theres a hundred threads on this site answering various questions about how to properly select or installation of various components and its rather obvious that the most common questions are some variation on how to either build a decent running performance engine at low cost or trouble shoot various issues with engines that are already built.the key is and always has been to carefully match the components being selected to provide and slightly exceed the expected required and carefully calculated, air flow, rpm range and expected stress levels so you can make and maintain the power expected with a margin for extended durability,so you overcome the inevitable minor air flow and friction losses.

its rather obvious most guys would rather be boiled alive than read what they see as near endless links or sub links but you might be amazed at what youll learn, I know I WAS AS I DID YEARS OF RESEARCH, and RESEARCHED HOW to do things correctly ....yes usually after finding out how NOT to do things, or spending far too much money, like most guys!.

it should be rather obvious that after 60-80 plus years since Chevy,Pontiac,Buick,Olds, Plymouth ,Ford and mopar first produced a v8 engines that a great deal of research and engineering time has gone into building and modifying those engines and that the more popular of those engines that have longer production runs lasting decades like the Chevy,Pontiac, and many Ford and mopar engine have had significant research done and parts produced. thus a bit of research into what HAS worked and what HAS BEEN successful and what has been shown to be the most successful trends should lead anyone whos willing to do some research to several previously successful combos that can be copied, or at least closely duplicated once the basic operational details are understood and logically one should understand the basics of why the basic components function like they do, and what previous combos or modifications failed miserably, as well as what succeeded , so previous mistakes can be avoided.

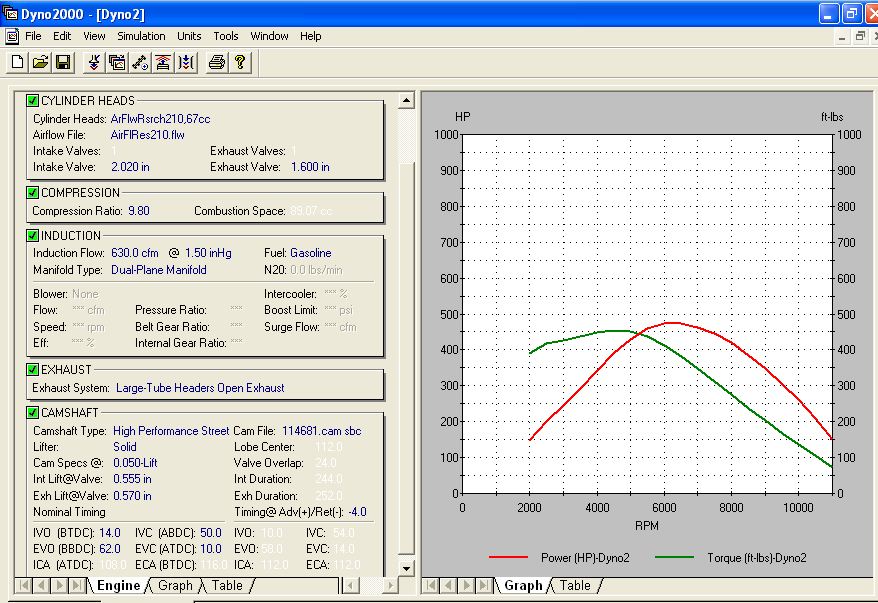

I was asked several dozen times for a good basic combo that won,t break the bank that would result in a nice street engine based on your basic first generation sbc, keep in mind low cost is relative and low cost and quality and long term durability may not be compatible, so I,m talking about a total fresh rebuilt where you have a good rebuild-able 350 block, and decide to build a fresh 383, that will produce over 430 hp at the fly wheel and should last 100K miles or more,ALL THE FACTORS REQUIRED IN THE BUILD CAN BE CALCULATED and it will be designed for street use where it will spend the vast majority of its life at under 4000rpm, and rarely see north of 6300rpm, so low speed torque is important just as upper peak power, so it should push you back in the seat easily if you floor the throttle but not be a problem if you want to drive across the country (well gas mileage will not be great) and compromises were made, but theres a big difference between building a performance engine you might reasonably expect to go 100K miles with minimal maintenance, and an all out race engine that will be rebuilt after each race or at least at the close of the season, that would be expected to spin 7000rpm and not be expected to perform below 4500rpm.

well, to start with a low cost build and I mean to minimize the cost every place I reasonably can, Id strongly suggest we keep cost to a minimum and start with a basic 350 first gen block thats no more than .030 over bore as the stock blocks are not all that rigid, Id maximize the blocks displacement with a SCAT CAST STEEL CRANK, BASED ROTATING ASSEMBLY, YES YOU WANT THE 7/16" CONNECTING ROD UPGRADE as its significantly stronger, 5.7" or 6" your choice ID prefer the 6" rods myself but either will work.

forged pistons are preferred but hyper-eutectic pistons will work ok if you keep the engine rpms reasonable (with a mild performance 383 thats generally about 6200rpm max) and the engine out of detonation.

Id select and edelbrock air gap intake and a 600cfm-700cfm vacuum secondary carb

http://www.flatlanderracing.com/scatsr-chevysbcast.html

on a street car Id prefer a manual transmission, and at least 3.35:1 rear gears but 3.73:1 are ideal

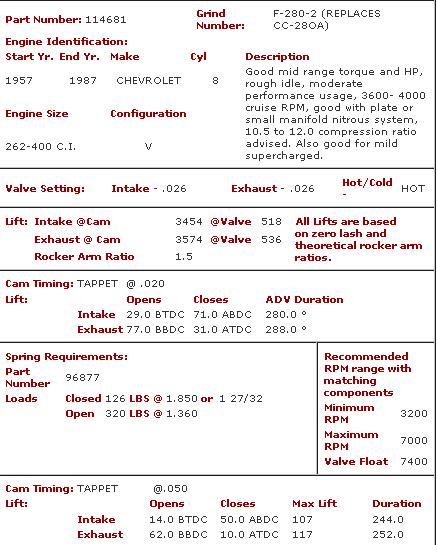

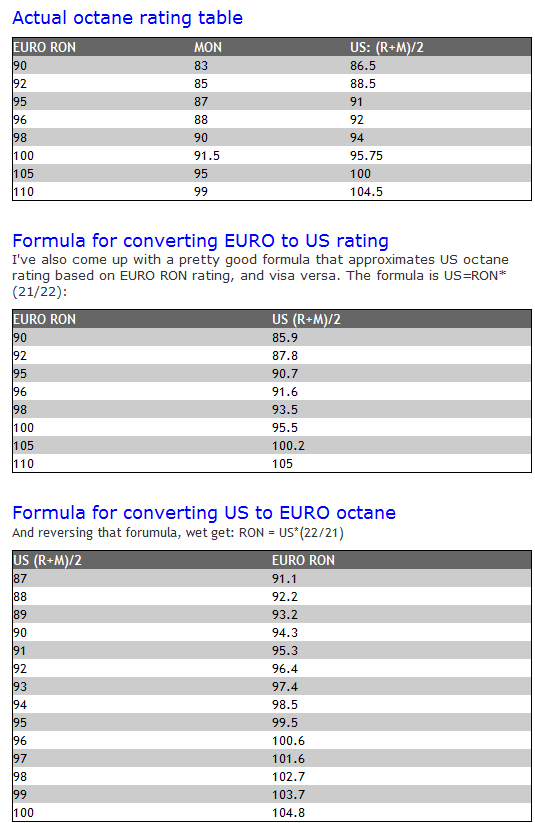

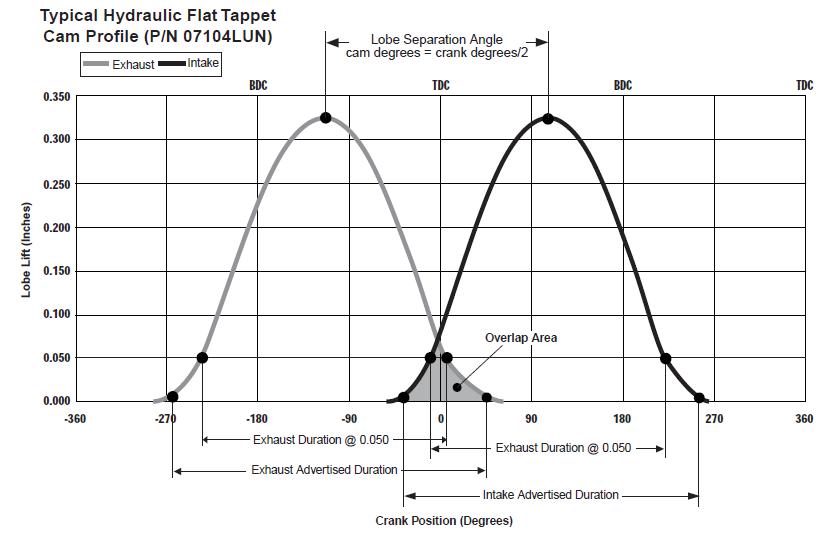

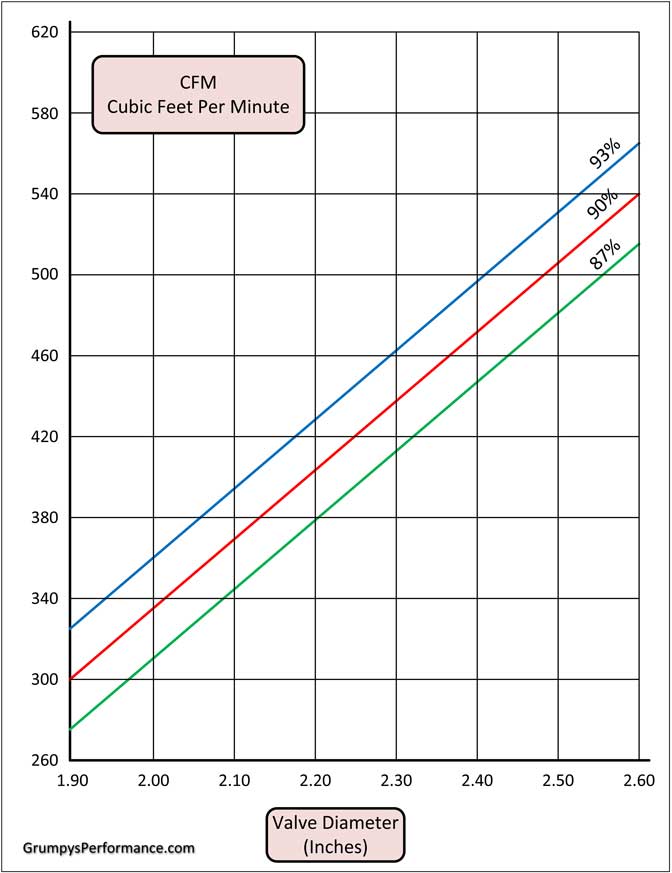

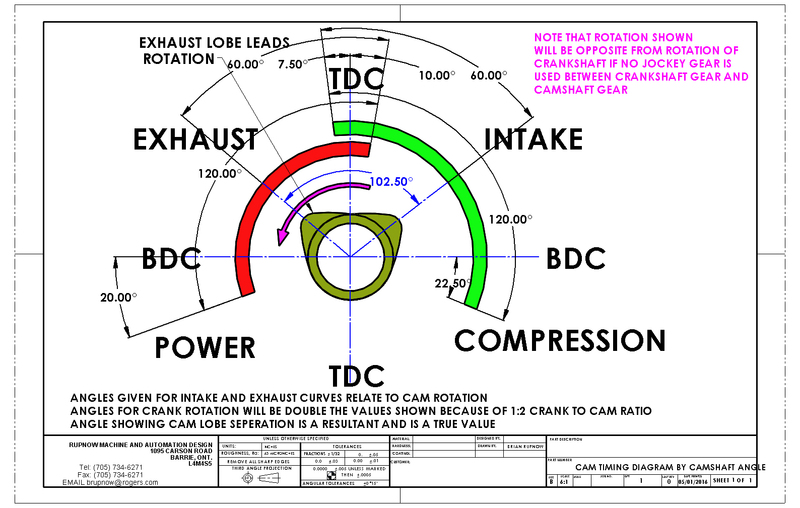

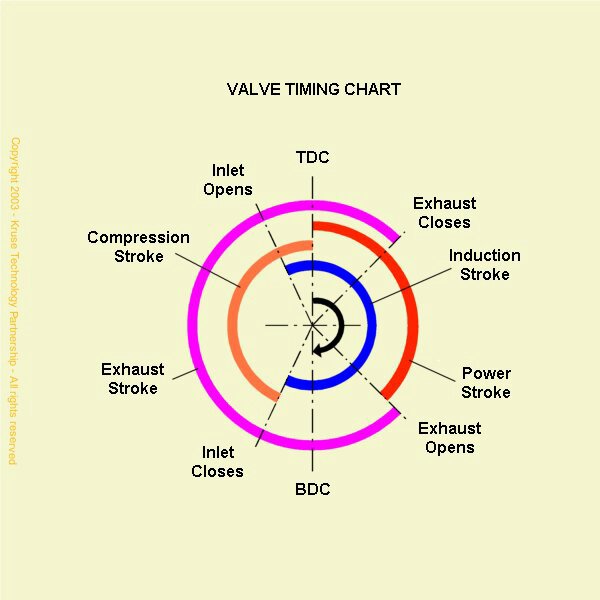

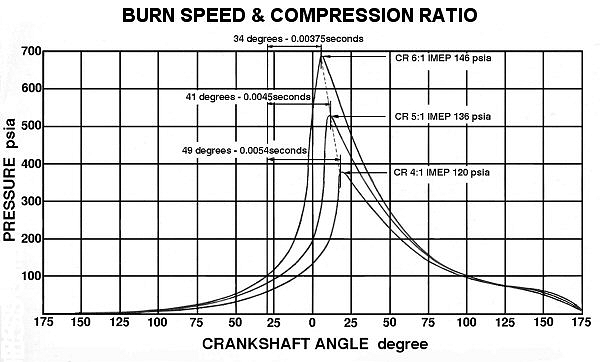

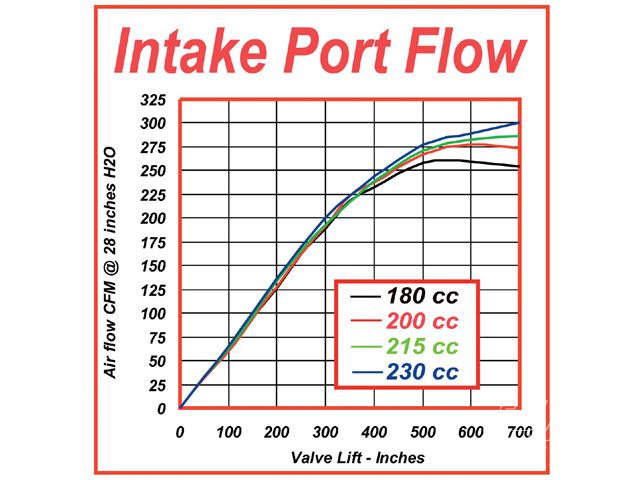

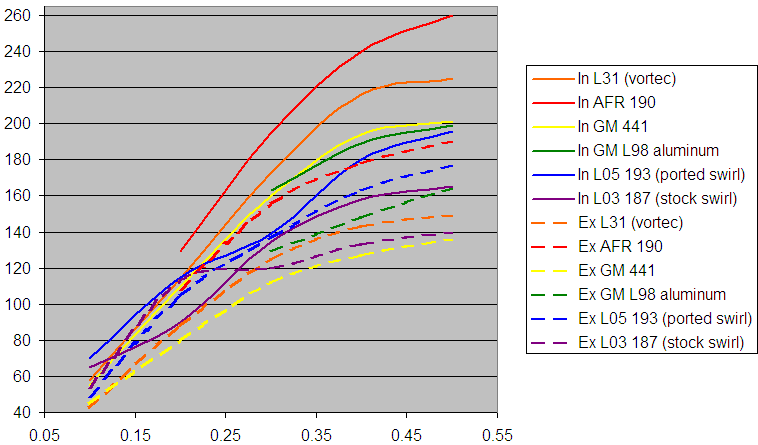

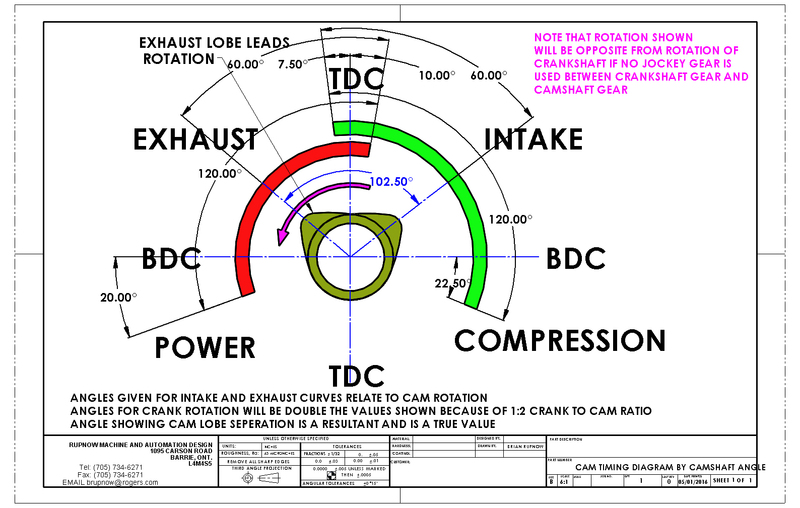

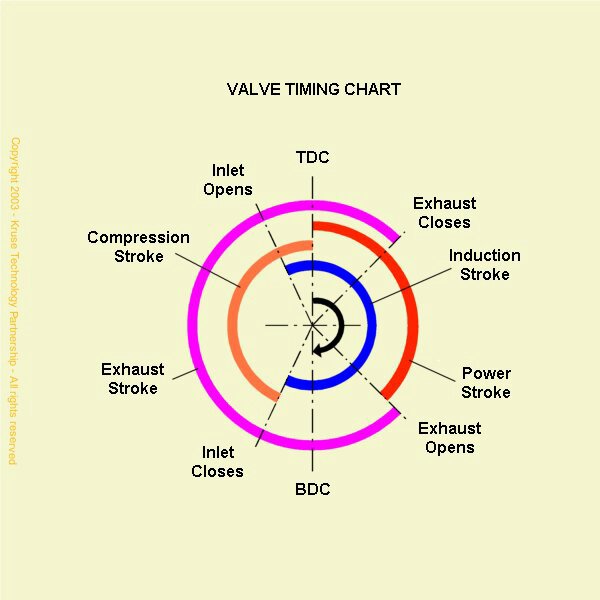

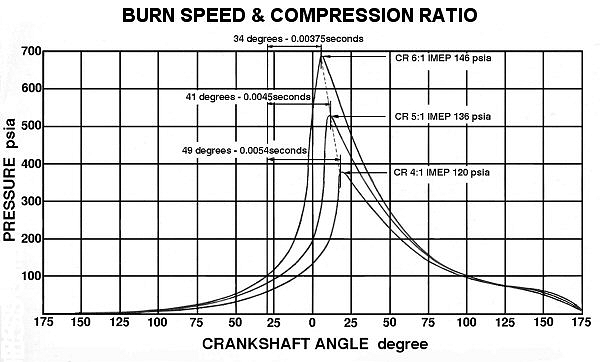

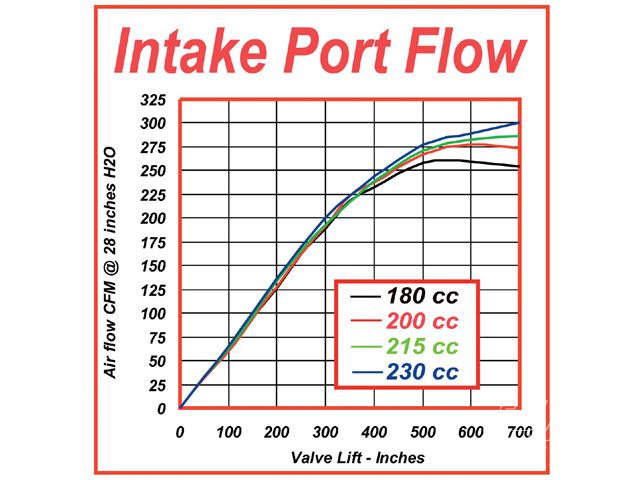

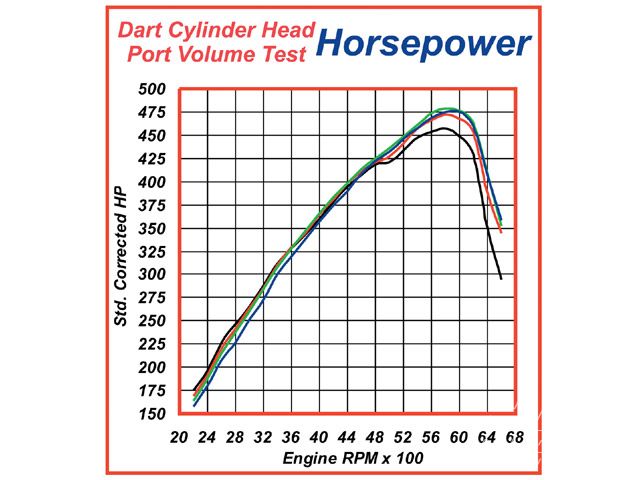

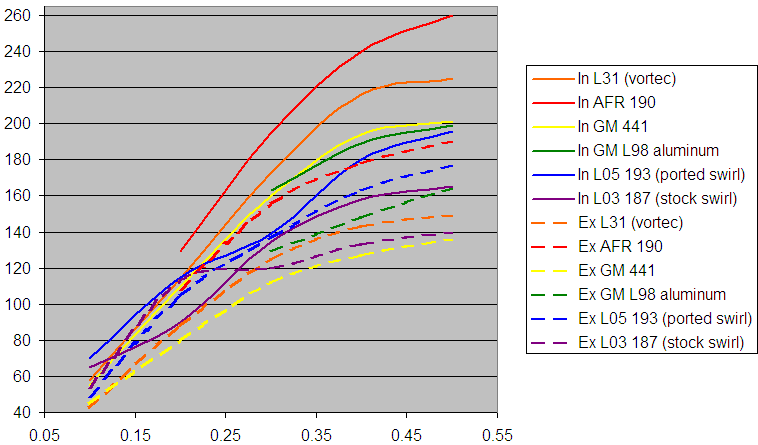

ID want about 9.5:1-10.5:1 static compression to maximize torque but obviously youll need to carefully select the cam timing to get a dynamic compression near 8:1 to run pump octane fuel and aluminum heads that flow at least 250 cfm at .0500 lift,to flow enough air to adequately fill a 383 cylinder at 6300rpm. and Id select a solid lifter flat tappet cam, or if forced into it a hydraulic flat tappet cam, with at least a .500 lift and a 235-245 dur. at .050 lift cam to maximize performance per dollar are about mandatory for maximizing performance , roller cams are great but they are expensive.

Id damn sure put the time in to find a decent 7-8 quart baffled oil pan with a effective windage screen,that fit the car because maintaining consistent oil pressure is mandatory for durability

heres a calculator to calculate ideal port cross sectional area

on a street driven 383 Id design the build to put that some place in the 4000rpm-4500rpm band

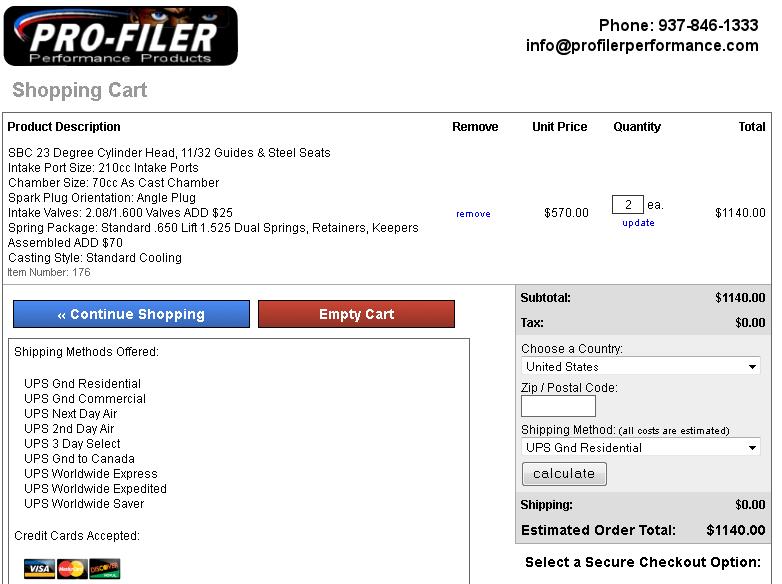

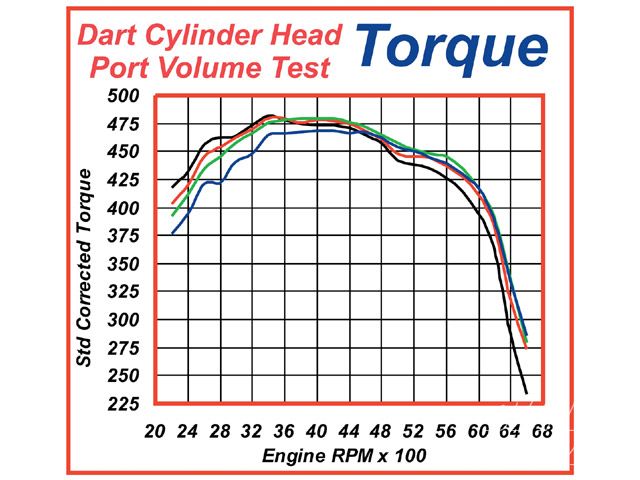

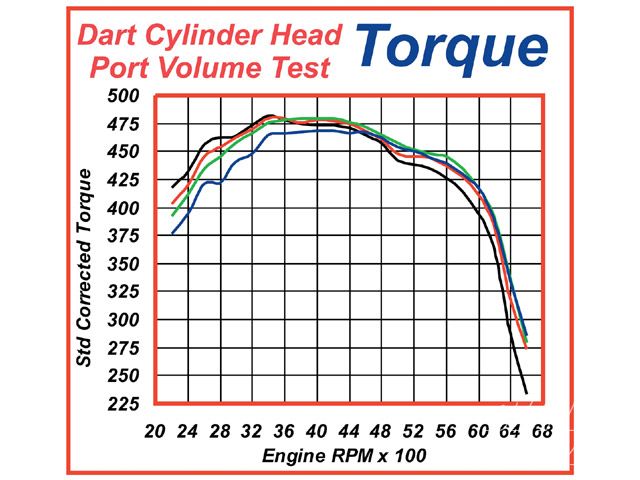

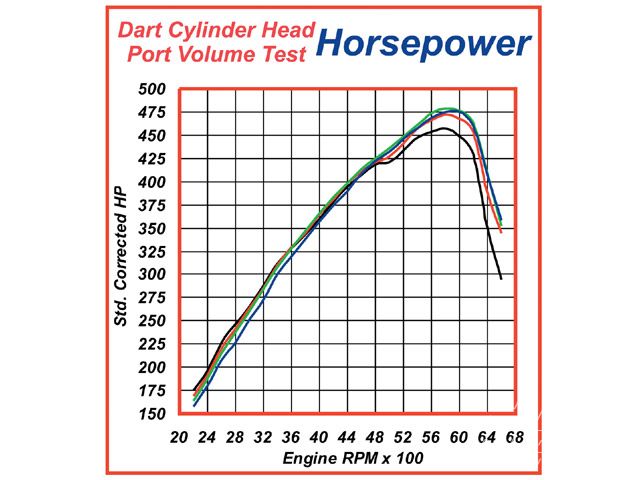

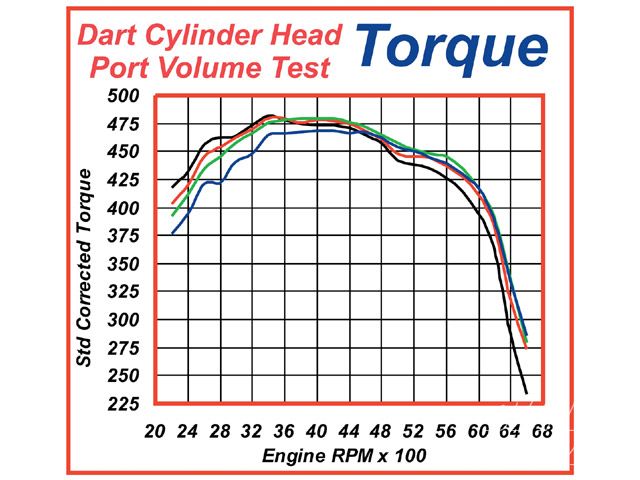

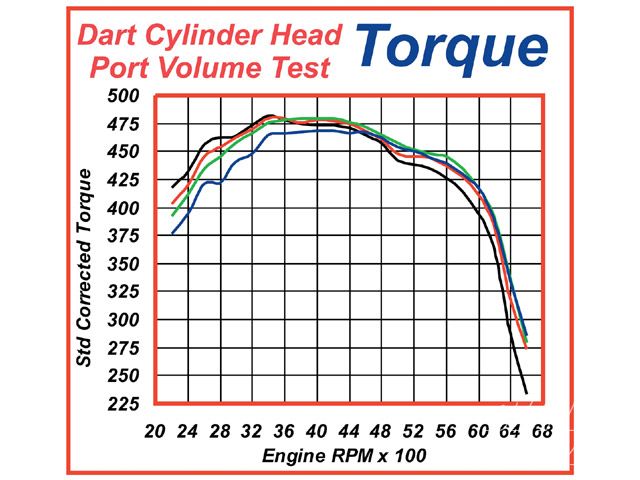

youll generally dump 30%-40% of your budget into good cylinder heads because they hold the key to much of the engines performance potential, on a 383, youll want a 195-215cc port size , if your intent on max power Id go with a larger port cross sectional area, a smaller port will restrict upper rpm power but result in more mid rpm torque ,your choices depending, mostly on gearing, and cam selection and intended operational rpm band.

now keep in mind this is NOT intended to be a max performance build , and you could rather obviously boost peak power with a with more compression, larger port heads, a well designed single plane intake and a larger carburetor and perhaps a wet nitrous plate, and a serious roller cam, but that would also add significantly to the engines cost and tend to make it far less likely to be useful for daily transportation.

a very common misconception, "that the intake runner size has the most effect on the engines torque curve,is mostly a myth" in reality ,compression ratio, cam timing and engine displacement and proper exhaust scavenging ALL have a larger effect on the engines torque that the intake runner cross sectional area.(yes getting it correct helps but your more likely to cause a problem by selecting an intake port and runner combo thats too small and restrictive than one thats too large in cross sectional area.

torque curve closely matches the cylinder fill efficiency ,

http://www.rbracing-rsr.com/runnertorquecalc.html

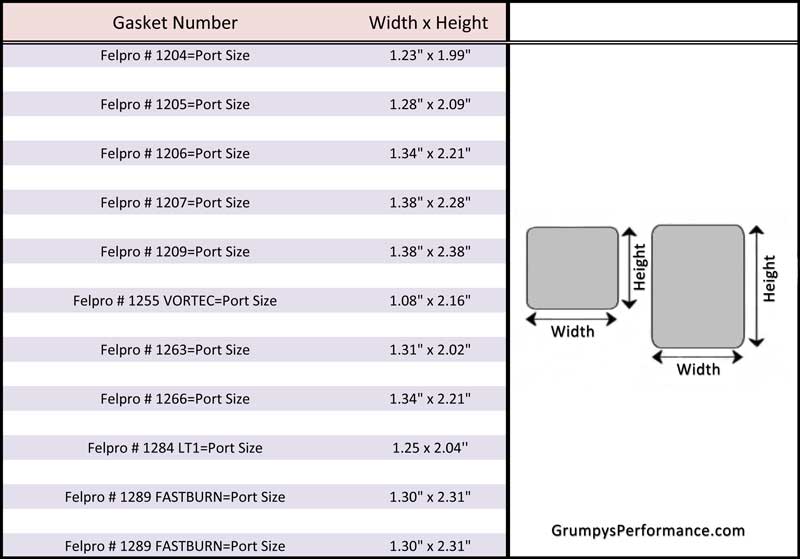

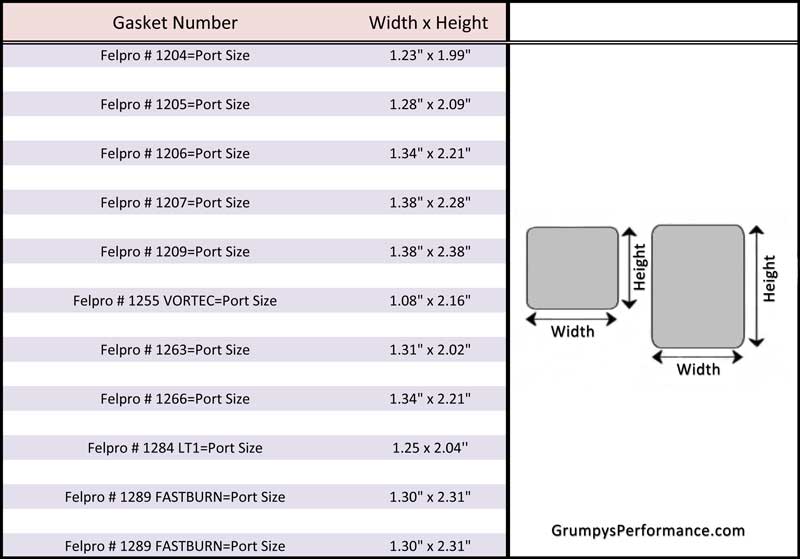

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

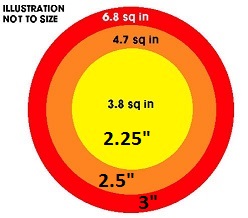

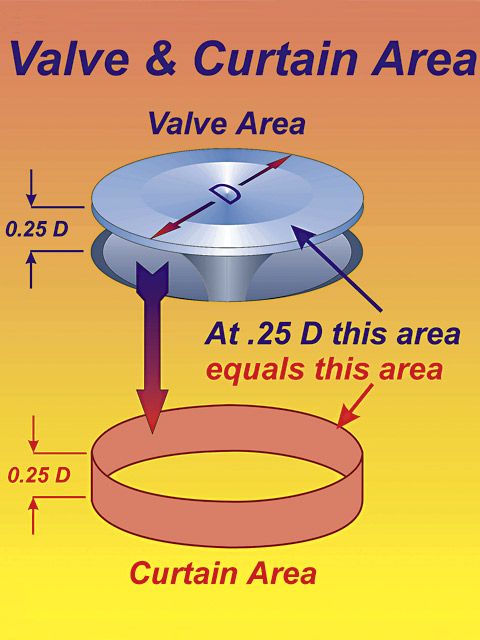

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

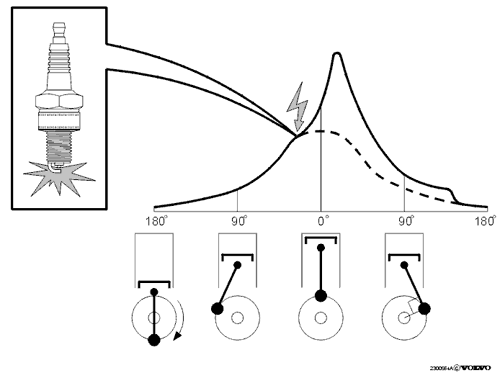

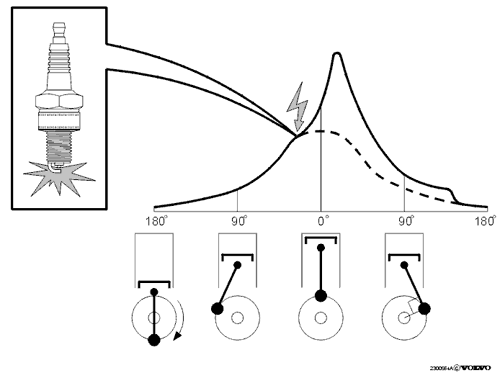

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

there are quite useful ,cam selection soft ware programs that get you in the ball park, but the final selection is based on far more factors than most of those software programs address

http://www.camquest.com/

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.wallaceracing.com/Calculators.htm

if you read thru the links theres a ton of detailed info, but the charts and calculators in the links and sub links will all tend to guide you to a similar conclusion, a semi mild 383SBC can use a cam with about a 235-245 duration at .050 lift with about a 108-110 LSA and ideally about 520- 530 lift so youll generally run 1.6:1 roller rocker to get the required lift at the valve, with a flat tappet cam, obviously if you have the cash exceeding that lift but keeping the duration tends to result in more power potential but it costs more., do the required calculations so the cam you select and the engines compression ration allows you to get to about that 8:1 dynamic compression, and discuss the cam selection with the cam manufacturer.

Id also point out that the closer you are geared to that base 3.336:1 range the lower the cam duration should be, and the closer you get to lets say 3.73:1 the closer you can get to the 245 duration end of the cam range, while all the cams in the range will work, its best to maximize power where the gearing maximizes your average rpm band at cruising speeds

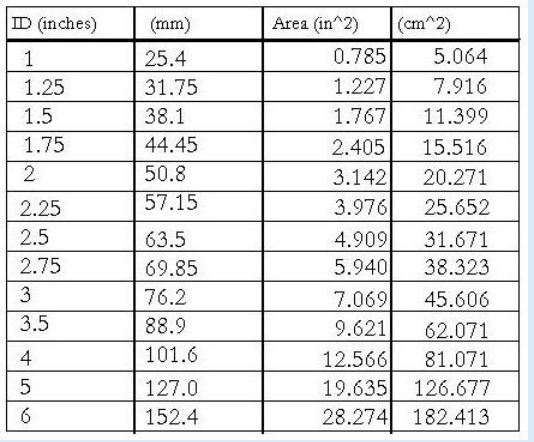

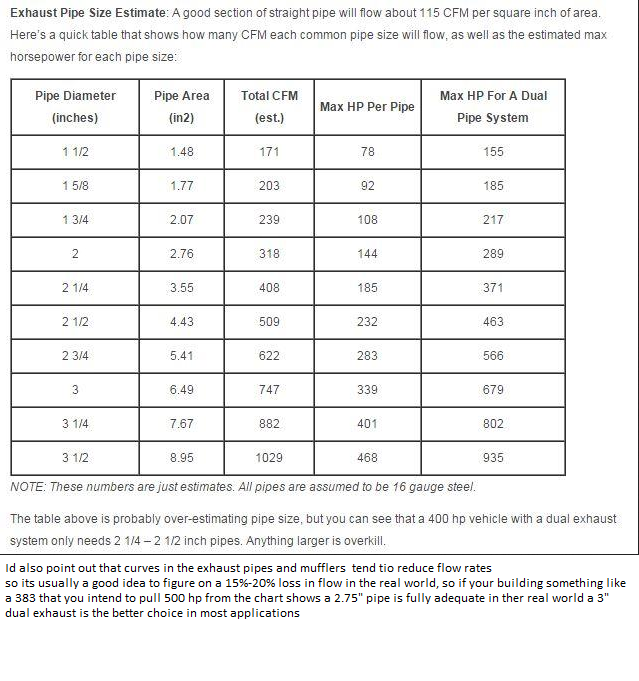

you can use calculators to figure out the best header config, but generally youll find its a 1.75" primary about 38-39" long with a 3" diam, 18"-20" long collector

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/auto.html

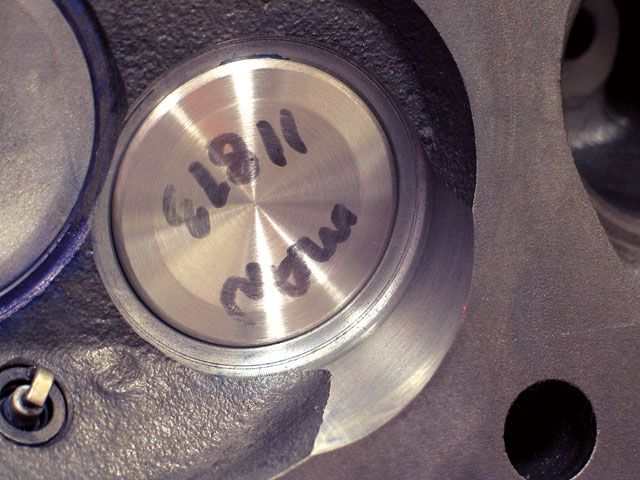

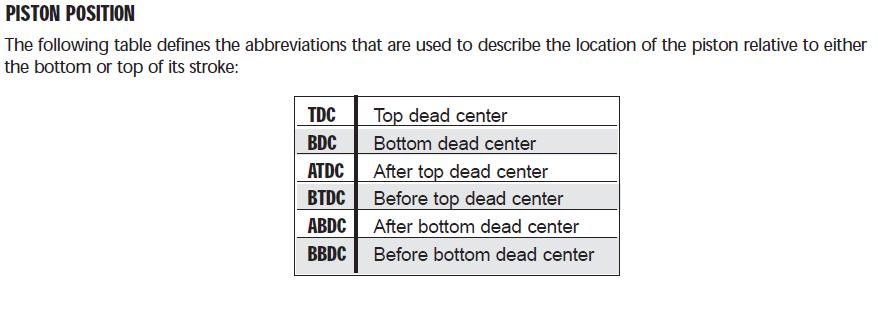

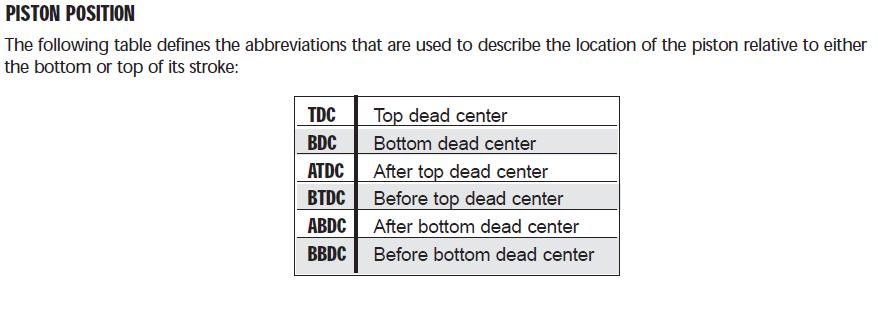

it should be rather obvious that youll need to know the exact distance the piston deck sits at TDC ,above or below the block deck surface and the valve notch recess or pop-up dome volume of the piston to do accurate quench or compression calculations

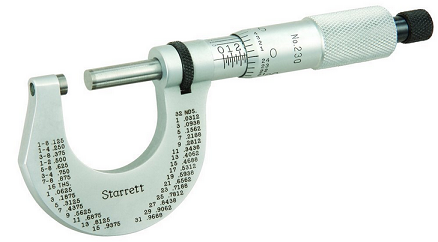

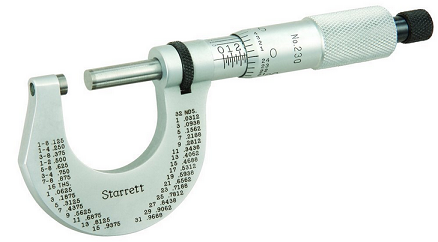

floridas hardly the ideal climate for keeping tools rust free so i generally take my set of micrometers out of the storage case and open and close them and spray them down with a light oil like WD 40 and place them back in the box then place the whole box in a 2 gallon zip lock bag in a shallow tupper ware type air tight storage box that is just the size to fit inside one of your tool chest drawers too protect the precision measuring tools , feeler gauges and plasti-gauge youll need to measure clearances correctly.when not in use along with the dial calipers.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

the reason I bring this up is I recently was over at a friends house where I needed to accurately measure a u-joint bearing cap and asked if he had a micrometer or dial caliper, he responded he had a very expensive looking imported micrometer, he had acquired recently at an estate yard sale for $30,

when he opened the very impressive looking brass and mahogany box the micrometer, inside was a solid rusted mass, I soaked it in marvel mystery oil and acetone mix for 30 minutes then gradually worked it loose and polished it up with 1500 grit wet/dry sand paper figuring no loss at this point and was amazed that after about 30 minutes of constant cleaning it not only looked fairly decent it seemed to read accurately on a test gauge so I think it was mostly ugly surface rust, but it sure looked horrible, and to someone who appreciates good tools,that was depressing.

btw look around at yard sales and estate sales every so often youll find amazing bargains in used precision tools

yes it sure helps to have the correct tools and know where to measure parts

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.harborfreight.com/3-piece-micrometer-set-66512.html

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

http://users.erols.com/srweiss/calcehp.htm

related info

viewtopic.php?f=44&t=38

http://garage.grumpysperformance.com/index.php?threads/cooler-denser-air.8961/#post-54528

http://www.rbracing-rsr.com/calculations.htm

http://airflowresearch.com/articles/article085/A-P1.htm

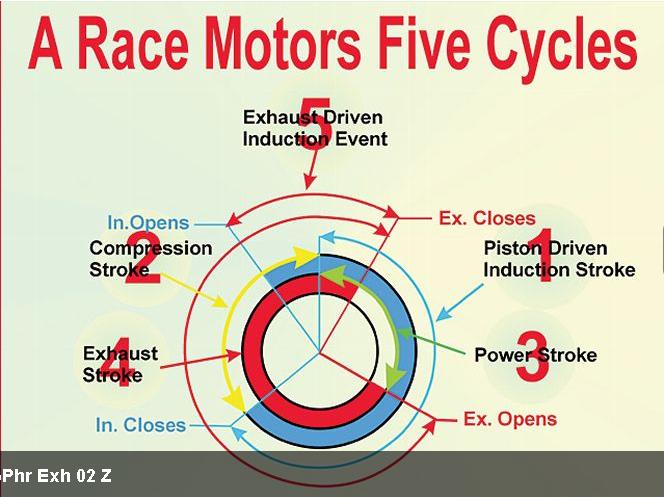

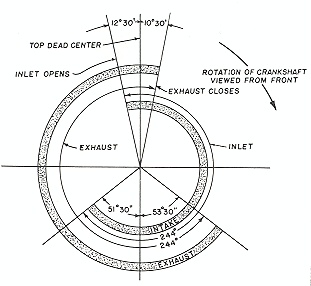

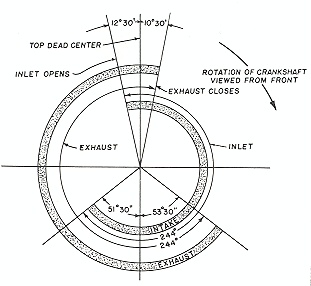

theres lots of charts in the links like this one that provide info, if you have a 383 thats about 48 cubic inches per cylinder, divided by intake valve diam. we get 23.7, looking at the chart we see a LSA of about 106 should be the most efficient

THIS CHARTS RATHER CONSERVATIVE ON SUGGESTED CAM DURATION BUT IT CERTAINLY SHOULD BE A USEFUL GUIDE

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide, when you use a cam with significantly more duration than suggested drive-ability and lower rpm power can suffer

4000 feet per minute in piston speed is generally considered a safe make on a mild performance build with upgraded components, a 383 with its 3.75" stroke would see that as about 6400rpm,but hydraulic lifters tend to float a bit lower so call it 6200rpm, look at the chart and we see a engine with the 383 roughly 48 cubic inch per cylinder needs a 230-240 duration to match that power band

its rather obvious most guys would rather be boiled alive than read what they see as near endless links or sub links but you might be amazed at what youll learn, I know I WAS AS I DID YEARS OF RESEARCH, and RESEARCHED HOW to do things correctly ....yes usually after finding out how NOT to do things, or spending far too much money, like most guys!.

it should be rather obvious that after 60-80 plus years since Chevy,Pontiac,Buick,Olds, Plymouth ,Ford and mopar first produced a v8 engines that a great deal of research and engineering time has gone into building and modifying those engines and that the more popular of those engines that have longer production runs lasting decades like the Chevy,Pontiac, and many Ford and mopar engine have had significant research done and parts produced. thus a bit of research into what HAS worked and what HAS BEEN successful and what has been shown to be the most successful trends should lead anyone whos willing to do some research to several previously successful combos that can be copied, or at least closely duplicated once the basic operational details are understood and logically one should understand the basics of why the basic components function like they do, and what previous combos or modifications failed miserably, as well as what succeeded , so previous mistakes can be avoided.

I was asked several dozen times for a good basic combo that won,t break the bank that would result in a nice street engine based on your basic first generation sbc, keep in mind low cost is relative and low cost and quality and long term durability may not be compatible, so I,m talking about a total fresh rebuilt where you have a good rebuild-able 350 block, and decide to build a fresh 383, that will produce over 430 hp at the fly wheel and should last 100K miles or more,ALL THE FACTORS REQUIRED IN THE BUILD CAN BE CALCULATED and it will be designed for street use where it will spend the vast majority of its life at under 4000rpm, and rarely see north of 6300rpm, so low speed torque is important just as upper peak power, so it should push you back in the seat easily if you floor the throttle but not be a problem if you want to drive across the country (well gas mileage will not be great) and compromises were made, but theres a big difference between building a performance engine you might reasonably expect to go 100K miles with minimal maintenance, and an all out race engine that will be rebuilt after each race or at least at the close of the season, that would be expected to spin 7000rpm and not be expected to perform below 4500rpm.

well, to start with a low cost build and I mean to minimize the cost every place I reasonably can, Id strongly suggest we keep cost to a minimum and start with a basic 350 first gen block thats no more than .030 over bore as the stock blocks are not all that rigid, Id maximize the blocks displacement with a SCAT CAST STEEL CRANK, BASED ROTATING ASSEMBLY, YES YOU WANT THE 7/16" CONNECTING ROD UPGRADE as its significantly stronger, 5.7" or 6" your choice ID prefer the 6" rods myself but either will work.

forged pistons are preferred but hyper-eutectic pistons will work ok if you keep the engine rpms reasonable (with a mild performance 383 thats generally about 6200rpm max) and the engine out of detonation.

Id select and edelbrock air gap intake and a 600cfm-700cfm vacuum secondary carb

http://www.flatlanderracing.com/scatsr-chevysbcast.html

on a street car Id prefer a manual transmission, and at least 3.35:1 rear gears but 3.73:1 are ideal

ID want about 9.5:1-10.5:1 static compression to maximize torque but obviously youll need to carefully select the cam timing to get a dynamic compression near 8:1 to run pump octane fuel and aluminum heads that flow at least 250 cfm at .0500 lift,to flow enough air to adequately fill a 383 cylinder at 6300rpm. and Id select a solid lifter flat tappet cam, or if forced into it a hydraulic flat tappet cam, with at least a .500 lift and a 235-245 dur. at .050 lift cam to maximize performance per dollar are about mandatory for maximizing performance , roller cams are great but they are expensive.

Id damn sure put the time in to find a decent 7-8 quart baffled oil pan with a effective windage screen,that fit the car because maintaining consistent oil pressure is mandatory for durability

heres a calculator to calculate ideal port cross sectional area

on a street driven 383 Id design the build to put that some place in the 4000rpm-4500rpm band

youll generally dump 30%-40% of your budget into good cylinder heads because they hold the key to much of the engines performance potential, on a 383, youll want a 195-215cc port size , if your intent on max power Id go with a larger port cross sectional area, a smaller port will restrict upper rpm power but result in more mid rpm torque ,your choices depending, mostly on gearing, and cam selection and intended operational rpm band.

now keep in mind this is NOT intended to be a max performance build , and you could rather obviously boost peak power with a with more compression, larger port heads, a well designed single plane intake and a larger carburetor and perhaps a wet nitrous plate, and a serious roller cam, but that would also add significantly to the engines cost and tend to make it far less likely to be useful for daily transportation.

a very common misconception, "that the intake runner size has the most effect on the engines torque curve,is mostly a myth" in reality ,compression ratio, cam timing and engine displacement and proper exhaust scavenging ALL have a larger effect on the engines torque that the intake runner cross sectional area.(yes getting it correct helps but your more likely to cause a problem by selecting an intake port and runner combo thats too small and restrictive than one thats too large in cross sectional area.

torque curve closely matches the cylinder fill efficiency ,

http://www.rbracing-rsr.com/runnertorquecalc.html

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

there are quite useful ,cam selection soft ware programs that get you in the ball park, but the final selection is based on far more factors than most of those software programs address

http://www.camquest.com/

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.wallaceracing.com/Calculators.htm

if you read thru the links theres a ton of detailed info, but the charts and calculators in the links and sub links will all tend to guide you to a similar conclusion, a semi mild 383SBC can use a cam with about a 235-245 duration at .050 lift with about a 108-110 LSA and ideally about 520- 530 lift so youll generally run 1.6:1 roller rocker to get the required lift at the valve, with a flat tappet cam, obviously if you have the cash exceeding that lift but keeping the duration tends to result in more power potential but it costs more., do the required calculations so the cam you select and the engines compression ration allows you to get to about that 8:1 dynamic compression, and discuss the cam selection with the cam manufacturer.

Id also point out that the closer you are geared to that base 3.336:1 range the lower the cam duration should be, and the closer you get to lets say 3.73:1 the closer you can get to the 245 duration end of the cam range, while all the cams in the range will work, its best to maximize power where the gearing maximizes your average rpm band at cruising speeds

you can use calculators to figure out the best header config, but generally youll find its a 1.75" primary about 38-39" long with a 3" diam, 18"-20" long collector

http://www.wallaceracing.com/header_length.php

http://www.bgsoflex.com/auto.html

it should be rather obvious that youll need to know the exact distance the piston deck sits at TDC ,above or below the block deck surface and the valve notch recess or pop-up dome volume of the piston to do accurate quench or compression calculations

floridas hardly the ideal climate for keeping tools rust free so i generally take my set of micrometers out of the storage case and open and close them and spray them down with a light oil like WD 40 and place them back in the box then place the whole box in a 2 gallon zip lock bag in a shallow tupper ware type air tight storage box that is just the size to fit inside one of your tool chest drawers too protect the precision measuring tools , feeler gauges and plasti-gauge youll need to measure clearances correctly.when not in use along with the dial calipers.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

the reason I bring this up is I recently was over at a friends house where I needed to accurately measure a u-joint bearing cap and asked if he had a micrometer or dial caliper, he responded he had a very expensive looking imported micrometer, he had acquired recently at an estate yard sale for $30,

when he opened the very impressive looking brass and mahogany box the micrometer, inside was a solid rusted mass, I soaked it in marvel mystery oil and acetone mix for 30 minutes then gradually worked it loose and polished it up with 1500 grit wet/dry sand paper figuring no loss at this point and was amazed that after about 30 minutes of constant cleaning it not only looked fairly decent it seemed to read accurately on a test gauge so I think it was mostly ugly surface rust, but it sure looked horrible, and to someone who appreciates good tools,that was depressing.

btw look around at yard sales and estate sales every so often youll find amazing bargains in used precision tools

yes it sure helps to have the correct tools and know where to measure parts

building a potentially impressive BBC

think twin turbo/ intercooled /e85/ 1300 plus hp with added oil cooler etc. think of this as a quick way to blow $33K minimum :facepalm: :like: YOUR CERTAINLY NOT GOING TO BUILD SOMETHING LIKE THIS AND EXPECT IT TO RUN ON THE LOCAL GAS STATIONS PUMP LOW OCTANE FUEL heads...

garage.grumpysperformance.com

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.harborfreight.com/3-piece-micrometer-set-66512.html

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

http://users.erols.com/srweiss/calcehp.htm

related info

viewtopic.php?f=44&t=38

http://garage.grumpysperformance.com/index.php?threads/cooler-denser-air.8961/#post-54528

http://www.rbracing-rsr.com/calculations.htm

http://airflowresearch.com/articles/article085/A-P1.htm

building a potentially impressive BBC

think twin turbo/ intercooled /e85/ 1300 plus hp with added oil cooler etc. think of this as a quick way to blow $33K minimum :facepalm: :like: YOUR CERTAINLY NOT GOING TO BUILD SOMETHING LIKE THIS AND EXPECT IT TO RUN ON THE LOCAL GAS STATIONS PUMP LOW OCTANE FUEL heads...

garage.grumpysperformance.com

theres lots of charts in the links like this one that provide info, if you have a 383 thats about 48 cubic inches per cylinder, divided by intake valve diam. we get 23.7, looking at the chart we see a LSA of about 106 should be the most efficient

THIS CHARTS RATHER CONSERVATIVE ON SUGGESTED CAM DURATION BUT IT CERTAINLY SHOULD BE A USEFUL GUIDE

the chart above can be used as a rough guide to match cam duration at .050 lift and static compression in engines obviously other factors come into play so its only a rough guide, when you use a cam with significantly more duration than suggested drive-ability and lower rpm power can suffer

4000 feet per minute in piston speed is generally considered a safe make on a mild performance build with upgraded components, a 383 with its 3.75" stroke would see that as about 6400rpm,but hydraulic lifters tend to float a bit lower so call it 6200rpm, look at the chart and we see a engine with the 383 roughly 48 cubic inch per cylinder needs a 230-240 duration to match that power band

Last edited by a moderator: