I get asked rather frequently ABOUT BUILDING LARGER DISPLACEMENT big block engines (MOSTLY CHEVY) AND I figured I'd point out a couple common thoughts and concepts, limitations etc.

its just a fact that you can generally produce a bit over 1-1.3 horse power per cubic inch of displacement in most chevy V8 engines

if you have selected and built one the better combos and select parts carefully you can do far better than that!

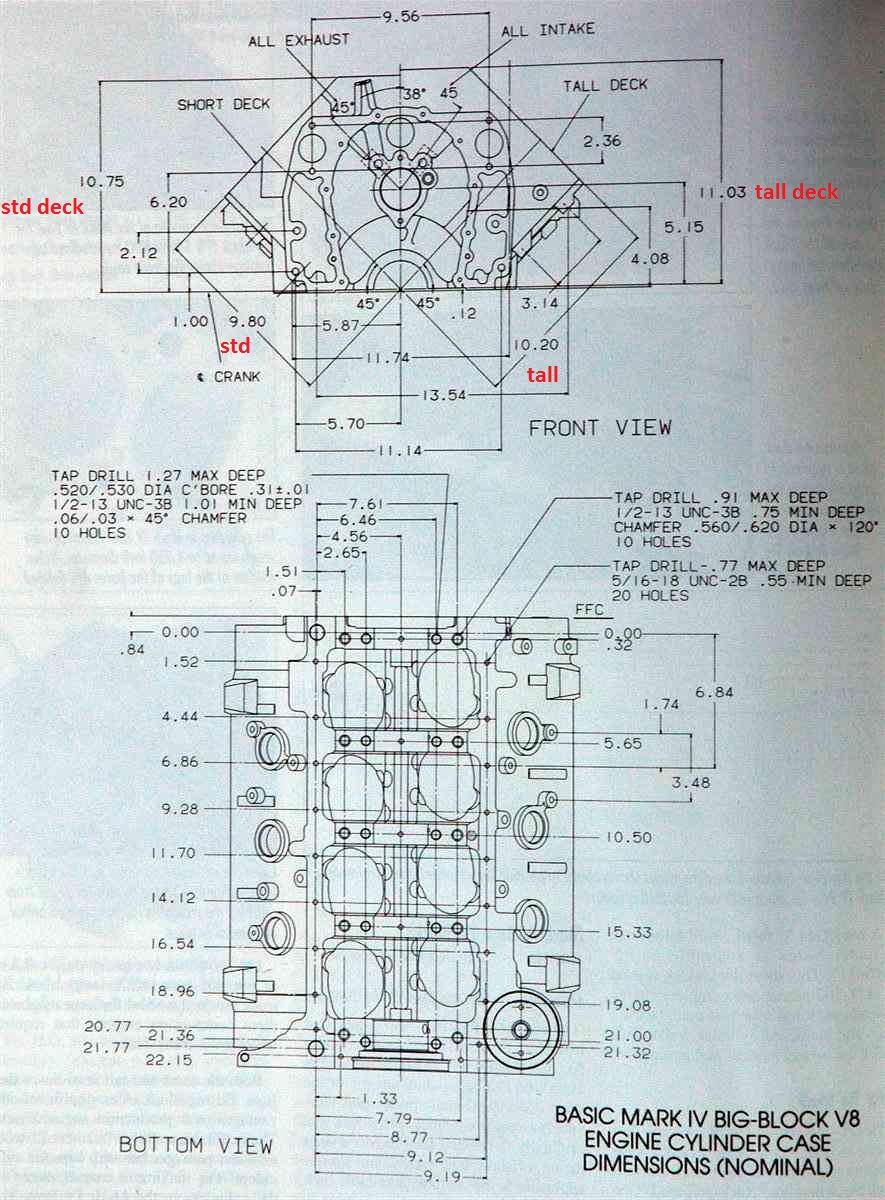

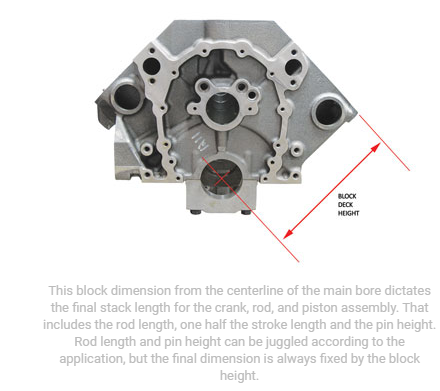

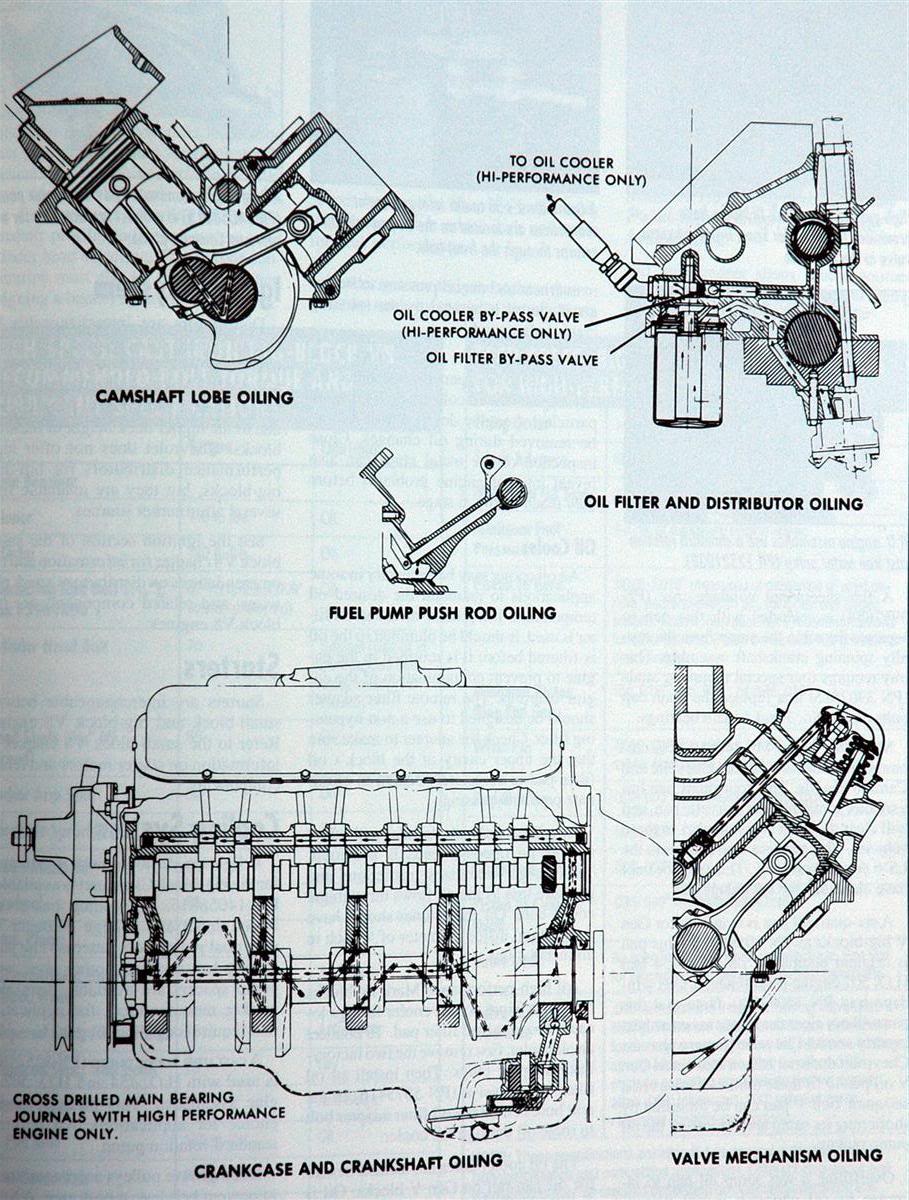

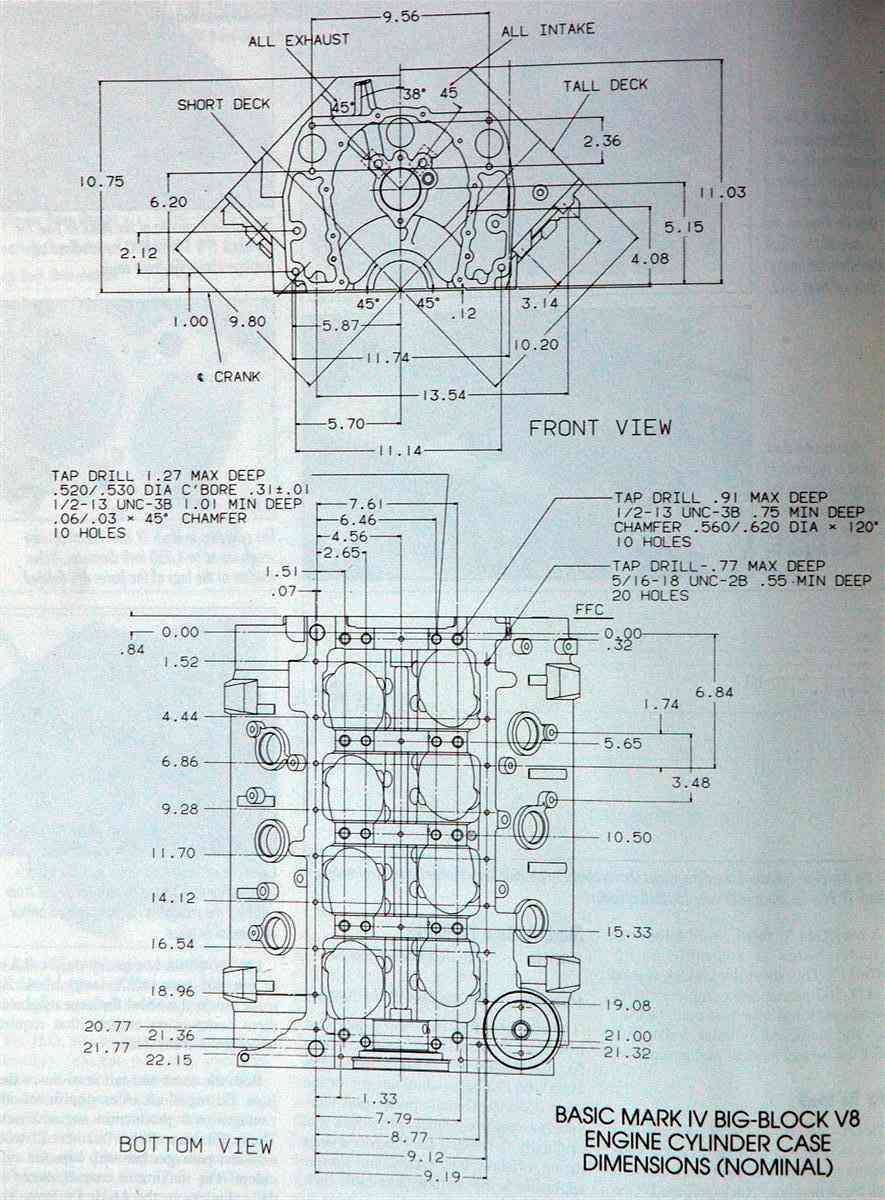

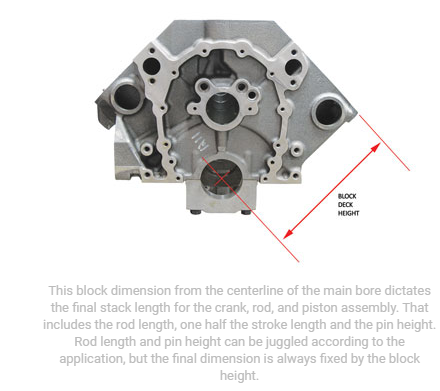

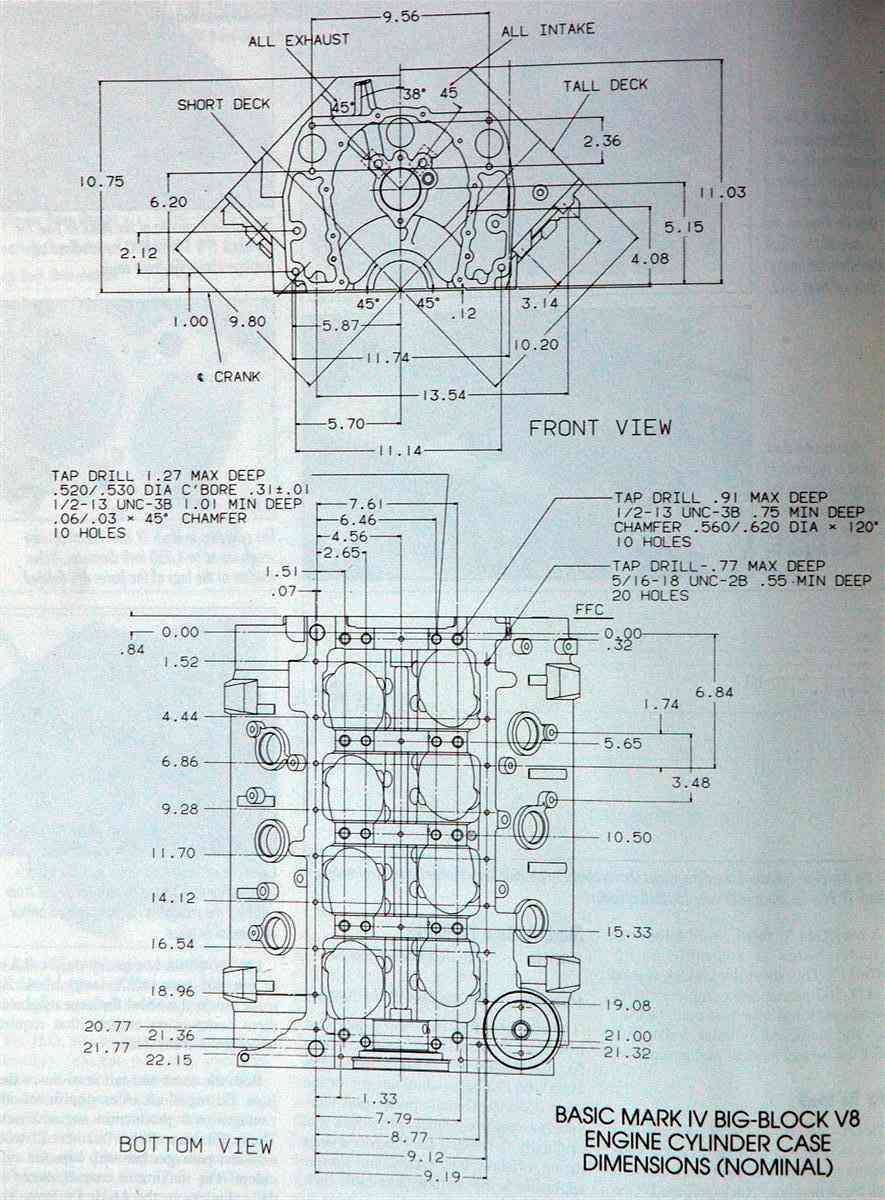

ok first if your starting out with the common 427-454 OEM blocks they commonly come in about a 4.25" bore and either the standard deck height of 9.8" and there's a few TRUCK TALL DECK BLOCKS in circulation with 10.2" deck heights , the far more common 9.8" pass car blocks vary in that they come in 2 bolt and 4 bolt main cap versions in the older mark.IV engines, the newer MARK.V and MARK.VI engines are the stronger 4 bolt main cap design, the heads and coolant passages. on the OEM components should be used with the engine block series they were designed for, as they may not easily interchange due to several differences in coolant passage lay out, most aftermarket heads have been redesigned with a compromise coolant passage location that will allow the heads to be used on any series block PROVIDED the correct head gasket is selected. most people PREFER the standard deck blocks as they are visually very similar from 366-454 factory displacements and will generally in the 427-454 versions that have factory 4.25" bores, will accept a 4.25" stroke crank, with some clearance work,and correctly selected components, and can be bored too a 4.310 bore (.060 over the stock bore size) a few blocks can take a .100 bore size but thats generally pushing past reasonable strength limitations on OEM blocks, both DART and WORLD PRODUCTS sell aftermarket blocks with thicker and stronger bore wall sizes.

the common combos being built are the 454, as its the most common factory block, the 468 which is simply the 454 with a .060 over size piston, and the 496 which uses the .60 over bore with a 4.25" stroker crank and longer 6.385 inch connecting rods rather than the stock 454 engines 6.135" rods and 4" stroke crank.

the longer rods are prefered to clear the larger counter weights on the longer stroke 4.25" stroker cranks (yes there are 4.25" stroke cranks that can be used with the stock 6.135" rods but there are several reasons why the longer rods are generally used.

AFTERMARKET blocks like the DART and WORLD PRODUCTS versions with the thicker castings are generally a good investment vs the stock blocks if you choose to build an engine that you intend to exceed about 600hp with.

the 496 BBC is basically the big block version of turning a 427-454 into a nearly as large as practical stroker, similar to the small block with its 4" bore and 3.48" stroke which gets bored .030 oversize and matched to a 3.75" stroker crank to produce a 383 SBC

IF your going to build a big block Chevy it usually helps to know your options and longer strokes and rods help.

Id also point out that doing the math before you purchase parts will save you a great deal of wasted cash,

and if that engine your contemplating is intended to exceed about 4200 feet per minute in piston speed or 6200rpm,

you might want too think seriously about 4340 forged steel crank, forged pistons, and rods with 7/16" ARP rod bolts

youll generally want to build a tall deck, engine with longer connecting rods to take full advantage of the tall deck architecture

the deck heights .400 taller so youll generally want connecting rods that are longer on the 4.25", stroke , stroker crank

IVE GENERALLY USED SCAT CRANK ROTATING ASSEMBLIES WITH 7/16" ARP ROD BOLTS and 6.385" 0r 6.535" rods as they are longer to compensate for the .400 taller deck height, a call to SCAT will get you the correct part number for a kit forged and internally balanced rotating assembly kit Phone: 310 370 5501

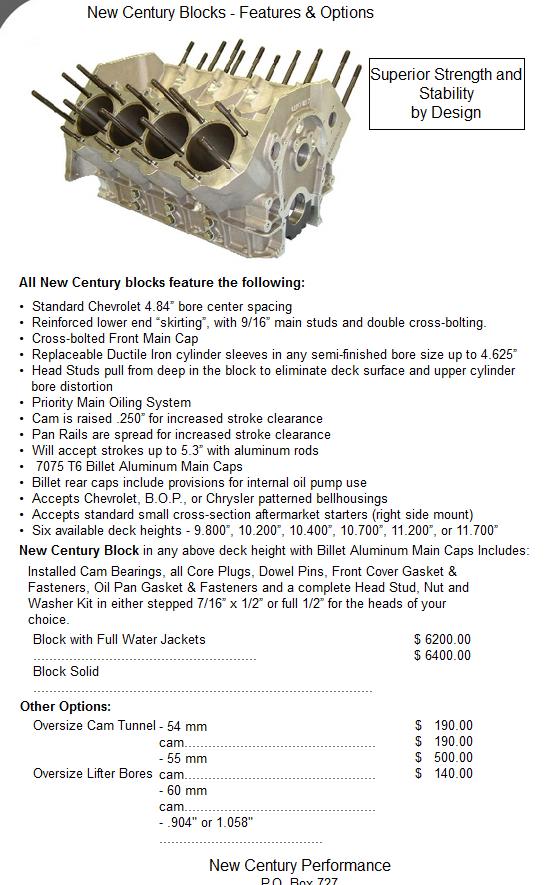

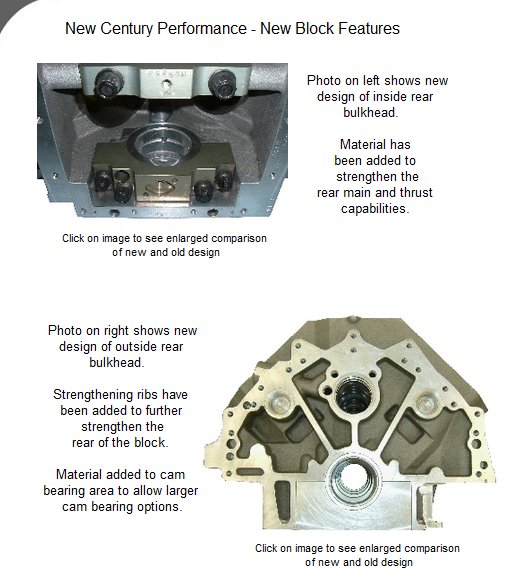

http://www.newcenturyperformance.com/Blocks.htm

http://garage.grumpysperformance.co...d-what-goes-in-the-dumpster.13135/#post-68515

ASK LOTS TO QUESTIONS & SHOP CAREFULLY,

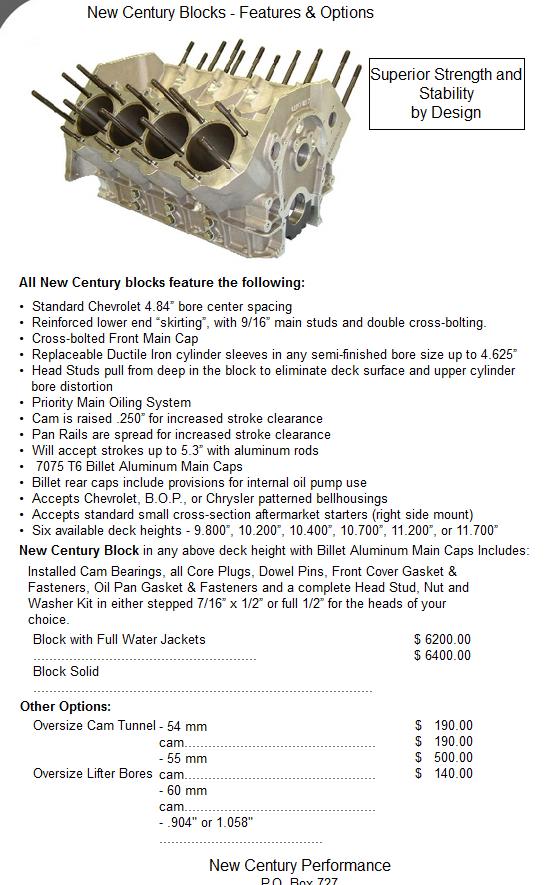

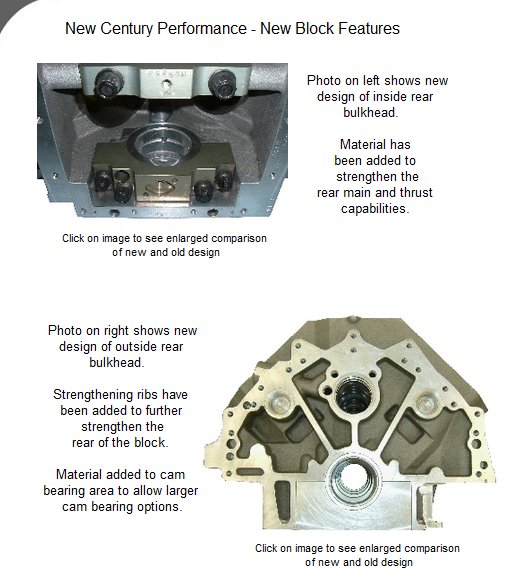

the better aftermarket aluminum blocks are both comparatively very expensive and noticeably lighter weight,

but do your research, as theres a big BIG difference in the structural rigidity, and strength, between the thicker aluminum blocks

designed for serious racing and those designed mostly to reduce weight, and duplicate the original iron block dimension-ally

interesting new option

the keys to making power are in the heads selected being matched ,

the keys to making power are in the heads selected being matched ,

to the compression ratio, cam timing, intake design and headers with a low restriction exhaust.

http://www.enginebuildermag.com/201...ton-compression-height-and-crankshaft-stroke/

When the Mark IV was installed in production vehicles for the first time in 1965, it carried the Turbo-Jet name on the air cleaner, displaced 396 cubic inches, and was rated at a maximum of 425 horsepower in the Corvettes.

Here’s a quick look at milestones in the big-block’s expanding and contracting history of displacement:

396 cid – introduced in 1965, with 4.094-in. x 3.760-in. bore and stroke (first production Mark IV engine).

427 cid – introduced in 1966, with 4.250-in. x 3.760-in. bore and stroke (aluminum versions used in COPO supercars).

366 cid – introduced in 1968, with 3.935-in. x 3.760-in. bore and stroke (tall-deck; used in truck applications).

402 cid – introduced in 1970, with 4.125-in. x 3.760-in. bore and stroke (advertised as 396 cid).

454 cid – introduced in 1970, with 4.250-in. x 4.000-in. bore and stroke.

502 cid – introduced in 1988, with 4.466-in. x 4.000-in. bore and stroke (Gen V block, originally developed for non-automotive applications; adapted later by Chevrolet Performance).

572 cid – introduced in 2003, with 4.560-in. x 4.375-in. bore and stroke (developed by Chevrolet Performance; no production vehicle applications).

http://www.jegs.com/i/Eagle/356/11512100/10002/-1?parentProductId=

http://www.superchevy.com/how-to/project-cars/0704ch-chevy-big-block/

http://www.scatcrankshafts.com/rotating-assembies/chevy-rotating-assemblies/

http://garage.grumpysperformance.co...r-heads-or-piston-dome-volume.2077/#post-9049

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/page-2#post-49183

http://garage.grumpysperformance.com/index.php?threads/deck-height-problems.3048/#post-8049

http://garage.grumpysperformance.com/index.php?threads/which-496-bbc-engine.12291/#post-60432

http://garage.grumpysperformance.com/index.php?threads/build-a-496-stroker-bbc.101/#post-49427

http://garage.grumpysperformance.com/index.php?threads/a-mid-range-454-bbc-build.8215/#post-54632

http://scatcrankshafts.com/

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

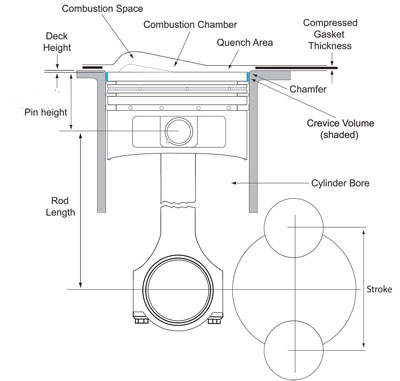

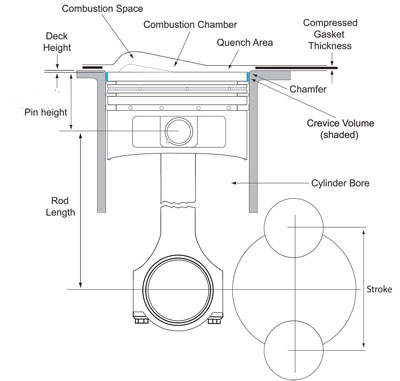

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

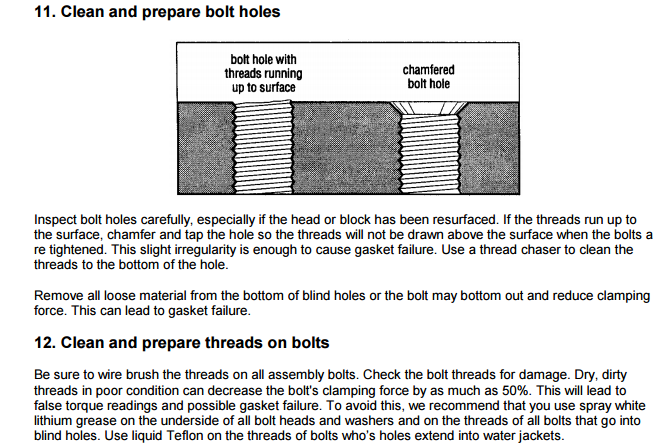

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

http://www.lunatipower.com/Tech/Pistons/CompressionHeight.aspx

http://www.doverusa.com/compression-height-calculator.php

https://www.uempistons.com/index.ph...n_comp&zenid=a1250756cef845700c8510712d829d4f

Piston compression height is the distance between the centerline of the pin to the flat part of the top of the piston. It's important to know this number when ordering pistons--especially custom ones--so that the piston falls in the right place in relation to the deck surface of the block (where the cylinder head bolts on). To figure out the best compression height, you need to know your block's deck height, the length of your connecting rods, and your crank stroke.

Block deck height is the distance from the centerline of the main journals to the block deck surface. For example, the small-block Chevys we tested last month were delivered at 9.020 inches, though this is commonly machined to 9.00--and giving or taking that 0.020 really makes a difference.

So assume you have a block with a 9.00-inch deck height, 6.000-inch connecting rods, and a stroke of 3.75 inches. First, divide the stroke by two and add that to the rod length: 3.75 / 2 = 1.875, and 1.875 + 6.00 = 7.875. Next, subtract that answer from the deck height: 9.00 – 7.875 = 1.125. So the answer is that the piston compression height should be 1.125 inches.

That will put the top of the piston exactly at the top of the engine block, which is usually best for quench and performance. If you want the piston to be 0.010 above or below the deck, simply add or subtract that amount from the compression height. Easy.

BORE x BORE x STROKE x 8 x .7854= displacement

example a 427 BBC

4.25 x 4.25 x 3.76 x8 x.7854=426.72 or 427 rounded off.

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

Id also point out that with increased displacement, increased compression ratios, etc. that result in much greater power levels, the drive train will need to be beefed up and a much larger and more efficient radiator and transmission fluid and engine oil cooler , larger more effective brakes etc. are almost mandatory additions.

common big block versions based on the larger bore 502 with its 4.477 bore size and a 4" crank can be upgraded with 4.5-4.6" bores and up to 4.5" stroke cranks

chevy sells a 572 cubic inch big block stroker crate engine that comes in either a nearly 600hp or 720hp versions.

yes theres lots of choices and it helps to keep in mind that there's a balance to be selected in displacement, compression ratio, cylinder head port size and cam timing, you generally won,t find it necessary to use huge heads or outrageous long duration cams to get a large displacement big block to make impressive power.

one very effective street combo can be built using the 4.5" bore and 4.25" stroke to build a 540 displacement engine, use a cylinder head in the 280cc-315 cc intake port size range, use a 10:1-10.5:1 compression and a roller cam in the 238-245 duration range at .050 lift ,with near .600-.650 lift on a 106-110 LSA with a single plane intake with a 850cfm-950cfm carb and long tube 2" headers and youll generally want a 3.31-3.54:1 rear gear ratio to build a 600 plus hp, and 600 ft lbs of torque, street engine, get the combo well matched and you might easily add significantly more to each figure.

yes the choice of components will need to be carefully thought out as each choice in components used must be matched to the displacement and compression ratio.

yeah! your unlikely to get over 9-10 mpg IF THAT but as a TOY thats sure to bring a big grin on any performance hot rodders face its not a bad option

http://www.chevrolet.com/performance/cr ... 720-r.html

http://www.hotrod.com/how-to/engine/100 ... ock-chevy/

http://www.superchevy.com/how-to/engine ... ate-motor/

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

reading the links and sub links will help immensely

you DO REALIZE you can't just drop the valve train parts, kits they sell,

into or on, those bare cast heads

and have the result work RIGHT???

http://garage.grumpysperformance.com/index.php?threads/valve-seat-runout.15104/#post-86003

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-81754

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-98674

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-48319

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-33298

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-11290

http://garage.grumpysperformance.co...and-setting-up-the-valve-train.181/#post-1397

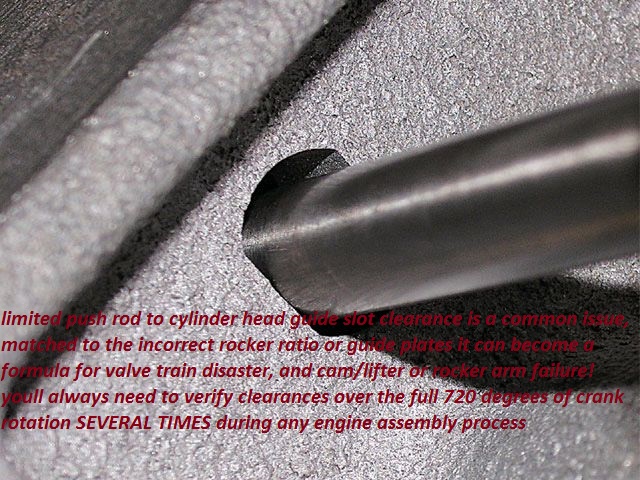

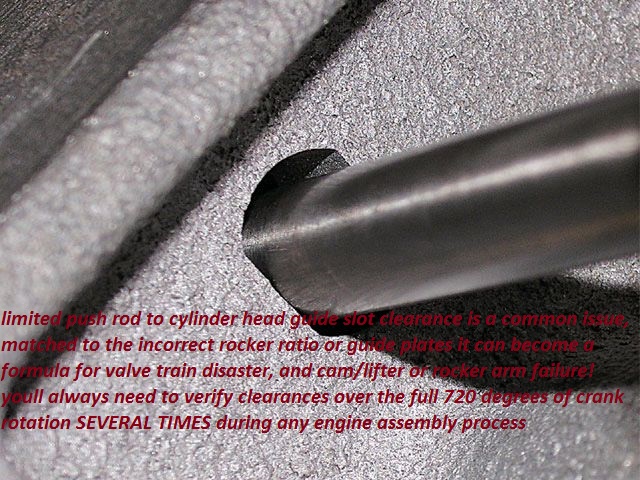

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

first CHEVK CLEARANCES AND GEOMETRY

the higher rocker ratio increases the effective acceleration rate of the cams lobe ramp, being transmitted to the valve so the higher ratio tends to cause valve control issues at a lower rpm level UNLESS the valve spring load rates increased to compensate. this allows a greater area of lift or open port area so the engine will tend to run better in the mid rpm range, generally making it well worth while as the mile duration cam can use the extra lift and duration at the valve.

some examples of ENGINE PORN TO DROOL OVER

viewtopic.php?f=87&t=951&p=1627&hilit=friends+similar+cars#p1627

http://www.hotrod.com/how-to/engine/080 ... ine-build/

http://www.superchevy.com/how-to/projec ... ock-build/

http://www.superchevy.com/how-to/engine ... s-insight/

http://www.enginebuildermag.com/2007/03 ... is-better/

http://datab.us/Search/Popular%2BStroke ... Ayf61OQfpQ

POWER TO WEIGHT CALCULATIONS

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://www.wallaceracing.com/et-hp-mph.php

https://robrobinette.com/et.htm

http://www.ajdesigner.com/fl_horsepower_elapsed_time/horsepower_elapsed_time.php

http://www.tuneruniversity.com/blog/2012/03/power-to-weight-ratio/

http://garage.grumpysperformance.com/index.php?threads/engine-swap-source-info.12068/

its just a fact that you can generally produce a bit over 1-1.3 horse power per cubic inch of displacement in most chevy V8 engines

if you have selected and built one the better combos and select parts carefully you can do far better than that!

ok first if your starting out with the common 427-454 OEM blocks they commonly come in about a 4.25" bore and either the standard deck height of 9.8" and there's a few TRUCK TALL DECK BLOCKS in circulation with 10.2" deck heights , the far more common 9.8" pass car blocks vary in that they come in 2 bolt and 4 bolt main cap versions in the older mark.IV engines, the newer MARK.V and MARK.VI engines are the stronger 4 bolt main cap design, the heads and coolant passages. on the OEM components should be used with the engine block series they were designed for, as they may not easily interchange due to several differences in coolant passage lay out, most aftermarket heads have been redesigned with a compromise coolant passage location that will allow the heads to be used on any series block PROVIDED the correct head gasket is selected. most people PREFER the standard deck blocks as they are visually very similar from 366-454 factory displacements and will generally in the 427-454 versions that have factory 4.25" bores, will accept a 4.25" stroke crank, with some clearance work,and correctly selected components, and can be bored too a 4.310 bore (.060 over the stock bore size) a few blocks can take a .100 bore size but thats generally pushing past reasonable strength limitations on OEM blocks, both DART and WORLD PRODUCTS sell aftermarket blocks with thicker and stronger bore wall sizes.

the common combos being built are the 454, as its the most common factory block, the 468 which is simply the 454 with a .060 over size piston, and the 496 which uses the .60 over bore with a 4.25" stroker crank and longer 6.385 inch connecting rods rather than the stock 454 engines 6.135" rods and 4" stroke crank.

the longer rods are prefered to clear the larger counter weights on the longer stroke 4.25" stroker cranks (yes there are 4.25" stroke cranks that can be used with the stock 6.135" rods but there are several reasons why the longer rods are generally used.

AFTERMARKET blocks like the DART and WORLD PRODUCTS versions with the thicker castings are generally a good investment vs the stock blocks if you choose to build an engine that you intend to exceed about 600hp with.

the 496 BBC is basically the big block version of turning a 427-454 into a nearly as large as practical stroker, similar to the small block with its 4" bore and 3.48" stroke which gets bored .030 oversize and matched to a 3.75" stroker crank to produce a 383 SBC

IF your going to build a big block Chevy it usually helps to know your options and longer strokes and rods help.

Id also point out that doing the math before you purchase parts will save you a great deal of wasted cash,

and if that engine your contemplating is intended to exceed about 4200 feet per minute in piston speed or 6200rpm,

you might want too think seriously about 4340 forged steel crank, forged pistons, and rods with 7/16" ARP rod bolts

youll generally want to build a tall deck, engine with longer connecting rods to take full advantage of the tall deck architecture

the deck heights .400 taller so youll generally want connecting rods that are longer on the 4.25", stroke , stroker crank

IVE GENERALLY USED SCAT CRANK ROTATING ASSEMBLIES WITH 7/16" ARP ROD BOLTS and 6.385" 0r 6.535" rods as they are longer to compensate for the .400 taller deck height, a call to SCAT will get you the correct part number for a kit forged and internally balanced rotating assembly kit Phone: 310 370 5501

http://www.newcenturyperformance.com/Blocks.htm

http://garage.grumpysperformance.co...d-what-goes-in-the-dumpster.13135/#post-68515

ASK LOTS TO QUESTIONS & SHOP CAREFULLY,

the better aftermarket aluminum blocks are both comparatively very expensive and noticeably lighter weight,

but do your research, as theres a big BIG difference in the structural rigidity, and strength, between the thicker aluminum blocks

designed for serious racing and those designed mostly to reduce weight, and duplicate the original iron block dimension-ally

interesting new option

to the compression ratio, cam timing, intake design and headers with a low restriction exhaust.

http://www.enginebuildermag.com/201...ton-compression-height-and-crankshaft-stroke/

When the Mark IV was installed in production vehicles for the first time in 1965, it carried the Turbo-Jet name on the air cleaner, displaced 396 cubic inches, and was rated at a maximum of 425 horsepower in the Corvettes.

Here’s a quick look at milestones in the big-block’s expanding and contracting history of displacement:

396 cid – introduced in 1965, with 4.094-in. x 3.760-in. bore and stroke (first production Mark IV engine).

427 cid – introduced in 1966, with 4.250-in. x 3.760-in. bore and stroke (aluminum versions used in COPO supercars).

366 cid – introduced in 1968, with 3.935-in. x 3.760-in. bore and stroke (tall-deck; used in truck applications).

402 cid – introduced in 1970, with 4.125-in. x 3.760-in. bore and stroke (advertised as 396 cid).

454 cid – introduced in 1970, with 4.250-in. x 4.000-in. bore and stroke.

502 cid – introduced in 1988, with 4.466-in. x 4.000-in. bore and stroke (Gen V block, originally developed for non-automotive applications; adapted later by Chevrolet Performance).

572 cid – introduced in 2003, with 4.560-in. x 4.375-in. bore and stroke (developed by Chevrolet Performance; no production vehicle applications).

http://www.jegs.com/i/Eagle/356/11512100/10002/-1?parentProductId=

http://www.superchevy.com/how-to/project-cars/0704ch-chevy-big-block/

http://www.scatcrankshafts.com/rotating-assembies/chevy-rotating-assemblies/

http://garage.grumpysperformance.co...r-heads-or-piston-dome-volume.2077/#post-9049

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/page-2#post-49183

http://garage.grumpysperformance.com/index.php?threads/deck-height-problems.3048/#post-8049

http://garage.grumpysperformance.com/index.php?threads/which-496-bbc-engine.12291/#post-60432

http://garage.grumpysperformance.com/index.php?threads/build-a-496-stroker-bbc.101/#post-49427

http://garage.grumpysperformance.com/index.php?threads/a-mid-range-454-bbc-build.8215/#post-54632

http://scatcrankshafts.com/

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

http://www.lunatipower.com/Tech/Pistons/CompressionHeight.aspx

http://www.doverusa.com/compression-height-calculator.php

https://www.uempistons.com/index.ph...n_comp&zenid=a1250756cef845700c8510712d829d4f

Piston compression height is the distance between the centerline of the pin to the flat part of the top of the piston. It's important to know this number when ordering pistons--especially custom ones--so that the piston falls in the right place in relation to the deck surface of the block (where the cylinder head bolts on). To figure out the best compression height, you need to know your block's deck height, the length of your connecting rods, and your crank stroke.

Block deck height is the distance from the centerline of the main journals to the block deck surface. For example, the small-block Chevys we tested last month were delivered at 9.020 inches, though this is commonly machined to 9.00--and giving or taking that 0.020 really makes a difference.

So assume you have a block with a 9.00-inch deck height, 6.000-inch connecting rods, and a stroke of 3.75 inches. First, divide the stroke by two and add that to the rod length: 3.75 / 2 = 1.875, and 1.875 + 6.00 = 7.875. Next, subtract that answer from the deck height: 9.00 – 7.875 = 1.125. So the answer is that the piston compression height should be 1.125 inches.

That will put the top of the piston exactly at the top of the engine block, which is usually best for quench and performance. If you want the piston to be 0.010 above or below the deck, simply add or subtract that amount from the compression height. Easy.

BORE x BORE x STROKE x 8 x .7854= displacement

example a 427 BBC

4.25 x 4.25 x 3.76 x8 x.7854=426.72 or 427 rounded off.

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

yes its common for a combo to have the piston deck height located .010-.015 above or below the deck of the block so you'll need to select a head gasket thickness that compensates, too allow your engine to get a .038-.044 piston deck to cylinder head QUENCH DISTANCE.

Id also point out that with increased displacement, increased compression ratios, etc. that result in much greater power levels, the drive train will need to be beefed up and a much larger and more efficient radiator and transmission fluid and engine oil cooler , larger more effective brakes etc. are almost mandatory additions.

common big block versions based on the larger bore 502 with its 4.477 bore size and a 4" crank can be upgraded with 4.5-4.6" bores and up to 4.5" stroke cranks

chevy sells a 572 cubic inch big block stroker crate engine that comes in either a nearly 600hp or 720hp versions.

yes theres lots of choices and it helps to keep in mind that there's a balance to be selected in displacement, compression ratio, cylinder head port size and cam timing, you generally won,t find it necessary to use huge heads or outrageous long duration cams to get a large displacement big block to make impressive power.

one very effective street combo can be built using the 4.5" bore and 4.25" stroke to build a 540 displacement engine, use a cylinder head in the 280cc-315 cc intake port size range, use a 10:1-10.5:1 compression and a roller cam in the 238-245 duration range at .050 lift ,with near .600-.650 lift on a 106-110 LSA with a single plane intake with a 850cfm-950cfm carb and long tube 2" headers and youll generally want a 3.31-3.54:1 rear gear ratio to build a 600 plus hp, and 600 ft lbs of torque, street engine, get the combo well matched and you might easily add significantly more to each figure.

yes the choice of components will need to be carefully thought out as each choice in components used must be matched to the displacement and compression ratio.

yeah! your unlikely to get over 9-10 mpg IF THAT but as a TOY thats sure to bring a big grin on any performance hot rodders face its not a bad option

http://www.chevrolet.com/performance/cr ... 720-r.html

http://www.hotrod.com/how-to/engine/100 ... ock-chevy/

http://www.superchevy.com/how-to/engine ... ate-motor/

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

reading the links and sub links will help immensely

you DO REALIZE you can't just drop the valve train parts, kits they sell,

into or on, those bare cast heads

and have the result work RIGHT???

http://garage.grumpysperformance.com/index.php?threads/valve-seat-runout.15104/#post-86003

http://garage.grumpysperformance.co...u-buy-bare-or-assembled-heads.534/#post-81754

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

How Valves Seal

Watch this video by Eric Weingartner, I learned alot, I think you will to ! .

garage.grumpysperformance.com

big block head comparison

(below youll find several links too some of the more exotic high flow racing BBC head designs from the aftermarket ) (these are not directly interchangeable with stock components,) and will generally require selecting matching expensive aftermarket intakes, from that heads manufacturer, and...

garage.grumpysperformance.com

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-98674

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-48319

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-33298

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-11290

http://garage.grumpysperformance.co...and-setting-up-the-valve-train.181/#post-1397

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

first CHEVK CLEARANCES AND GEOMETRY

the higher rocker ratio increases the effective acceleration rate of the cams lobe ramp, being transmitted to the valve so the higher ratio tends to cause valve control issues at a lower rpm level UNLESS the valve spring load rates increased to compensate. this allows a greater area of lift or open port area so the engine will tend to run better in the mid rpm range, generally making it well worth while as the mile duration cam can use the extra lift and duration at the valve.

some examples of ENGINE PORN TO DROOL OVER

viewtopic.php?f=87&t=951&p=1627&hilit=friends+similar+cars#p1627

http://www.hotrod.com/how-to/engine/080 ... ine-build/

http://www.superchevy.com/how-to/projec ... ock-build/

http://www.superchevy.com/how-to/engine ... s-insight/

http://www.enginebuildermag.com/2007/03 ... is-better/

http://datab.us/Search/Popular%2BStroke ... Ayf61OQfpQ

POWER TO WEIGHT CALCULATIONS

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://www.wallaceracing.com/et-hp-mph.php

https://robrobinette.com/et.htm

http://www.ajdesigner.com/fl_horsepower_elapsed_time/horsepower_elapsed_time.php

http://www.tuneruniversity.com/blog/2012/03/power-to-weight-ratio/

http://garage.grumpysperformance.com/index.php?threads/engine-swap-source-info.12068/

Last edited by a moderator: