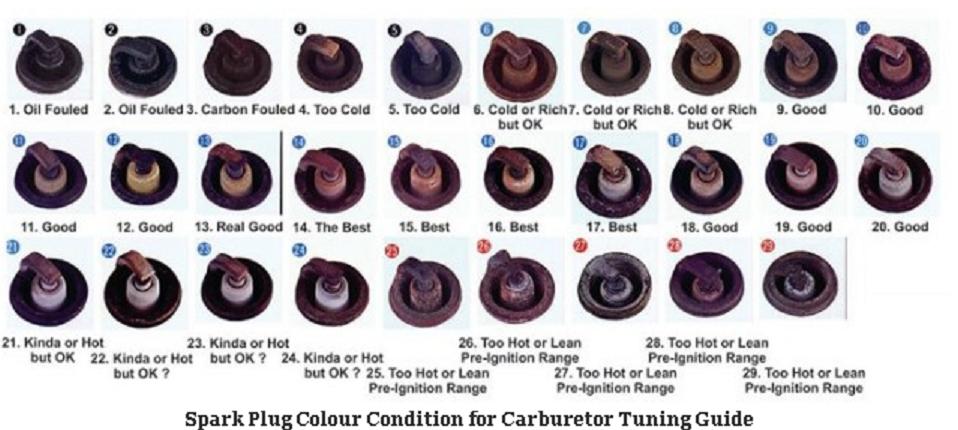

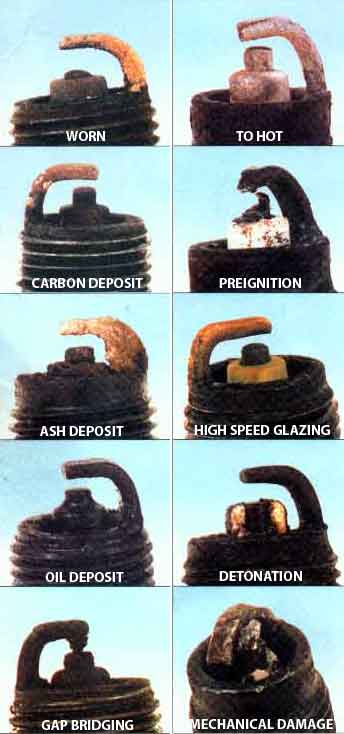

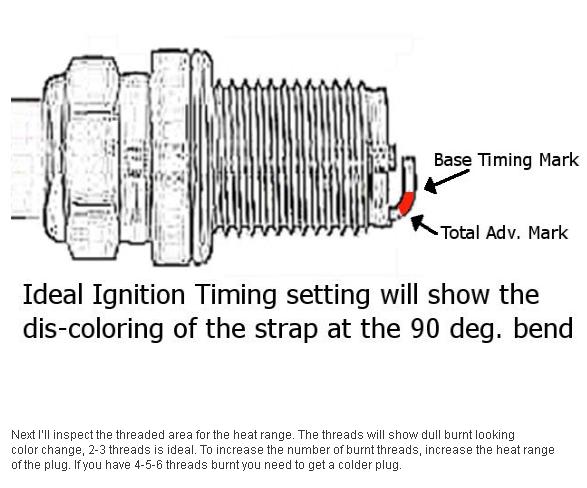

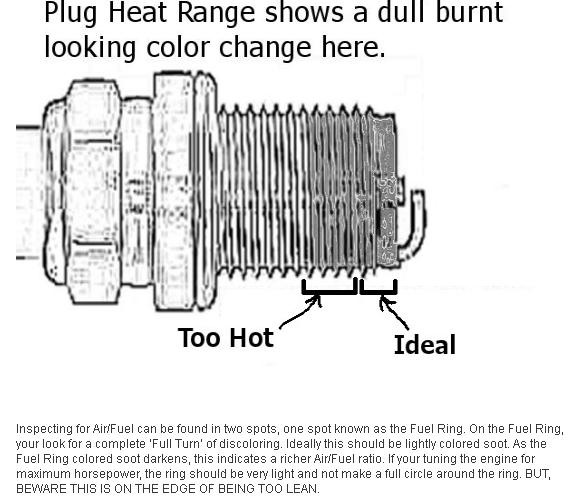

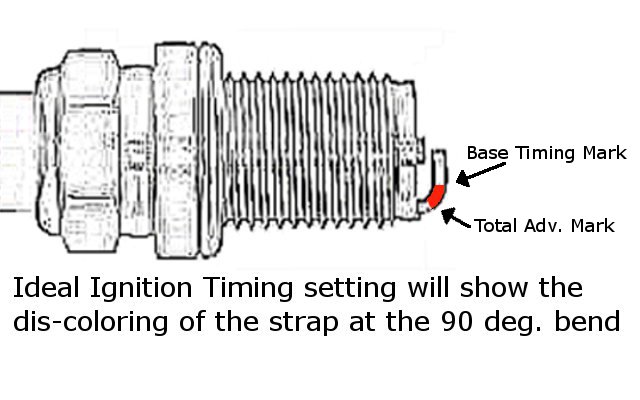

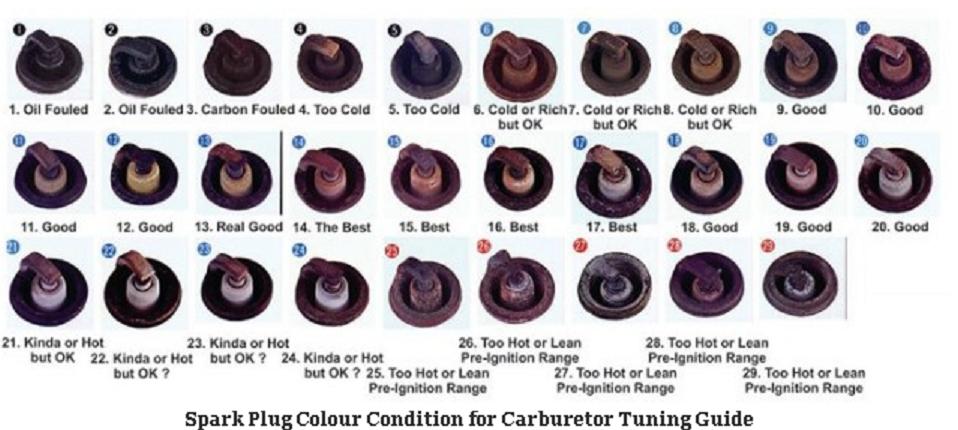

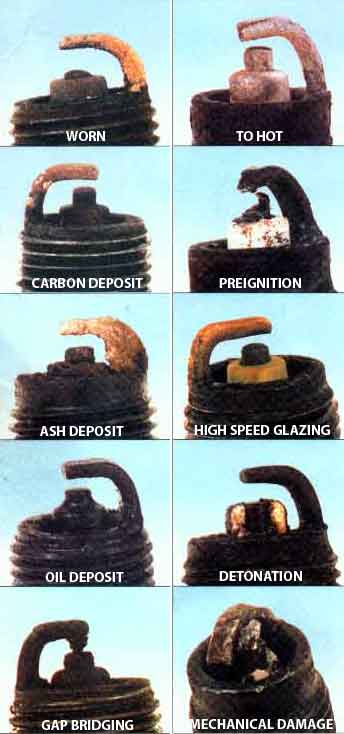

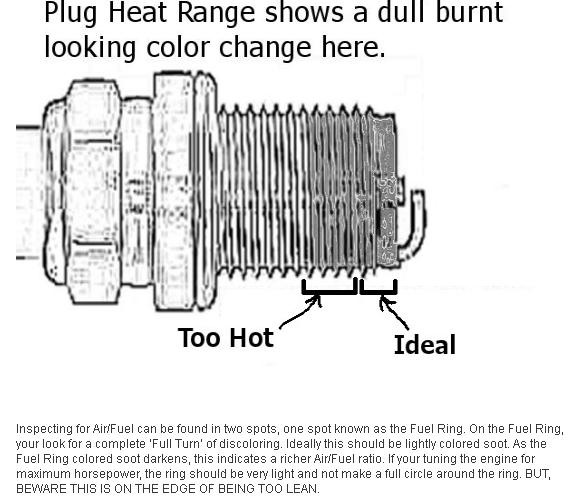

learning to correctly read plugs is a KEY FACTOR in learning how to tune and diagnose engine conditions, ignition temperatures,fuel/air ratios and detect detonation

example

Here is a link to AC Delco for information on the codes.

On the R45TSX for example:

R=resistor spark plug

45=heat range

T=tapered plug

S=extended tip

X=wide gap

http://www.acdelco.com/parts/sparkplugs ... cation.jsp

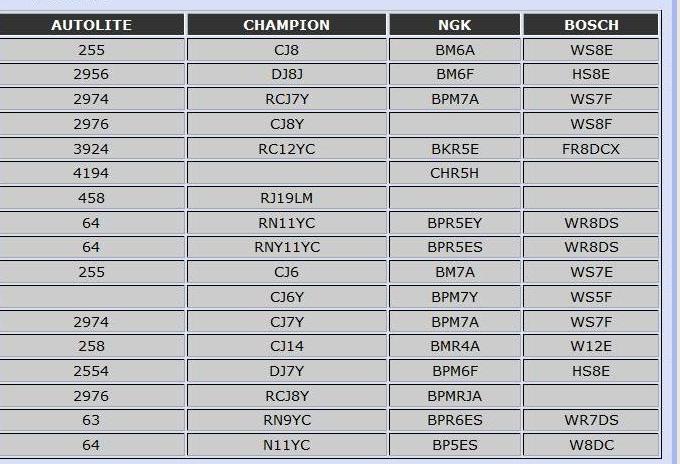

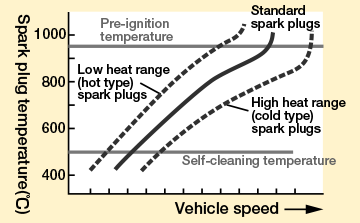

some reference chart info

http://www.sparkplug-crossreference.com ... ence8.html

http://www.spark-plugs.co.uk/pages/tech ... htm#ISOJIS

http://www.summitracing.com/parts/msd-3508

http://www.pcmforless.com/index.php?opt ... &Itemid=56

http://www.mirage-performance.com/tech/sparkplugs.html

http://go.mrgasket.com/pdf/sparkplugs/U ... erence.pdf

http://www.autorepairinstructions.com/?cat=7

http://www.kennedysdynotune.com/Spark Plug Tech.htm

IF your trying to tune an engine or track down a problem,When you inspect plugs ,pull all 8 plugs , drill some (8) 1/2 holes in 2 parallel lines in a 12"" section of 2"X6" wood and label the holes, to indicate the cylinders

2-4-6-8

1-3-5-7

so you can stick the porcelain ends , of each plug ,the wires snap onto, into the holes so you can photograph and inspect the tips and electrodes in clear detail as they can tell you a great deal about the engines running conditions

viewtopic.php?f=50&t=892&hilit=+socket

I frequently get asked what brand of plugs I use or suggest,

Ive had good luck with

AC DELCO

NGK

BOSCH PLATINUM plugs

most gapped at .043-.045

these are companys making a decent plug, your engine might run better with something else but Ive had good results with these brands

all work well in most LT1 and L98 chevy SB engines

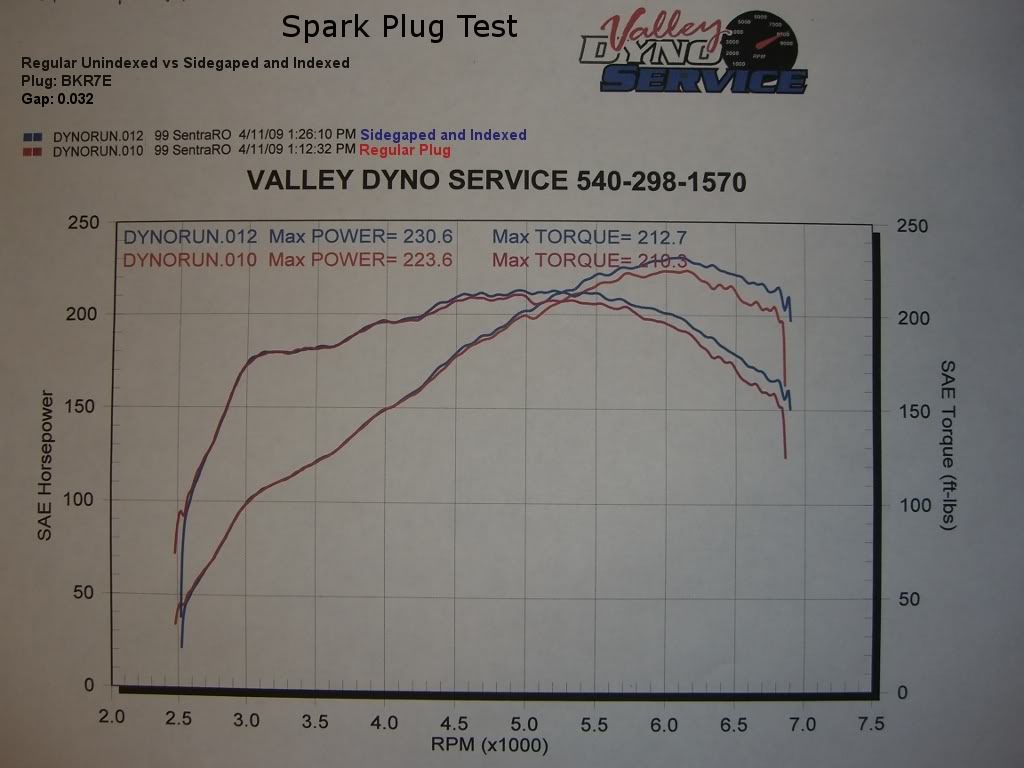

just stick to the single electrode ground designs as in most cases Ive found the multi ground plugs cost more and don,t provide ANY improvement, and before you go linking in tests showing plug brand XYZ makes 5- 7 extra hp you should realize any decent experienced dyno operator can rig the results that much, either way at will, and if company xyz pays you several hundred dollars to show their plugs provide a small margin of extra power you can bet your butt the dyno operator will find it!

and when the next company ABC stops by for a TEST, you can bet they also show a small advantage

reading plugs can tell you a great deal, but if you don,t read thru and understand the linked info youll be at a big disadvantage heres a very useful chart, depicting plug conditions to look for indicating combustion chamber temp and air/fuel ratio indicators

http://www.4secondsflat.com/plug_chart.html

http://www.4secondsflat.com/Spark_plug_reading.html

http://www.dragstuff.com/techarticles/r ... plugs.html

http://www.custom-car.us/ignition/spark ... range.aspx

http://ngksparkplugs.com/tech_support/s ... p?mode=nml

http://www.autorepairinstructions.com/?cat=7

viewtopic.php?f=70&t=5428

http://www.power-21.com/AutolitePower21 ... preads.pdf

http://kb-silvolite.com/article.php?action=read&A_id=63

http://www.autohausaz.com/html/spark-pl ... wires.html

http://en.wikipedia.org/wiki/Spark_plug

http://www.ngksparkplugs.com/techinfo/s ... lation.asp

http://www.verrill.com/moto/sellingguid ... rchart.htm

http://www.strappe.com/plugs.html

http://www.wallaceracing.com/plug-reading-lm.html

cross reference

http://www.angelfire.com/extreme4/skido ... ERENCE.htm

viewtopic.php?f=50&t=1853&p=4848#p4848

QUOTE

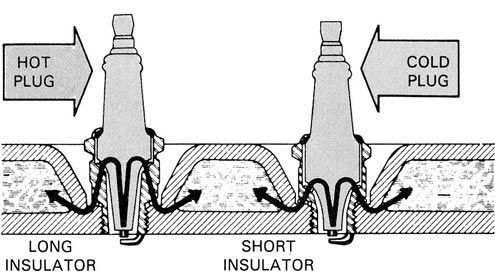

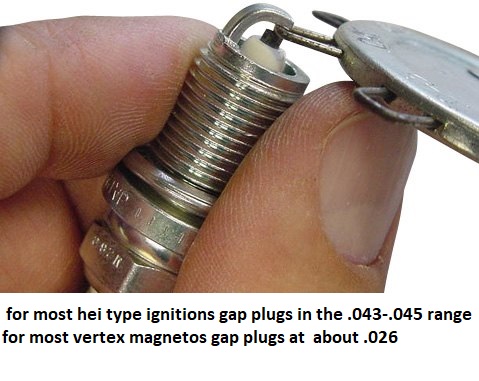

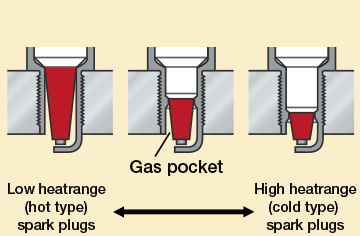

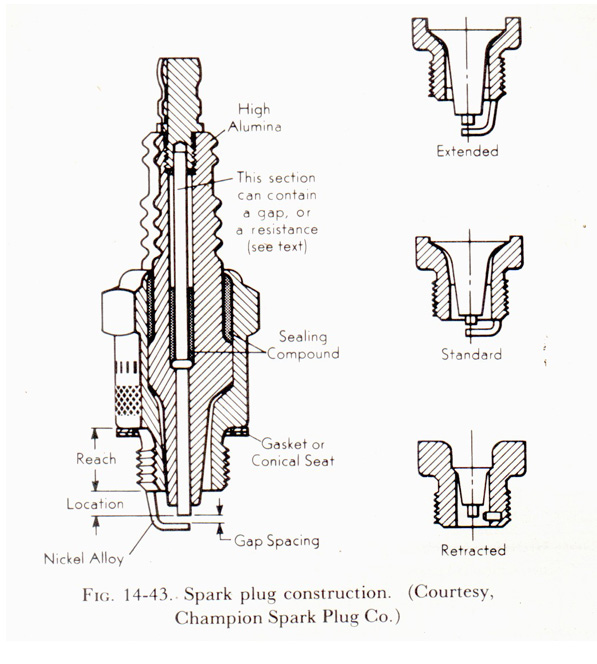

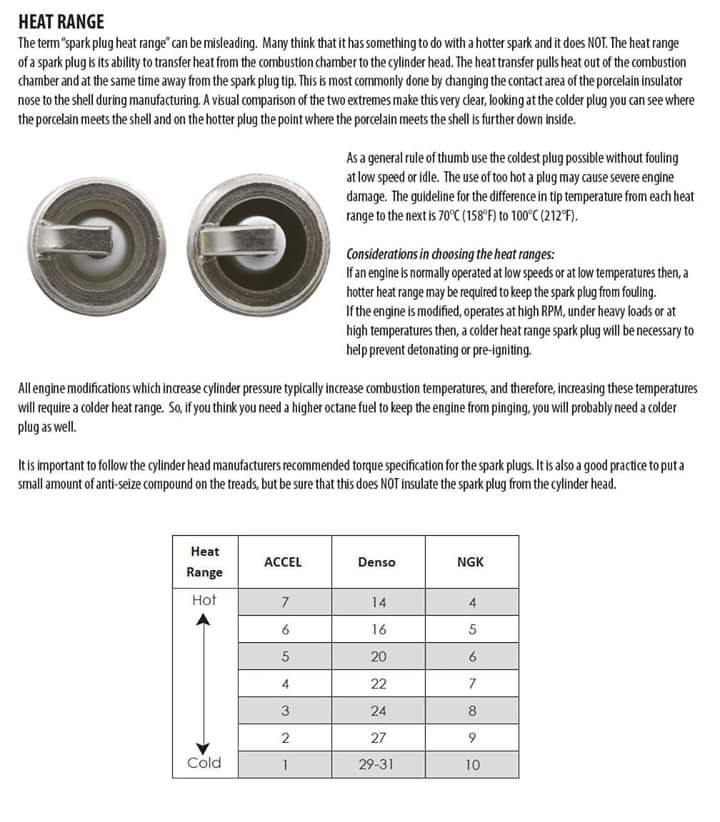

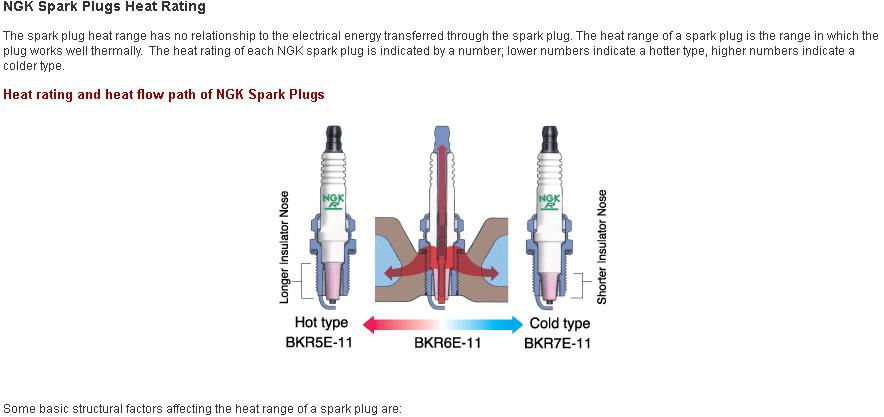

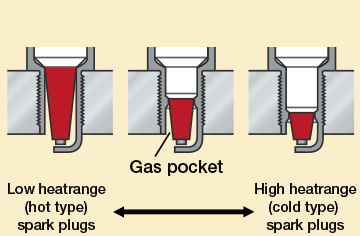

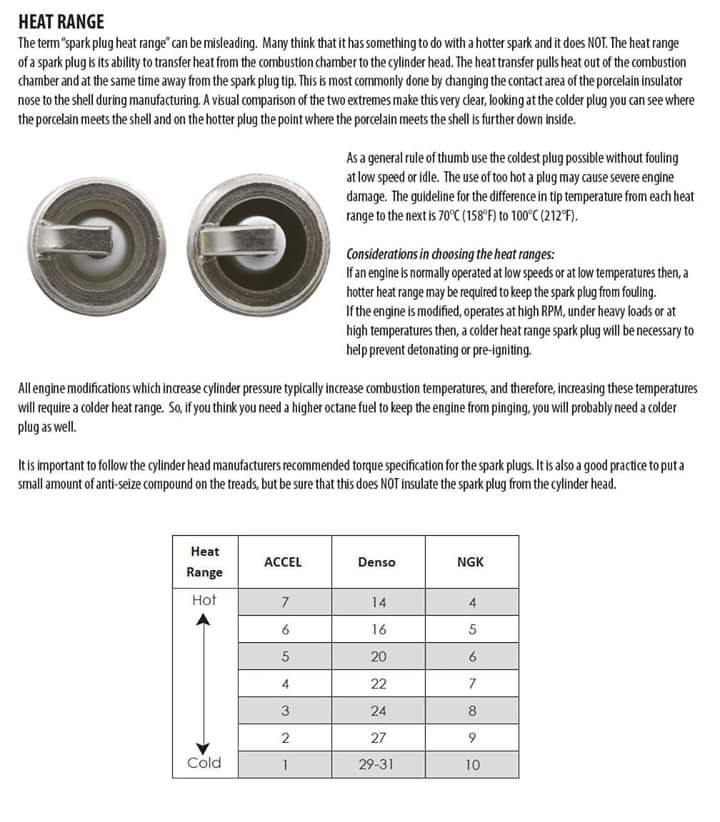

"Heat range

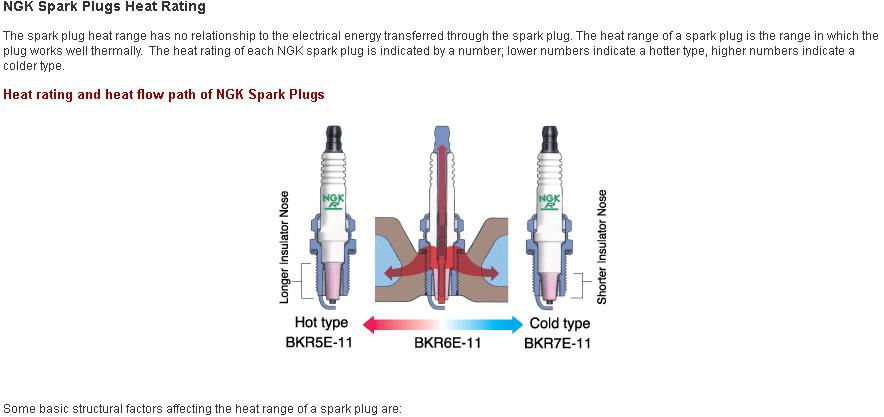

The operating temperature of a spark plug is the actual physical temperature at the tip of the spark plug within the running engine. This is determined by a number of factors, but primarily the actual temperature within the combustion chamber. There is no direct relationship between the actual operating temperature of the spark plug and spark voltage. However, the level of torque currently being produced by the engine will strongly influence spark plug operating temperature because the maximum temperature and pressure occurs when the engine is operating near peak torque output (torque and RPM directly determine the power output). The temperature of the insulator responds to the thermal conditions it is exposed to in the combustion chamber but not vice versa. If the tip of the spark plug is too hot it can cause pre-ignition leading to detonation/knocking and damage may occur. If it is too cold, electrically conductive deposits may form on the insulator causing a loss of spark energy or the actual shorting-out of the spark current.

A spark plug is said to be "hot" if it is a better heat insulator, keeping more heat in the tip of the spark plug. A spark plug is said to be "cold" if it can conduct more heat out of the spark plug tip and lower the tip's temperature. Whether a spark plug is "hot" or "cold" is known as the heat range of the spark plug. The heat range of a spark plug is typically specified as a number, with some manufacturers using ascending numbers for hotter plugs and others doing the opposite, using ascending numbers for colder plugs.

The heat range of a spark plug (i.e. in scientific terms its thermal conductivity characteristics) is affected by the construction of the spark plug: the types of materials used, the length of insulator and the surface area of the plug exposed within the combustion chamber. For normal use, the selection of a spark plug heat range is a balance between keeping the tip hot enough at idle to prevent fouling and cold enough at maximum power to prevent pre-ignition leading to engine knocking. By examining "hotter" and "cooler" spark plugs of the same manufacturer side by side, the principle involved can be very clearly seen; the cooler plugs have more substantial ceramic insulators filling the gap between the center electrode and the shell, effectively carrying off the heat, while the hotter plugs have less ceramic material, so that the tip is more isolated from the body of the plug and retains heat better.

Heat from the combustion chamber escapes through the exhaust gases, the side walls of the cylinder and the spark plug itself. The heat range of a spark plug has only a minute effect on combustion chamber and overall engine temperature. A cold plug will not materially cool down an engine's running temperature. (Too hot of a plug may, however, indirectly lead to a runaway pre-ignition condition that can increase engine temperature.) Rather, the main effect of a "hot" or "cold" plug is to affect the temperature of the tip of the spark plug.

It was common before the modern era of computerized fuel injection to specify at least a couple of different heat ranges for plugs for an automobile engine; a hotter plug for cars which were mostly driven mildly around the city, and a colder plug for sustained high speed highway use. This practice has, however, largely become obsolete now that cars' fuel/air mixtures and cylinder temperatures are maintained within a narrow range, for purposes of limiting emissions. Racing engines, however, still benefit from picking a proper plug heat range. Very old racing engines will sometimes have two sets of plugs, one just for starting and another to be installed once the engine is warmed up, for actually driving the car."

learn how read the spark plugs their condition will tell you a good deal about cylinder burn conditions, get an IR temp gun,vacuum gauge and timing light they are a great tuning and diagnostic aid,as they can indicate problems like a clogged cat or faulty ignition, etc. don,t solely relie on a single indicator

http://www.strappe.com/plugs.html

http://performanceunlimited.com/illustrations/sparkplugs.html

http://www.dragstuff.com/techarticles/s ... rence.html

http://www.ngksparkplugs.com/techinfo/s ... country=US

the plugs are normally done (the electrodes cut back)with a dremel tool cutting disk

http://www.autorepairinstructions.com/?cat=7

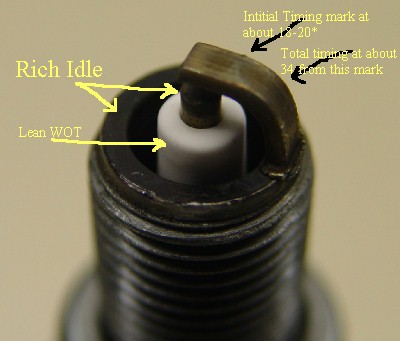

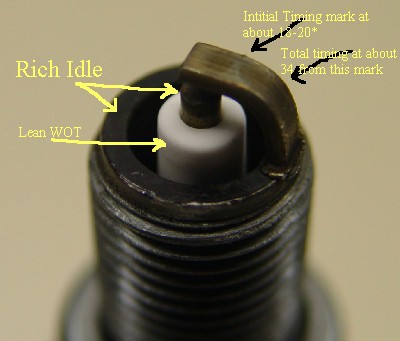

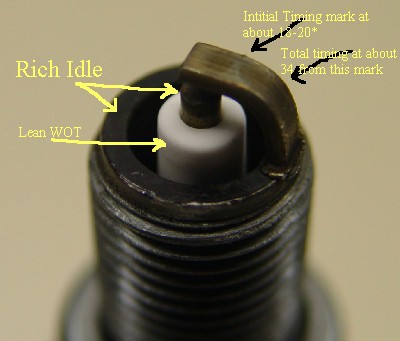

heres a good indication of plugs running a bit rich at idle and real lean in the upper rpm range

keep in mind that different brands of plugs will have different lengths that can be critical with ignition wire to header clearances

http://www.centuryperformance.com/spark ... g-192.html

http://www.carcraft.com/techarticles/sp ... index.html

a few places to look for more info on plugs

http://www.centuryperformance.com/spark ... pg-26.html

http://www.dragstuff.com/techarticles/h ... plugs.html

http://opc.mr2oc.com/online_parts_catal ... _plugs.jpg

http://www.gofastzone.com/techtips/sparkplugs/sparkplugs.htm

http://www.ngksparkplugs.ca/documents/partnumberkey.pdf

http://www.autohausaz.com/html/spark-pl ... wires.html

http://www.acdelco.com/html/pi_plugs_ident.htm

http://www.autolite.com/framer.cgi?page=http://www.autolite.com/products/racing.htm

http://members.uia.net/pkelley2/sparkplugreading.html

http://www.circletrack.com/enginetech/c ... index.html

http://www.atlanticjetsports.com/_techtalk/00000005.htm

http://www.strappe.com/plugs.html

http://www.babcox.com/editorial/cm/cm59910.htm

http://www.4secondsflat.com/Spark_plug_reading.html

http://www.ngksparkplugs.com/techinfo/spark_plugs/partnumberkey.pdf

http://www.nightrider.com/biketech/spkplghnbook.htm

http://www.tsrsoftware.com/sparkplug.htm

viewtopic.php?f=70&t=1809&p=4671#p4671

http://www.gnttype.org/techarea/engine/plugs.html

http://www.dansmc.com/sparkplugs1.htm

http://www.ngksparkplugs.com/techinfo/spark_plugs/overviewp2.asp

http://www.pajjakid.com/ubipa/sparkplugs.htm

http://www.edelbrock.com/automotive/sparkplugs.html

http://www.bullittarchive.com/Maintenance/Sparkplugoverview/

http://www.powerarc.com/sparkplug.htm

http://www.carcraft.com/techarticles/64378/

http://www.wakularacing.com/TechnicalInfo.htm

https://garage.grumpysperformance.com/index.php?threads/reading-plugs.5428/

http://www.geocities.com/MotorCity/Flats/3877/spark.html

BTW IF YOU WANT TO AVOID ETHANOL LACED FUEL

http://pure-gas.org/

but its spread over all the links, if you can get that skill mastered your well ahead of most guys who fail to take the time and effort to learn that skill

guys frequently ask me what plug gap to use, Provided your ignition functions correctly and your using the correct heat range plugs and a reasonably close fuel/air ratio and timing advance, Ive never seen any improvements in gaps tighter or wider than .045.

Ive never seen any advantage to gaps over .045 and Ive seen plug gaps as wide as .060 or under .035 cause misfires with some ignitions in a FEW applications so after years of testing and racing I generally set plug gaps at .045, if your having issues with misses at .045 its not the plug gap thats the cause,its some other problem with your ignition or fuel/air ratio or ignition timing advance,high resistance ignition wire, moisture,a bad coil,loose connections, firing order or arcing ignition etc..

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

BTW some of the older guys will remember that the SBC used to have 13/16" spark plugs and they were changed to the smaller 5/8" style in the early 1970s, and if your wondering why they changed it was because they found that smaller diam. plug threads allowed slightly larger coolant passages and allowed moving the plug location slightly closer to the exhaust valve and also allowed a slightly changed angle all of which allowed lower emissions, better control on combustion and less chance of stripped or cross threading plugs.

post very clear pictures of your spark plugs, label the cylinder # they came from, and measure the fuel pressure you can tell a good deal if you know those factors and how to read plugs.

most engine misses are related to either fuel/air ratio changes or ignition, so the first step is isolate the problem, or the cause, it could be the timing, advance curve, fuel pressure , a vacuum leak,or a defective ignition etc, you need to do a few tests

they make adapter crush gaskets

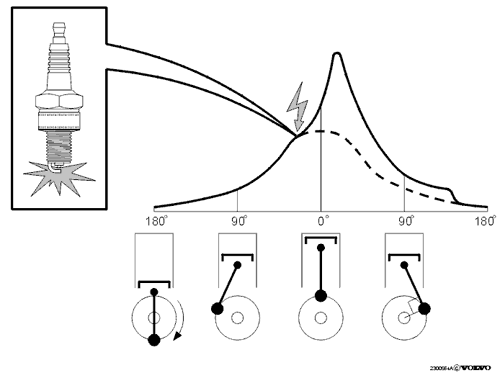

A spark plug only functions completely when its center electrode temperature is between these temperatures of about 500°C and 950°C.The sole purpose of an ignition system is to serve the spark plugs, and to start the combustion process, the electrical current generated by the coil must be strong enough to jump across the gap at the tip of the spark plug. Every engine has a unique specification for its spark plugs’ gap, which is why it’s incredibly important to properly gap a spark plug for optimum performance.

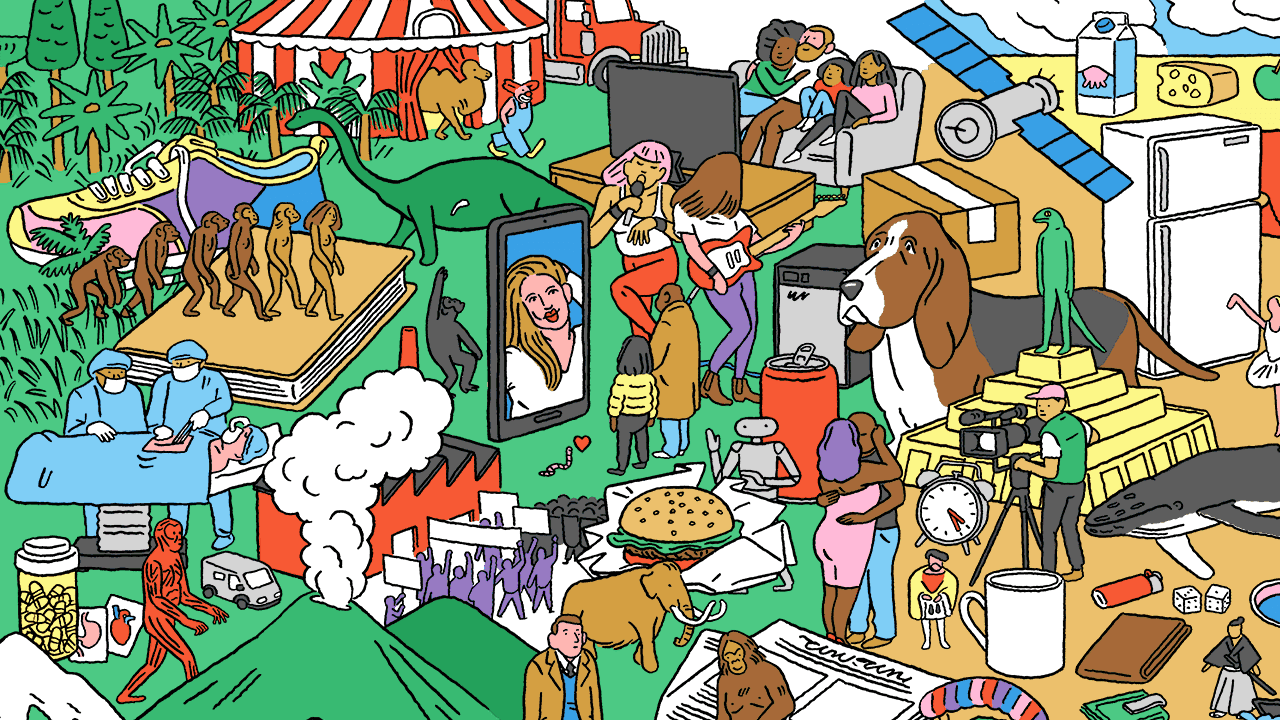

The following examples detail the typical temperatures of various combustion-related engine parts during normal operation:

- Intake valve: 475° F

- Exhaust valve: 1,200° F

- Spark plug: 1,100° F

- Piston face: 575° F

- Cylinder wall: 375° F

"The most commonly known flammable liquid is gasoline.

It has a flash point of about −50° F (−65° C). The ignition temperature is about 495° F (232(232° C) [sic], a comparatively low figure."

The temperature of the burning gases inside the combustion chamber is typically around 2,800° F. In a diesel engine, this temperature remains fairly steady. In a gasoline-powered engine, the temperature can climb to 4,500° F or more under certain circumstances. However, the vehicle's engine cooling system keeps the walls of the combustion chamber at a temperature of between 265° F and 475° F.

Heat Range | Basic Knowledge | SPARK PLUG | Automotive Service Parts and Accessories | DENSO Global Website

An explanation of the relationship between the degree of dispersion of the heat the spark plug is subjected to and vehicle speed.

What is the temperature inside the combustion chamber of an engine?

Answer (1 of 9): As there appears to already be some engineering based answers, I will defer from a scientific answer, and give you my real world aviation experience. Flying my PA-31–325 Navajo, it being equipped with two turbo charged, air cooled six cylinder engines producing 325 horsepower eac...

How Hot Does A Combustion Chamber Get In A Vehicle? [The Answer Might Surprise You!]

Whether you're a weekend DIY mechanic, a diehard gearhead, or just a vehicle owner curious about how your car works, you may want to know more about how the engine burns fuel to create power. Many common questions center on what causes engine overheating. You may be wondering just how hot it...

vehq.com

vehq.com

Heat Range | Basic Knowledge | SPARK PLUG | Automotive Service Parts and Accessories | DENSO Global Website

An explanation of the relationship between the degree of dispersion of the heat the spark plug is subjected to and vehicle speed.

While Autolite engineers pre-gap spark plugs for the most popular applications, a spark plug may be designed for two different engines. These engines may specify distinctive gaps. Before you install new spark plugs, reference your manual and adjust the gap using a spark plug gap tool or gauge.

- If the gap is too wide, the electrical voltage may not be high enough to arc across, which would result in a misfire.

- If the gap is too narrow, the spark may not ignite a lean air/fuel mixture, which would also result in a misfire.

- A spark plug’s voltage requirement is directly proportional to the size of the gap.

You can be sure that the Autolite spark plug recommended for your application has been engineered to meet the requirements of your engine and that the gap can easily be adjusted as required. Visit Autolite.com for more tech tips and to learn about out full line of premium plugs.

- If you need to widen the gap, use the spark plug gap tool to pull back on the ground strap (also called the side electrode).

- If you need to close up the gap, gently tap the ground strap electrode on a hard surface.

- Do not touch the center electrode or the insulator during this procedure, since these can be damaged.

https://www.jegs.com/i/Moroso/710/71900/10002/-1

there are both 13/16" and 5/8" spark plug sockets, used on most chevy engines,

and both tapered and flat seats that use a crush washer seal design

Harbor Freight Tools – Quality Tools at Discount Prices Since 1977

Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you!

Performance Tool W38162 Performance Tool Spark Plug Sockets | Summit Racing

Free Shipping - Performance Tool Spark Plug Sockets with qualifying orders of $109. Shop Sockets and Drive Bits at Summit Racing.

THE >>> TS <<< STANDS FOR "TAPERED SEAT" PLUGS.

NO STEEL GASKET

http://www.harborfreight.com/3x-magnify ... 94367.html

having a spark plug holder with numbered holes and a good inspection tool helps

testing ignition coil

http://www.aa1car.com/library/ignition_coils.htm

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

The images below are pages out of the ACDelco plug catalog and shows the old and new numbering system. The new system doesn't have as detailed "intelligence" built into it like the old system.

WATCH THE VIDEO

Recommended Spark Plugs for Vortec Heads

- AC Delco Rapid Fire Spark Plugs R44LTS

- AC Delco Rapid Fire Spark Plugs MR43LTS

- AC Delco RapidFire No 3 Sparkplug

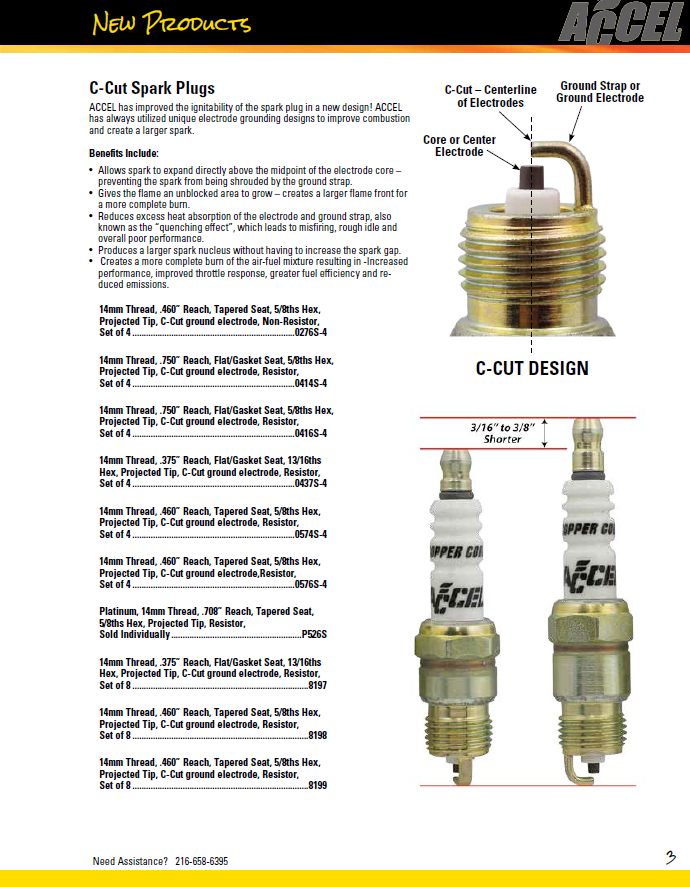

- ACCEL P526S U-Groove “SHORTY” Double Platinum (approximately 3/16″ shorter then R44LTS)

- ACCEL 516

- Autolite 26

- Autolite 104

- Champion RS12YC

- Bosch HR10B

- Bosch HR10BX

- Bosch HR9DC

http://garage.grumpysperformance.com/index.php?threads/spark-plug-info.202/

http://garage.grumpysperformance.co...that-some-guys-don-t-look-at-the-clues.11176/

http://garage.grumpysperformance.com/index.php?threads/changing-long-over-due-spark-plugs.10404/

http://garage.grumpysperformance.com/index.php?threads/why-use-anti-seize-paste.9424/

http://garage.grumpysperformance.co...ition-wires-getting-the-header-clearance.840/

http://www.summitracing.com/parts/PIT-229/

Ive found its a whole lot faster to use a quality IR temp gun, to locate a individual cylinder that's mis-firing as it tends to run significantly cooler than adjacent cylinders, or hotter if its a vacuum leak at times, as lean F/A mixes tend to run hotter

(Ive used this one for years)

http://www.professionalequipment.com/ex ... ermometer/

Wide temperature range from -58 to 1832°F (-50 to 1000°C)

many temp guns don,t read high enough or accurately enough

http://www.professionalequipment.com/ex ... ermometer/

that you can use on the engine to check ALL 8 exhaust temps, individually, this quickly locates plugged injectors or vacuum leaks ETC

Wide temperature range from -58 to 1832°F

when selecting an IR gun for automotive use, you really want to be able to read from 0 F deg-about 1400F deg. to cover most conditions you'll test for

READ THRU LINKS AND SUB LINKS

http://www.4secondsflat.com/Spark_plug_reading.html

viewtopic.php?f=70&t=3949&p=25481#p25481

learning to correctly read plugs is a KEY FACTOR in learning how to tune and diagnose engine conditions, ignition temperatures,fuel/air ratios and detect detonation

example

Here is a link to AC Delco for information on the codes.

On the R45TSX for example:

R=resistor spark plug

45=heat range

T=tapered plug

S=extended tip

X=wide gap

http://www.acdelco.com/parts/sparkplugs ... cation.jsp

some reference chart info

http://www.sparkplug-crossreference.com ... ence8.html

http://www.spark-plugs.co.uk/pages/tech ... htm#ISOJIS

http://www.summitracing.com/parts/msd-3508

http://www.pcmforless.com/index.php?opt ... &Itemid=56

http://www.mirage-performance.com/tech/sparkplugs.html

http://go.mrgasket.com/pdf/sparkplugs/U ... erence.pdf

http://www.autorepairinstructions.com/?cat=7

plug fouling, issues

hi, Im wondering if an auto spark plug can burn carbon off once it is all carboned up if the changes are made to the engine to give the proper air fuel mix. Can plugs be cleaned of carbon and can plugs be bead blasted to clean or does it ruin the plug. What would be a way to clean the plug? Or...

garage.grumpysperformance.com

http://www.kennedysdynotune.com/Spark Plug Tech.htm

IF your trying to tune an engine or track down a problem,When you inspect plugs ,pull all 8 plugs , drill some (8) 1/2 holes in 2 parallel lines in a 12"" section of 2"X6" wood and label the holes, to indicate the cylinders

2-4-6-8

1-3-5-7

so you can stick the porcelain ends , of each plug ,the wires snap onto, into the holes so you can photograph and inspect the tips and electrodes in clear detail as they can tell you a great deal about the engines running conditions

viewtopic.php?f=50&t=892&hilit=+socket

I frequently get asked what brand of plugs I use or suggest,

Ive had good luck with

AC DELCO

NGK

BOSCH PLATINUM plugs

most gapped at .043-.045

these are companys making a decent plug, your engine might run better with something else but Ive had good results with these brands

all work well in most LT1 and L98 chevy SB engines

just stick to the single electrode ground designs as in most cases Ive found the multi ground plugs cost more and don,t provide ANY improvement, and before you go linking in tests showing plug brand XYZ makes 5- 7 extra hp you should realize any decent experienced dyno operator can rig the results that much, either way at will, and if company xyz pays you several hundred dollars to show their plugs provide a small margin of extra power you can bet your butt the dyno operator will find it!

and when the next company ABC stops by for a TEST, you can bet they also show a small advantage

reading plugs can tell you a great deal, but if you don,t read thru and understand the linked info youll be at a big disadvantage heres a very useful chart, depicting plug conditions to look for indicating combustion chamber temp and air/fuel ratio indicators

http://www.4secondsflat.com/plug_chart.html

http://www.4secondsflat.com/Spark_plug_reading.html

http://www.dragstuff.com/techarticles/r ... plugs.html

http://www.custom-car.us/ignition/spark ... range.aspx

http://ngksparkplugs.com/tech_support/s ... p?mode=nml

http://www.autorepairinstructions.com/?cat=7

viewtopic.php?f=70&t=5428

http://www.power-21.com/AutolitePower21 ... preads.pdf

http://kb-silvolite.com/article.php?action=read&A_id=63

http://www.autohausaz.com/html/spark-pl ... wires.html

http://en.wikipedia.org/wiki/Spark_plug

http://www.ngksparkplugs.com/techinfo/s ... lation.asp

http://www.verrill.com/moto/sellingguid ... rchart.htm

http://www.strappe.com/plugs.html

http://www.wallaceracing.com/plug-reading-lm.html

cross reference

http://www.angelfire.com/extreme4/skido ... ERENCE.htm

viewtopic.php?f=50&t=1853&p=4848#p4848

QUOTE

"Heat range

The operating temperature of a spark plug is the actual physical temperature at the tip of the spark plug within the running engine. This is determined by a number of factors, but primarily the actual temperature within the combustion chamber. There is no direct relationship between the actual operating temperature of the spark plug and spark voltage. However, the level of torque currently being produced by the engine will strongly influence spark plug operating temperature because the maximum temperature and pressure occurs when the engine is operating near peak torque output (torque and RPM directly determine the power output). The temperature of the insulator responds to the thermal conditions it is exposed to in the combustion chamber but not vice versa. If the tip of the spark plug is too hot it can cause pre-ignition leading to detonation/knocking and damage may occur. If it is too cold, electrically conductive deposits may form on the insulator causing a loss of spark energy or the actual shorting-out of the spark current.

A spark plug is said to be "hot" if it is a better heat insulator, keeping more heat in the tip of the spark plug. A spark plug is said to be "cold" if it can conduct more heat out of the spark plug tip and lower the tip's temperature. Whether a spark plug is "hot" or "cold" is known as the heat range of the spark plug. The heat range of a spark plug is typically specified as a number, with some manufacturers using ascending numbers for hotter plugs and others doing the opposite, using ascending numbers for colder plugs.

The heat range of a spark plug (i.e. in scientific terms its thermal conductivity characteristics) is affected by the construction of the spark plug: the types of materials used, the length of insulator and the surface area of the plug exposed within the combustion chamber. For normal use, the selection of a spark plug heat range is a balance between keeping the tip hot enough at idle to prevent fouling and cold enough at maximum power to prevent pre-ignition leading to engine knocking. By examining "hotter" and "cooler" spark plugs of the same manufacturer side by side, the principle involved can be very clearly seen; the cooler plugs have more substantial ceramic insulators filling the gap between the center electrode and the shell, effectively carrying off the heat, while the hotter plugs have less ceramic material, so that the tip is more isolated from the body of the plug and retains heat better.

Heat from the combustion chamber escapes through the exhaust gases, the side walls of the cylinder and the spark plug itself. The heat range of a spark plug has only a minute effect on combustion chamber and overall engine temperature. A cold plug will not materially cool down an engine's running temperature. (Too hot of a plug may, however, indirectly lead to a runaway pre-ignition condition that can increase engine temperature.) Rather, the main effect of a "hot" or "cold" plug is to affect the temperature of the tip of the spark plug.

It was common before the modern era of computerized fuel injection to specify at least a couple of different heat ranges for plugs for an automobile engine; a hotter plug for cars which were mostly driven mildly around the city, and a colder plug for sustained high speed highway use. This practice has, however, largely become obsolete now that cars' fuel/air mixtures and cylinder temperatures are maintained within a narrow range, for purposes of limiting emissions. Racing engines, however, still benefit from picking a proper plug heat range. Very old racing engines will sometimes have two sets of plugs, one just for starting and another to be installed once the engine is warmed up, for actually driving the car."

learn how read the spark plugs their condition will tell you a good deal about cylinder burn conditions, get an IR temp gun,vacuum gauge and timing light they are a great tuning and diagnostic aid,as they can indicate problems like a clogged cat or faulty ignition, etc. don,t solely relie on a single indicator

http://www.strappe.com/plugs.html

http://performanceunlimited.com/illustrations/sparkplugs.html

http://www.dragstuff.com/techarticles/s ... rence.html

http://www.ngksparkplugs.com/techinfo/s ... country=US

the plugs are normally done (the electrodes cut back)with a dremel tool cutting disk

http://www.autorepairinstructions.com/?cat=7

heres a good indication of plugs running a bit rich at idle and real lean in the upper rpm range

keep in mind that different brands of plugs will have different lengths that can be critical with ignition wire to header clearances

http://www.centuryperformance.com/spark ... g-192.html

http://www.carcraft.com/techarticles/sp ... index.html

a few places to look for more info on plugs

http://www.centuryperformance.com/spark ... pg-26.html

http://www.dragstuff.com/techarticles/h ... plugs.html

http://opc.mr2oc.com/online_parts_catal ... _plugs.jpg

http://www.gofastzone.com/techtips/sparkplugs/sparkplugs.htm

http://www.ngksparkplugs.ca/documents/partnumberkey.pdf

http://www.autohausaz.com/html/spark-pl ... wires.html

http://www.acdelco.com/html/pi_plugs_ident.htm

http://www.autolite.com/framer.cgi?page=http://www.autolite.com/products/racing.htm

http://members.uia.net/pkelley2/sparkplugreading.html

http://www.circletrack.com/enginetech/c ... index.html

http://www.atlanticjetsports.com/_techtalk/00000005.htm

http://www.strappe.com/plugs.html

http://www.babcox.com/editorial/cm/cm59910.htm

http://www.4secondsflat.com/Spark_plug_reading.html

http://www.ngksparkplugs.com/techinfo/spark_plugs/partnumberkey.pdf

http://www.nightrider.com/biketech/spkplghnbook.htm

http://www.tsrsoftware.com/sparkplug.htm

viewtopic.php?f=70&t=1809&p=4671#p4671

http://www.gnttype.org/techarea/engine/plugs.html

http://www.dansmc.com/sparkplugs1.htm

http://www.ngksparkplugs.com/techinfo/spark_plugs/overviewp2.asp

http://www.pajjakid.com/ubipa/sparkplugs.htm

http://www.edelbrock.com/automotive/sparkplugs.html

http://www.bullittarchive.com/Maintenance/Sparkplugoverview/

http://www.powerarc.com/sparkplug.htm

http://www.carcraft.com/techarticles/64378/

http://www.wakularacing.com/TechnicalInfo.htm

https://garage.grumpysperformance.com/index.php?threads/reading-plugs.5428/

http://www.geocities.com/MotorCity/Flats/3877/spark.html

BTW IF YOU WANT TO AVOID ETHANOL LACED FUEL

http://pure-gas.org/

Last edited by a moderator: