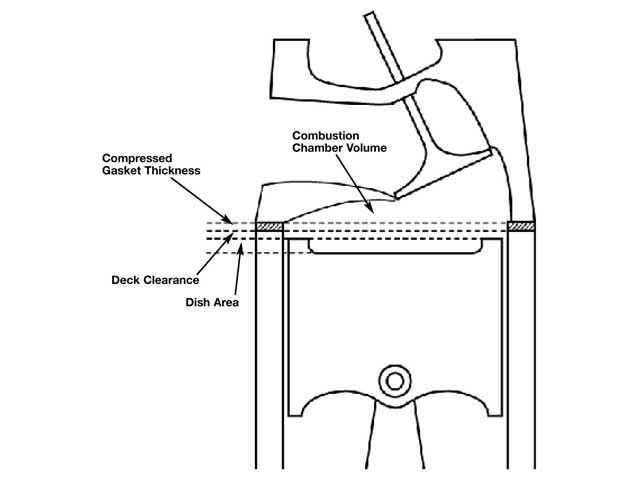

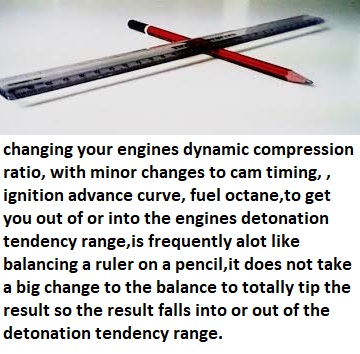

as usual a multi level aproach, here will help and each change will add to your ability to reduce or avoid the detonation issue!

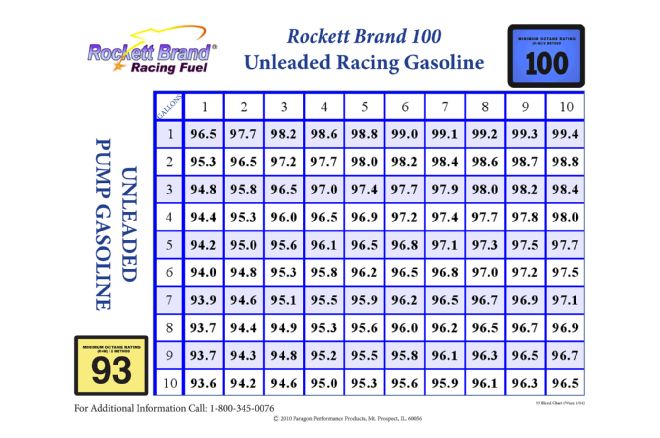

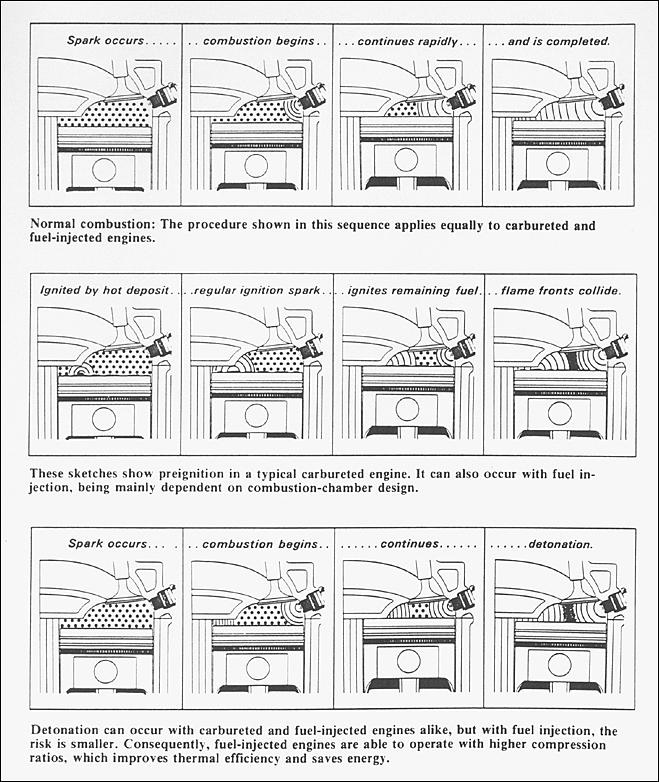

I think that the two keys here are that if the ignition curve and engine temps remain at current levels, Rick will need to both increase the fuels octane, rating, and change the ignition advance and probably richen the mix, (that tends too cool the burn and make detonation less likely.

(the swapping too the 4.11:1-4.56:1 rear gear certainly won,t hurt) the higher number rear gear ratio, can be helpful to increase the cars engines tolerance for not getting into conditions that are favorable to detonation, buy rapidly increasing the rpm range it operates in, while Im sure the engine can be tuned to operate well with the current 3.73:1 rear gear, swapping to a 4.11:1-4.56:1 rear gear

makes the engine tune less critical

dropping the oil temps with an oil cooler would also help reduce the engines tendency to get into detonation

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

GENERALLY your fuel/air ratio should be in these ranges

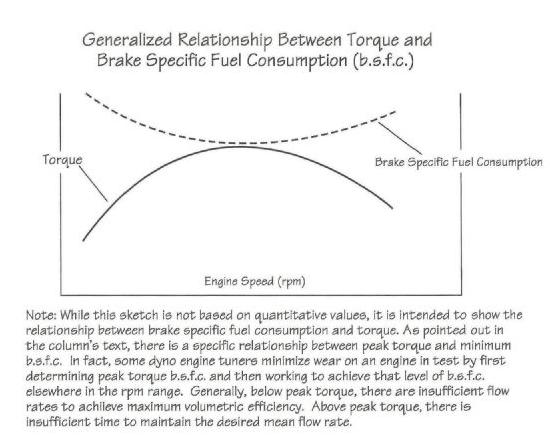

Idle- up too about 2500 rpm try for 14.7:1-15:1 f/a ratio

from about 2500 rpm- too about 4500 rpm try to smoothly and predictably transition the fuel/air ratio mix richer to about 13.5:1

from about 4500 rpm- too about 6500 rpm and higher ,try to smoothly and predictably transition the fuel/air ratio mix richer to about 12.5:1

this is only a starting point on the tune but it generally gets you in the ball park and tends to reduce the chances of the engine reaching detonation conditions.

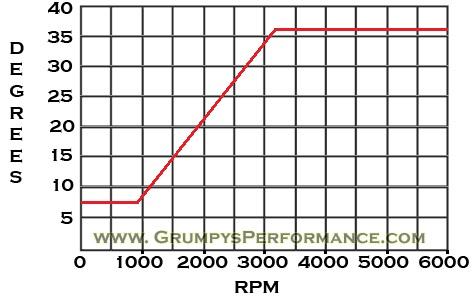

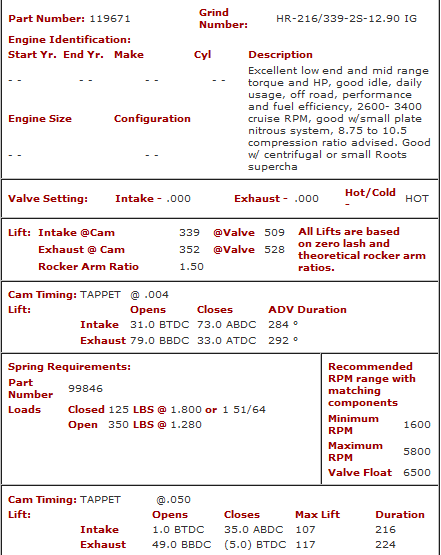

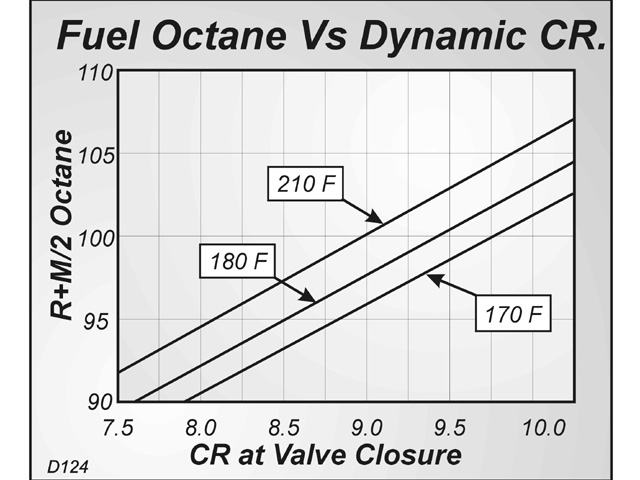

the ignition advance curve needs to be checked, the chart below is a very good starting point to work from, and USE OF A RICHER FUEL/AIR MIX, WILL AT TIMES BE REQUIRED IN THE OFF IDLE TO 3500 rpm range