BTW, if your looking to buy a welder ID strongly advise taking a course on welding FIRST, at a local trade school or welding equipment vendor,

(watch the videos, and be aware WELDING IS DANGEROUS, obviously you could electrocute yourself is you fail to think about safety issues

and some chemicals turn to poisonous gases when heated)

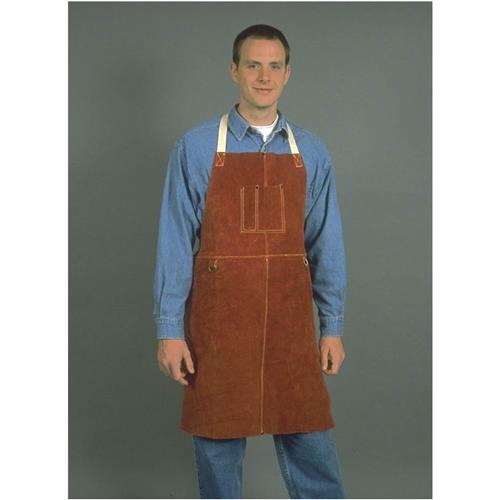

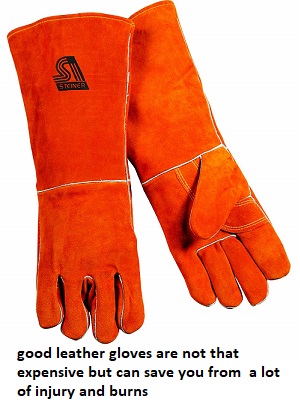

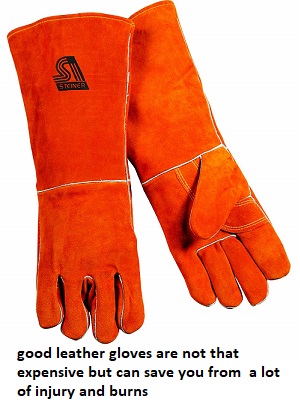

so you understand what your looking at and what to expect and so you have a good feel for what your looking to do and what equipment is necessary, and you darn well need the correct protective equipment,. like a face shield, long sleeve jacket gloves apron, shoes etc. If you have a local miller or lincoln welding dealer you may want to stop by and ask for advice, on both the correct welder best matching your intended uses and any auxiliary equipment or accessories and the type of gases, wire and settings that best match your application.

you might also want to ask if theres welding classes available locally,

yeah! Im always amazed at the number of guys that don,t think of the potential consequences,

vs the cost laid out , and select better quality over lower price,

and how spending a bit more on better quality,has advantages, in many

tools, or materials or safer working conditions, might prevent MAJOR injury

example, jack stands , floor jacks, fire extinguishers,exhaust fans, lighting in the shop,

car lifts , mechanics creepers, ratchet wrenches,and a few hundred other times when,

the less expensive options are far more likely to result in injury

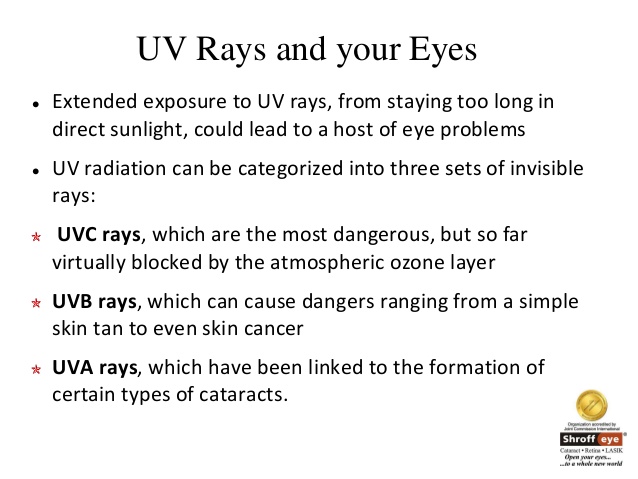

keep in mind your clothing your wearing and use of a face shield DO MATTER, don,t make the mistake of learning the hard way thru burns all electric welding gives off some radiation and your very likely to get a sun burn or eye damage or worse without at least a decent face shield, (the better self darkening designs with adjustable shading are preferred, and use prescription sun glasses not contact lens,under the self darkening hood, when welding if you need corrective lenses) and use long pants and a long sleeve shirt, and two layers of something semi substantial like denim or leather are better than a single layer, but even then a leather apron and shirt , over those under-layers helps prevent radiation burns obviously some clothing is superior to others, in protection, and resistance to burning, so don,t take your new welder home and start welding without proper protection.

www.everlastgenerators.com

don,t forget to buy a decent self darkening helmet, welders jacket and gloves, fire extinguisher

www.everlastgenerators.com

don,t forget to buy a decent self darkening helmet, welders jacket and gloves, fire extinguisher

yes theres a reason tanks need to be tested every few years, a failure can be LETHAL

http://store.cyberweld.com/leatweljac.html

wear long sleeves, and high collar, (of thick material like leather, denim ,canvas and leather or canvas gloves, the radiation will cause surface burns on exposed skin,and yes you need a face shield

https://www.amazon.com/gp/product/B...page?ie=UTF8&psc=1&tag=yellowbulletconvert-20

http://www.harborfreight.com/blue-flame ... 91214.html

yes the HF self darkening hoods work, but there are far better quality hoods available

https://toolsforwelding.com/badass-welding-hoods-helmets-masks/

BTW if your looking for a light duty mig that will weld up to 3/16" millers got this on sale

and it will do about 80% of the automotive welding that most guys get into,

but keep in mind, when you purchase a MIG welder you still need a shield gas tank ,gauges , mig wire, a face shield etc, with any welder so that price of the welder alone is not all inclusive

http://www.welders-direct.com/mm5/merchant.mvc?Store_Code=WD&Screen=PROD&Product_Code=907692

120 volt feed $549

I know a couple guys who bought these lincoln mig welders and they find they have zero complaints, but then , keep in mind I find that, its almost universal, that unless you do a good bit of welding on a nearly constant basis, with several different welders, and know what your looking at when the welds are done, youll tend to think darn near any welder you own is doing a decent job regardless of reality, simply because youve got little to use as a comparison.

http://www.welders-direct.com/mm5/m...Code=WD&Product_Code=K2473-2&Category_Code=MW

230 volt feed $878

yes I admit Im a tool junky but after using a buddies 252 miller I saved up for over a year to get one, yes I rarely use it to near its max capacity but keep in mind duty cycle limitations are nearly something you can ignore on most welding

http://www.welders-direct.com/mm5/m..._Code=WD&Product_Code=907321&Category_Code=MW

230 volt feed $2450

normally $59.99 for $39.99 limit 1

http://store.cyberweld.com/welhelandgog.html

YES A MILLER SPEED GLASS HELMET IS HIGHER QUALITY< AND WORTH THE COST< YOU ONLY HAVE ONE SET OF EYES< BUT IF YOU RARELY WELD THE HF HELMET WORKS FAR BETTER THAN THE PRICE MIGHT LEAD YOU TO BELIEVE

http://store.cyberweld.com/welhelandgog.html

http://www.harborfreight.com/adjustable ... 46526.html

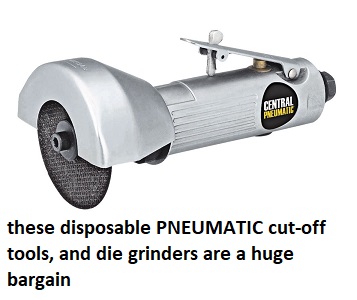

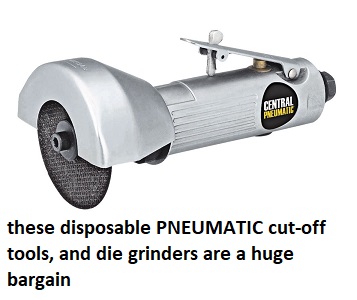

any time your working around power tools especially cutting tools a face shield is a good idea, cutting discs on die grinders and similar tools can shatter UN-expectedly with painful results

http://www.lowes.com/pd_190724-47120-SG ... ueryType=1

a few suggestions

http://www.tuffrhino.com/MIG_WEAR_FR_We ... fr1025.htm

http://www.grizzly.com/products/Leather ... -Bib/H7435

http://www.toughweld.com/products/4225- ... hide-apron

http://www.grizzly.com/products/Leather ... t-XL/H9888

http://www.harborfreight.com/adjustable ... 46092.html

http://www.harborfreight.com/1-pair-fir ... 41054.html

http://www.bing.com/shopping/keepsafe-w ... ORM=CMSMEE

then after your at least familiar with what your looking at and for, stop by a few large welding shops and ask the owner if hes ever considered upgrading his equipment? stop by a few welder dealers and ask about trade ins.?

most will jump at the chance to unload older equipment if given a reasonable offer, the TRICK is knowing EXACTLY what your looking at, having a good idea as to age and condition and value and getting a DEAL, Id generally avoid anything priced higher than 1/2-1/3 of current retail.

thats one great reason , on an endless list of reasons to own,

and know how to use a a decent quality MIG or TIG welder,

I don,t see how anyone in this hobby can function,

without a decent welder , drill press and a decent tool chest

youll gain a great deal of experience and skill with the welder as you practice,

and youll eventually find a die grinder and carbide cut-off wheel handy for removing ,

the minor welds in that progress youll have made.

https://www.harborfreight.com/3-in-high-speed-air-cut-off-tool-60243.html

https://www.harborfreight.com/3-in-...el-10-pc-61180.html?_br_psugg_q=cut+off+wheel

we have a whole welding section

http://garage.grumpysperformance.com/index.php?forums/welding-tips-and-welders.60/

https://www.eastwood.com/welders/mig-welders.html

https://store.cyberweld.com/millerw...MI5IS68_L23QIVHbjACh3lSA4REAAYASAAEgI64_D_BwE

https://www.lincolnelectric.com/en-us/equipment/Pages/welders.aspx

https://www.weldersupply.com/C/42/TigMachines

READ THIS

viewtopic.php?f=27&t=81

viewtopic.php?f=27&t=26&p=34#p34

http://www.weldfabulous.com/Welders/c195588/

http://www.welders-direct.com/

check with your local welding supply store

http://www.davencorp.tv/store/viewitem.php?productid=15

but be fair! include all the accessories in your bid!

look around your local area for the guy or guys that do welder repairs, they can very often get you a decent deal on a used welder or point you to someone whos looking to upgrade their current equipment that you might be able to make a good deal for on their older equipment.

just stick to name brands , and ID STRONGLY ADVISE STICKING TO WELDERS that REQUIRE a 220volt single phase electrical feed

lincoln

miller

ESAB

HOBART

HTP

THERMADYNE

because having access to parts and service and manuals is MANDATORY

if you do buy equipment that's USED ask for a demonstration on BOTH the thin sheet metal like patching a fender and exhaust pipes and thicker 1/4-3/8" thick stuff

A good welder can USUALLY get the job done using cheap equipment. A bad welder will screw it up using the best equipment money can buy. BUT Good equipment helps and its a bigger help to the inexperienced then to the journeyman.

THAT'S VERY TRUE UP to a point, and that point is reached when the amps are not available to drive the heat fast and deep enough to get the job done correctly, you can,t just go over and over a spot and get a good result.

YOU don,t need to spend a ton of cash either, but YOU DO NEED to know the differences and advantages and characteristics of welders so ID strongly advise taking a welding course at a local college or night school a trade school etc. before spending your cash as its sure to pay off in much better choices being made.

HERES THE MIG I PURCHASED

MILLER 252

http://www.welders-direct.com/mm5/merch ... gory_Code=

FOR MY SHOP, (IT COST $2200) IT HAS AN OPTIONAL KIT THAT WILL ALLOW YOU TO MIG ALUMINUM< BUT ITS RATHER EXPENSIVE

(about $1100)

http://www.welders-direct.com/mm5/merch ... ode=130831

but its a TOP QUALITY MIG THAT WILL HANDLE 95% OF AUTOMOTIVE WELDING IF YOU GET THE OPTIONAL KIT

DON,t forget the welder requires a MATCHED electrical feed in your garage and it may require a tank of shield gas and may require accessories or longer cords, and consumables like wire for MIG units or sticks of filler rod for stick or tig welders, all those things add up fast!

every application has its ideal tool and you'll be better off taking a welding class at some college or trade school or finding some friends who have experience and welders to play with BEFORE making a choice than just blindly buying ANY welder

BUT LIKE I SUGGESTED THE SMART ROUTE is to take a class at a local trade school or college and know what your doing and what you want BEFORE buying a welder

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

YOU DON,T NEED SOMETHING LIKE THIS BUT ITS GREAT TO PLAY WITHI think youll be much happier with a name brand 220 volt 180-210 amp mig for your shop in the long run,

lincoln

miller

ESAB

HOBART

HTP

THERMADYNE

ALL have decent examples

Id ask several welding shops in YOUR area for advice as to the BRAND and DEALERS who supply the best SUPPORT in YOUR AREA

...YES you do generally get what you pay for in features and quality, so look into features, duty cycles and warranty's, service/support

BTW HAVE A GOOD FIRE EXTINGUISHER HANDY, and it helps to have a buddy with you to hold stuff, get stuff and put out minor fires you don,t see instantly with a hood on, and while most of this is OBVIOUS to the more experienced guys, try not to weld where its wet, or you near anything that can easily burn, and youll need to wear the correct gear and use common sense while welding

at a minimum wear a NON-SYNTHETIC ,(many synthetics melt instantly or are very flammable) VS (cotton, denim, and leather don,t generally flare or burn instantly ), wear long DENIM sleeve shirts, long leg slacks and sturdy leather boots,(cleated thick rubber soles that insulate helps) with the DENIM slacks OVER the boots not tucked loosely into open tops like cowboy boots and a use self darkening helmet, and wearing leather welders gloves and a reversed cotton baseball cap sure won,t hurt if your doing a good deal of welding, simply because YOU WILL EVENTUALLY get radiation burns (fairly quickly from the arc/flash of welding if you don,t ) on exposed skin,

(think of this as a bad sun burn, OR WORSE, that can happen in minutes in some cases) and repeated exposure too radiation burns is never a good idea.

and welders tend to create HEAT, sparks and falling bits of red hot metallic crud that makes sandals, short sleeve shirts and shorts a very dumb idea in most cases. keep a DECENT SIZE CO2 fire extinguisher handy, and a water hose with a spray nozzle that pressurized kept near by is a good idea.

never weld over your head if you can move the part to where you can weld at bench ;level, yeah! it takes longer to remove and install the parts like exhausts or mufflers and yeah! its not always practical, but both safety and weld quality benefit, so if you have the option weld on a bench vs the car!

THINK! before welding, HOT stuff falling on tender bits of your anatomy or starting the car on fires seldom FUN, and clamps, use of a barrier for shielding the stuff near the weld location with a wet towel or sheet of galvanized metal , use a GREAT GROUND, or in rare cases flowing water , it is only common sense, but be aware that you can also get ELECTROCUTED if your REALLY DUMB, SO THINK IT THRU BEFORE you start, have a buddy help, and know what your doing, before you get in over your skill/knowledge level

if your using an oxy-acetylene torch, make DAMN SURE the tanks are turned off before putting them away,and the fittings are tight and nothings leaking before use,and be sure local laws don,t prohibit you from home use of a oxy-acetylene welder

http://www.denimexpress.com/

http://www.tuffrhino.com/Welders_Clothing_s/61.htm?Click=20&source=google&segment=productpage&paidKeyword=welders pants&adVariation=6&gclid=CN7B8IuV0o0CFQyPYAodPEEPZA

https://weldingsupply.securesites.com/cgi-bin/einstein.pl?Next::1:UNDEF:OR:terms::PS

https://www.millerwelds.com/equipment/welders/stick-smaw

BTW at this point you might be wondering if the time effort and expense is worth it in acquiring and learning to use a welder ,,,I have yet to meet a dedicated & experienced HOT RODDER who doesn,t think his welder is almost a mandatory part of the shop, they will easily pay for themselves in most shops in under a year, and some times in MUCH less time....

EXAMPLE

Ive seen guys fabricate custom exhaust systems from 3" stainless that would easily cost $2000 plus at most muffler shops for under $700 in parts , Ive built custom transmission mounts for $45 that listed for over $200 in catalogs, etc.

(watch the videos, and be aware WELDING IS DANGEROUS, obviously you could electrocute yourself is you fail to think about safety issues

and some chemicals turn to poisonous gases when heated)

so you understand what your looking at and what to expect and so you have a good feel for what your looking to do and what equipment is necessary, and you darn well need the correct protective equipment,. like a face shield, long sleeve jacket gloves apron, shoes etc. If you have a local miller or lincoln welding dealer you may want to stop by and ask for advice, on both the correct welder best matching your intended uses and any auxiliary equipment or accessories and the type of gases, wire and settings that best match your application.

you might also want to ask if theres welding classes available locally,

yeah! Im always amazed at the number of guys that don,t think of the potential consequences,

vs the cost laid out , and select better quality over lower price,

and how spending a bit more on better quality,has advantages, in many

tools, or materials or safer working conditions, might prevent MAJOR injury

example, jack stands , floor jacks, fire extinguishers,exhaust fans, lighting in the shop,

car lifts , mechanics creepers, ratchet wrenches,and a few hundred other times when,

the less expensive options are far more likely to result in injury

keep in mind your clothing your wearing and use of a face shield DO MATTER, don,t make the mistake of learning the hard way thru burns all electric welding gives off some radiation and your very likely to get a sun burn or eye damage or worse without at least a decent face shield, (the better self darkening designs with adjustable shading are preferred, and use prescription sun glasses not contact lens,under the self darkening hood, when welding if you need corrective lenses) and use long pants and a long sleeve shirt, and two layers of something semi substantial like denim or leather are better than a single layer, but even then a leather apron and shirt , over those under-layers helps prevent radiation burns obviously some clothing is superior to others, in protection, and resistance to burning, so don,t take your new welder home and start welding without proper protection.

Welders, Plasma Cutters, Welding Products - Everlast

Welding products for the professional or hobbyist. Everlast Power Equipments full line of welders, welding products and generators will help you complete any welding project.

yes theres a reason tanks need to be tested every few years, a failure can be LETHAL

http://store.cyberweld.com/leatweljac.html

wear long sleeves, and high collar, (of thick material like leather, denim ,canvas and leather or canvas gloves, the radiation will cause surface burns on exposed skin,and yes you need a face shield

https://www.amazon.com/gp/product/B...page?ie=UTF8&psc=1&tag=yellowbulletconvert-20

http://www.harborfreight.com/blue-flame ... 91214.html

yes the HF self darkening hoods work, but there are far better quality hoods available

https://toolsforwelding.com/badass-welding-hoods-helmets-masks/

BTW if your looking for a light duty mig that will weld up to 3/16" millers got this on sale

and it will do about 80% of the automotive welding that most guys get into,

but keep in mind, when you purchase a MIG welder you still need a shield gas tank ,gauges , mig wire, a face shield etc, with any welder so that price of the welder alone is not all inclusive

http://www.welders-direct.com/mm5/merchant.mvc?Store_Code=WD&Screen=PROD&Product_Code=907692

120 volt feed $549

I know a couple guys who bought these lincoln mig welders and they find they have zero complaints, but then , keep in mind I find that, its almost universal, that unless you do a good bit of welding on a nearly constant basis, with several different welders, and know what your looking at when the welds are done, youll tend to think darn near any welder you own is doing a decent job regardless of reality, simply because youve got little to use as a comparison.

http://www.welders-direct.com/mm5/m...Code=WD&Product_Code=K2473-2&Category_Code=MW

230 volt feed $878

yes I admit Im a tool junky but after using a buddies 252 miller I saved up for over a year to get one, yes I rarely use it to near its max capacity but keep in mind duty cycle limitations are nearly something you can ignore on most welding

http://www.welders-direct.com/mm5/m..._Code=WD&Product_Code=907321&Category_Code=MW

230 volt feed $2450

normally $59.99 for $39.99 limit 1

http://store.cyberweld.com/welhelandgog.html

YES A MILLER SPEED GLASS HELMET IS HIGHER QUALITY< AND WORTH THE COST< YOU ONLY HAVE ONE SET OF EYES< BUT IF YOU RARELY WELD THE HF HELMET WORKS FAR BETTER THAN THE PRICE MIGHT LEAD YOU TO BELIEVE

AZ Light Speed said:Something else to consider with auto darkening helmets is, how many and where are the sensors located.

Over my 30 years as a TIG welder I have use several different auto darkening helmets. A lot of the welding would be classified as out of position welding. The placement of the sensors is more important, because it doesn't matter how fast the lens reacts if the sensor keep getting blocked by your hand, the torch, clamps or anything else and it keeps turn on and off while your welding.

The helmets that have more sensors are better, you want at least four sensors one at each corner of the lens, so it wont matter if your looking up or down, or left or right. Was flashed more times with helmets with only two sensors than any thing else. I use a Miller Elite. Money well spent as you only get one set of eyes.

http://store.cyberweld.com/welhelandgog.html

http://www.harborfreight.com/adjustable ... 46526.html

any time your working around power tools especially cutting tools a face shield is a good idea, cutting discs on die grinders and similar tools can shatter UN-expectedly with painful results

http://www.lowes.com/pd_190724-47120-SG ... ueryType=1

a few suggestions

http://www.tuffrhino.com/MIG_WEAR_FR_We ... fr1025.htm

http://www.grizzly.com/products/Leather ... -Bib/H7435

http://www.toughweld.com/products/4225- ... hide-apron

http://www.grizzly.com/products/Leather ... t-XL/H9888

http://www.harborfreight.com/adjustable ... 46092.html

http://www.harborfreight.com/1-pair-fir ... 41054.html

http://www.bing.com/shopping/keepsafe-w ... ORM=CMSMEE

then after your at least familiar with what your looking at and for, stop by a few large welding shops and ask the owner if hes ever considered upgrading his equipment? stop by a few welder dealers and ask about trade ins.?

most will jump at the chance to unload older equipment if given a reasonable offer, the TRICK is knowing EXACTLY what your looking at, having a good idea as to age and condition and value and getting a DEAL, Id generally avoid anything priced higher than 1/2-1/3 of current retail.

thats one great reason , on an endless list of reasons to own,

and know how to use a a decent quality MIG or TIG welder,

I don,t see how anyone in this hobby can function,

without a decent welder , drill press and a decent tool chest

youll gain a great deal of experience and skill with the welder as you practice,

and youll eventually find a die grinder and carbide cut-off wheel handy for removing ,

the minor welds in that progress youll have made.

https://www.harborfreight.com/3-in-high-speed-air-cut-off-tool-60243.html

https://www.harborfreight.com/3-in-...el-10-pc-61180.html?_br_psugg_q=cut+off+wheel

we have a whole welding section

http://garage.grumpysperformance.com/index.php?forums/welding-tips-and-welders.60/

https://www.eastwood.com/welders/mig-welders.html

https://store.cyberweld.com/millerw...MI5IS68_L23QIVHbjACh3lSA4REAAYASAAEgI64_D_BwE

https://www.lincolnelectric.com/en-us/equipment/Pages/welders.aspx

https://www.weldersupply.com/C/42/TigMachines

READ THIS

viewtopic.php?f=27&t=81

viewtopic.php?f=27&t=26&p=34#p34

http://www.weldfabulous.com/Welders/c195588/

http://www.welders-direct.com/

check with your local welding supply store

http://www.davencorp.tv/store/viewitem.php?productid=15

but be fair! include all the accessories in your bid!

look around your local area for the guy or guys that do welder repairs, they can very often get you a decent deal on a used welder or point you to someone whos looking to upgrade their current equipment that you might be able to make a good deal for on their older equipment.

just stick to name brands , and ID STRONGLY ADVISE STICKING TO WELDERS that REQUIRE a 220volt single phase electrical feed

lincoln

miller

ESAB

HOBART

HTP

THERMADYNE

because having access to parts and service and manuals is MANDATORY

if you do buy equipment that's USED ask for a demonstration on BOTH the thin sheet metal like patching a fender and exhaust pipes and thicker 1/4-3/8" thick stuff

A good welder can USUALLY get the job done using cheap equipment. A bad welder will screw it up using the best equipment money can buy. BUT Good equipment helps and its a bigger help to the inexperienced then to the journeyman.

THAT'S VERY TRUE UP to a point, and that point is reached when the amps are not available to drive the heat fast and deep enough to get the job done correctly, you can,t just go over and over a spot and get a good result.

YOU don,t need to spend a ton of cash either, but YOU DO NEED to know the differences and advantages and characteristics of welders so ID strongly advise taking a welding course at a local college or night school a trade school etc. before spending your cash as its sure to pay off in much better choices being made.

HERES THE MIG I PURCHASED

MILLER 252

http://www.welders-direct.com/mm5/merch ... gory_Code=

FOR MY SHOP, (IT COST $2200) IT HAS AN OPTIONAL KIT THAT WILL ALLOW YOU TO MIG ALUMINUM< BUT ITS RATHER EXPENSIVE

(about $1100)

http://www.welders-direct.com/mm5/merch ... ode=130831

but its a TOP QUALITY MIG THAT WILL HANDLE 95% OF AUTOMOTIVE WELDING IF YOU GET THE OPTIONAL KIT

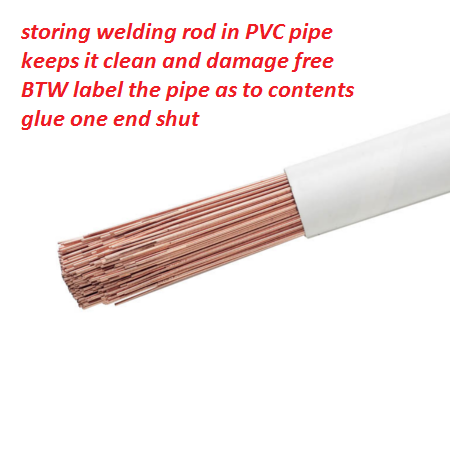

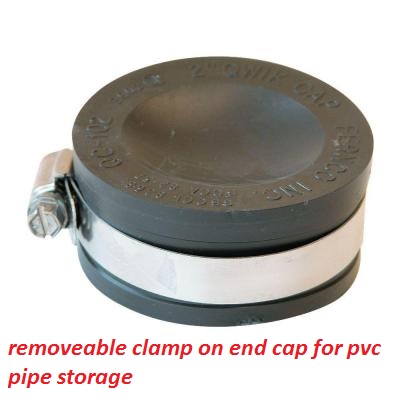

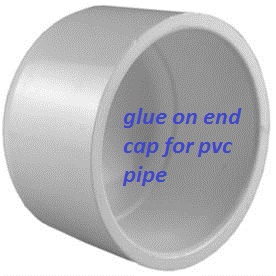

DON,t forget the welder requires a MATCHED electrical feed in your garage and it may require a tank of shield gas and may require accessories or longer cords, and consumables like wire for MIG units or sticks of filler rod for stick or tig welders, all those things add up fast!

every application has its ideal tool and you'll be better off taking a welding class at some college or trade school or finding some friends who have experience and welders to play with BEFORE making a choice than just blindly buying ANY welder

BUT LIKE I SUGGESTED THE SMART ROUTE is to take a class at a local trade school or college and know what your doing and what you want BEFORE buying a welder

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-31684

YOU DON,T NEED SOMETHING LIKE THIS BUT ITS GREAT TO PLAY WITHI think youll be much happier with a name brand 220 volt 180-210 amp mig for your shop in the long run,

lincoln

miller

ESAB

HOBART

HTP

THERMADYNE

ALL have decent examples

Id ask several welding shops in YOUR area for advice as to the BRAND and DEALERS who supply the best SUPPORT in YOUR AREA

...YES you do generally get what you pay for in features and quality, so look into features, duty cycles and warranty's, service/support

BTW HAVE A GOOD FIRE EXTINGUISHER HANDY, and it helps to have a buddy with you to hold stuff, get stuff and put out minor fires you don,t see instantly with a hood on, and while most of this is OBVIOUS to the more experienced guys, try not to weld where its wet, or you near anything that can easily burn, and youll need to wear the correct gear and use common sense while welding

at a minimum wear a NON-SYNTHETIC ,(many synthetics melt instantly or are very flammable) VS (cotton, denim, and leather don,t generally flare or burn instantly ), wear long DENIM sleeve shirts, long leg slacks and sturdy leather boots,(cleated thick rubber soles that insulate helps) with the DENIM slacks OVER the boots not tucked loosely into open tops like cowboy boots and a use self darkening helmet, and wearing leather welders gloves and a reversed cotton baseball cap sure won,t hurt if your doing a good deal of welding, simply because YOU WILL EVENTUALLY get radiation burns (fairly quickly from the arc/flash of welding if you don,t ) on exposed skin,

(think of this as a bad sun burn, OR WORSE, that can happen in minutes in some cases) and repeated exposure too radiation burns is never a good idea.

and welders tend to create HEAT, sparks and falling bits of red hot metallic crud that makes sandals, short sleeve shirts and shorts a very dumb idea in most cases. keep a DECENT SIZE CO2 fire extinguisher handy, and a water hose with a spray nozzle that pressurized kept near by is a good idea.

never weld over your head if you can move the part to where you can weld at bench ;level, yeah! it takes longer to remove and install the parts like exhausts or mufflers and yeah! its not always practical, but both safety and weld quality benefit, so if you have the option weld on a bench vs the car!

THINK! before welding, HOT stuff falling on tender bits of your anatomy or starting the car on fires seldom FUN, and clamps, use of a barrier for shielding the stuff near the weld location with a wet towel or sheet of galvanized metal , use a GREAT GROUND, or in rare cases flowing water , it is only common sense, but be aware that you can also get ELECTROCUTED if your REALLY DUMB, SO THINK IT THRU BEFORE you start, have a buddy help, and know what your doing, before you get in over your skill/knowledge level

if your using an oxy-acetylene torch, make DAMN SURE the tanks are turned off before putting them away,and the fittings are tight and nothings leaking before use,and be sure local laws don,t prohibit you from home use of a oxy-acetylene welder

http://www.denimexpress.com/

http://www.tuffrhino.com/Welders_Clothing_s/61.htm?Click=20&source=google&segment=productpage&paidKeyword=welders pants&adVariation=6&gclid=CN7B8IuV0o0CFQyPYAodPEEPZA

https://weldingsupply.securesites.com/cgi-bin/einstein.pl?Next::1:UNDEF:OR:terms::PS

https://www.millerwelds.com/equipment/welders/stick-smaw

BTW at this point you might be wondering if the time effort and expense is worth it in acquiring and learning to use a welder ,,,I have yet to meet a dedicated & experienced HOT RODDER who doesn,t think his welder is almost a mandatory part of the shop, they will easily pay for themselves in most shops in under a year, and some times in MUCH less time....

EXAMPLE

Ive seen guys fabricate custom exhaust systems from 3" stainless that would easily cost $2000 plus at most muffler shops for under $700 in parts , Ive built custom transmission mounts for $45 that listed for over $200 in catalogs, etc.

Last edited by a moderator: