grumpy I just installed a ford 9" differential, with 4.10 rear gears, and a set of good wide tires on my ford 1966 fair-lane with a 460 ford v8 , ever since the install of the new differential ,rear gear change, and better, traction,tires it starts missing in third gear?

the engines not been touched, and its always run decent, with its old 3.08 or similar gearing, since we installed that rear end differential. the engines always run very well, and I did not touch a thing under the hood, so this comes as a big surprise. any ideas

when your trying to isolate and test any issue it helps to mentally step back and ask yourself ,

"what condition has changed or been induced that might explain this"

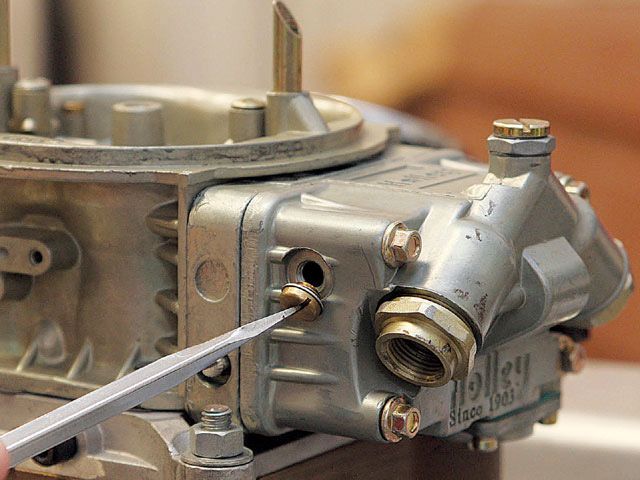

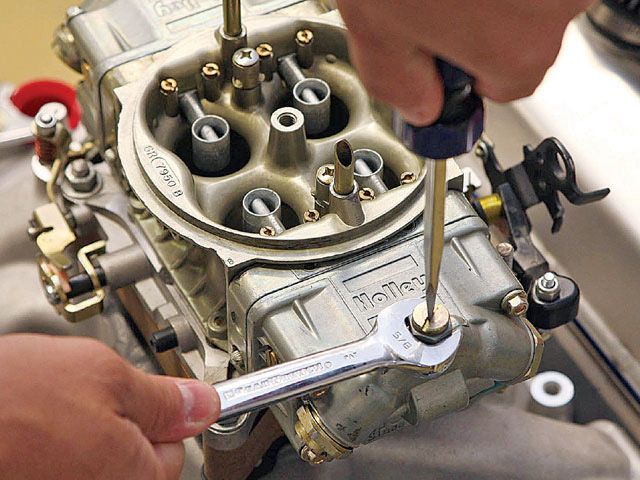

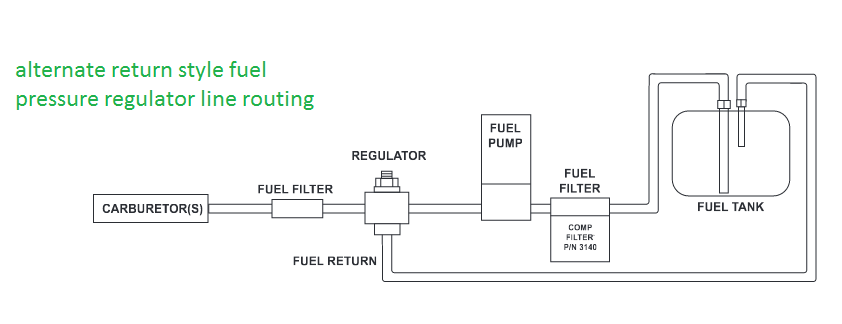

then test your theory...Id start by installing a fuel pressure gauge sensor for the remote dash mount fuel pressure gauge at the carb inlet port and having someone watch it carefully as you made a few hard acceleration runs,

have you adjusted both the fuel bowl fuel levels so the idling engine shows fuel just level with the sight plugs lower edge.

no it does not mater if its a manual engine driven fuel pump or its an electric fuel pump, you need to verify fuel delivery consistent pressure at the carb inlet.

now it may be something else but Id suspect that either the fuel pump has a hard time over coming the initial inertial loads that are reduced once the cars launched,Id suggest you install a fuel pressure gauge where you can see it hooked up to the carbs inlet port and verify you maintain a consistent 6-7 psi , if the pressure drops noticeably at any time, during a run, that fuel system needs upgrading.

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

or the oil pan contents sloshing to the rear uncover the pick-up and your oil pressure sensor is cutting electric to the fuel pump or ignition, until the oil pressure returns

Id sure throw an extra quart of oil in the engine and install a fuel pressure gauge to isolate those two potential sources before looking further

http://www.hotrod.com/articles/9-inch-ford-rearend-strongest-rearend-due-hypoid-distance/

http://garage.grumpysperformance.com/index.php?threads/rear-differential-width.2186/#post-5879

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

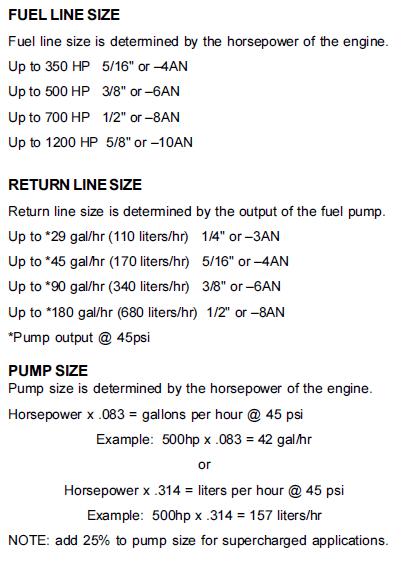

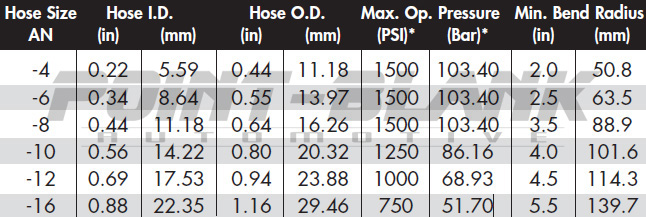

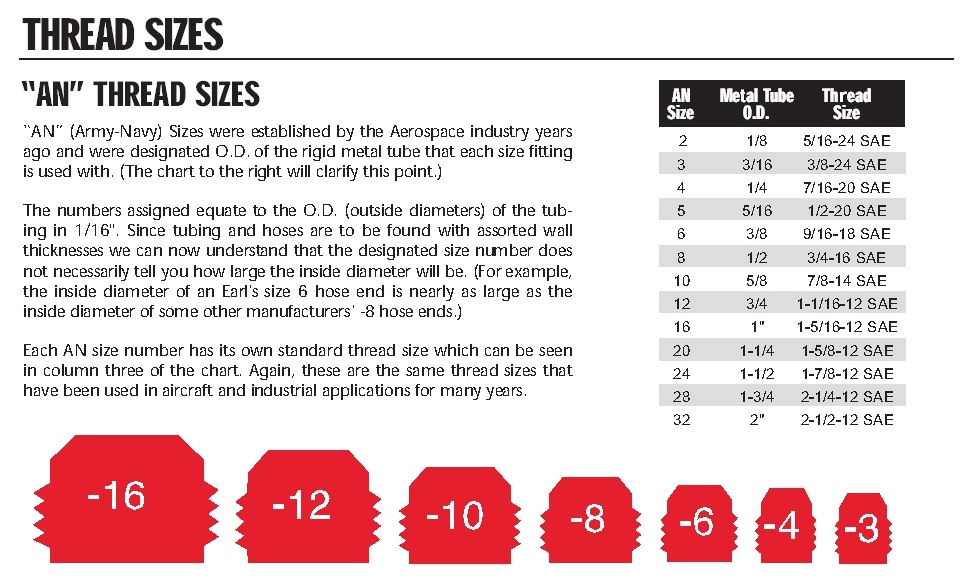

Fuel Hose Sizes

AN SizeTube or Hose ODTube or Hose ID

-6 3/8” .297”

-8 1/2” .391”

-10 5/8” .484”

-12 3/4” .609”

Last edited: