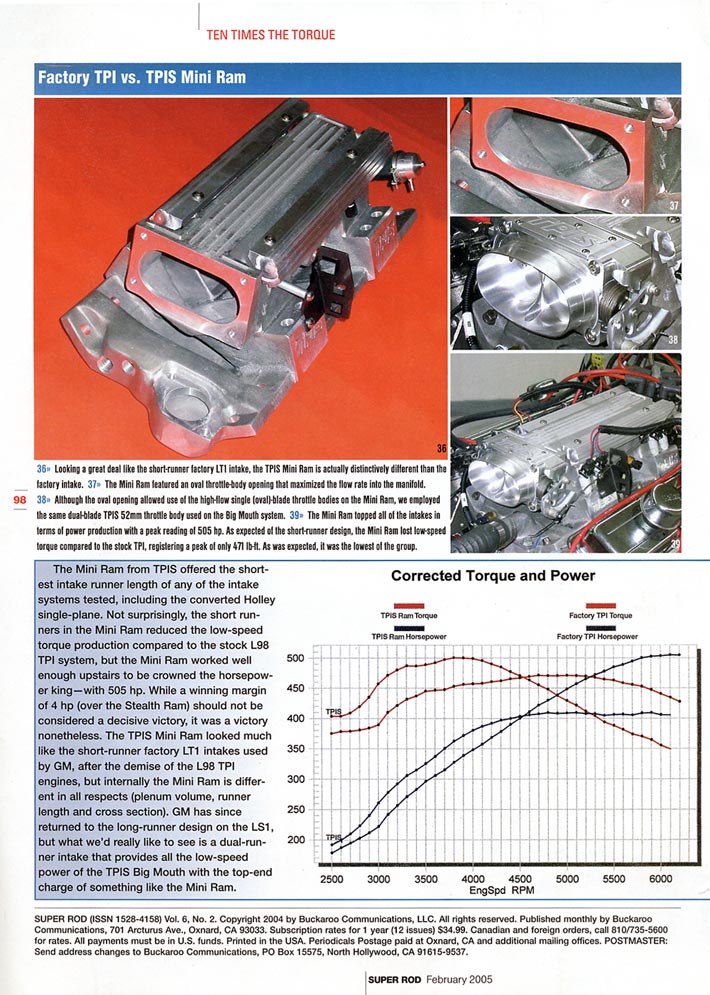

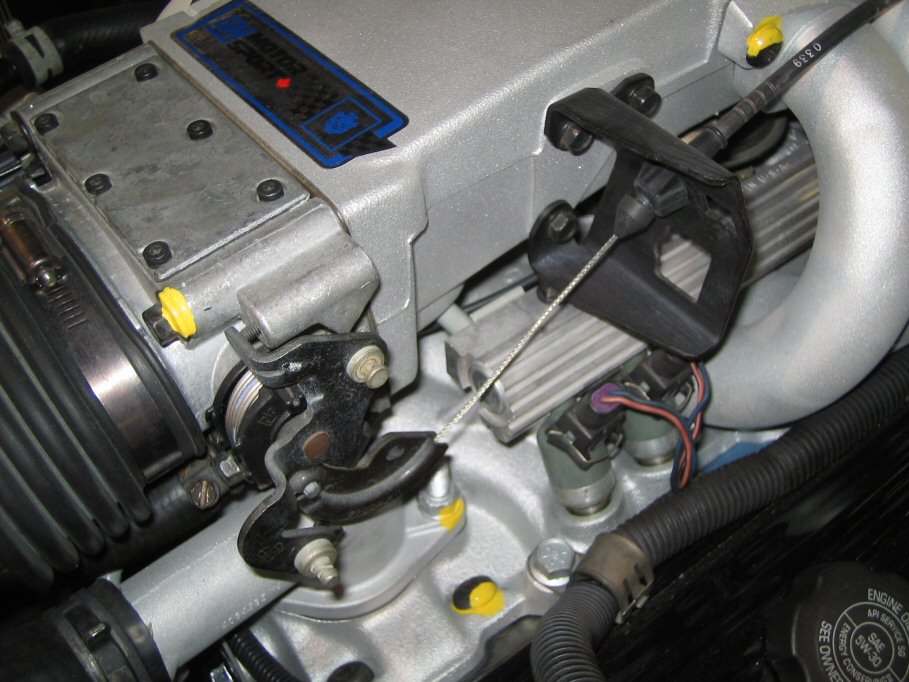

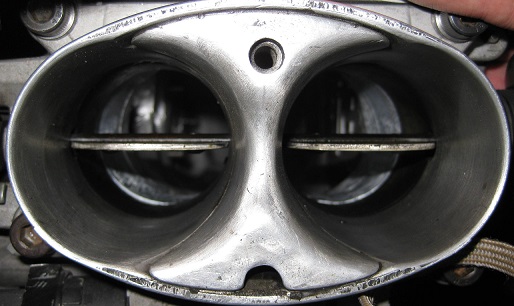

I get asked frequently if installing a larger than the stock 48mm TPI throttle body will significantly help on a corvette engine, Ill save you some reading right off if you want, yes a 58mm can potentially increase hp if your engines highly modified and your still using a stock 48mm throttle body and there are usually minimal power gains on even a stock engine but the restriction a stock 48mm throttle body represents is not as significant and the gains to be had are not that large in most cases, your intake manifold and cam plus your heads are the major restrictions. the stock 48mm throttle body flows about 700cfm and has more than enough flow to support about 475hp-500hp, bored to 52mm it will support about 500hp,-525hp, a 58mm can support about 600hp, but keep in mind theres lots of factors other than just throttle body size that determine potential hp

stock with zero mods the L98 throttle body flows at least 700cfm, and mildly cleaned up with an air foil 780cfm is frequently seen on flow bench testing

viewtopic.php?f=44&t=9565&p=35285&hilit=port+tuned+restriction#p35285

viewtopic.php?f=55&t=1509&p=3459&hilit=base+runner+plenum#p3459

http://garage.grumpysperformance.co...rger-intake-runners-l98-tpi.13785/#post-70716

Ive always been rather amused at the guys who do swap to a 58mm throttle body on a stock or nearly stock tpi intake because the darn things are so restrictive even if ported that they can,t possibly use the increased flow, especially if sucking air thru a MAF sensor that flows about 670cfm

if your engine doesn,t have the necessary components to make at least 450hp, like decent heads cam and low restriction exhaust headers, your wasting your money on a 58mm throttle body on a nearly stock TPI equipped engine, youll need MUCH better heads,at least 383 displacement, a low restriction exhaust and a cam with at least 220 duration before air flow rates even approach the limits of the stock l98 throttle body

read this link

viewtopic.php?f=55&t=641&p=12915&hilit=58mm#p12915

using or modifying a throttle body to flow more than 1000cfm -1200 cfm like a 58mm twin bore potentially flows is a waste of money, heres why

the largest displacement sbc your likely to build is a 434cid, that requires a 4" stroke crank and you'll be limited to about 6500rpm even with top quality parts if you want the engine to last any time at all, now you might not realize it but the time necessary to fill the cylinders gets limited very quickly at higher rpms and the volumetric efficiency falls off quickly after about 5000rpm simply because theres just not enough time to allow the cylinders to fill completely. at 5000 rpm theres 41.6 intake strokes per second, per cylinder, by 6500 rpm its up to 54 intake strokes per second, per cylinder that's only 0.018 seconds for the intake port to flow into the cylinder per intake stroke. but theres yet another factor!!! that's the time for the full intake stroke!!!, while theres 720 degrees in the repetitive cycle and Ive given you a full 360 degrees worth of time, the truth is that your cam/engine combo, seldom allows anywhere near that duration!!!! even a radical race cam seldom exceeds 250 degrees in effective duration for port flow, so you'll need to knock about 45% off that time, now your down to only about 0.012 seconds or less of effective flow per intake stroke per cylinder, is it any wonder the cylinder can,t fully fill at high rpms??

now the theoretical 434 were working with here even if it could fill its cylinders 100% at 6500rpm which is totally impossible at that rpm would require 434 (the displacement) x 3250(the number of intake strokes)=1410500 (the full 100% in cubic inches /1728(to change to cfm) = only 816cfm.... now even if you could ram tune the exhaust and intake pulse perfectly and get the cylinders to pack the cylinders to 120% (a total impossibility without a supercharger or turbo) that's till only 979 cfm

but in the real world your volumetric efficiency falls off fast after 5000 rpm with a 4" stroke and you'll be exceptionally lucky to pull 80% efficiency at over 5000rpm

drop your displacement to a more common 383 and your rpm limit to the fairly common 6500rpm and you'll drop even the theoretical air flow requirement to below 875cfm

http://users.erols.com/srweiss/calchpaf.htm

http://users.erols.com/srweiss/calccarb.htm

heres the ramjet ZL1 454

http://www.sallee-chevrolet.com/ChevyBigBlockV8s/ramjetzl1.html

yeah you might not believe it but it got a stock 48mm twin bore TPI style chevy throttle body feeding that 454 engine, do you think Chevy would do that if it was a significant restriction to hp production??

the restriction is not the throttle body its the port size, valve size and flow the heads have and intake manifold runners restriction,and cam lift and duration... install an intake manifold,cam and heads that can flow 300cfm and the 58mm aftermarket throttle body will still effectively feed the engine, remember that while even 300cfm ports at full flow only pull air about 250 degrees out of 720 degrees in the cycle and are spaced 90 degrees apart, that means that 1000cfm can feed all 8 cylinders a full 833cfm they could in theory flow ,and that 300cfm per port can support roughly 600hp

OK IVE JUST GOT TO ASK?

why would you buy a 52mm vs a 58MM throttle body????

now PLEASE don,t get me wrong,

the 52MM has a nice improvement in air flow over the stock throttle body, but in most cases that extra air flow is not used, especially on a mild engine or one with stock gearing and displacement, and the 58mm won,t in most cases increase the performance, and yes IM well aware from testing that the MAF sensors and the intake manifolds , and heads are the big restrictions, and that with out inproving those areas the stock throttle body works just fine.

BUT NEITHER WILL THE 58MM HURT a damn thing EITHER??

I tried BOTH on my 383 with BOTH the TPI and STEALTH RAM intakes, (I borrowed a friends 52mm to test) and there was no real differance untill I was up in the 6000rpm range, and even then the differance was minor, but again WHY buy the smaller unit, that could potentially be a restriction with future mods done??

its NOT like a carb, you won,t get a big loss of throttle response, in fact I could detect ZERO difference once it was correctly tuned) or for that matter experience any down side to the larger unit provided of course your tuning skills are decent.

and before you guys get crazy, do some research!

I don,t remember ever seeing a dyno on anyone else s engine EITHER that showed a LOSS to the larger unit, just a few that showed no IMPROVEMENT in a particular application, and if your thinking of pointing out a lack of throttle response that's been repeatedly shown to be due to tuning issues like low fuel pressure, too small of injectors,or the TPS voltage was off the mark, the IAC was not set correctly or the ignition timing curve was not ideal, or in a few cases the compression ratio was to low for the cam collected, get the LCA or duration wrong for the application and AIR FLOW REVERSION in the runners CAN cause problems, like a bog when you transition from idle to W.O.T. almost instantly, but in no case IVE seen was the extra potential air flow a problem, especially once you realize that the plenum/ports carry only AIR, and the fuels injected in the last 4 inches of the runners

http://www.airflowresearch.com/super-chevy-sep-2013-195cc-sbc.php

BTW

http://www.sallee-chevrolet.com/frame.html?/sales.html

RAM JET 502 - FACTORY FUEL-INJECTED BIG-BLOCK POWER

P/N 12499121 [Old P/N 12497323]

The recipe is simple; one part attitude, one part driving perfection, one part leading factory technology, and five hundred and two parts hungry rat motor. Ram Jet 502, you either have one, or you want one! When the idea of an all new big block fuel injection system first came up, we all thought it was a good one. When it was proposed that it be integrated with our 502 crate engine, we thought someone had clearly lost their mind. Who could possibly need the awesome, flat, broad torque curve only available with a long runner dry manifold? And who would want the neck-snapping throttle response of MEFI 4 controlled port fuel injectors? And what would be the need for aggressive tunnel ram styling? But then we remembered we’re not building 100 mile per gallon, 0 to 60 in a week, eco scooters. We’re in the hot rod business! So we called together engine management system experts from GM Power train, our own GMPP engineers, and fuel injected race engine builder and GMPP Pro Mod racer Harold Martin. After some great discussions, a little debate, a lot of late nights and 50 gallons of coffee we had an intake manifold design like no other. By leveraging leading fuel management technology, numerous production developed components, the industry standard MEFI 4 controller and the great Ram Jet name from the 50’s, the Ram Jet 502 is reality.

The new undisputed heavy weight champion, the Ram Jet 502, makes 502 horsepower at 5100 rpm and 565 ft.lbs. of torque at 3200 rpm. The instantly throttle responsive Ram Jet 502 drives like no other big block you’ve ever driven. With over 500 ft. lbs. of torque from 2,200 to 5200 rpm, the Ram Jet 502 is a tire shredding monster making more torque throughout its operating range. This is possible because Ram Jet has a larger plenum and runners than would ever be possible in a carburetor application. This means greater intake efficiency and greater torque without sacrificing drive-ability. The Ram Jet manifold is so efficient that we’re able to make all of this horsepower and torque with a production L98 throttle body assembly, you know, the one that Firebird and Camaro owners always replace when trying to make more power in their 350 engines. It’s all about airflow quality, velocity, and fuel and spark management. You’ll just have to drive one to appreciate it. If the one-second cold starts, no stalling, instant throttle response, and the solid pull from idle to red line don’t convince you that a Ram Jet 502 is for you, then maybe you would be more interested an a competitor’s futuristic dream of a 100 mile per gallon, 0 to 60 in a week, eco scooter or a good old fashion bicycle for those weekend events to impress all your friends at the local hot rod club or for those weekend cruses out on the highway to impress everyone else on the road.

The Ram Jet 502 is designed for ease of installation needing only 12V, ground, fuel feed and fuel return to run. Included are an instruction sheet, service manual and diagnostic tool for ease of installation and service. As with any GM Performance Parts Ram Jet engine, an in tank fuel pump is recommended to avoid possible vapor lock. See instruction sheet for fuel pump recommendations. Also included is complete throttle linkage that accepts your production throttle cable and transmission cable. Includes pre-programmed MEFI 4 ECM and wiring harness. This revised electronic and closed loop system gives a much smoother idle and better performance then the MEFI 3 ECM system it replaced.

The Ram Jet manifold stands eleven inches tall as measured from the front and rear “china wall†on the cylinder block. That’s just half an inch taller than a typical single plane high rise manifold, Holley carb and air cleaner combo.

RAM JET 502 TECHNICAL INFORMATION

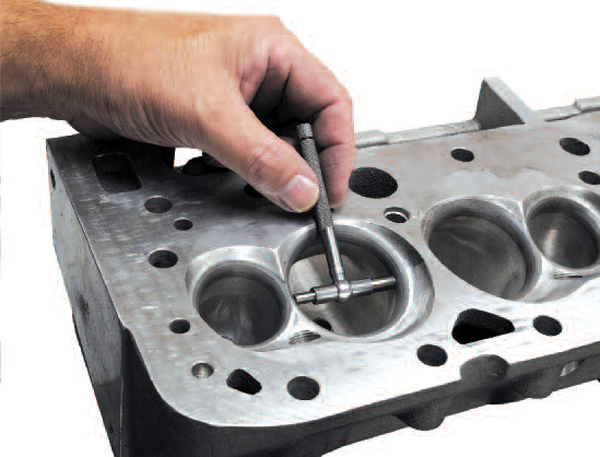

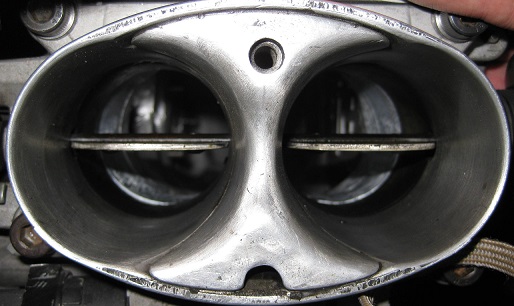

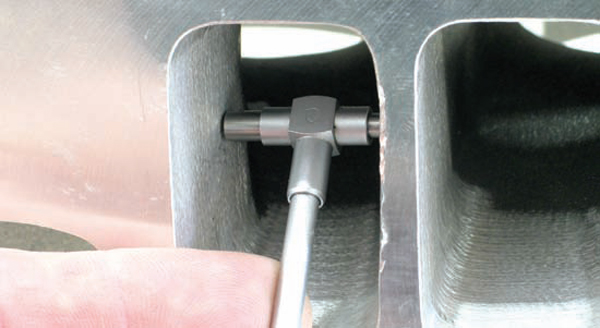

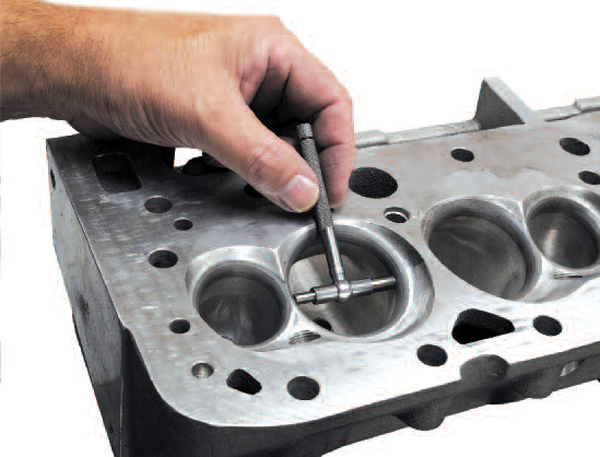

HERES A FEW PICTURES of a rather extensively ported edelbrock TPI intake, which was up untill the advent of the "FIRST" intake one of the better options

a great deal of the info you may want can be calculated after carefully measuring the intake port and runner length and cross sectional areas.(remember its not the intake port gasket cross sectional opening, cross sectional area, its the smallest part of the port cross sectional area and valve throat areas that limit port flow rates)

if as an example we selected a port with about a 2 sq inch cross sectional area, you'll find max torque on a 350 will fall near 4000-rpm and port stall near 6000-rpm thus it makes sense to match the cam timing and lift/duration and the drive train gearing to match the rpm range,power curve and port flow.

or put a bit differently, theres no sense in selecting a cam designed to operate well at 7600 rpm if you port stalls at 6300 rpm

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calchpaf.htm

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

http://www.summitracing.com/parts/cca-5605/overview/

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-26322

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

stock with zero mods the L98 throttle body flows at least 700cfm, and mildly cleaned up with an air foil 780cfm is frequently seen on flow bench testing

viewtopic.php?f=44&t=9565&p=35285&hilit=port+tuned+restriction#p35285

viewtopic.php?f=55&t=1509&p=3459&hilit=base+runner+plenum#p3459

http://garage.grumpysperformance.co...rger-intake-runners-l98-tpi.13785/#post-70716

if your engine doesn,t have the necessary components to make at least 450hp, like decent heads cam and low restriction exhaust headers, your wasting your money on a 58mm throttle body on a nearly stock TPI equipped engine, youll need MUCH better heads,at least 383 displacement, a low restriction exhaust and a cam with at least 220 duration before air flow rates even approach the limits of the stock l98 throttle body

read this link

viewtopic.php?f=55&t=641&p=12915&hilit=58mm#p12915

using or modifying a throttle body to flow more than 1000cfm -1200 cfm like a 58mm twin bore potentially flows is a waste of money, heres why

the largest displacement sbc your likely to build is a 434cid, that requires a 4" stroke crank and you'll be limited to about 6500rpm even with top quality parts if you want the engine to last any time at all, now you might not realize it but the time necessary to fill the cylinders gets limited very quickly at higher rpms and the volumetric efficiency falls off quickly after about 5000rpm simply because theres just not enough time to allow the cylinders to fill completely. at 5000 rpm theres 41.6 intake strokes per second, per cylinder, by 6500 rpm its up to 54 intake strokes per second, per cylinder that's only 0.018 seconds for the intake port to flow into the cylinder per intake stroke. but theres yet another factor!!! that's the time for the full intake stroke!!!, while theres 720 degrees in the repetitive cycle and Ive given you a full 360 degrees worth of time, the truth is that your cam/engine combo, seldom allows anywhere near that duration!!!! even a radical race cam seldom exceeds 250 degrees in effective duration for port flow, so you'll need to knock about 45% off that time, now your down to only about 0.012 seconds or less of effective flow per intake stroke per cylinder, is it any wonder the cylinder can,t fully fill at high rpms??

now the theoretical 434 were working with here even if it could fill its cylinders 100% at 6500rpm which is totally impossible at that rpm would require 434 (the displacement) x 3250(the number of intake strokes)=1410500 (the full 100% in cubic inches /1728(to change to cfm) = only 816cfm.... now even if you could ram tune the exhaust and intake pulse perfectly and get the cylinders to pack the cylinders to 120% (a total impossibility without a supercharger or turbo) that's till only 979 cfm

but in the real world your volumetric efficiency falls off fast after 5000 rpm with a 4" stroke and you'll be exceptionally lucky to pull 80% efficiency at over 5000rpm

drop your displacement to a more common 383 and your rpm limit to the fairly common 6500rpm and you'll drop even the theoretical air flow requirement to below 875cfm

http://users.erols.com/srweiss/calchpaf.htm

http://users.erols.com/srweiss/calccarb.htm

heres the ramjet ZL1 454

http://www.sallee-chevrolet.com/ChevyBigBlockV8s/ramjetzl1.html

yeah you might not believe it but it got a stock 48mm twin bore TPI style chevy throttle body feeding that 454 engine, do you think Chevy would do that if it was a significant restriction to hp production??

the restriction is not the throttle body its the port size, valve size and flow the heads have and intake manifold runners restriction,and cam lift and duration... install an intake manifold,cam and heads that can flow 300cfm and the 58mm aftermarket throttle body will still effectively feed the engine, remember that while even 300cfm ports at full flow only pull air about 250 degrees out of 720 degrees in the cycle and are spaced 90 degrees apart, that means that 1000cfm can feed all 8 cylinders a full 833cfm they could in theory flow ,and that 300cfm per port can support roughly 600hp

OK IVE JUST GOT TO ASK?

why would you buy a 52mm vs a 58MM throttle body????

now PLEASE don,t get me wrong,

the 52MM has a nice improvement in air flow over the stock throttle body, but in most cases that extra air flow is not used, especially on a mild engine or one with stock gearing and displacement, and the 58mm won,t in most cases increase the performance, and yes IM well aware from testing that the MAF sensors and the intake manifolds , and heads are the big restrictions, and that with out inproving those areas the stock throttle body works just fine.

BUT NEITHER WILL THE 58MM HURT a damn thing EITHER??

I tried BOTH on my 383 with BOTH the TPI and STEALTH RAM intakes, (I borrowed a friends 52mm to test) and there was no real differance untill I was up in the 6000rpm range, and even then the differance was minor, but again WHY buy the smaller unit, that could potentially be a restriction with future mods done??

its NOT like a carb, you won,t get a big loss of throttle response, in fact I could detect ZERO difference once it was correctly tuned) or for that matter experience any down side to the larger unit provided of course your tuning skills are decent.

and before you guys get crazy, do some research!

I don,t remember ever seeing a dyno on anyone else s engine EITHER that showed a LOSS to the larger unit, just a few that showed no IMPROVEMENT in a particular application, and if your thinking of pointing out a lack of throttle response that's been repeatedly shown to be due to tuning issues like low fuel pressure, too small of injectors,or the TPS voltage was off the mark, the IAC was not set correctly or the ignition timing curve was not ideal, or in a few cases the compression ratio was to low for the cam collected, get the LCA or duration wrong for the application and AIR FLOW REVERSION in the runners CAN cause problems, like a bog when you transition from idle to W.O.T. almost instantly, but in no case IVE seen was the extra potential air flow a problem, especially once you realize that the plenum/ports carry only AIR, and the fuels injected in the last 4 inches of the runners

http://www.airflowresearch.com/super-chevy-sep-2013-195cc-sbc.php

BTW

http://www.sallee-chevrolet.com/frame.html?/sales.html

RAM JET 502 - FACTORY FUEL-INJECTED BIG-BLOCK POWER

P/N 12499121 [Old P/N 12497323]

The recipe is simple; one part attitude, one part driving perfection, one part leading factory technology, and five hundred and two parts hungry rat motor. Ram Jet 502, you either have one, or you want one! When the idea of an all new big block fuel injection system first came up, we all thought it was a good one. When it was proposed that it be integrated with our 502 crate engine, we thought someone had clearly lost their mind. Who could possibly need the awesome, flat, broad torque curve only available with a long runner dry manifold? And who would want the neck-snapping throttle response of MEFI 4 controlled port fuel injectors? And what would be the need for aggressive tunnel ram styling? But then we remembered we’re not building 100 mile per gallon, 0 to 60 in a week, eco scooters. We’re in the hot rod business! So we called together engine management system experts from GM Power train, our own GMPP engineers, and fuel injected race engine builder and GMPP Pro Mod racer Harold Martin. After some great discussions, a little debate, a lot of late nights and 50 gallons of coffee we had an intake manifold design like no other. By leveraging leading fuel management technology, numerous production developed components, the industry standard MEFI 4 controller and the great Ram Jet name from the 50’s, the Ram Jet 502 is reality.

The new undisputed heavy weight champion, the Ram Jet 502, makes 502 horsepower at 5100 rpm and 565 ft.lbs. of torque at 3200 rpm. The instantly throttle responsive Ram Jet 502 drives like no other big block you’ve ever driven. With over 500 ft. lbs. of torque from 2,200 to 5200 rpm, the Ram Jet 502 is a tire shredding monster making more torque throughout its operating range. This is possible because Ram Jet has a larger plenum and runners than would ever be possible in a carburetor application. This means greater intake efficiency and greater torque without sacrificing drive-ability. The Ram Jet manifold is so efficient that we’re able to make all of this horsepower and torque with a production L98 throttle body assembly, you know, the one that Firebird and Camaro owners always replace when trying to make more power in their 350 engines. It’s all about airflow quality, velocity, and fuel and spark management. You’ll just have to drive one to appreciate it. If the one-second cold starts, no stalling, instant throttle response, and the solid pull from idle to red line don’t convince you that a Ram Jet 502 is for you, then maybe you would be more interested an a competitor’s futuristic dream of a 100 mile per gallon, 0 to 60 in a week, eco scooter or a good old fashion bicycle for those weekend events to impress all your friends at the local hot rod club or for those weekend cruses out on the highway to impress everyone else on the road.

The Ram Jet 502 is designed for ease of installation needing only 12V, ground, fuel feed and fuel return to run. Included are an instruction sheet, service manual and diagnostic tool for ease of installation and service. As with any GM Performance Parts Ram Jet engine, an in tank fuel pump is recommended to avoid possible vapor lock. See instruction sheet for fuel pump recommendations. Also included is complete throttle linkage that accepts your production throttle cable and transmission cable. Includes pre-programmed MEFI 4 ECM and wiring harness. This revised electronic and closed loop system gives a much smoother idle and better performance then the MEFI 3 ECM system it replaced.

The Ram Jet manifold stands eleven inches tall as measured from the front and rear “china wall†on the cylinder block. That’s just half an inch taller than a typical single plane high rise manifold, Holley carb and air cleaner combo.

RAM JET 502 TECHNICAL INFORMATION

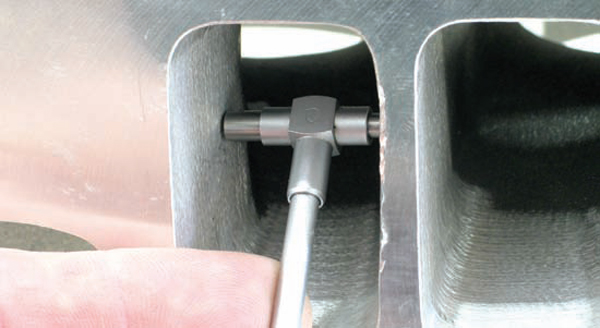

HERES A FEW PICTURES of a rather extensively ported edelbrock TPI intake, which was up untill the advent of the "FIRST" intake one of the better options

a great deal of the info you may want can be calculated after carefully measuring the intake port and runner length and cross sectional areas.(remember its not the intake port gasket cross sectional opening, cross sectional area, its the smallest part of the port cross sectional area and valve throat areas that limit port flow rates)

if as an example we selected a port with about a 2 sq inch cross sectional area, you'll find max torque on a 350 will fall near 4000-rpm and port stall near 6000-rpm thus it makes sense to match the cam timing and lift/duration and the drive train gearing to match the rpm range,power curve and port flow.

or put a bit differently, theres no sense in selecting a cam designed to operate well at 7600 rpm if you port stalls at 6300 rpm

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calchpaf.htm

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

http://www.summitracing.com/parts/cca-5605/overview/

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-26322

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

Last edited by a moderator: