http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

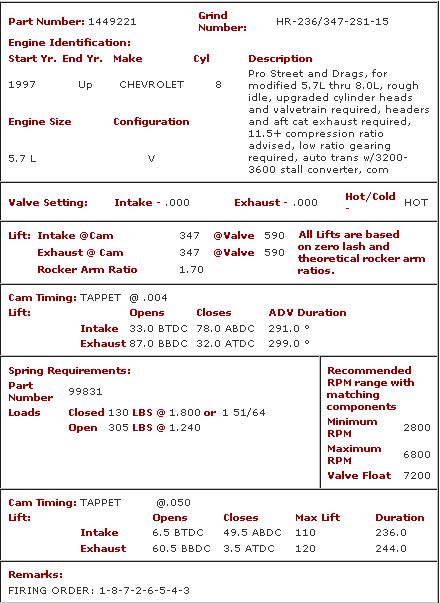

BTW theres two common vortec intake manifold gaskets, these vortec heads have taller ports than the standard 23 degree first gen SBC heads

The Fel Pro 1255 is .120 thick

The GM 89017465 is .060 thick

if your restricted to heads that came on most cars then mildly reworked standard 170cc port vortec heads are a decent choice

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

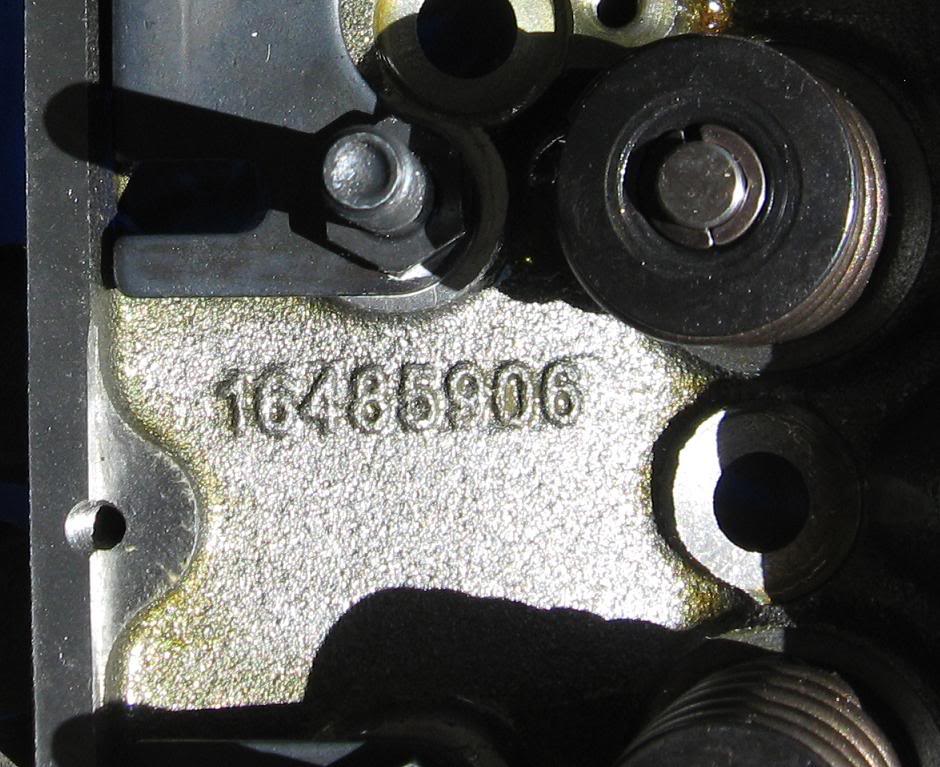

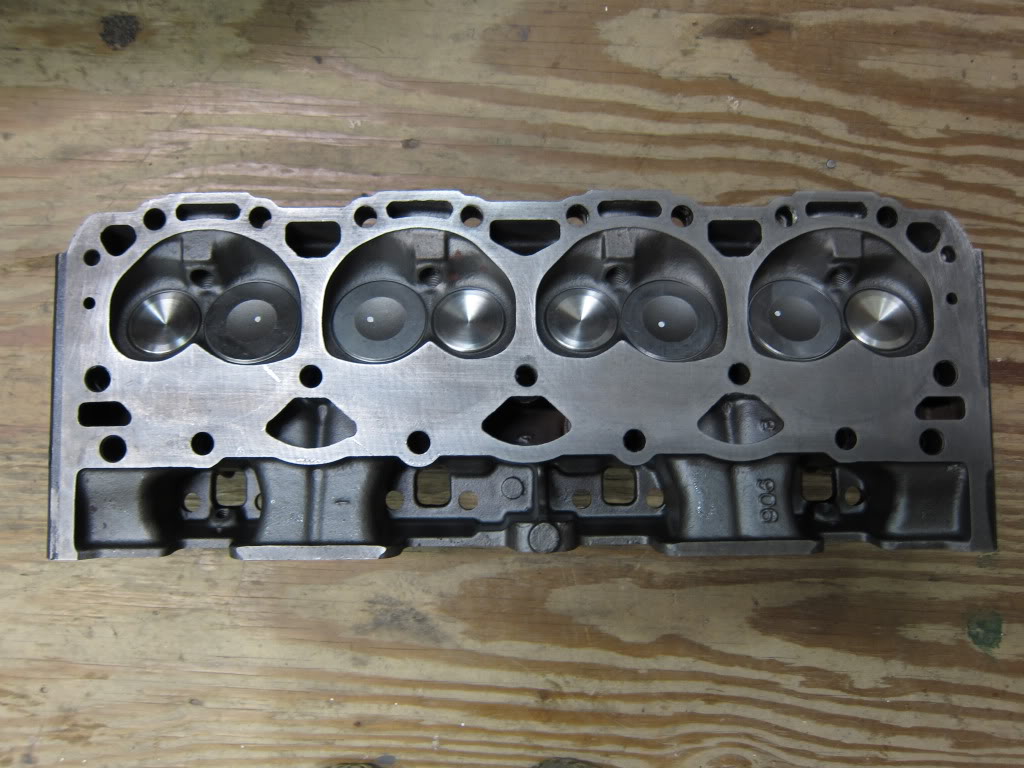

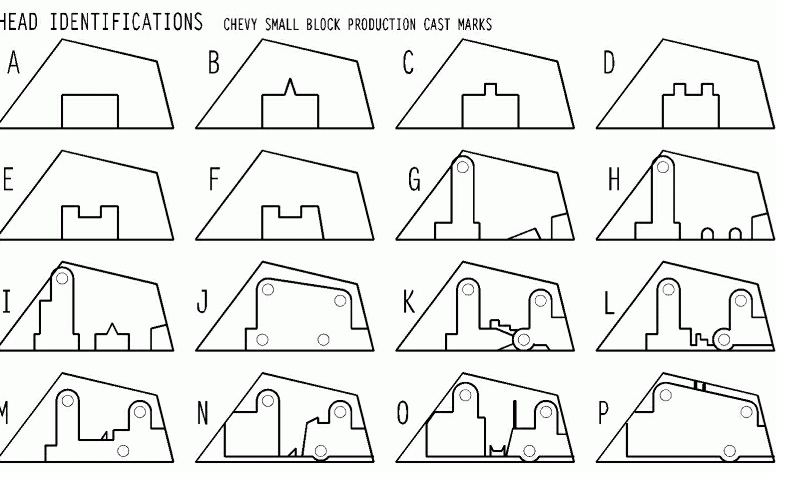

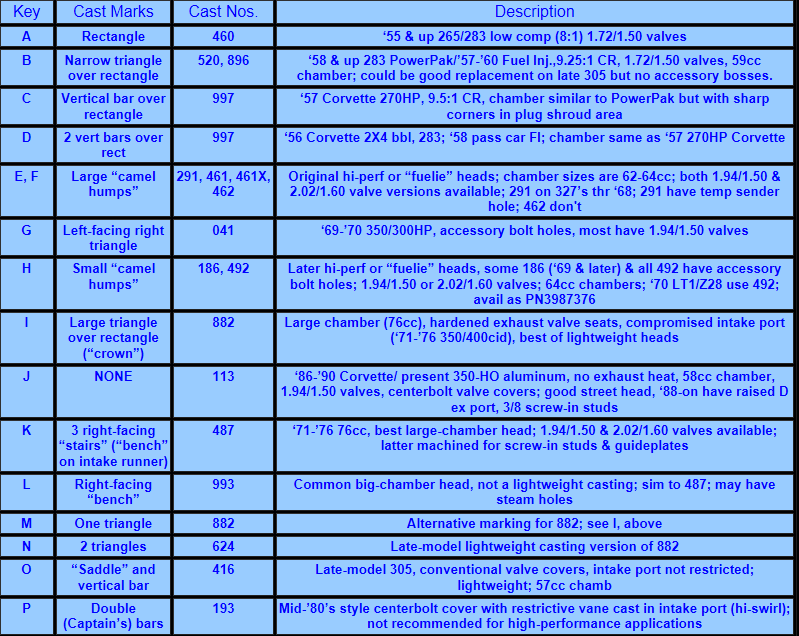

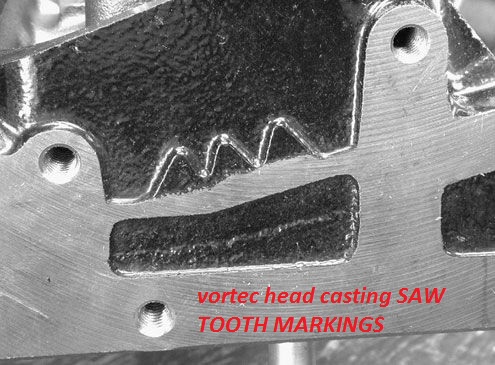

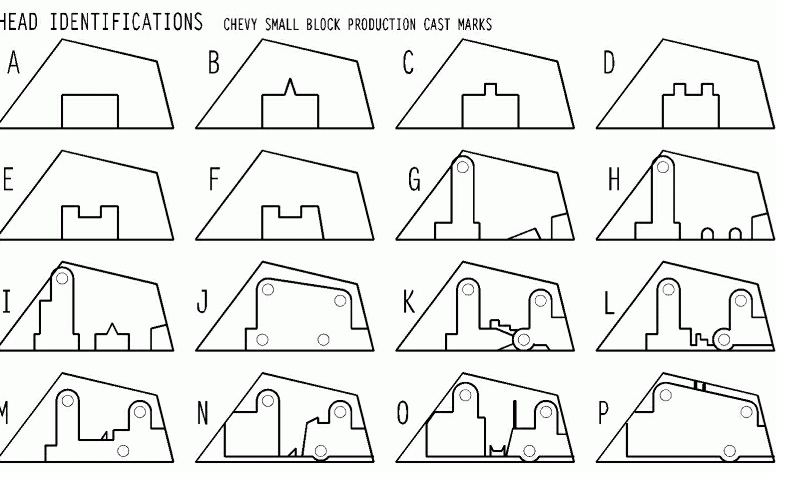

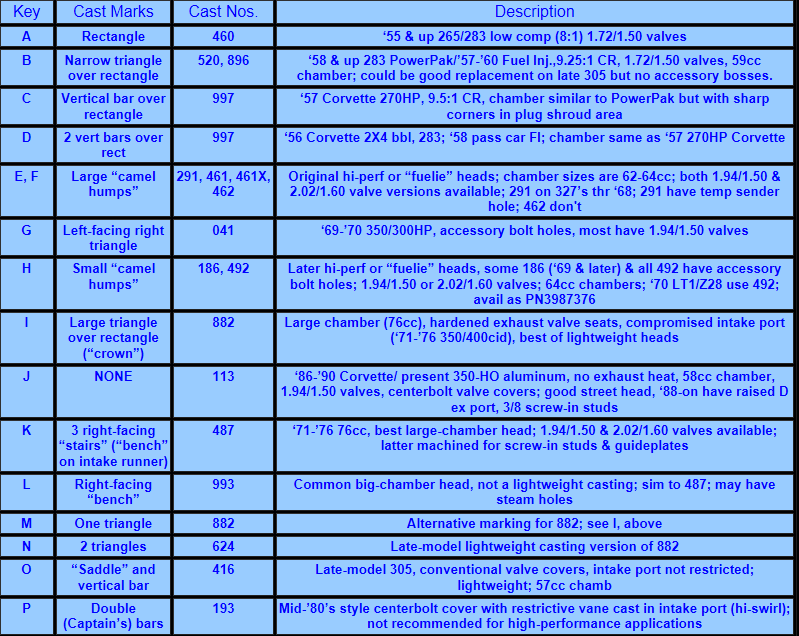

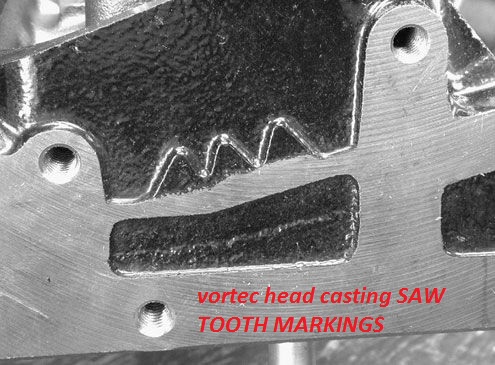

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

The L31 Vortec comes in two different casting numbers, 10239906 (#906) or 12558062 (#062). Originally, the stock #906 casting head was available in two versions. One version had an Inconel exhaust seat with single angle valve grind and was available on 1 ton trucks. The other version was the traditional three angle valve grind. Other than that, the #906 is the same as the #062 head.

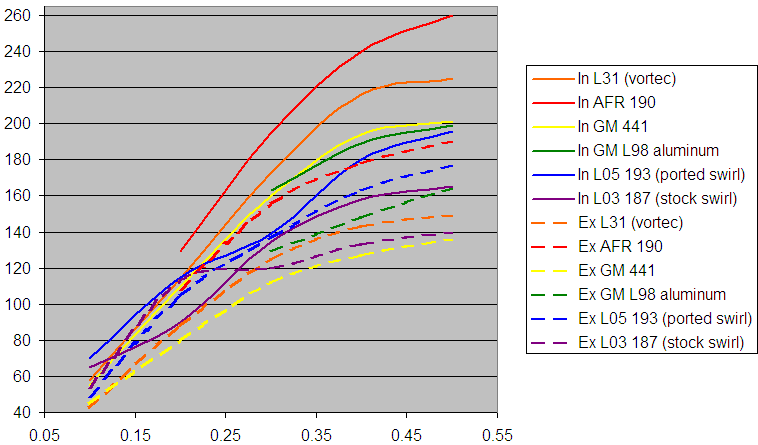

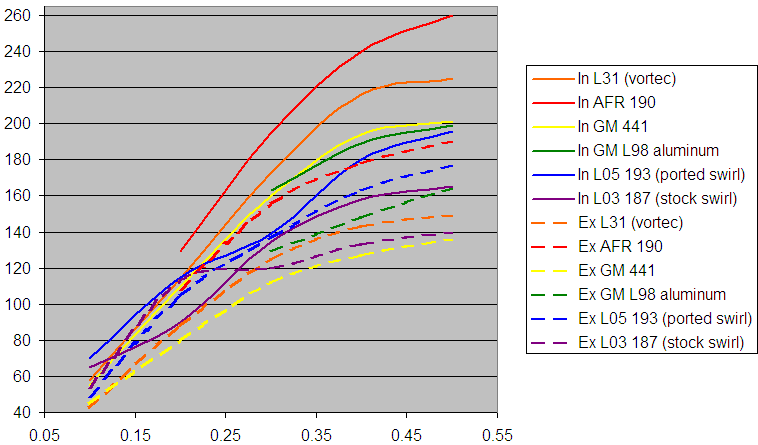

GM Performance Parts Bowtie Vortecs are offered in “small port” (#25534351), which has 185cc intake ports/65cc exhaust ports, or the “large port” (#25534445), which features 225cc intake ports/77cc exhaust ports. Both GM factory and GM Performance Parts Vortecs come with 1.94 intake/1.50 exhaust valves. According to the engineers at GM, “Stepping them up to 2.02 valves doesn’t help them any, so it’s not recommended. The port was designed to match the 1.94 valves. With the Vortec flow velocity,vortec heads out flow most of the early fuelie heads most of the older guys used to rave about but they pale in comparison to the better current aftermarket heads available

http://chevyhiperformance.com/howto/97458/

http://www.2quicknovas.com/vortecheads.html

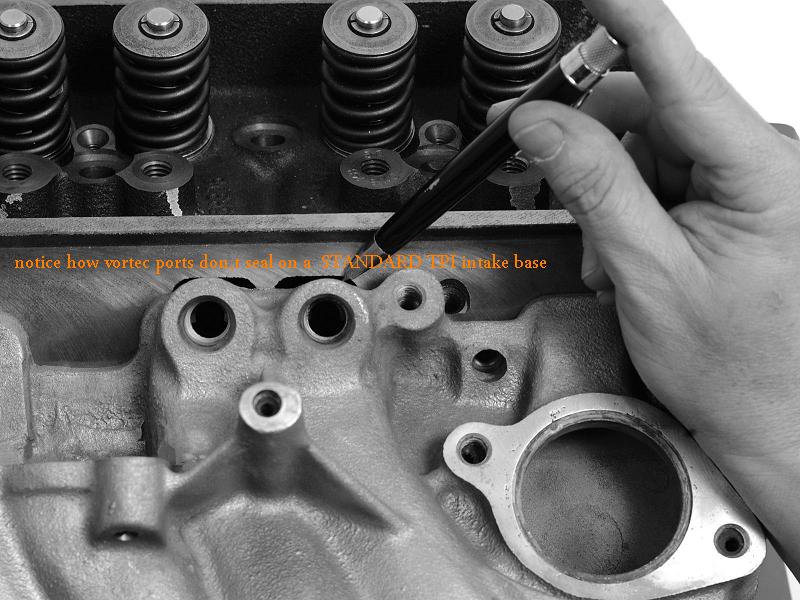

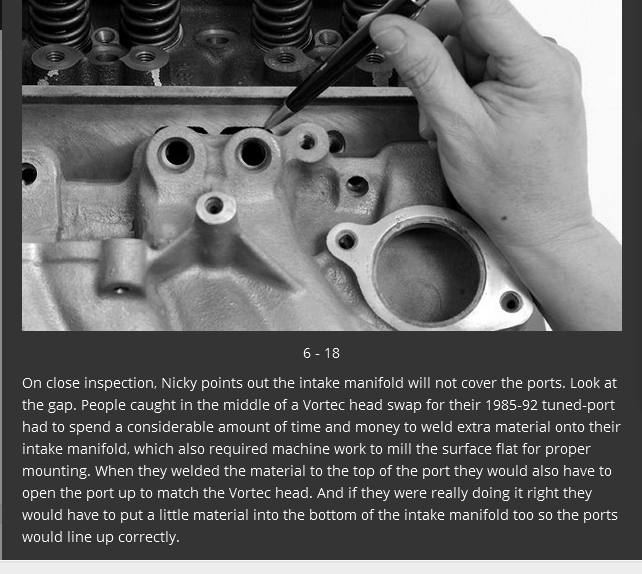

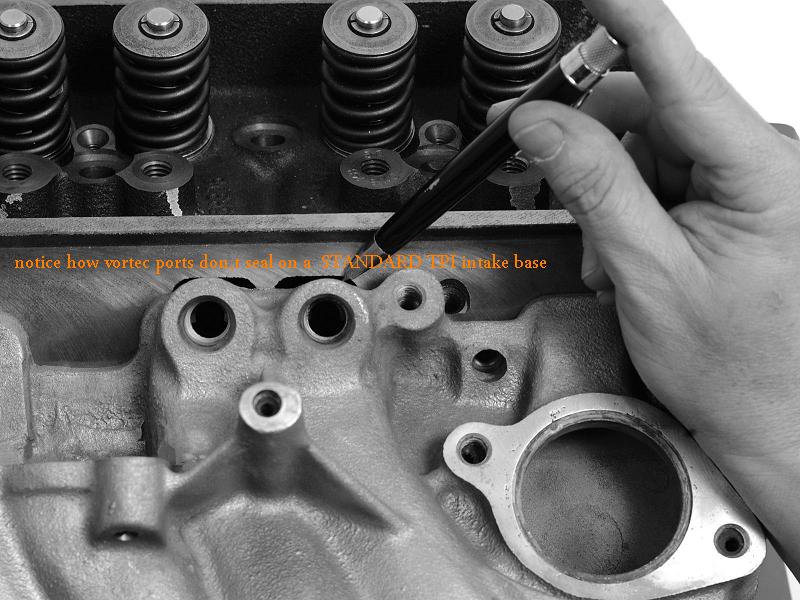

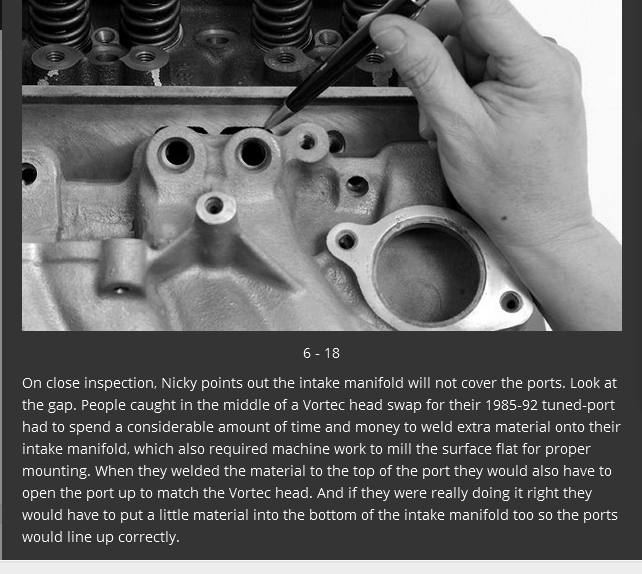

Youll need to do a test fit to verify, your intake can be used, some will work, some won,t both VORTEC and LT1/LT4 heads have slightly higher port locations than the standard first gen intakes , the vortec heads are a closer match to the LT1 than the first gen heads, youll need to measure carefully, I needed to weld my intake runners to add aluminum before I could port them to match my heads ports

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

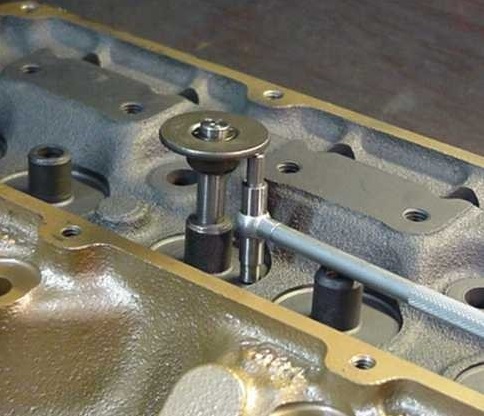

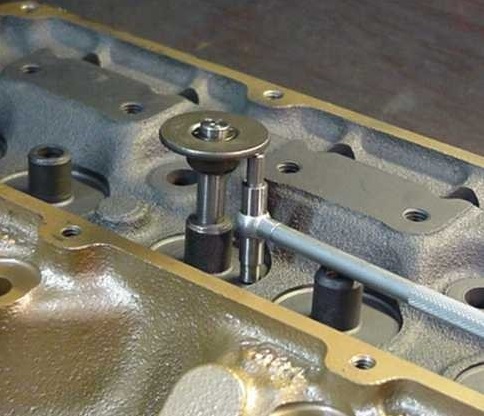

When checking valve spring installed height and valve clearances you can,t guess,.its mandatory you don,t guess and actually measure clearances, valve spring michrometers are not expensive and owning or borrowing one for your engine assembly makes a good deal of sense, you can get close with SNAP GAUGES, and a 2" standard michrometer or a vernier caliper

http://www.kmotion.biz/instht.htm

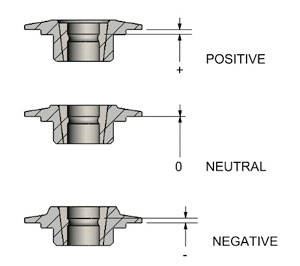

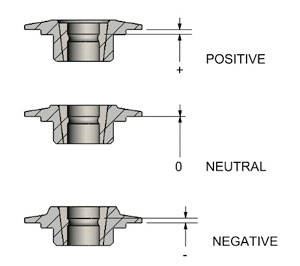

there are PLUS .050, standard and NEG .050 height retainers and valve cups and shims to adjust the installed valve spring height and location in regard to the cylinder head and valve guides

http://www.superchevy.com/how-to/engine ... ewall.html

many standard intakes don,t fit some vortec heads because the vortec head ports extend higher, so a VORTEC STEALTH RAM should be a closer match than a first gen stealth ram intake

http://www.babcox.com/editorial/us/us110128.htm

http://www.73-87.com/chp/gm3504.htm

http://www.babcox.com/editorial/ar/eb120121.htm

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

http://64.90.9.168/cranecams/pdf/512e.pdf

http://www.summitracing.com/

CCA-982-KIT Chevrolet: 262-400, conical valve spring kit

http://www.streetrodstuff.com/Products/115/

http://www.carcraft.com/techarticles/116_0306_vort/index1.html

http://www.kendrick-auto.com/vortec_cs_gm_head.htm

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radias

(13) have a local machine shop clearance the retainer to valve guide distance and add aftermarket springs and valve seals

(14) there are valve keepers available that add .050 extra clearance(USE THEM) but make sure the valve springs you use and the rocker/valve train geometry are set up correctly to work with the larger valve spring height and clearance!

(15) use the CORRECT matching rockers

(16) adding, machining for, screw in rocker studs is a good idea!

(17) your wasteing time and money runing a vortec head engine with an extreme high rpm cam,and intake, especially on a larger 383-427 displacement engine, the heads are designed to make massive torque in the 2000rpm-5500rpm range on a 350 displacement engine, they will not efficiently feed a 7000rpm combo on a larger engine so build your engine with that in mind

(18)if you intend to build a killer 383-427 sbc with vortec (STYLE) heads ID STRONGLY SUGGEST UPGRADING TO

E-Tec 200

Edelbrock E-Tec 200 heads have 200cc rectangular intake ports and 78cc exhaust ports. They outflow the “fast burn†aluminum heads by 10% on the intake and 17% on the exhaust, making power up to 6500 rpm. 64cc combustion chambers produce approximately 10.2:1 compression when used with flat-top pistons in 350-inch engines. E-Tec 200 heads come with 2.02" intake and 1.60" exhaust valves.

E-Tec 200

Chamber Size Bare (single) Complete (single)

64cc #60969* #60989*

BTW theres two common vortec intake manifold gaskets, these vortec heads have taller ports than the standard 23 degree first gen SBC heads

The Fel Pro 1255 is .120 thick

The GM 89017465 is .060 thick

if your restricted to heads that came on most cars then mildly reworked standard 170cc port vortec heads are a decent choice

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

VORTEC HEADS YOULL FIND IN SALVAGE YARDS HAVE THESE HEAD MARKINGS

The L31 Vortec comes in two different casting numbers, 10239906 (#906) or 12558062 (#062). Originally, the stock #906 casting head was available in two versions. One version had an Inconel exhaust seat with single angle valve grind and was available on 1 ton trucks. The other version was the traditional three angle valve grind. Other than that, the #906 is the same as the #062 head.

GM Performance Parts Bowtie Vortecs are offered in “small port” (#25534351), which has 185cc intake ports/65cc exhaust ports, or the “large port” (#25534445), which features 225cc intake ports/77cc exhaust ports. Both GM factory and GM Performance Parts Vortecs come with 1.94 intake/1.50 exhaust valves. According to the engineers at GM, “Stepping them up to 2.02 valves doesn’t help them any, so it’s not recommended. The port was designed to match the 1.94 valves. With the Vortec flow velocity,vortec heads out flow most of the early fuelie heads most of the older guys used to rave about but they pale in comparison to the better current aftermarket heads available

http://chevyhiperformance.com/howto/97458/

http://www.2quicknovas.com/vortecheads.html

Youll need to do a test fit to verify, your intake can be used, some will work, some won,t both VORTEC and LT1/LT4 heads have slightly higher port locations than the standard first gen intakes , the vortec heads are a closer match to the LT1 than the first gen heads, youll need to measure carefully, I needed to weld my intake runners to add aluminum before I could port them to match my heads ports

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

When checking valve spring installed height and valve clearances you can,t guess,.its mandatory you don,t guess and actually measure clearances, valve spring michrometers are not expensive and owning or borrowing one for your engine assembly makes a good deal of sense, you can get close with SNAP GAUGES, and a 2" standard michrometer or a vernier caliper

http://www.kmotion.biz/instht.htm

there are PLUS .050, standard and NEG .050 height retainers and valve cups and shims to adjust the installed valve spring height and location in regard to the cylinder head and valve guides

http://www.superchevy.com/how-to/engine ... ewall.html

many standard intakes don,t fit some vortec heads because the vortec head ports extend higher, so a VORTEC STEALTH RAM should be a closer match than a first gen stealth ram intake

http://www.babcox.com/editorial/us/us110128.htm

http://www.73-87.com/chp/gm3504.htm

http://www.babcox.com/editorial/ar/eb120121.htm

http://sallee-chevrolet.com/Cylinder_Heads/Vortec.html

http://64.90.9.168/cranecams/pdf/512e.pdf

http://www.summitracing.com/

CCA-982-KIT Chevrolet: 262-400, conical valve spring kit

http://www.streetrodstuff.com/Products/115/

http://www.carcraft.com/techarticles/116_0306_vort/index1.html

http://www.kendrick-auto.com/vortec_cs_gm_head.htm

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radias

(13) have a local machine shop clearance the retainer to valve guide distance and add aftermarket springs and valve seals

(14) there are valve keepers available that add .050 extra clearance(USE THEM) but make sure the valve springs you use and the rocker/valve train geometry are set up correctly to work with the larger valve spring height and clearance!

(15) use the CORRECT matching rockers

(16) adding, machining for, screw in rocker studs is a good idea!

(17) your wasteing time and money runing a vortec head engine with an extreme high rpm cam,and intake, especially on a larger 383-427 displacement engine, the heads are designed to make massive torque in the 2000rpm-5500rpm range on a 350 displacement engine, they will not efficiently feed a 7000rpm combo on a larger engine so build your engine with that in mind

(18)if you intend to build a killer 383-427 sbc with vortec (STYLE) heads ID STRONGLY SUGGEST UPGRADING TO

E-Tec 200

Edelbrock E-Tec 200 heads have 200cc rectangular intake ports and 78cc exhaust ports. They outflow the “fast burn†aluminum heads by 10% on the intake and 17% on the exhaust, making power up to 6500 rpm. 64cc combustion chambers produce approximately 10.2:1 compression when used with flat-top pistons in 350-inch engines. E-Tec 200 heads come with 2.02" intake and 1.60" exhaust valves.

E-Tec 200

Chamber Size Bare (single) Complete (single)

64cc #60969* #60989*

Last edited by a moderator: