tracking down a "NOISE" especially engine or drive train

First of all - don't assume your problem or noise is cause by your repairs or recent work, thats NOT always the case, but its always a good idea to verify everything.. It is likely one of those corollary laws related to Murphy's law - never assume that you problem is caused by the last thing you changed on your motor. something unrelated breaks occasionally while the work your doing is being done. Guys always seen too jump to the assumption that whatever they changed caused the problem. Unfortunately, it ends up being a coincidence - and those people spend a lot of time and money chasing a problem that they assume is related to the work they did. You HAVE to be systematic and thorough diagnosing the problem

do yourself a favor if you have only one lifter ticking, and swap the rocker and push rod thats clicking with one at a different location on the other cylinder head, and see if the clicking moves with the rocker and push rod or remains at the original location, and check the valve spring and rocker stud during the swap process as a first test.you might also very carefully inspect the push rod slot to push rod side clearance , AS I have seen cases where it rubbed and would not allow the push rod to seat centered in the lifter seat during the full cycle thru the rocker arc.

you need to do a step-by-step test and verify approach to isolate and locate the source of the noise or problem, the only logical route to take is to look at each potential area that COULD be a problem and verify it is either the cause or not the cause,it will be reasonably easy to locate the source of the noise if you put the car up on 4 frame support,jack stands or a two post lift and have a friend rotate the tires as you look for the source, run the various accessories, test things with a shop manual to verify function, use a multi meter and don,t assume anything works until you prove it does. think about when the problem occurs and under what conditions , you might need to start the car or hit the brakes , run the engine or adjust something, test sensors etc.but with the car up off the tires it should be far easier to locate the noise origin

you always need to verify the true problem before looking for solutions, Assuming youve located the lifter tick to a single cylinder location, do this quick test, look carefully for an exhaust gasket leak, if you don,t find one .swap a couple rocker arms that are NOT near each other and see if the problem stays with the lifter or rocker arm location

a good many lifter ticks are rocker related

try to locate the source to the engine,transmission ,drive train, rear differential, brakes, etc. is the source related to the gear the cars in?, tire rotation> in or out of gear? is the noise consistent in forward, reverse? on/off the brakes, is it electrical in nature? are your fluid levels ok? are all the vacuum lines, and electrical connectors and grounds connected?

basic logical step by step testing can tell you a good deal

CORVETTES are WELL KNOWN for strange noises, and other cars are hardly exempt.

PRIME SUSPECTS

LOOSE TORQUE CONVERTER BOLTS

BAD U-JOINTS

BAD WHEEL BEARINGS

LOOSE FLYWHEEL or FLEX PLATE,

BAD THROW OUT BEARING

BAD BRAKES

LOOSE VACUUM OR ELECTRICAL CONNECTIONS

LOOSE or WORN, BELT DRIVEN, ENGINE ACCESSORIES

power accessories like window, or fan motors

exhaust leaks

lack of lubrication on moving interior parts like seat tracks

looe or damaged body,engine or transmission mounts

loose cross members.

You should be able to locate the source of the noise or at least the area its coming from to concentrate further investigation. by locating the area, on the cars body or when the noise occures durring either a brief test drive or putting the car up on a lift!

Try to find out and isolate the problem too,

if its

engine speed,(rpm)

engine temp.

or wheel rotation,

transmission gear

or car speed

or body movement

stearing system or brakes or

(suspension) related

ALWAYS HELPS TO HAVE A SHOP MANUAL

viewtopic.php?f=80&t=728&p=8392&hilit=sensor+location#p8392

(1)

pull the plugs take CLEAR detailed PICTURES of EACH plug label them as to original location and post the pictures

http://www.harborfreight.com/3x-magnify ... 94367.html

having a spark plug holder with numbered holes and a good inspection tool helps

http://garage.grumpysperformance.com/index.php?threads/vacuum-gauge-help.9453/#post-34623

http://www.summitracing.com/parts/PIT-229/

viewtopic.php?f=70&t=202

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

(2)

do a compression test, post the results

viewtopic.php?f=87&t=332&hilit=+leak+down+

(3) whats a vacuum gauge indicate at

http://www.secondchancegarage.com/public/186.cfm

idle

1200rpm

3000rpm

viewtopic.php?f=44&t=4775&p=15947&hilit=vacuum+gauge+tuning#p15947

whats your ignition timing curve, yes I know your sure its correct , chances are 99.9%ITS NOT!

you need to verify both TRUE TDC and have a damper thats marked with a timing tape or a marked damper cover and you need to use a QUALITY timing light and graph out the timing from 800rpm-3600rpm in 300 rpm steps

viewtopic.php?f=70&t=4683&p=12672&hilit=propane+leaks#p12672

viewtopic.php?f=44&t=4949&p=13698&hilit=rocker+stud#p13698

http://garage.grumpysperformance.com/index.php?threads/the-trucks-just-not-running-well.13435/

(4)

yes Im sure your sure the valves are adjusted correctly and your clearances in the valve train are correct, but unless YOU personally verified EVERY ROCKER AND SPRING ETC,inspect closely for broken valve springs, burnt rocker bearings loose rocker studs etc. its almost surely not been done and checked correctly YES YOULL NEED TO REMOVE BOTH VALVE COVERS TO INSPECT THE VALVE TRAIN.

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=196

(5) whats your oil pressure read at operating temps (200f)

at idle from 800rpm-3600rpm in 300 rpm steps

(6) do you have a INFRARED TEMP GUN? whats the exhaust temps read on each cylinder, at idle after 15 minutes run time?

viewtopic.php?f=4&t=1337&p=2921&hilit=+infrared#p2921

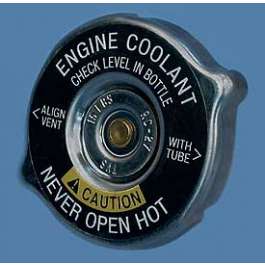

(7) if you start the engine with the radiator cap removed and the radiator filled to the top do you see coolant flow and any bubbles?

(8) have you done a vacuum

leak test with an unlit propane torch?

viewtopic.php?f=62&t=882&p=1390&hilit=vacuum+leaks+propane#p1390

(9)have you pulled and inspected each rocker and inspected each closely?

(10) did you degree in the cam or just use the DOT-TO-DOT index install?

(11) have you put the car up on a two post lift and had someone run the engine while you listen under the car?

does the noise change with RPMS, is it directly related to either RPMS or if the trans gears are changed

(12) is the noise related to steering wheel changes or tire rotation or car speed or during changes in direction ,braking or acceleration?

(13) have you verified all the fluids like power steering, brake fluid, oil in the engine coolant are full?

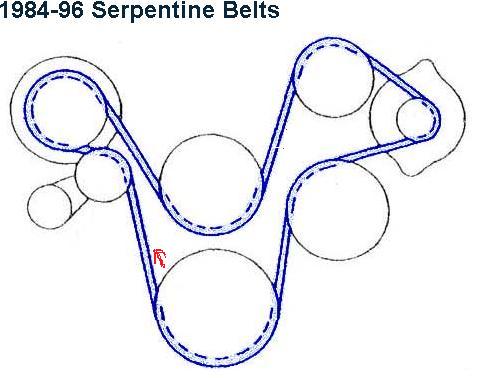

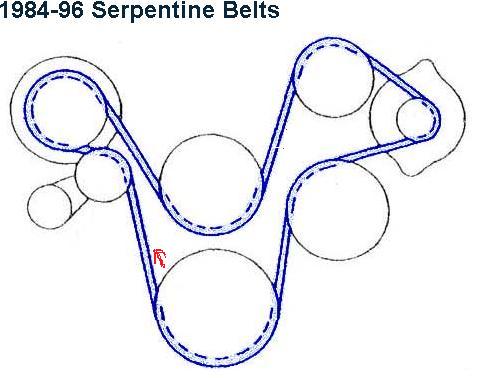

(14)have you removed the serpentine belt and run the engine briefly to see it the accessory drive belt being removed so most of the accessory's don,t spin stops the noise?

viewtopic.php?f=32&t=258&p=3693&hilit=serpentine#p3693

viewtopic.php?f=87&t=3060&p=20088&hilit=serpentine#p20088

(15) have you verified the sensors and fuel flow and pressure?

viewtopic.php?f=32&t=596&p=14674&hilit=propane+leaks#p14674

viewtopic.php?f=55&t=109&p=8207&hilit=vacuum+gauge+tuning#p8207

viewtopic.php?f=44&t=808&p=11560&hilit=throwing+parts#p11560

(16) are you sure its not a leaking exhaust or header gasket?

(17) the most common issues I see are valve train geometry or clearance issues, or related to improper bearing clearances, or assembly.

in an ideal world the rocker pushes strait down the valve stem center line to reduce friction,but having the rocker wear pattern centered on the valve tip is far LESS important than having it rather narrow indicating less side thrust or drag on the valve

and having the rocker geometry a bit off as long as the clearances are correct, is unlikely to cause noise issues as much as long term valve guide wear issues.

Noise is usually the result of clearance issues like the slot in the rocker or rocker ball or body binding on the rocker stud or rocker adjustment nut, or the valve retainer touching the rocker body or spring bind etc. or badly adjusted valves , and id bet 80% of the engines I see have improperly adjusted valves of valve train clearance issues

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=181

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=1376

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=6237&p=32472&hilit=tracking+down#p32472

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=196

viewtopic.php?f=56&t=3107&p=8291#p8291

viewtopic.php?f=87&t=10077&p=39367#p39367

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=3834

viewtopic.php?f=54&t=3519

viewtopic.php?f=54&t=150

viewtopic.php?f=52&t=6237&p=19552&hilit=tracking+down#p19552

viewtopic.php?f=52&t=7716&p=29797&hilit=locating+noise#p29797

viewtopic.php?f=45&t=7021&p=23229&hilit=cracked+flexplate#p23229

viewtopic.php?f=70&t=1701&p=5252&hilit=distributor+gear+wear#p5252

viewtopic.php?f=32&t=6011&p=18597&hilit=noid#p18597

viewtopic.php?f=55&t=635&p=12710&hilit=noid#p12710

viewtopic.php?f=55&t=606&p=7969&hilit=noid#p7969

theres at least a dozen more things to check but that will get you started

BTW

if your doing a SBC to BBC engine swap, you might need this bit of info on frame mounts

First of all - don't assume your problem or noise is cause by your repairs or recent work, thats NOT always the case, but its always a good idea to verify everything.. It is likely one of those corollary laws related to Murphy's law - never assume that you problem is caused by the last thing you changed on your motor. something unrelated breaks occasionally while the work your doing is being done. Guys always seen too jump to the assumption that whatever they changed caused the problem. Unfortunately, it ends up being a coincidence - and those people spend a lot of time and money chasing a problem that they assume is related to the work they did. You HAVE to be systematic and thorough diagnosing the problem

do yourself a favor if you have only one lifter ticking, and swap the rocker and push rod thats clicking with one at a different location on the other cylinder head, and see if the clicking moves with the rocker and push rod or remains at the original location, and check the valve spring and rocker stud during the swap process as a first test.you might also very carefully inspect the push rod slot to push rod side clearance , AS I have seen cases where it rubbed and would not allow the push rod to seat centered in the lifter seat during the full cycle thru the rocker arc.

you need to do a step-by-step test and verify approach to isolate and locate the source of the noise or problem, the only logical route to take is to look at each potential area that COULD be a problem and verify it is either the cause or not the cause,it will be reasonably easy to locate the source of the noise if you put the car up on 4 frame support,jack stands or a two post lift and have a friend rotate the tires as you look for the source, run the various accessories, test things with a shop manual to verify function, use a multi meter and don,t assume anything works until you prove it does. think about when the problem occurs and under what conditions , you might need to start the car or hit the brakes , run the engine or adjust something, test sensors etc.but with the car up off the tires it should be far easier to locate the noise origin

you always need to verify the true problem before looking for solutions, Assuming youve located the lifter tick to a single cylinder location, do this quick test, look carefully for an exhaust gasket leak, if you don,t find one .swap a couple rocker arms that are NOT near each other and see if the problem stays with the lifter or rocker arm location

a good many lifter ticks are rocker related

try to locate the source to the engine,transmission ,drive train, rear differential, brakes, etc. is the source related to the gear the cars in?, tire rotation> in or out of gear? is the noise consistent in forward, reverse? on/off the brakes, is it electrical in nature? are your fluid levels ok? are all the vacuum lines, and electrical connectors and grounds connected?

basic logical step by step testing can tell you a good deal

CORVETTES are WELL KNOWN for strange noises, and other cars are hardly exempt.

PRIME SUSPECTS

LOOSE TORQUE CONVERTER BOLTS

BAD U-JOINTS

BAD WHEEL BEARINGS

LOOSE FLYWHEEL or FLEX PLATE,

BAD THROW OUT BEARING

BAD BRAKES

LOOSE VACUUM OR ELECTRICAL CONNECTIONS

LOOSE or WORN, BELT DRIVEN, ENGINE ACCESSORIES

power accessories like window, or fan motors

exhaust leaks

lack of lubrication on moving interior parts like seat tracks

looe or damaged body,engine or transmission mounts

loose cross members.

You should be able to locate the source of the noise or at least the area its coming from to concentrate further investigation. by locating the area, on the cars body or when the noise occures durring either a brief test drive or putting the car up on a lift!

Try to find out and isolate the problem too,

if its

engine speed,(rpm)

engine temp.

or wheel rotation,

transmission gear

or car speed

or body movement

stearing system or brakes or

(suspension) related

ALWAYS HELPS TO HAVE A SHOP MANUAL

viewtopic.php?f=80&t=728&p=8392&hilit=sensor+location#p8392

(1)

pull the plugs take CLEAR detailed PICTURES of EACH plug label them as to original location and post the pictures

http://www.harborfreight.com/3x-magnify ... 94367.html

having a spark plug holder with numbered holes and a good inspection tool helps

http://garage.grumpysperformance.com/index.php?threads/vacuum-gauge-help.9453/#post-34623

http://www.summitracing.com/parts/PIT-229/

viewtopic.php?f=70&t=202

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

(2)

do a compression test, post the results

viewtopic.php?f=87&t=332&hilit=+leak+down+

(3) whats a vacuum gauge indicate at

http://www.secondchancegarage.com/public/186.cfm

idle

1200rpm

3000rpm

viewtopic.php?f=44&t=4775&p=15947&hilit=vacuum+gauge+tuning#p15947

whats your ignition timing curve, yes I know your sure its correct , chances are 99.9%ITS NOT!

you need to verify both TRUE TDC and have a damper thats marked with a timing tape or a marked damper cover and you need to use a QUALITY timing light and graph out the timing from 800rpm-3600rpm in 300 rpm steps

viewtopic.php?f=70&t=4683&p=12672&hilit=propane+leaks#p12672

viewtopic.php?f=44&t=4949&p=13698&hilit=rocker+stud#p13698

http://garage.grumpysperformance.com/index.php?threads/the-trucks-just-not-running-well.13435/

(4)

yes Im sure your sure the valves are adjusted correctly and your clearances in the valve train are correct, but unless YOU personally verified EVERY ROCKER AND SPRING ETC,inspect closely for broken valve springs, burnt rocker bearings loose rocker studs etc. its almost surely not been done and checked correctly YES YOULL NEED TO REMOVE BOTH VALVE COVERS TO INSPECT THE VALVE TRAIN.

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=196

(5) whats your oil pressure read at operating temps (200f)

at idle from 800rpm-3600rpm in 300 rpm steps

(6) do you have a INFRARED TEMP GUN? whats the exhaust temps read on each cylinder, at idle after 15 minutes run time?

viewtopic.php?f=4&t=1337&p=2921&hilit=+infrared#p2921

(7) if you start the engine with the radiator cap removed and the radiator filled to the top do you see coolant flow and any bubbles?

(8) have you done a vacuum

leak test with an unlit propane torch?

viewtopic.php?f=62&t=882&p=1390&hilit=vacuum+leaks+propane#p1390

(9)have you pulled and inspected each rocker and inspected each closely?

(10) did you degree in the cam or just use the DOT-TO-DOT index install?

(11) have you put the car up on a two post lift and had someone run the engine while you listen under the car?

does the noise change with RPMS, is it directly related to either RPMS or if the trans gears are changed

(12) is the noise related to steering wheel changes or tire rotation or car speed or during changes in direction ,braking or acceleration?

(13) have you verified all the fluids like power steering, brake fluid, oil in the engine coolant are full?

(14)have you removed the serpentine belt and run the engine briefly to see it the accessory drive belt being removed so most of the accessory's don,t spin stops the noise?

viewtopic.php?f=32&t=258&p=3693&hilit=serpentine#p3693

viewtopic.php?f=87&t=3060&p=20088&hilit=serpentine#p20088

(15) have you verified the sensors and fuel flow and pressure?

viewtopic.php?f=32&t=596&p=14674&hilit=propane+leaks#p14674

viewtopic.php?f=55&t=109&p=8207&hilit=vacuum+gauge+tuning#p8207

viewtopic.php?f=44&t=808&p=11560&hilit=throwing+parts#p11560

(16) are you sure its not a leaking exhaust or header gasket?

(17) the most common issues I see are valve train geometry or clearance issues, or related to improper bearing clearances, or assembly.

in an ideal world the rocker pushes strait down the valve stem center line to reduce friction,but having the rocker wear pattern centered on the valve tip is far LESS important than having it rather narrow indicating less side thrust or drag on the valve

and having the rocker geometry a bit off as long as the clearances are correct, is unlikely to cause noise issues as much as long term valve guide wear issues.

Noise is usually the result of clearance issues like the slot in the rocker or rocker ball or body binding on the rocker stud or rocker adjustment nut, or the valve retainer touching the rocker body or spring bind etc. or badly adjusted valves , and id bet 80% of the engines I see have improperly adjusted valves of valve train clearance issues

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=181

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=1376

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=6237&p=32472&hilit=tracking+down#p32472

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=196

viewtopic.php?f=56&t=3107&p=8291#p8291

viewtopic.php?f=87&t=10077&p=39367#p39367

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=3834

viewtopic.php?f=54&t=3519

viewtopic.php?f=54&t=150

viewtopic.php?f=52&t=6237&p=19552&hilit=tracking+down#p19552

viewtopic.php?f=52&t=7716&p=29797&hilit=locating+noise#p29797

viewtopic.php?f=45&t=7021&p=23229&hilit=cracked+flexplate#p23229

viewtopic.php?f=70&t=1701&p=5252&hilit=distributor+gear+wear#p5252

viewtopic.php?f=32&t=6011&p=18597&hilit=noid#p18597

viewtopic.php?f=55&t=635&p=12710&hilit=noid#p12710

viewtopic.php?f=55&t=606&p=7969&hilit=noid#p7969

theres at least a dozen more things to check but that will get you started

BTW

if your doing a SBC to BBC engine swap, you might need this bit of info on frame mounts

Last edited by a moderator: