rebuilt or new chevy 383 crank[B said:liljack][/B]

Okay guys have a question before I spend the money on parts. I'm wanting to put a more peppy motor in my 1987 Chevy V10 swb. Right now it's got a 350 with mild cam aftermarket carb/intake combo is all. I'm wanting to build something that has some pep to it without busting something when I get on it. I have a 010 350 .40 over block, thinking of getting 1/4" (.250) domes, speedmaster (procomp) H beam 4340 rods, Sig Erson .444/.420 lift cam, double roller timing chain, 461 double hump heads that's been punched out to 2.08/1.96 valves, 1.5 ratio rockers, 750 edelbrock, accel distributor and super coil with 8.8mm wires. Okay on to my question will I have a clearance issue with the valves hitting pistons ? Will I need shorter push rods ? Thanks guys

http://www.superchevy.com/how-to/project-cars/sucp-0706-small-block-chevy-stroker-kit/

DEAL IN PROVEN FACTS NEVER GUESS , NEVER ASSUME

first step.

before you start panicking and potentially wasting money and time.

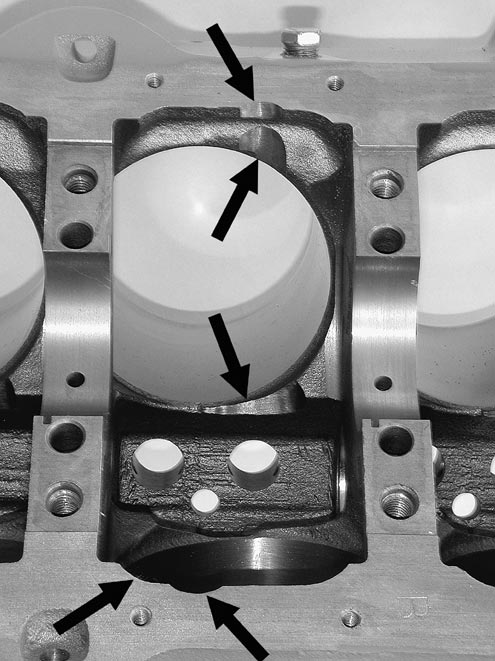

would be to assemble a single piston and rod assembly without rings,

but ideally with some old bearings on the crank and connecting rod and install the cam, in the block

( indexed with a simple,dot to dot timing on the timing gear sets should be ok at this point)

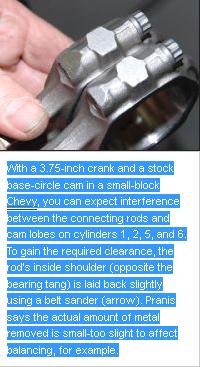

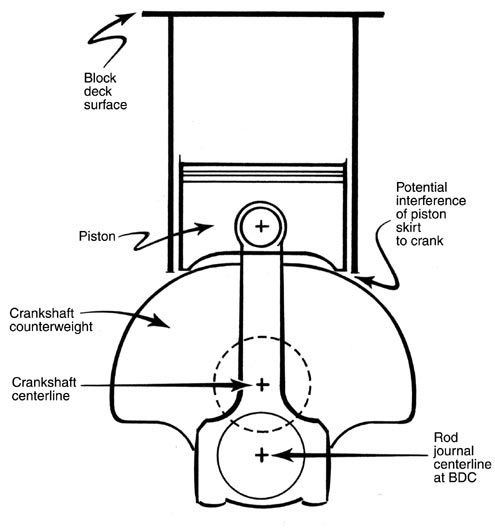

move that connecting rod and piston to all 8 locations and very carefully verify clearances (remember the rod clearance bevel faces the crank counter weight and the piston valve clearances face the outer block)through the full 720 degree rotational cycle, remember the cam spins at 1/2 the crank speed so the cam lobe comes close to the rod every other rotation,

and actually verify you DO, have or DON,T have a potential clearance problem

theres zero sense in runninbg around pulling your hair out and screaming until,

theres actually a PROVEN ISSUE too SOLVE (THERE MAY NOT BE!)

now if you find theres an issue to be solved you proceed using facts

and while your checking the cam lobe to connecting rod clearance check the connecting rod to block clearance ....yes the same minimum .060-.080 clearance is suggested

http://garage.grumpysperformance.co...earances-and-journal-surface.9955/#post-38385

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

generally its a minor easily done clearance job

http://www.scatcrankshafts.com/index.htm

don,t forget to verify the cam to connecting rod clearances

a cams VALVE LIFT is determined by the DISTANCE the lifter moves as the cam rotates under the lifter base as it moves from the cam lobe base circle

(the closest the lifter comes to the cams center line)

up to the cam lobes ramp to the lobes peak,

(the furthest the lifter up off or from the cams center line)

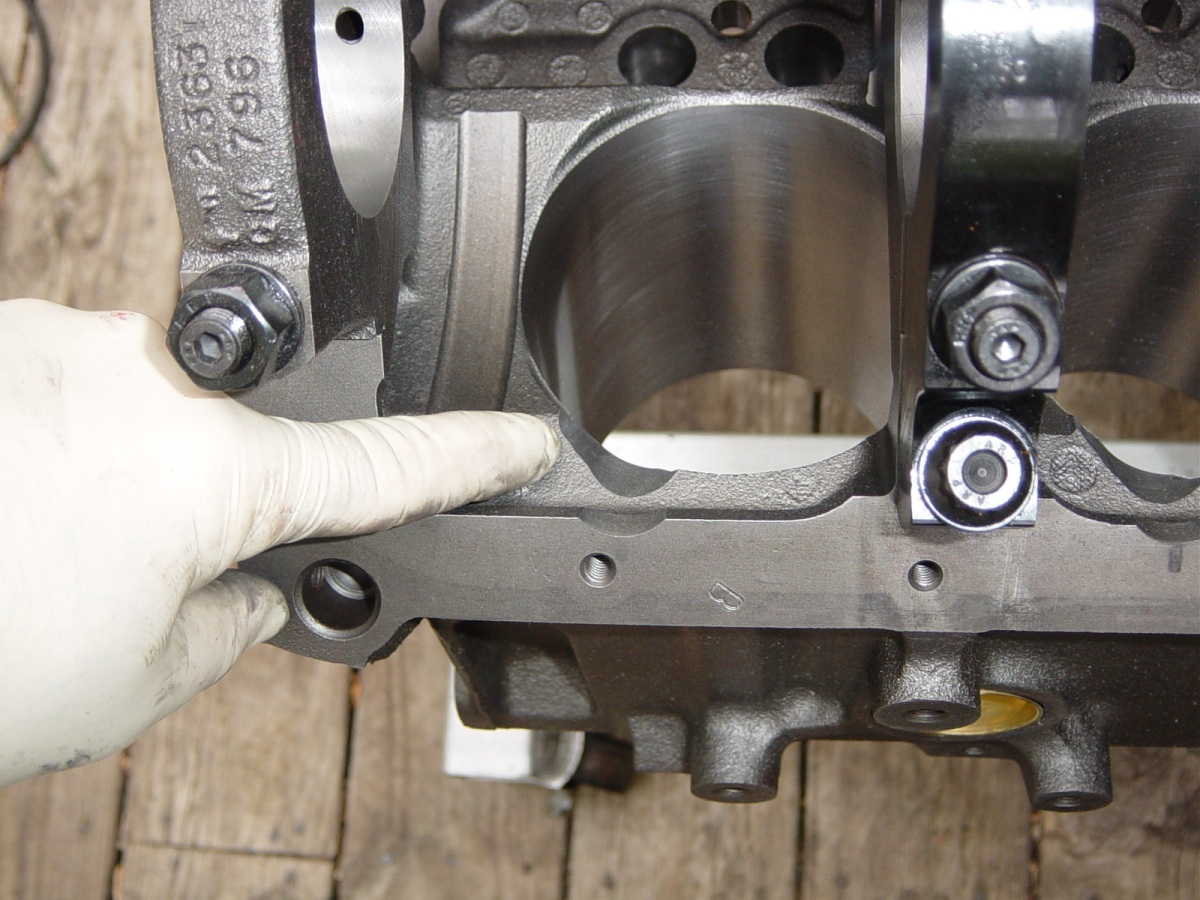

don,t forget to carefully check the piston skirt to crank counter weight clearance, it should be a MINIMUM of .080 thousands

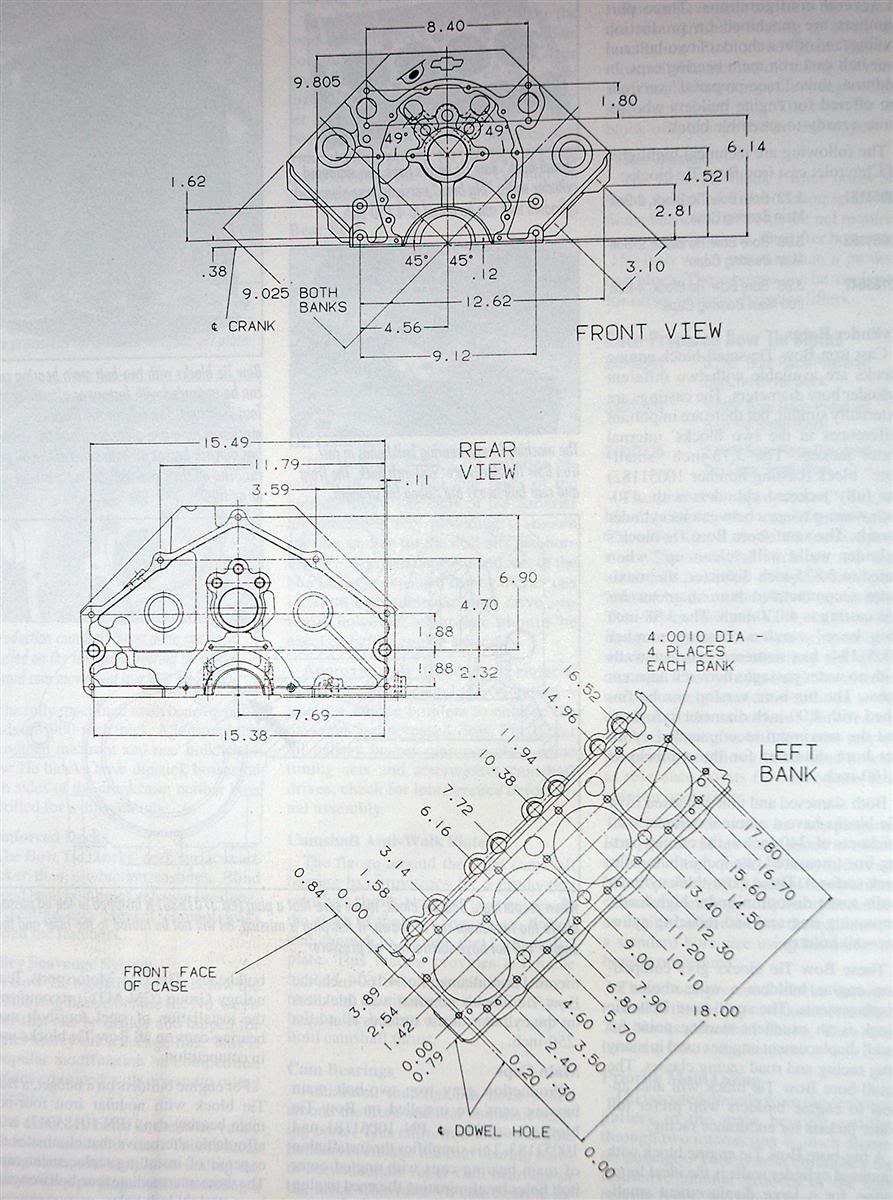

heres some pictures taken of an engine assembly that use a crank designed for a MINIMUM of a 6.25" connecting rod that was used with a 6.135" connecting rod

you can clearly see where the piston pin boss was being hit bye the counter weights, even though the builder checked one piston and found it had .025 clearance during assembly

the result was a trashed engine with lots of damage

http://www.chevrolet.com/performance/crate-engines.html

http://www.hotrod.com/articles/hrdp-0503-chevy-383-engine/

http://www.superchevy.com/how-to/en...-build-a-383-small-block-engine-sledgehammer/

http://www.superchevy.com/how-to/project-cars/sucp-0706-small-block-chevy-stroker-kit/

http://www.chevyhardcore.com/tech-stories/engine/building-the-little-383-small-block-that-could/

http://www.hotrod.com/articles/ccrp-0808-383-stroker-small-block-chevy/

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

“Quality means doing it right when no one is looking.”

― Henry Ford

“Quality is like buying oats. If you want nice, clean, fresh oats, you must pay a fair price. However, if you can be satisfied with oats that have already been through the horse ... that comes a little cheaper.”

an hour to a week spent in careful research,

before you buy or install parts,

can save you months or frustration

and easily 300%-to 500% of the eventually,

cost incurred in buying cheaper parts,in this hobby!

it sounds like you've got a decent starting point that can be tweaked to provide more power but without knowing a few more facts, like what the trucks transmission is, your rear gear,ratio,and if you need to pass emission testing, your really working at a dis-advantage.

you need to actually MEASURE the valve train clearances, push rod length and piston to valve clearances so you can,t just guess!

Id strongly suggest that you step back and not get into a rush to throw a list of available parts together, and then try to deal with the potential problems that usually result.

the key to building any good performance engine correctly is to plan it out precisely,and do so with a KNOWLEDGE BASE , you get from reading up on what the more successful engine builders have previously accomplished,buying and reading a few books as a reference helps, and selecting components that match the intended rpm range and power band, will result in the best engine build for the cost outlay in most cases!

yeah! I'm well aware that 99% of the guys (including myself) learn the skills and develop insight in this hobby through trial & error, but thats both time consuming and totally unnecessary, and a waste of time and money!

having a mentor with decades of experience sure helps you avoid most problems, and asking detailed questions if far cheaper and faster than trying to figure out why some part broke or won,t fit correctly.

if you take the effort to CAREFULLY read the thread links below you'll find that a few well matched components can produce much better results than you might imagine, and certainly it increases the odds you'll have a far better finished project than randomly matched parts would have resulted in.

get out a legal pad, read the links carefully, list the questions your sure to have and lets discuss both what you have to work with in terms of tools, parts and of course finances that limit ALL of our projects!

if your like most guys you would love to go out and buy a long list of components or duplicate some engine build in a magazine article (where they fail to mention all the machine work costs and things they did to get the result without mentioning those parts of mods in the article)

but like most of us you don,t have a bottomless checking account balance or $200K in tools

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

yes you'll ALWAYS NEED to verify clearances carefully when assembling any engine and no, you can,t assume everything will fit just because its part of a component list thats suppose to fit correctly, simply because manufacturing is an imprecise process and mistake do get made occasionally!

if you build enough engines youll eventually see a strong relationship, between higher initial cost and that spending a bit more on heads and rotating assembly and valve train components tends to significantly reduce the problems and increase the engines long term durability.

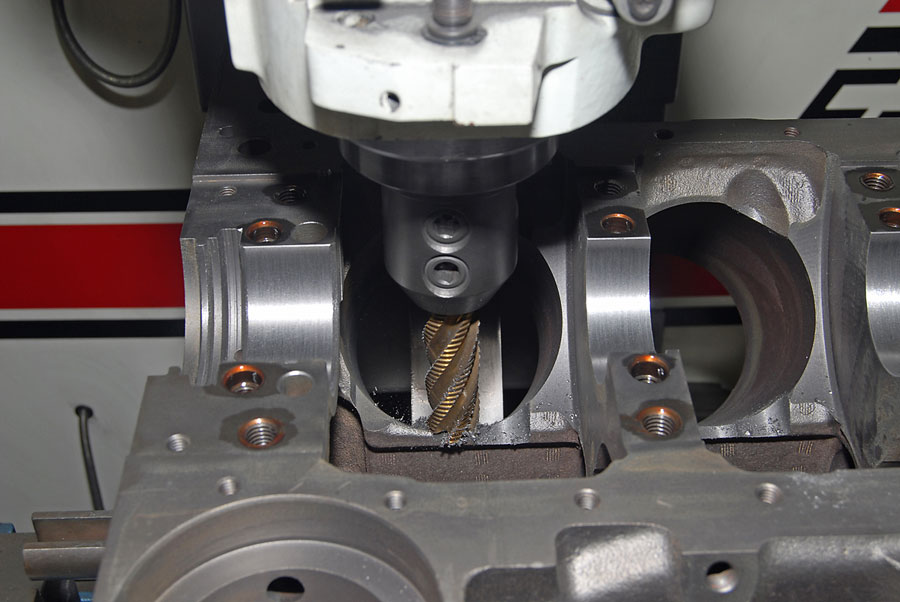

Ive occasionally been asked what you can do too reduce the slack in the timing chain if your blocks been line honed,

to straiten the main bearings and that resulted in a slightly closer crank to cam center-line distance,

that results in a slightly increased slack in the stock timing chain sets.

a negligible amount of metal is generally removed from the main bearing saddles in the block, they usually try very hard to minimize that, metal removal so standard parts still fit,during a line hone , but they do sell slightly tighter timing chain sets to correct excess slack if that's required.

https://www.summitracing.com/parts/clo-9-3100-5

Timing Chain and Gear Set, Original True Roller, Double Roller, -0.005 in., Iron/Steel Sprockets, Chevy, Small Block, Set

for line honed blocks where the crank is .005 closer to the cam

https://www.summitracing.com/parts/clo-9-3100-10

for line honed blocks where the crank is .010 closer to the cam

Timing Chain and Gear Set, Original True Roller, Double Roller, -0.010 in., Iron/Steel Sprockets, Chevy, Small Block, Set

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://garage.grumpysperformance.com/index.php?threads/stroker-tips-by-len-emanuelson.1249/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52466

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.co...ting-started-in-the-car-hobby.339/#post-60187

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

http://www.northernautoparts.com/part/ek-ek1097alb

http://garage.grumpysperformance.co...good-street-combo-your-after.5078/#post-14856

http://garage.grumpysperformance.com/index.php?threads/matching-parts-and-a-logical-plan.7722/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://www.wallaceracing.com/Calculators.htm

Last edited: