ALEX said:Grumpy, I noticed my valve train got really noisy after I went to a test and tune nite at the track, I located the cause after careful inspection, one of the lifters had started coming apart,..what caused hydraulic lifters to come apart ?

the better quality hydraulic and solid flat tappet lifters have hardened bases

btw the best deal I found lately on basic hydraulic flat tappet lifters

http://www.summitracing.com/parts/sum-ht817/overview/

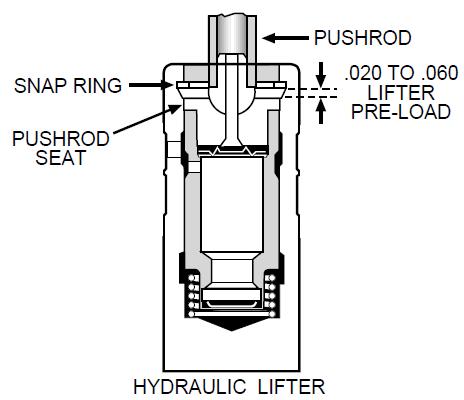

adjust the lifter pre-load too loose and the push rod can bounce on the lifter push-rod seat and eventually pop the retention spring lock, rev the engine high enough to enter valve float conditions and even with the proper lifter pre=loads the lifters take a sever beating and nasty things can happen, valve spring harmonics can also beat the hell out of a hydraulic lifter in some cases

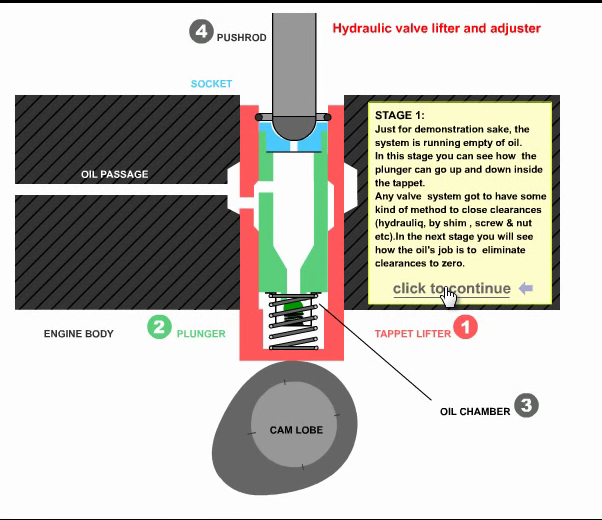

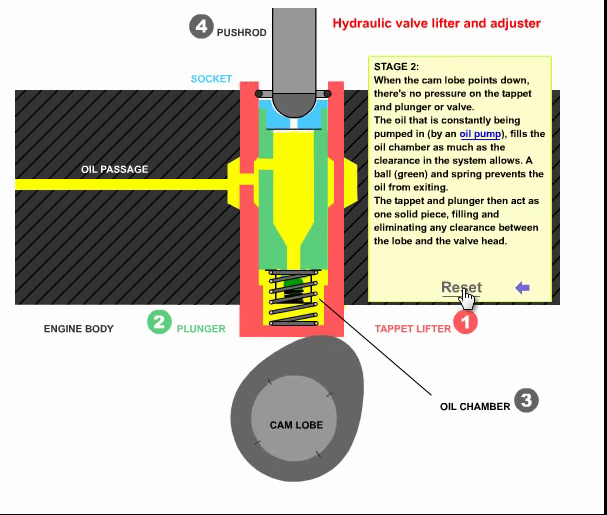

most all hydraulic lifters have a floating push rod seat held in by a retainer clip, and supported by hydraulic oil pressure supplied by the engine oil pump, the combination of lack of enough valve spring to keep the lifter securely on the cam lobe at high rpm, and the impact forces of the lifter if its lofted or got flipped off the cam lobe, if the engine reaches a valve float or unstable valve control rpm,due to valve train harmonics, and lost contact with the cams lobe , can cause damage!

As the rpms drop due to loss of power,valve spring pressure regains control it slams back onto the cam lobe during valve float,and/ or combined with the lack of proper pre-load on the valve adjustment can effect this, I generally suggest a minimum of a 1/4 turn past the point where the lifter stops clicking at idle, and a 1/2 turn certainly won,t hurt most engines.

(entering valve float rpm which is usually in the case of many hydraulic lifters with stock valve spring load rates in or near 5800rpm-6200rpm)allows the floating lifter push rod seat to bounce against the retainer clip, eventually this tends to break or dislodge the clip, especially the weaker spring wire clips vs the c-clip style

many more modern oil formulations lack the correct additives for flat tappet lifters, so be very sure you check to see what oil your using and if its designed for flat tappet lifter applications

read this

http://garage.grumpysperformance.com/index.php?threads/junk-hydraulic-lifters-mystery-solved.12263/

viewtopic.php?f=52&t=2627&p=6780&hilit=acceleration+ramp#p6780

viewtopic.php?f=52&t=181

http://garage.grumpysperformance.com/index.php?threads/busted-valve-spring.7716/#post-29797

viewtopic.php?f=52&t=181&p=1192&hilit=girdle#p1192

viewtopic.php?f=52&t=663&p=911&hilit=girdle#p911

viewtopic.php?f=52&t=2632&p=6790&hilit=girdle#p6790

Last edited by a moderator: