the basic concept behind the design of the crossram intake is to maximize the individual intake runner length , while maintaining as close to a direct strait shot at each cylinder heads intake valve, as possible so ram tuning, or use of the fuel/air masses inertia can be used along with exhaust scavenging to maximize the cylinder fill efficiency and yet not having to deal with the height penalty that the more common tunnel-ram or individual stack injection, and frequently while utilizing two 4 barrel carbs

BTW the cam we used to get the best results with in the past on retro Z28 builds was a crane 110921 flat tappet solid lifter ,but the current roller cams would do even better, keep in mind that the cross-ram intake works best on a 350-406 with a cam and gearing that keeps the engine in the 3500rpm-7000rpm band, so both the cam and the intake design match that OPERATIONAL RPM BAND

and REQUIRES a decent set of high flow rate heads, (generally look for heads that reach or exceed 250cfm at .600 lift) with a matching 10.5:1-12.5:1 cpr and generally a 4.11:1-4.56:1 rear gear and manual transmission, when road racing, to operate correctly in its intended rpm band and flow rate. you could drop back to a 3.73:1-3.90:1 on a street car

[/color]

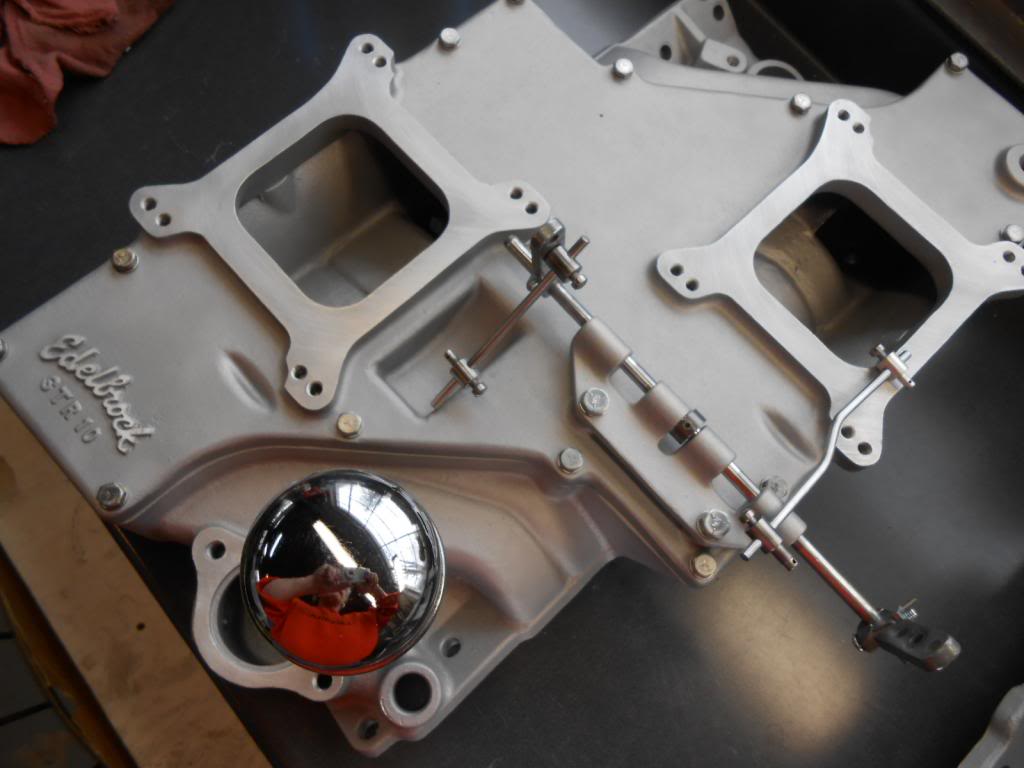

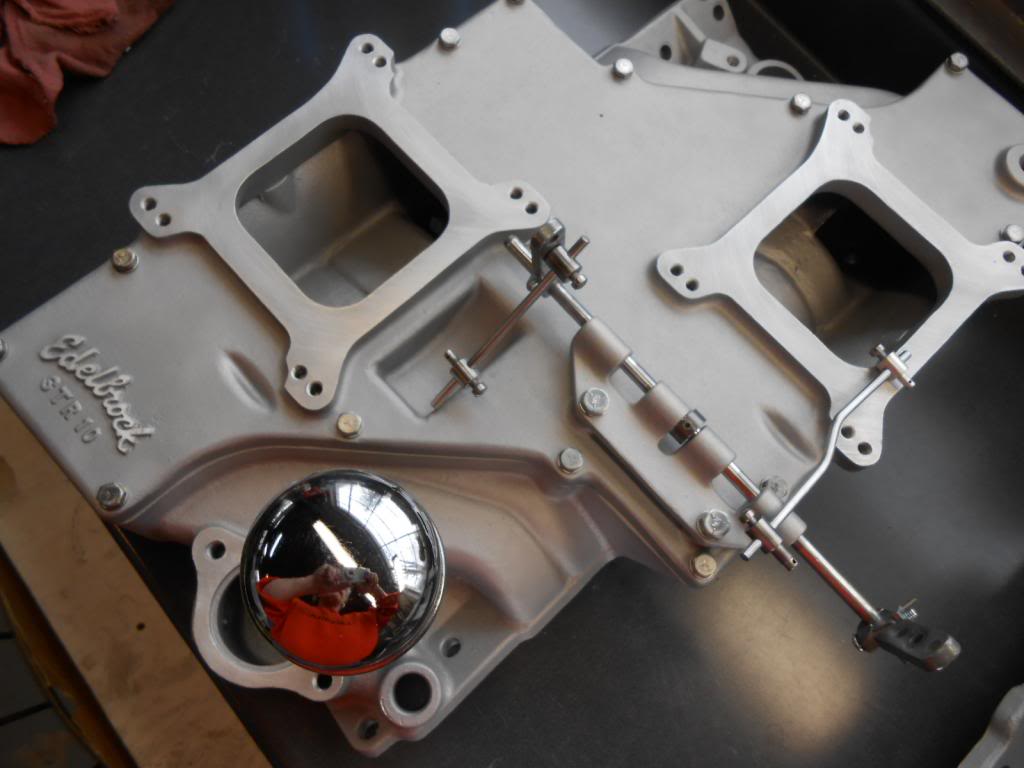

STR-10 BELOW

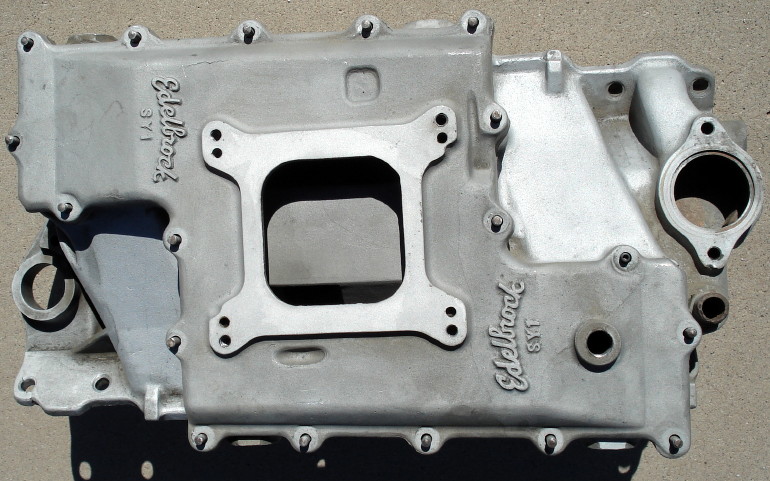

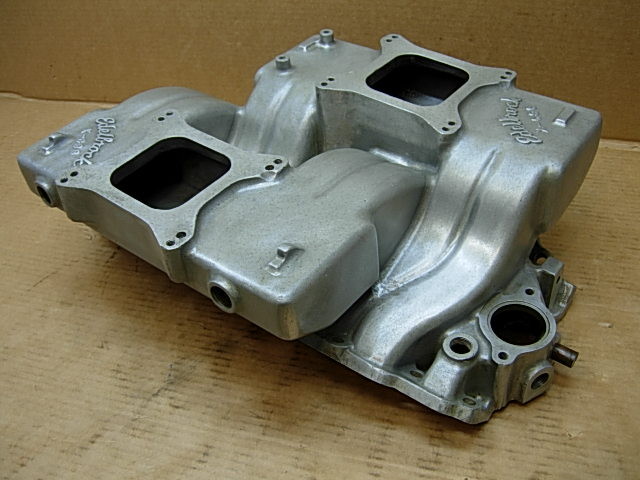

EDELBROCKS SBC CROSS RAM

http://www.camaro-untoldsecrets.com/art ... ossram.htm

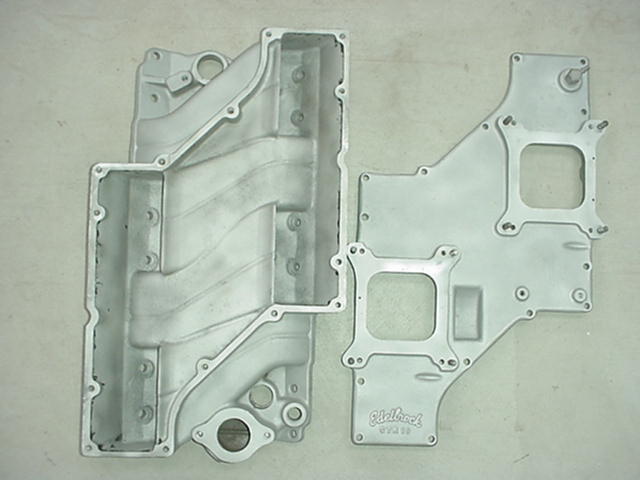

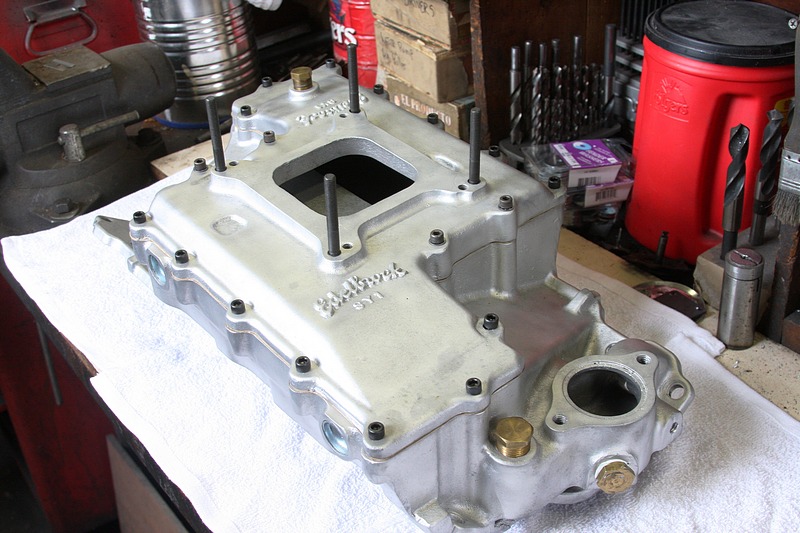

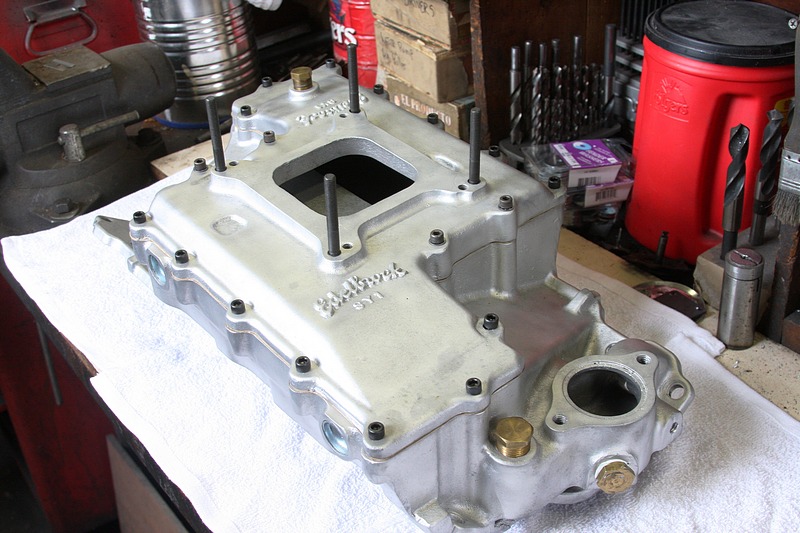

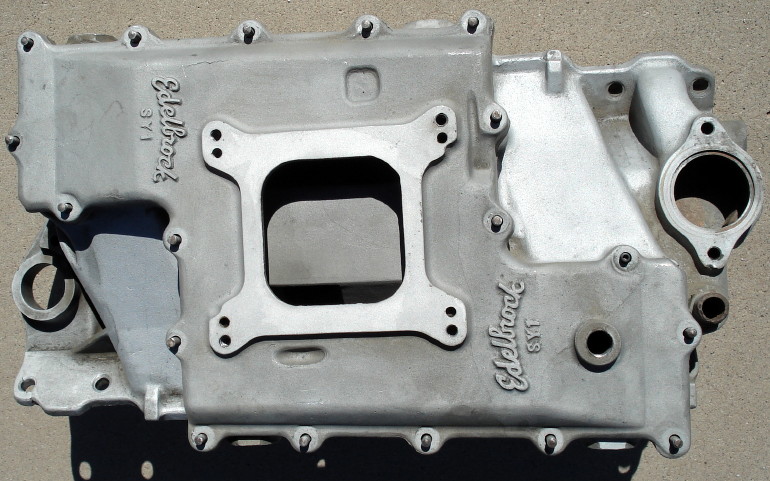

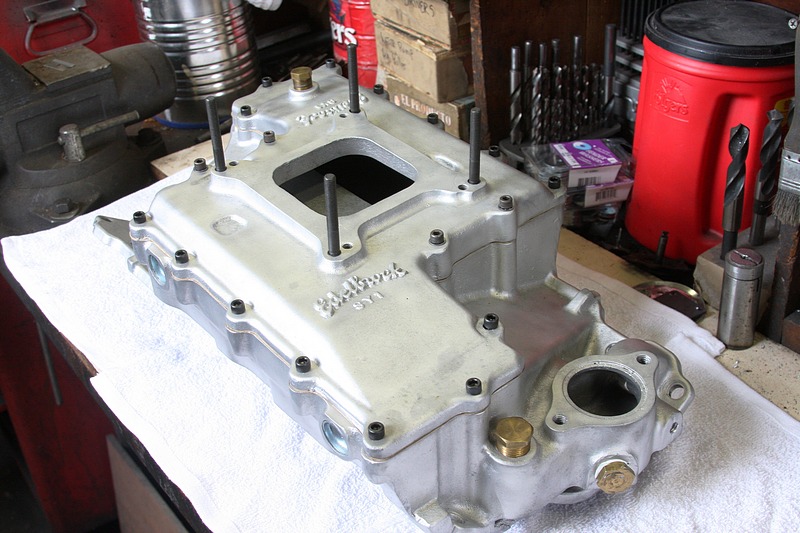

SMOKEYRAM (SY1)BELOW

when they were easy to get at the local speed shops buying a smokey ram, installing a crane solid lifter flat tappet cam #110921in a 11:1 compression ratio, 377,383,406 SBC with a 750-780 cfm vacuum secondary arbitrator with decent long tube 1 3/4" headers and a low restriction exhaust, in a camaro, nova or vega engine swap car with a muncie 4 speed and a 3.90:1-4.33:1 rear gear was almost a mandatory combo back in the mid 70s if you wanted to kick butt and take names

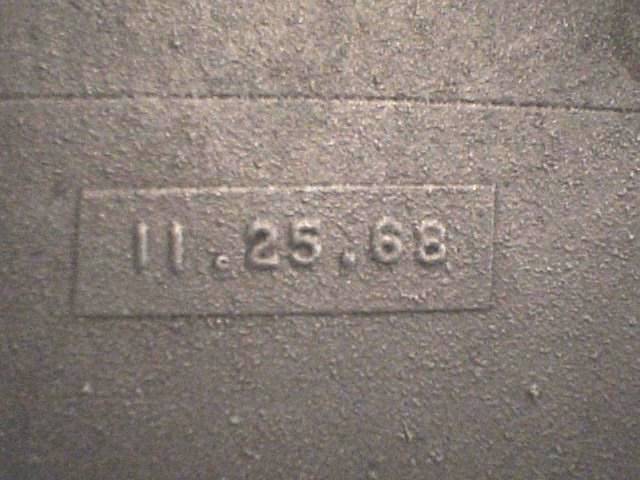

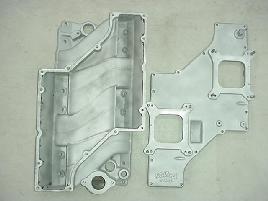

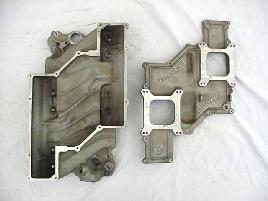

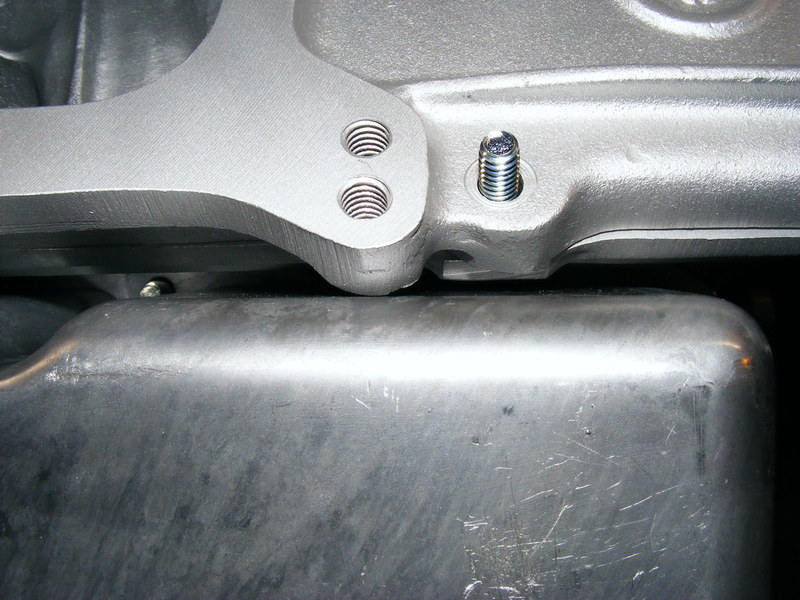

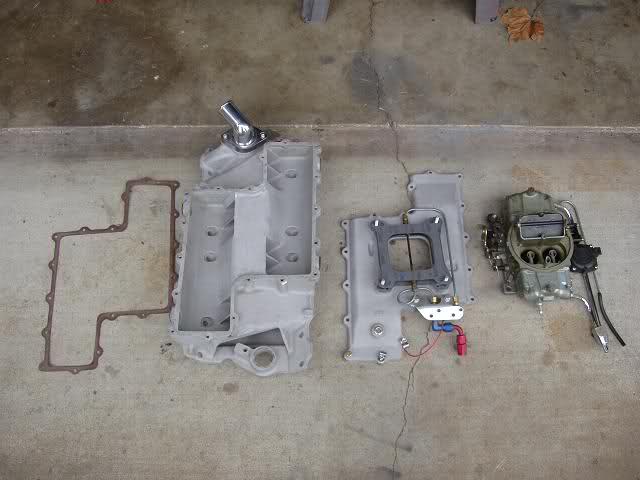

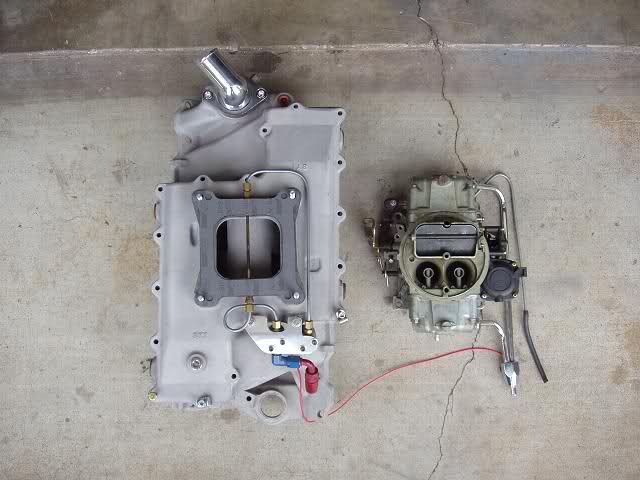

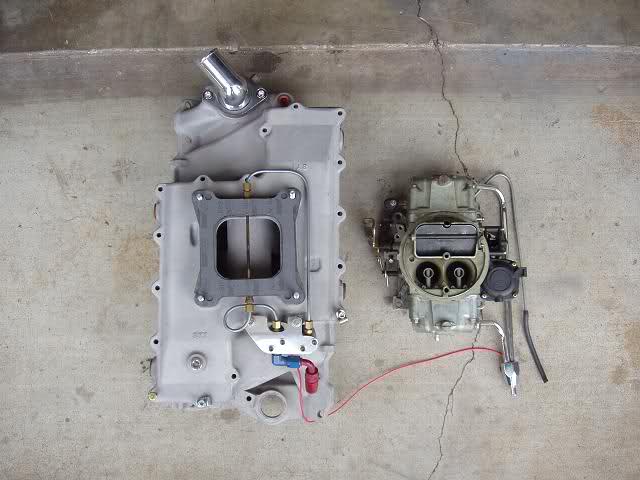

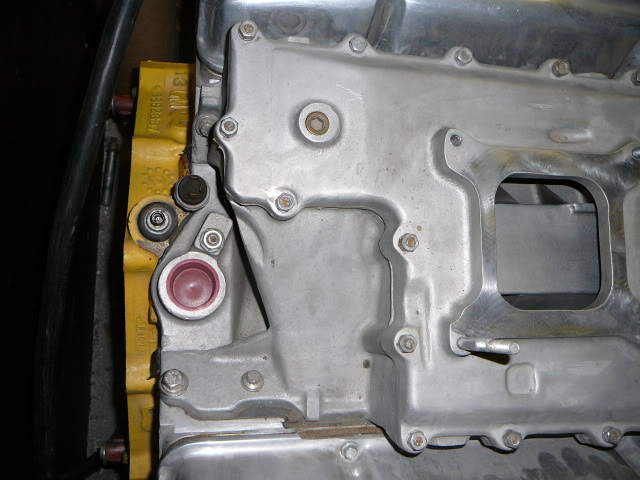

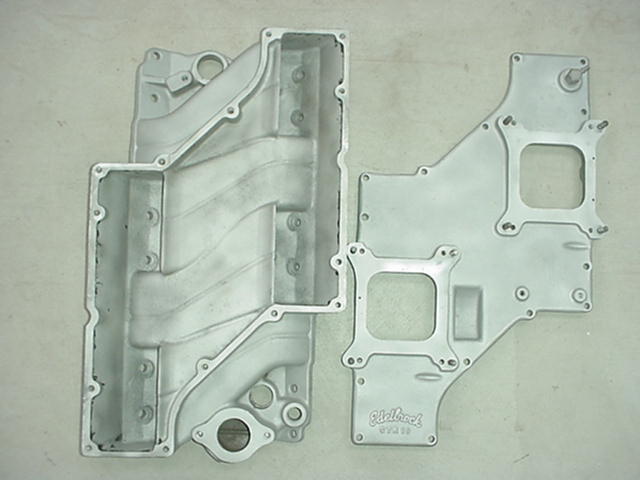

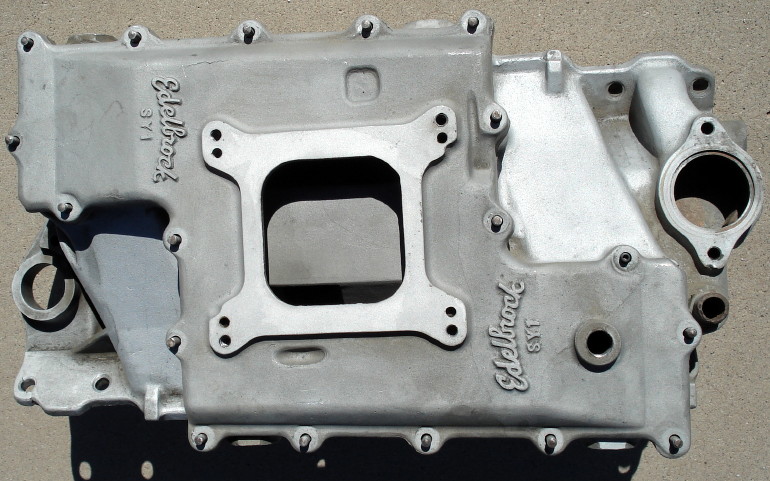

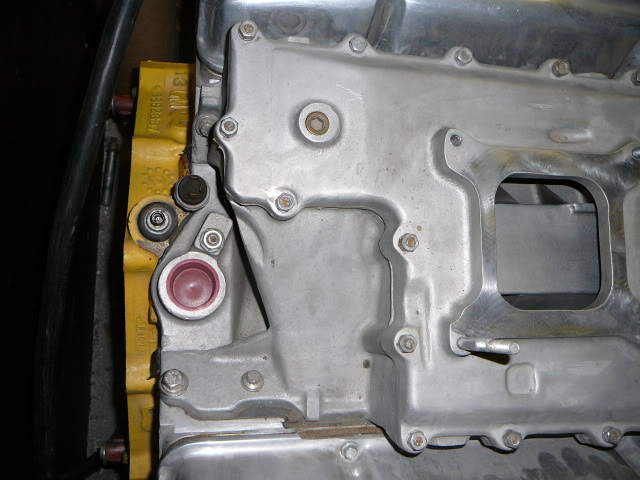

when the first few SMOKEY RAM INTAKES WERE SOLD they found several distributors would not fully seat until the intake was notched to provide the required clearance, look closely at the intake above (an early version with no clearance notch) then the two below that had the notch machined

and you,ll never be the first guy to install a wet nitrous plate and a healthy ,longer duration solid lifter cam like a crane 110921 on a 383

SMOKEYRAM (SY1)BELOW

Ive had good results with a smokey ram with a 750 cfm holley and

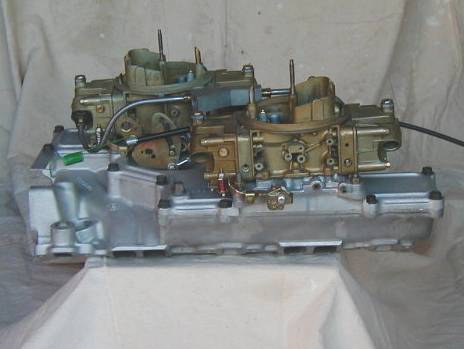

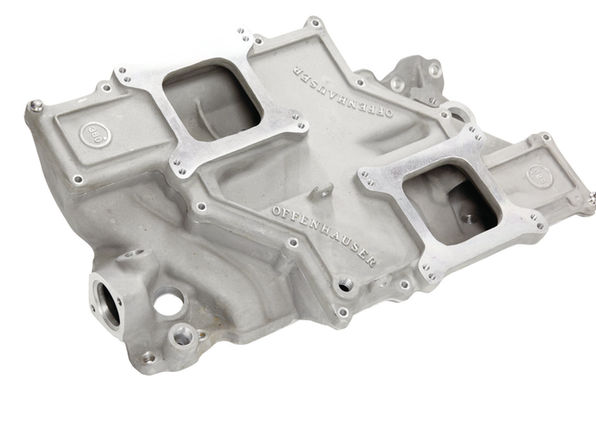

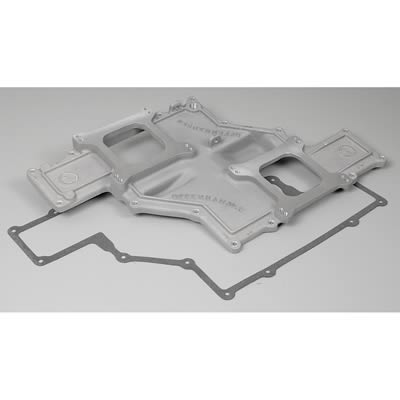

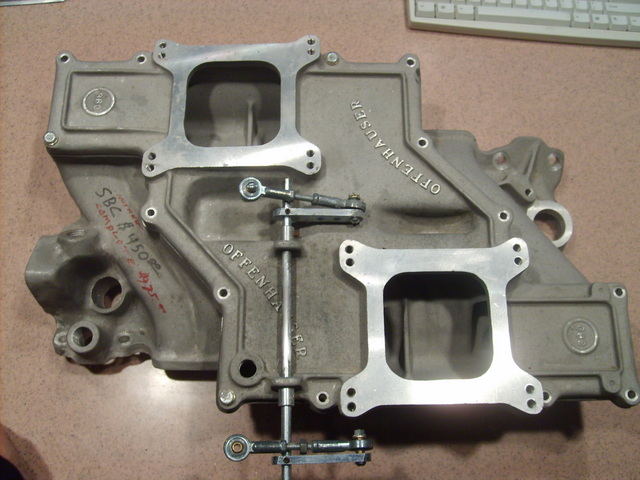

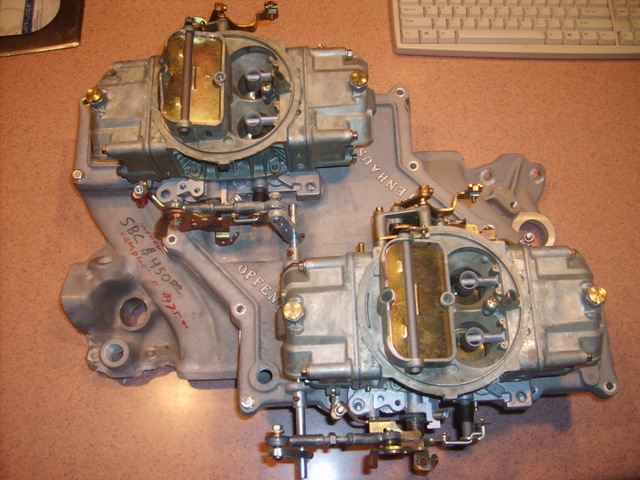

Ive used the offanhauser cross-ram with several carb combinations

and gotten good results, Id generally prefer two 450-500 cfm carbs on the cross-ram but two 600 cfm would work just fine!

the important thing is carefully matching the throttles /linkage and maintaining a constant 5.5 psi of fuel pressure and Id sure prefer a fuel pump that would be rated to supply about 120-140 gph at 5 psi.

a crane 110921 flat tappet solid lifter cam,

decent heads that flow at least 250 cfm at .500 lift

(brodix IK 200 are popular) (as are 195 cc AFR)

http://www.jegs.com/i/Brodix/158/1021007/10002/-1

https://www.summitracing.com/parts/afr-1036/overview/

good 1.6:1 roller rockers,

long tube headers, a low restriction 3" dual exhaust, (obviously use premium gas)

on a 377-406 10.5:1 or higher compression SBC with the drive train differential gearing

(usually with a manual transmission) in the 4.11-4.33:1 range seems to work rather well

especially in a 3000 lb or lighter car, if you drive the car like the devil himself was after your soul and was only 100 yards behind you and gaining on every lap!(so it rarely drops below 3500-rpm and spends a good percentage of the time bouncing between 4500 rpm and 6500 rpm

USEFUL LINKS

http://garage.grumpysperformance.com/index.php?threads/yes-offys-still-around.1468/#post-6357

http://www.wallskid.com/c/small-block-chevy-cross-ram_|rKmBts5HrkD7LgWJ4o2CXBYhxN0k*|5qQiC0m3AGdg/

http://garage.grumpysperformance.com/index.php?threads/will-dual-quads-work-ok.5888/

http://garage.grumpysperformance.com/index.php?threads/the-cross-ram-intake.623/#post-834

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/

http://garage.grumpysperformance.com/index.php?threads/dual-quad.11867/

http://garage.grumpysperformance.com/index.php?threads/thinking-of-swapping-to-dual-quads.11709/

http://garage.grumpysperformance.com/index.php?threads/spark-plug-info.202/

http://garage.grumpysperformance.com/index.php?threads/verifying-your-real-advance-curve.4683/

http://garage.grumpysperformance.com/index.php?threads/reading-plugs.5428/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

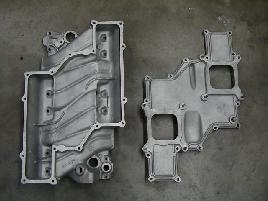

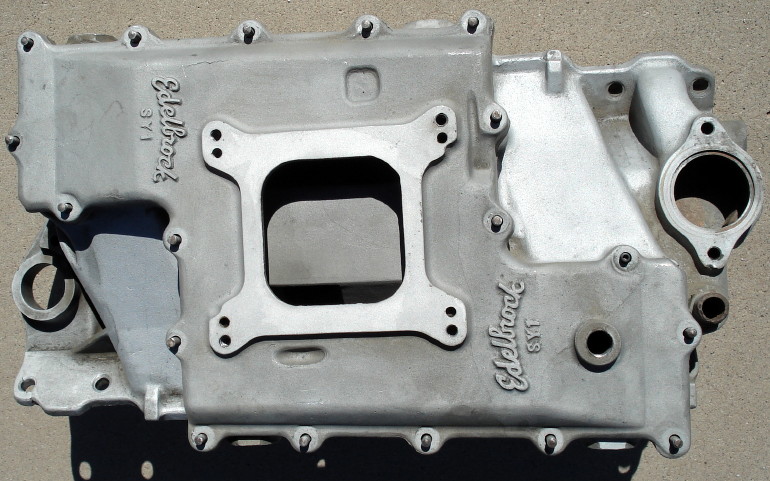

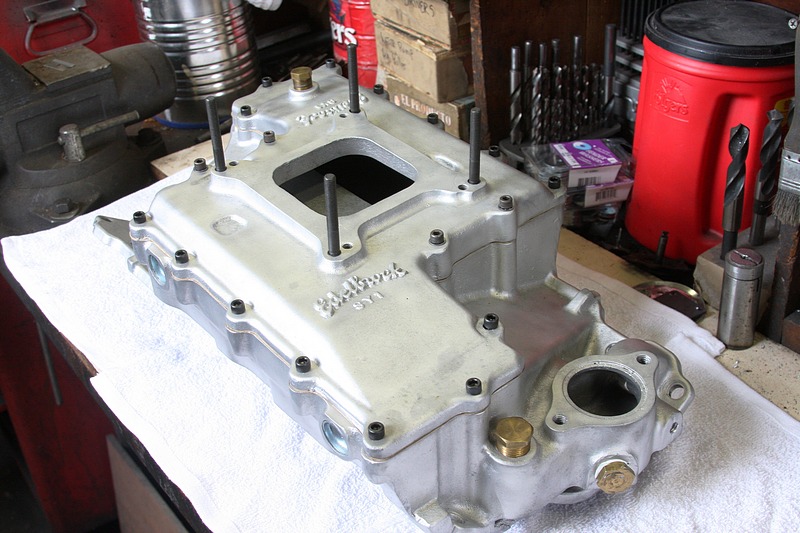

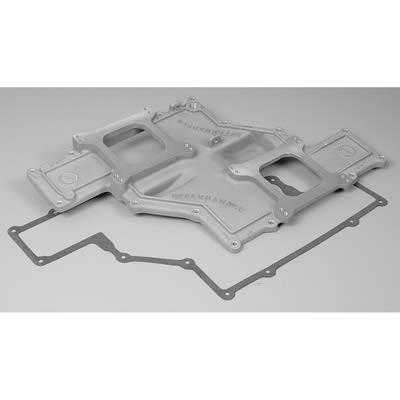

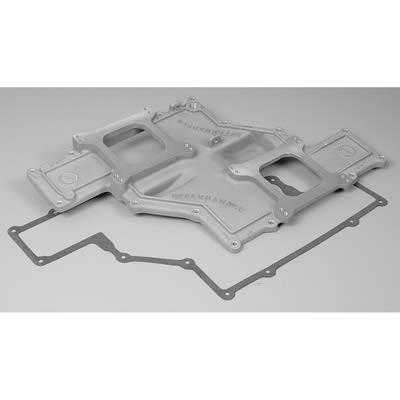

OFFY BELOW

max stock spring lift clearance is about .470 lift,either of these cams works, both like 1.6:1 ratio rockers

the milder one is the better choice for a daily driver, the longer duration version gives slightly more peak hp but its also slightly less street traffic friendly

E110018K

specs>> 270/280 204/214 .420/.443 112 $111.72

buy now

E110020K

specs>> 275/278 209/216 .435/.455 112 $111.72

most of the SBC cross ram intakes share a common plenum, but there are several designs with a dual plenum , where each carburetor feeds the opposite bank of cylinders exclusively

http://www.pbm-erson.com/store.php?catId=334&parent=333&grandparent=327

http://www.camaro-untoldsecrets.com/art ... ossram.htm

viewtopic.php?f=87&t=2045

http://reviews.ebay.com/Cross-ram-manif ... 1:STORES:5

http://www.inglese.com/

http://www.kinsler.com/page--GM--17.html

http://force-efi.com/weber.htm

http://www.mooneyesusa.com/Store/index. ... 205077441a

the cross ram can be a challenge to tune correctly but they work great once correctly tweaked http://www.cranecams.com/index.php?show ... vl=2&prt=5

best with the manual trans and 4.11-4.56 rear gears in a light car.

you might find this interesting

http://www.camaros.org/crossram.shtml

viewtopic.php?f=87&t=8379&p=29224#p29224

http://www.camaro-untoldsecrets.com/art ... ossram.htm

the offy intakes still available and twin 600 cfm carbs tend to work great...but theres been lots of improvements in things like roller rockers and intakes since then, and a very similar built 383 is almost certainly going to be faster

http://www.camaro-untoldsecrets.com/art ... ossram.htm

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... t=OFY-5903

http://store.summitracing.com/partdetai ... t=OFY-5902

http://jobyteknik.homeip.net/corvette/2002-11_offy_installation/

viewtopic.php?f=86&t=1397

http://www.moparmusclemagazine.com/tech ... index.html

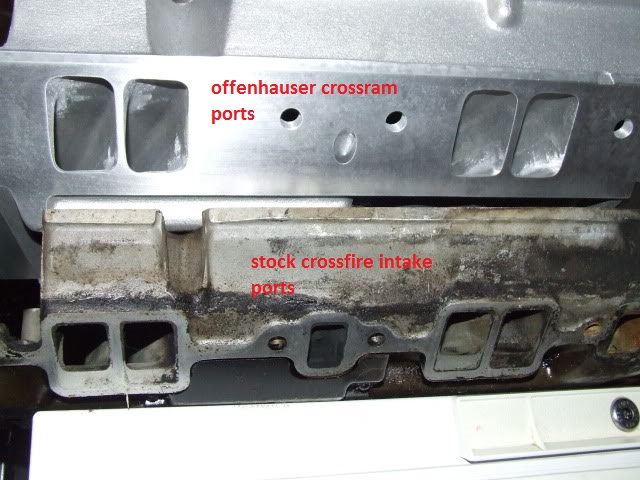

for a huge improvement in runner flow rates, yeah! it requires fabrication and a custom intake lid , if you want to convert it to efi but all the parts for carb use are easily available, but the results are far better flow than the stock CROSSFIRE crossram intake can ever provide

PORT SIZE FLOW AND THE RELATION TO CAM DURATION

FIRST, This will not be anything more that a brief glimpse into a subject that takes years to understand fully and Im sure there are a few people on the site that can give more exact info! This is meant to apply to the 350-383 sbc engines most of us are useing

My purpose is merely to give an idea as to the relationship between the factors and yes IM ignoring several minor factors to make things easier to understand like dynamic compression and valve timing overlap

But lets look a a few concepts

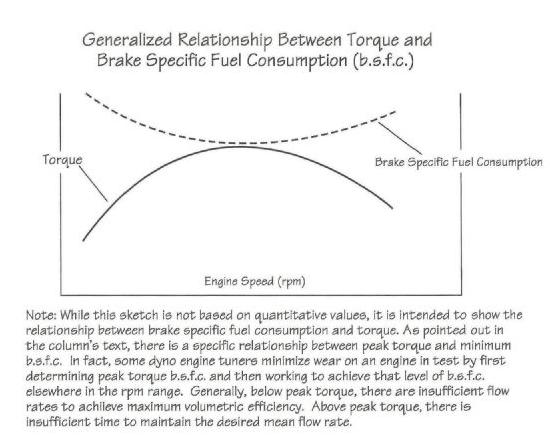

(1) There are 720 degrees in a 4 cycle engines repetitive cycle of which between about 200degrees to about 250 degrees actually allow air to pass into the cylinder, (the valves open far enough to flow meaningful air flow) and the piston has a maximum ability to draw air into that cylinder based mostly on the engines displacement and the inertia of column of air in both the intake port and the suction (or negative pressure the PROPERLY designed headers provide) this produced a max air flow thru the ports, the greater the volume of fuel/air mix effectively burn per power stroke the greater the engines potential torque production, the faster you spin an engine the greater the NUMBER OF POWER STROKES PER MINUTE, and up to the point where the cylinder filling effectiveness starts falling off due to not enough time available to fill that cylinder the torque increases, above that rpm or peak torque itss a race between more power stokes and lower power per stroke

(2) look at this diagram

(3)

As air enters an engine it normally travels thru both an intake system and the cylinder heads intake port to eventually pass into the cylinder thru the valve. The valves in a normal small block corvette engine are between 1.94 and 2.08 in diameter, thats between 2.9sq inches and 3.4 sq inches of area, but because the valves require a seat that at a minimum are about 85%-90% of that flow area we find that the intake port even with out any valve has a max flow of not more than about 90% of the flow thru a port of valve size. Or in this case 2.46 sq inches-2.9 sq inches of port area, Since you gain little if any flow having a port thats substantially larger than the valves AT NORMAL ATMOSPHERIC pressures and since you cant substantially increase the valve sizes for several mechanical reasons you must improve efficiency, this is done in two major ways, you can match the intake port length and cross sectional area to the engines most efficient rpm range on the intake side, to build a positive pressure behind the intake valve as it opens and match the exhaust length and diameter on the exhaust side to provide a negative pressure to help draw in more volume this will require the cam timing match that same rpm range of course. By experimentation its been found that air flow port speeds in the 200-320 cubic feet per minute range are about the best for a chevy V-8 now lets say you have a 383. 383/8=47.875 cubic inches per cylinder, the rpm range most used is 1500rpm-6000rpm so thats where are cam and port size must match, you can do the math , (47.875 x ½ engine rpms = cubic inches, divided by your cams effective flow duration, (use 210-235) as a default for a stock cam) x 720 degrees/1728 (the number of cubic inches in a cubic foot) to get the theoretical max port flow required (I will save you the trouble its 250cfm-275cfm at max rpms and about 2.4-2.9 sq inches of port cross section, depending on where you want the torque peak, or use this handy calculator,

Intake Runner Area = Cylinder Volume X Peak Torque RPM 88200

Or this helpful site

Either way youll find that youll want a port size in the 2.4sq “2.9 sq inch area

Now use this calculator to figure ideal port length, REMEMBER youll need to add the 6 in the cylinder head to the intake runner length to get the total length and you can,t exceed the engines REDLINE RPM which with hydrolic lifters seldom is higher than 6400rpm

http://www.bgsoflex.com/intakeln.html

Ever wonder why your engines torque curve gets higher with the engines rpm level until about 4000rpm-5500rpm(DEPENDING ON YOUR COMBO) but fades above that rpm level?

well it depends on several factors, first as long as the cylinders can fill completely you get a good fuel/air burn so you get a good cylinder pressure curve against the piston each time the cylinder fires, THE ENGINES TORQUE CURVE INCREASES WITH THE NUMBER OF EFFECTIVE POWER STROKES PER SECOND, at very low speeds theres not enough air velocity to mix the fuel correctly or produce a effective ram tuning effect but as the rpms increase the cylinders fill very efficiently until the rpms reach a point where the cylinders just dont have the time necessary to flow

enough air through the valves to fill the cylinders , remember a 5000rpm the intake valve out of 720 degs. in each cycle opens for about 250degs of effective flow even with a hot roller cam, now thats only about 35% of the time and theres 41.6 intake strokes per second , thats only 1/60th of a second for air to flow into the cylinder

Its your engines ability to fill the cylinders that increases your power and the more efficiently you do that the higher the rpm level you can accomplish that at the more power your engine makes, remember the formula for hp is (torque x rpm/ 5252=hp) so moving the torque curve higher in the rpm range increases hp but at some point the time available to fill the cylinders becomes so short that efficiency begins to drop off rapidly, the peak of efficiency is reached normally in the 4500rpm-5500rpm range, and as rpms increase its a race between more power strokes per minute trying to raise the power and the increasingly less effective percentage of cylinder filling dropping the power.

Volumetric Efficiency

The volumetric efficiency of a 4-stroke engine is the relationship between the quantity of intake air and the piston displacement. In other words, volumetric efficiency is the ratio between the charge that actually enters the cylinder and the amount that could enter under ideal conditions. Piston displacement is used since it is difficult to measure the amount of charge that would enter the cylinder under ideal conditions. An engine would have 100% volumetric efficiency if, at atmospheric pressure and normal temperature, an amount of air exactly equal to piston displacement could be drawn into the cylinder. This is not possible, except by supercharging, because the passages through which the air must flow offer a resistance, the force pushing the air into the cylinder is only atmospheric, and the air absorbs heat during the process. so, volumetric efficiency is determined by measuring (with an orifice or venturi type meter) the amount of air taken in by the engine, converting the amount to volume, and comparing this volume to the piston displacement.

this increases until the torque peak then falls as the rpms increase. Here is a rough guide to match duration to port flow at different rpm level

if youve been following along youll find that youll need intake ports about 2.3-2.9 sq inches in cross section, and between 12 and 21 long (DEPENDS ON WHERE THE ENGINE IS DESIGNED TO MAKE MAX HP) and cam timing in the 215@.050 to -240@.050 lift range, as the rpms or displacement increase either the port flow or the cams duration must increase or the engines cylinder fill efficiency rpm will drop!

Now this is important, as the port flow efficiency goes up though the use of longer and larger intake ports the cam duration could remain the same or even be lower and you get more efficient cylinder filling as the rpms increase, that’s why high efficiency port designs like on the LS1 can use lower duration cams to flow similar total air flow thru the ports than the lower efficiency ports like the old fuelie heads could but at some point all ports reach max flow and an increase in the time the valves remain open at higher rpms increases the cylinder fill efficiency and that increases the engines ability to make torque at that rpm range

if you pick a smaller runner or longer runner you should pick a cam with a shorter duration to match the resulting lower torque peak that will likely result

Id like to point out something here!

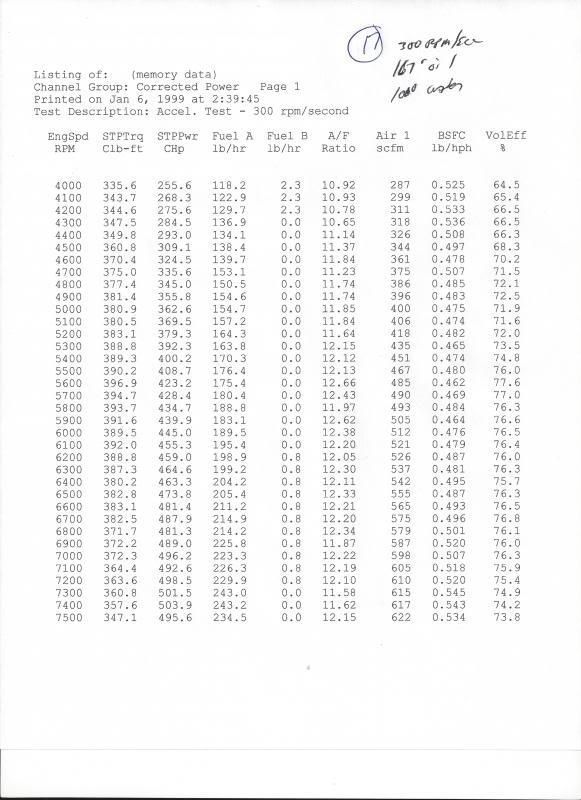

EXAMPLE (DYNO SHEET)

LOOK CLOSELY AT THE TORQUE CURVE

heres the combo

SBC 407

· Block, 509, +30, Zero deck, Blanked water passages, Clearanced oil ways, Lifter valley vents, ARP main & head studs, Durabond cam & Clevite 77 main bearings.

· Crank, Scat 4340 forged steel, 3.75â€Â, internal balance, Pioneer SFI balancer + ARP bolt.

· Rods, Comp. Products 6.00†H beam bronze bushed + ARP bolts Clevite 77 bearings.

· Pistons, SRP #4032 flat top, 5cc relief, Speed Pro plasma moly file fit rings.

· Complete rotating assembly balanced. Including - Flywheel, Clutch, Balancer & Crank pulley.

· Heads, AFR 210 Race Ready, 76cc, 2.080/1.600 valves, drilled for steam. FelPro #1014 gasket.

· Cam, Comp. Cams Magnum #12-450-8 (286HR) Hydraulic roller.

230/230 @ .050, .377 lift 110 LSA 106 ICL.

· Pushrods, Howards Cams heavy wall 5/16 7.4 long.

· Rockers, Pro Magnum roller, 1.6, 7/16 stud.

· Lifters, Pro Magnum hydraulic roller. AFR Hydr-Rev kit.

· Comp Cams Springs #950 + #740 retainers installed at 1.875

· AFR rev kit, AFR stud girdle.

· Lube, Melling M99HVS pump, Canton 7qt 5 trap pan with inbuilt windage and scraper, Cooler, Accumulator, oil stat, remote filter.

· Holley 800cfm #4780C, 1spacer, Victor Jr single plane.

· Static CR 10.32, Dynamic CR 7.9.

· Quench 0.0415 (Gasket .039+ .0025 down hole).

· MSD Pro Billet Street Dizzy, MSD 6AL, MSD Blaster 2 coil, MSD 8,5mm leads.

RPM BHP Torque

3800 367.3 507.7

3900 384.0 517.1

4000 395.1 518.8

4100 407.9 522.5

4200 418.9 523.8

4300 429.4 524.5

4400 439.6 524.7

4500 449.6 524.7

4600 462.1 527.6

4700 467.4 522.3

4800 476.6 521.5

4900 485.4 520.3

5000 489.2 513.9

5100 498.5 513.4

5200 496.0 501.0

5300 506.1 501.5

5400 508.4 494.5

5500 508.7 485.8

5600 505.6 474.2

5700 505.8 466.0

5800 505.8 458.0

5900 494.6 440.3

6000 491.9 430.6

Id like to point out something here to those of you who keep insisting that your required to run small ports sizes and dual plane intakes to make decent mid range torque

look closely at what the combo uses

Heads, AFR 210 Race Ready, 76cc, 2.080/1.600 valves, drilled for steam. FelPro #1014 gasket.

· Cam, Comp. Cams Magnum #12-450-8 (286HR) Hydraulic roller.

230/230 @ .050, .377 lift 110 LSA 106 ICL.

Holley 800cfm #4780C, 1 spacer, Victor Jr single plane

like IVE CONSTANTLY SAID, ITS THE CAM AND PROPERLY MATCHED COMPRESSION RATIO THAT HAS THE LARGEST EFFECT ON THE ENGINES TORQUE POTENTIAL, while its true that smaller ports can increase the volumetric efficiency at low rpms, they are not always required, and the tend to hurt the high rpm performance, you also don,t need a great deal of duration in the cam you pick,if the heads your useing flow decently, notice hes only running 230 @.050 lift

LARGE ports matched to the correct compression ratio and cam can make very good torque.

as always its the total combo OF PARTS and how the parts match the displacement and intended rpm range, NOT the result of a SINGLE PART choice!

if you want to build something responsive for street/strip use, these smaller 4 barrel carbs below ,make tuning easier on a car used mostly on the street

http://www.holley.com/0-8007.asp

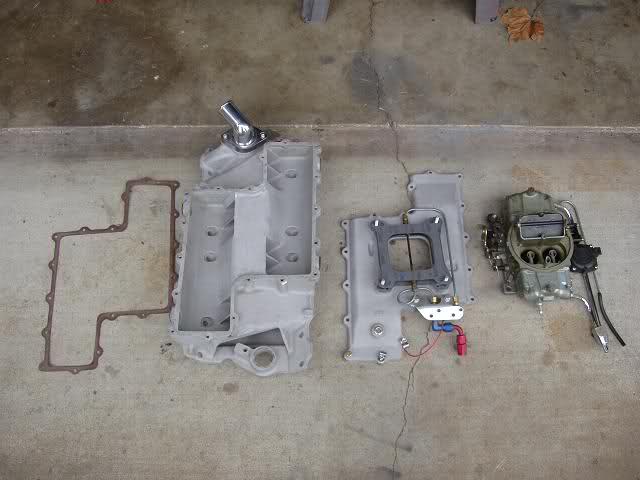

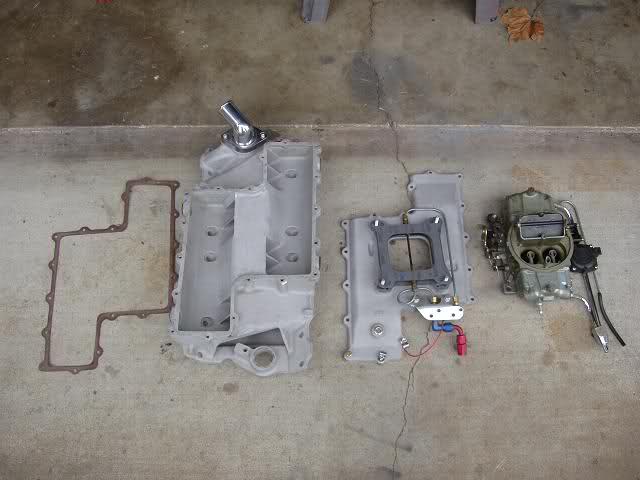

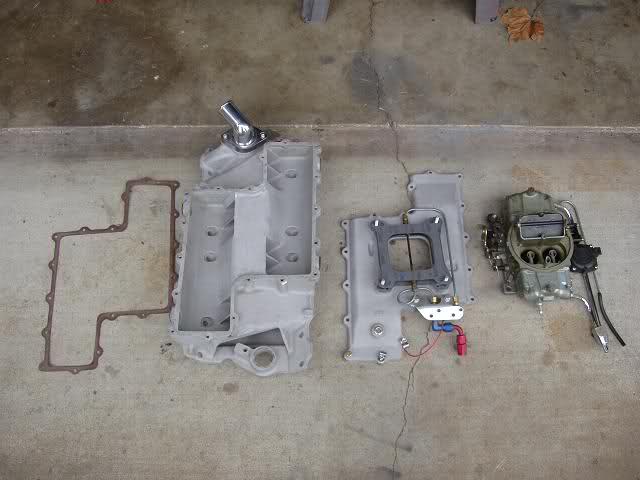

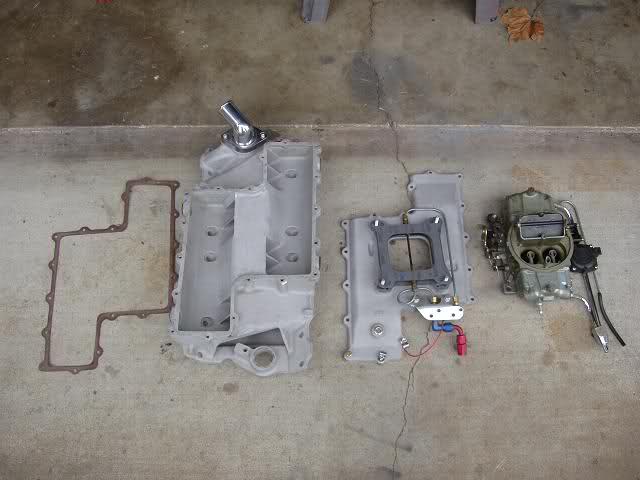

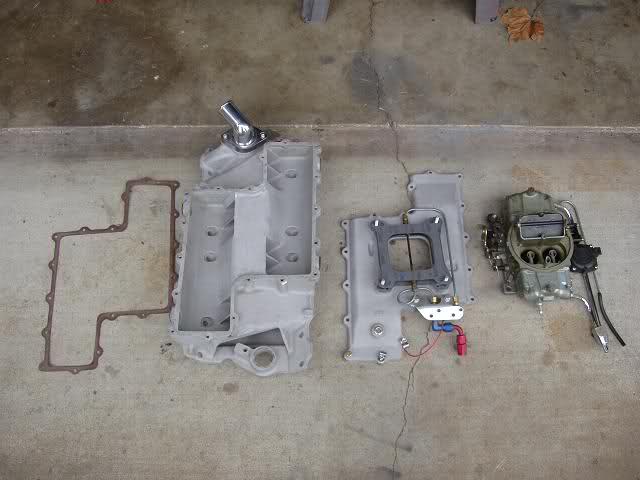

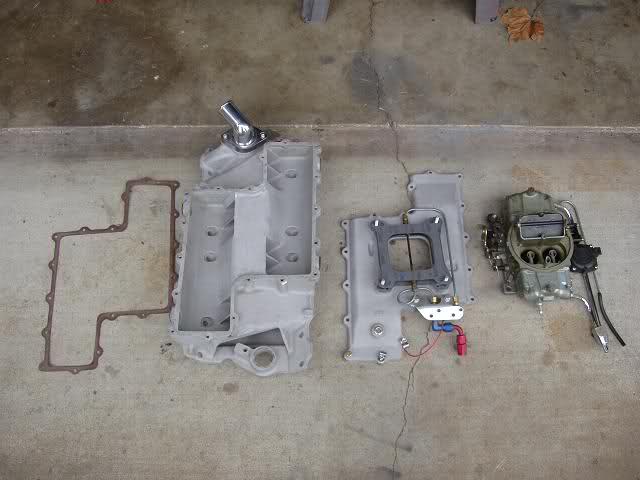

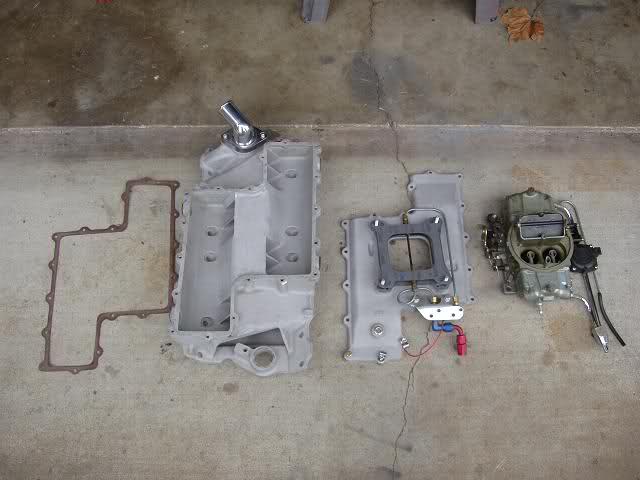

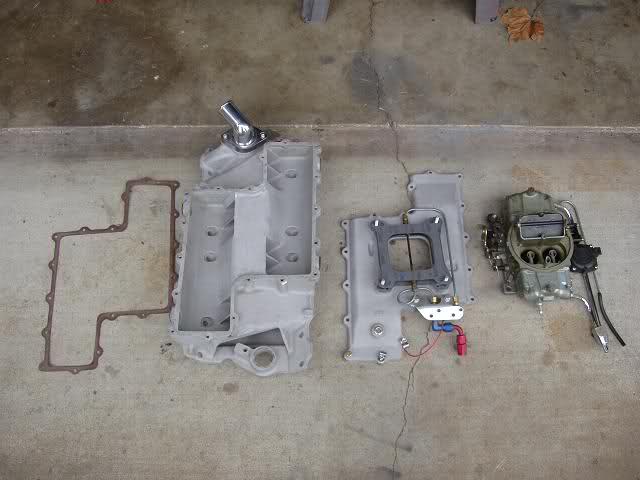

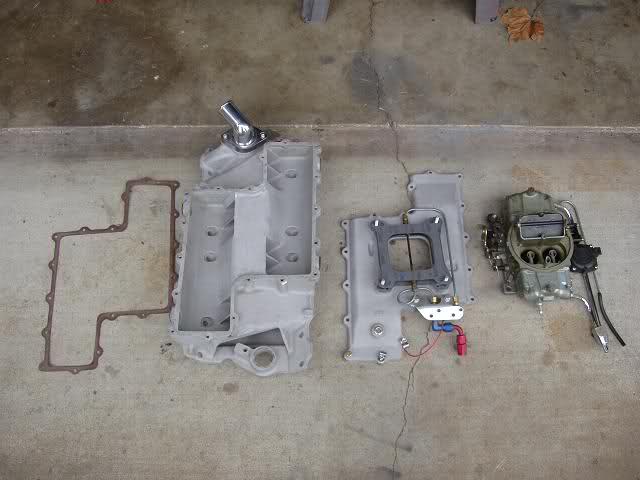

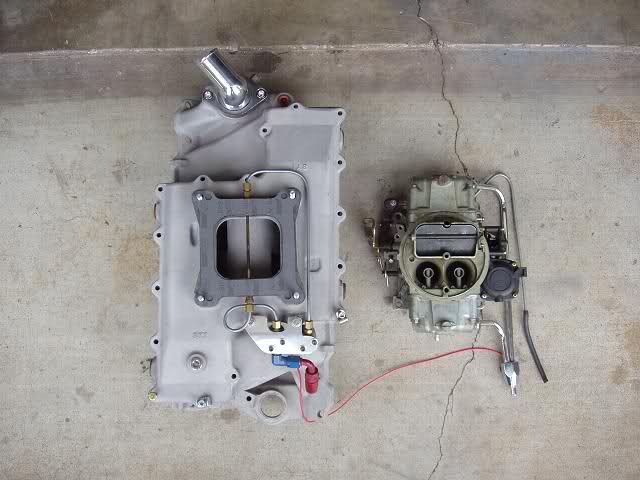

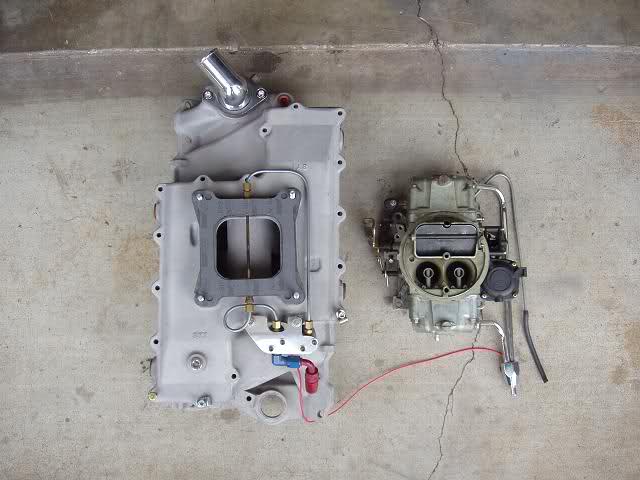

OFFY BELOW [/b]

http://www.grumpysperformance.com/ofy11.jpg

http://www.grumpysperformance.com/ofy22.jpg

http://www.grumpysperformance.com/manifoldmu1.jpg

http://www.grumpysperformance.com/manifoldcarbsrt0.jpg

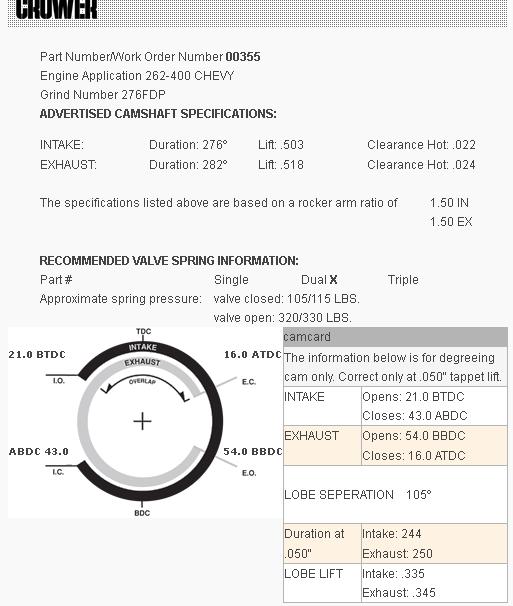

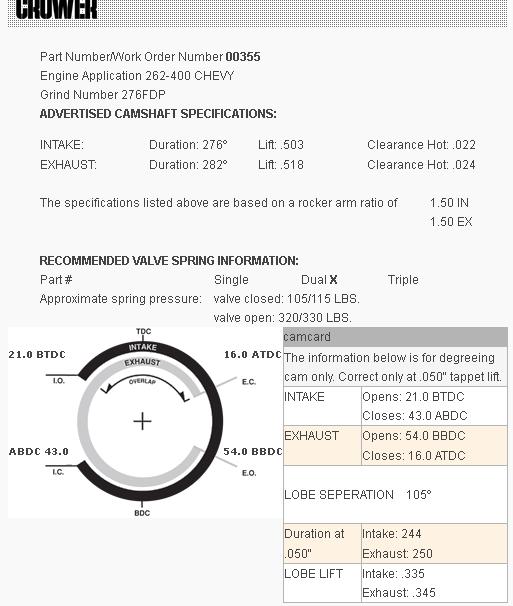

those intakes respond well to about 11:1 -12:1 compression and a crane 110921, or crower 00355 solid lifter cam ,and require a great set of cylinder heads and a low restriction exhaust, I generally ran 1.6:1 roller rockers and a manual transmission with 3.73:1-to-4.11:1 rear gears in a fairly light weight car

the basic power band in a 383 will be about 3700rpm-6300rpm. the combo won,t run well until about 3500rpm, but then hold on

If I was building one today ID

probable throw some 210cc profiler or AFR heads

http://www.profilerperformance.com/raci ... -23-degree

http://www.airflowresearch.com/index.php?cPath=24_33

viewtopic.php?f=55&t=3431&p=9088&hilit=crossram#p9088

viewtopic.php?f=44&t=623&p=834&hilit=+crossram#p834

http://www.grumpysperformance.com/crane110921.jpg

BTW the cam we used to get the best results with in the past on retro Z28 builds was a crane 110921 flat tappet solid lifter ,but the current roller cams would do even better, keep in mind that the cross-ram intake works best on a 350-406 with a cam and gearing that keeps the engine in the 3500rpm-7000rpm band, so both the cam and the intake design match that OPERATIONAL RPM BAND

and REQUIRES a decent set of high flow rate heads, (generally look for heads that reach or exceed 250cfm at .600 lift) with a matching 10.5:1-12.5:1 cpr and generally a 4.11:1-4.56:1 rear gear and manual transmission, when road racing, to operate correctly in its intended rpm band and flow rate. you could drop back to a 3.73:1-3.90:1 on a street car

[/color]

STR-10 BELOW

EDELBROCKS SBC CROSS RAM

http://www.camaro-untoldsecrets.com/art ... ossram.htm

SMOKEYRAM (SY1)BELOW

when they were easy to get at the local speed shops buying a smokey ram, installing a crane solid lifter flat tappet cam #110921in a 11:1 compression ratio, 377,383,406 SBC with a 750-780 cfm vacuum secondary arbitrator with decent long tube 1 3/4" headers and a low restriction exhaust, in a camaro, nova or vega engine swap car with a muncie 4 speed and a 3.90:1-4.33:1 rear gear was almost a mandatory combo back in the mid 70s if you wanted to kick butt and take names

when the first few SMOKEY RAM INTAKES WERE SOLD they found several distributors would not fully seat until the intake was notched to provide the required clearance, look closely at the intake above (an early version with no clearance notch) then the two below that had the notch machined

and you,ll never be the first guy to install a wet nitrous plate and a healthy ,longer duration solid lifter cam like a crane 110921 on a 383

SMOKEYRAM (SY1)BELOW

Ive had good results with a smokey ram with a 750 cfm holley and

Ive used the offanhauser cross-ram with several carb combinations

and gotten good results, Id generally prefer two 450-500 cfm carbs on the cross-ram but two 600 cfm would work just fine!

the important thing is carefully matching the throttles /linkage and maintaining a constant 5.5 psi of fuel pressure and Id sure prefer a fuel pump that would be rated to supply about 120-140 gph at 5 psi.

a crane 110921 flat tappet solid lifter cam,

decent heads that flow at least 250 cfm at .500 lift

(brodix IK 200 are popular) (as are 195 cc AFR)

http://www.jegs.com/i/Brodix/158/1021007/10002/-1

https://www.summitracing.com/parts/afr-1036/overview/

good 1.6:1 roller rockers,

long tube headers, a low restriction 3" dual exhaust, (obviously use premium gas)

on a 377-406 10.5:1 or higher compression SBC with the drive train differential gearing

(usually with a manual transmission) in the 4.11-4.33:1 range seems to work rather well

especially in a 3000 lb or lighter car, if you drive the car like the devil himself was after your soul and was only 100 yards behind you and gaining on every lap!(so it rarely drops below 3500-rpm and spends a good percentage of the time bouncing between 4500 rpm and 6500 rpm

USEFUL LINKS

http://garage.grumpysperformance.com/index.php?threads/yes-offys-still-around.1468/#post-6357

http://www.wallskid.com/c/small-block-chevy-cross-ram_|rKmBts5HrkD7LgWJ4o2CXBYhxN0k*|5qQiC0m3AGdg/

http://garage.grumpysperformance.com/index.php?threads/will-dual-quads-work-ok.5888/

http://garage.grumpysperformance.com/index.php?threads/the-cross-ram-intake.623/#post-834

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/

http://garage.grumpysperformance.com/index.php?threads/dual-quad.11867/

http://garage.grumpysperformance.com/index.php?threads/thinking-of-swapping-to-dual-quads.11709/

http://garage.grumpysperformance.com/index.php?threads/spark-plug-info.202/

http://garage.grumpysperformance.com/index.php?threads/verifying-your-real-advance-curve.4683/

http://garage.grumpysperformance.com/index.php?threads/reading-plugs.5428/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

OFFY BELOW

max stock spring lift clearance is about .470 lift,either of these cams works, both like 1.6:1 ratio rockers

the milder one is the better choice for a daily driver, the longer duration version gives slightly more peak hp but its also slightly less street traffic friendly

E110018K

specs>> 270/280 204/214 .420/.443 112 $111.72

buy now

E110020K

specs>> 275/278 209/216 .435/.455 112 $111.72

most of the SBC cross ram intakes share a common plenum, but there are several designs with a dual plenum , where each carburetor feeds the opposite bank of cylinders exclusively

http://www.pbm-erson.com/store.php?catId=334&parent=333&grandparent=327

http://www.camaro-untoldsecrets.com/art ... ossram.htm

viewtopic.php?f=87&t=2045

http://reviews.ebay.com/Cross-ram-manif ... 1:STORES:5

http://www.inglese.com/

http://www.kinsler.com/page--GM--17.html

http://force-efi.com/weber.htm

http://www.mooneyesusa.com/Store/index. ... 205077441a

the cross ram can be a challenge to tune correctly but they work great once correctly tweaked http://www.cranecams.com/index.php?show ... vl=2&prt=5

best with the manual trans and 4.11-4.56 rear gears in a light car.

you might find this interesting

http://www.camaros.org/crossram.shtml

viewtopic.php?f=87&t=8379&p=29224#p29224

http://www.camaro-untoldsecrets.com/art ... ossram.htm

the offy intakes still available and twin 600 cfm carbs tend to work great...but theres been lots of improvements in things like roller rockers and intakes since then, and a very similar built 383 is almost certainly going to be faster

http://www.camaro-untoldsecrets.com/art ... ossram.htm

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... t=OFY-5903

http://store.summitracing.com/partdetai ... t=OFY-5902

http://jobyteknik.homeip.net/corvette/2002-11_offy_installation/

viewtopic.php?f=86&t=1397

http://www.moparmusclemagazine.com/tech ... index.html

for a huge improvement in runner flow rates, yeah! it requires fabrication and a custom intake lid , if you want to convert it to efi but all the parts for carb use are easily available, but the results are far better flow than the stock CROSSFIRE crossram intake can ever provide

PORT SIZE FLOW AND THE RELATION TO CAM DURATION

FIRST, This will not be anything more that a brief glimpse into a subject that takes years to understand fully and Im sure there are a few people on the site that can give more exact info! This is meant to apply to the 350-383 sbc engines most of us are useing

My purpose is merely to give an idea as to the relationship between the factors and yes IM ignoring several minor factors to make things easier to understand like dynamic compression and valve timing overlap

But lets look a a few concepts

(1) There are 720 degrees in a 4 cycle engines repetitive cycle of which between about 200degrees to about 250 degrees actually allow air to pass into the cylinder, (the valves open far enough to flow meaningful air flow) and the piston has a maximum ability to draw air into that cylinder based mostly on the engines displacement and the inertia of column of air in both the intake port and the suction (or negative pressure the PROPERLY designed headers provide) this produced a max air flow thru the ports, the greater the volume of fuel/air mix effectively burn per power stroke the greater the engines potential torque production, the faster you spin an engine the greater the NUMBER OF POWER STROKES PER MINUTE, and up to the point where the cylinder filling effectiveness starts falling off due to not enough time available to fill that cylinder the torque increases, above that rpm or peak torque itss a race between more power stokes and lower power per stroke

(2) look at this diagram

(3)

As air enters an engine it normally travels thru both an intake system and the cylinder heads intake port to eventually pass into the cylinder thru the valve. The valves in a normal small block corvette engine are between 1.94 and 2.08 in diameter, thats between 2.9sq inches and 3.4 sq inches of area, but because the valves require a seat that at a minimum are about 85%-90% of that flow area we find that the intake port even with out any valve has a max flow of not more than about 90% of the flow thru a port of valve size. Or in this case 2.46 sq inches-2.9 sq inches of port area, Since you gain little if any flow having a port thats substantially larger than the valves AT NORMAL ATMOSPHERIC pressures and since you cant substantially increase the valve sizes for several mechanical reasons you must improve efficiency, this is done in two major ways, you can match the intake port length and cross sectional area to the engines most efficient rpm range on the intake side, to build a positive pressure behind the intake valve as it opens and match the exhaust length and diameter on the exhaust side to provide a negative pressure to help draw in more volume this will require the cam timing match that same rpm range of course. By experimentation its been found that air flow port speeds in the 200-320 cubic feet per minute range are about the best for a chevy V-8 now lets say you have a 383. 383/8=47.875 cubic inches per cylinder, the rpm range most used is 1500rpm-6000rpm so thats where are cam and port size must match, you can do the math , (47.875 x ½ engine rpms = cubic inches, divided by your cams effective flow duration, (use 210-235) as a default for a stock cam) x 720 degrees/1728 (the number of cubic inches in a cubic foot) to get the theoretical max port flow required (I will save you the trouble its 250cfm-275cfm at max rpms and about 2.4-2.9 sq inches of port cross section, depending on where you want the torque peak, or use this handy calculator,

Intake Runner Area = Cylinder Volume X Peak Torque RPM 88200

Or this helpful site

Either way youll find that youll want a port size in the 2.4sq “2.9 sq inch area

Now use this calculator to figure ideal port length, REMEMBER youll need to add the 6 in the cylinder head to the intake runner length to get the total length and you can,t exceed the engines REDLINE RPM which with hydrolic lifters seldom is higher than 6400rpm

http://www.bgsoflex.com/intakeln.html

Ever wonder why your engines torque curve gets higher with the engines rpm level until about 4000rpm-5500rpm(DEPENDING ON YOUR COMBO) but fades above that rpm level?

well it depends on several factors, first as long as the cylinders can fill completely you get a good fuel/air burn so you get a good cylinder pressure curve against the piston each time the cylinder fires, THE ENGINES TORQUE CURVE INCREASES WITH THE NUMBER OF EFFECTIVE POWER STROKES PER SECOND, at very low speeds theres not enough air velocity to mix the fuel correctly or produce a effective ram tuning effect but as the rpms increase the cylinders fill very efficiently until the rpms reach a point where the cylinders just dont have the time necessary to flow

enough air through the valves to fill the cylinders , remember a 5000rpm the intake valve out of 720 degs. in each cycle opens for about 250degs of effective flow even with a hot roller cam, now thats only about 35% of the time and theres 41.6 intake strokes per second , thats only 1/60th of a second for air to flow into the cylinder

Its your engines ability to fill the cylinders that increases your power and the more efficiently you do that the higher the rpm level you can accomplish that at the more power your engine makes, remember the formula for hp is (torque x rpm/ 5252=hp) so moving the torque curve higher in the rpm range increases hp but at some point the time available to fill the cylinders becomes so short that efficiency begins to drop off rapidly, the peak of efficiency is reached normally in the 4500rpm-5500rpm range, and as rpms increase its a race between more power strokes per minute trying to raise the power and the increasingly less effective percentage of cylinder filling dropping the power.

Volumetric Efficiency

The volumetric efficiency of a 4-stroke engine is the relationship between the quantity of intake air and the piston displacement. In other words, volumetric efficiency is the ratio between the charge that actually enters the cylinder and the amount that could enter under ideal conditions. Piston displacement is used since it is difficult to measure the amount of charge that would enter the cylinder under ideal conditions. An engine would have 100% volumetric efficiency if, at atmospheric pressure and normal temperature, an amount of air exactly equal to piston displacement could be drawn into the cylinder. This is not possible, except by supercharging, because the passages through which the air must flow offer a resistance, the force pushing the air into the cylinder is only atmospheric, and the air absorbs heat during the process. so, volumetric efficiency is determined by measuring (with an orifice or venturi type meter) the amount of air taken in by the engine, converting the amount to volume, and comparing this volume to the piston displacement.

this increases until the torque peak then falls as the rpms increase. Here is a rough guide to match duration to port flow at different rpm level

if youve been following along youll find that youll need intake ports about 2.3-2.9 sq inches in cross section, and between 12 and 21 long (DEPENDS ON WHERE THE ENGINE IS DESIGNED TO MAKE MAX HP) and cam timing in the 215@.050 to -240@.050 lift range, as the rpms or displacement increase either the port flow or the cams duration must increase or the engines cylinder fill efficiency rpm will drop!

Now this is important, as the port flow efficiency goes up though the use of longer and larger intake ports the cam duration could remain the same or even be lower and you get more efficient cylinder filling as the rpms increase, that’s why high efficiency port designs like on the LS1 can use lower duration cams to flow similar total air flow thru the ports than the lower efficiency ports like the old fuelie heads could but at some point all ports reach max flow and an increase in the time the valves remain open at higher rpms increases the cylinder fill efficiency and that increases the engines ability to make torque at that rpm range

if you pick a smaller runner or longer runner you should pick a cam with a shorter duration to match the resulting lower torque peak that will likely result

Id like to point out something here!

EXAMPLE (DYNO SHEET)

LOOK CLOSELY AT THE TORQUE CURVE

heres the combo

SBC 407

· Block, 509, +30, Zero deck, Blanked water passages, Clearanced oil ways, Lifter valley vents, ARP main & head studs, Durabond cam & Clevite 77 main bearings.

· Crank, Scat 4340 forged steel, 3.75â€Â, internal balance, Pioneer SFI balancer + ARP bolt.

· Rods, Comp. Products 6.00†H beam bronze bushed + ARP bolts Clevite 77 bearings.

· Pistons, SRP #4032 flat top, 5cc relief, Speed Pro plasma moly file fit rings.

· Complete rotating assembly balanced. Including - Flywheel, Clutch, Balancer & Crank pulley.

· Heads, AFR 210 Race Ready, 76cc, 2.080/1.600 valves, drilled for steam. FelPro #1014 gasket.

· Cam, Comp. Cams Magnum #12-450-8 (286HR) Hydraulic roller.

230/230 @ .050, .377 lift 110 LSA 106 ICL.

· Pushrods, Howards Cams heavy wall 5/16 7.4 long.

· Rockers, Pro Magnum roller, 1.6, 7/16 stud.

· Lifters, Pro Magnum hydraulic roller. AFR Hydr-Rev kit.

· Comp Cams Springs #950 + #740 retainers installed at 1.875

· AFR rev kit, AFR stud girdle.

· Lube, Melling M99HVS pump, Canton 7qt 5 trap pan with inbuilt windage and scraper, Cooler, Accumulator, oil stat, remote filter.

· Holley 800cfm #4780C, 1spacer, Victor Jr single plane.

· Static CR 10.32, Dynamic CR 7.9.

· Quench 0.0415 (Gasket .039+ .0025 down hole).

· MSD Pro Billet Street Dizzy, MSD 6AL, MSD Blaster 2 coil, MSD 8,5mm leads.

RPM BHP Torque

3800 367.3 507.7

3900 384.0 517.1

4000 395.1 518.8

4100 407.9 522.5

4200 418.9 523.8

4300 429.4 524.5

4400 439.6 524.7

4500 449.6 524.7

4600 462.1 527.6

4700 467.4 522.3

4800 476.6 521.5

4900 485.4 520.3

5000 489.2 513.9

5100 498.5 513.4

5200 496.0 501.0

5300 506.1 501.5

5400 508.4 494.5

5500 508.7 485.8

5600 505.6 474.2

5700 505.8 466.0

5800 505.8 458.0

5900 494.6 440.3

6000 491.9 430.6

Id like to point out something here to those of you who keep insisting that your required to run small ports sizes and dual plane intakes to make decent mid range torque

look closely at what the combo uses

Heads, AFR 210 Race Ready, 76cc, 2.080/1.600 valves, drilled for steam. FelPro #1014 gasket.

· Cam, Comp. Cams Magnum #12-450-8 (286HR) Hydraulic roller.

230/230 @ .050, .377 lift 110 LSA 106 ICL.

Holley 800cfm #4780C, 1 spacer, Victor Jr single plane

like IVE CONSTANTLY SAID, ITS THE CAM AND PROPERLY MATCHED COMPRESSION RATIO THAT HAS THE LARGEST EFFECT ON THE ENGINES TORQUE POTENTIAL, while its true that smaller ports can increase the volumetric efficiency at low rpms, they are not always required, and the tend to hurt the high rpm performance, you also don,t need a great deal of duration in the cam you pick,if the heads your useing flow decently, notice hes only running 230 @.050 lift

LARGE ports matched to the correct compression ratio and cam can make very good torque.

as always its the total combo OF PARTS and how the parts match the displacement and intended rpm range, NOT the result of a SINGLE PART choice!

if you want to build something responsive for street/strip use, these smaller 4 barrel carbs below ,make tuning easier on a car used mostly on the street

http://www.holley.com/0-8007.asp

OFFY BELOW [/b]

http://www.grumpysperformance.com/ofy11.jpg

http://www.grumpysperformance.com/ofy22.jpg

http://www.grumpysperformance.com/manifoldmu1.jpg

http://www.grumpysperformance.com/manifoldcarbsrt0.jpg

those intakes respond well to about 11:1 -12:1 compression and a crane 110921, or crower 00355 solid lifter cam ,and require a great set of cylinder heads and a low restriction exhaust, I generally ran 1.6:1 roller rockers and a manual transmission with 3.73:1-to-4.11:1 rear gears in a fairly light weight car

the basic power band in a 383 will be about 3700rpm-6300rpm. the combo won,t run well until about 3500rpm, but then hold on

If I was building one today ID

probable throw some 210cc profiler or AFR heads

http://www.profilerperformance.com/raci ... -23-degree

http://www.airflowresearch.com/index.php?cPath=24_33

viewtopic.php?f=55&t=3431&p=9088&hilit=crossram#p9088

viewtopic.php?f=44&t=623&p=834&hilit=+crossram#p834

http://www.grumpysperformance.com/crane110921.jpg

Last edited by a moderator: