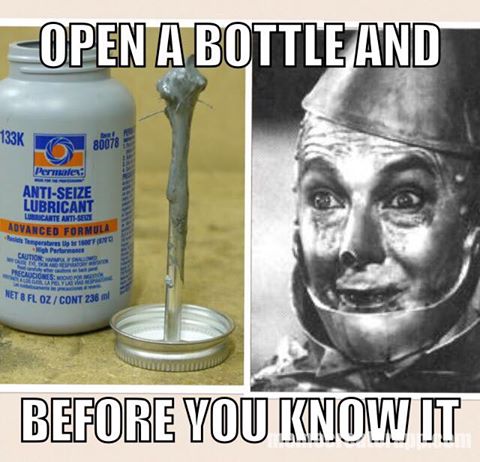

many guys damage threads on Wheel studs thru careless cross threading them during assembly or forgetting to use a bit of oil or grease on the studs threads so they rust, because they forget to place a finger tip worth of moly axle grease on the lug threads before they get installed to prevent both corrosion and cross threading problems, which are easily avoided if you finger start the locking bolts on the studs several full revolutions before you use anything like air tools and ease the threads onto the stud by hand , rather than trying to start them on the threads with an air ratchet

harbor freight sells a cheap torque multiplier, if you find the nuts are hard to remove, and using an air tool to start and seat the lug nuts is frequently a great way to screw up the stud threads.

http://www.harborfreight.com/torque-mul ... 93645.html

you may want to read this thread, and MANY RACING ASSOCIATIONS REQUIRE 5/8" DIAM. wheel studs and wheel lock nuts that allow the studs to protrude, or extend thru the nuts

http://www.chevytalk.org/fusionbb/showt ... id/209918/

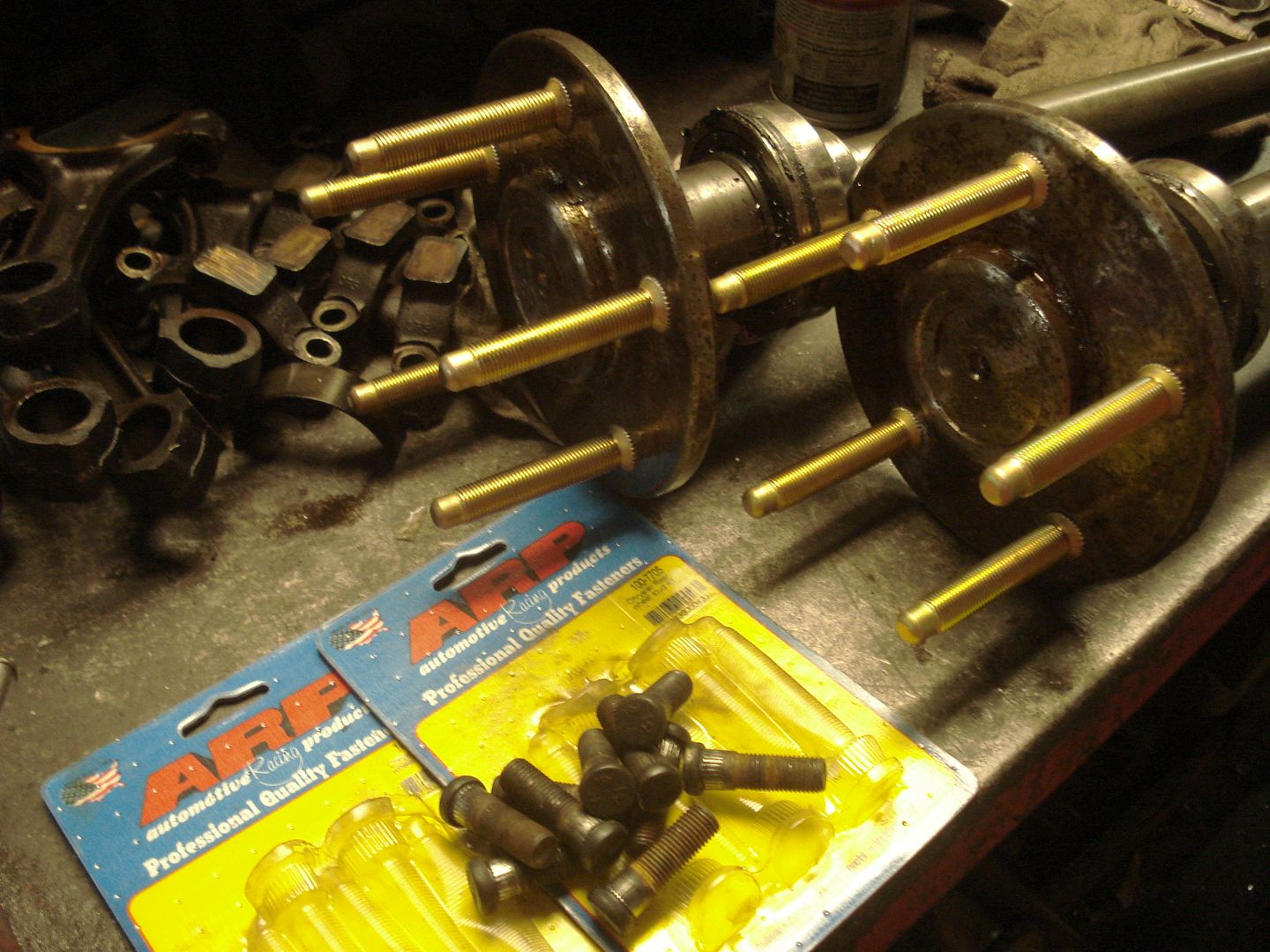

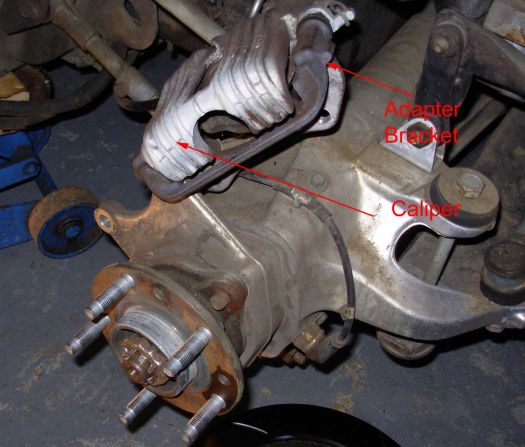

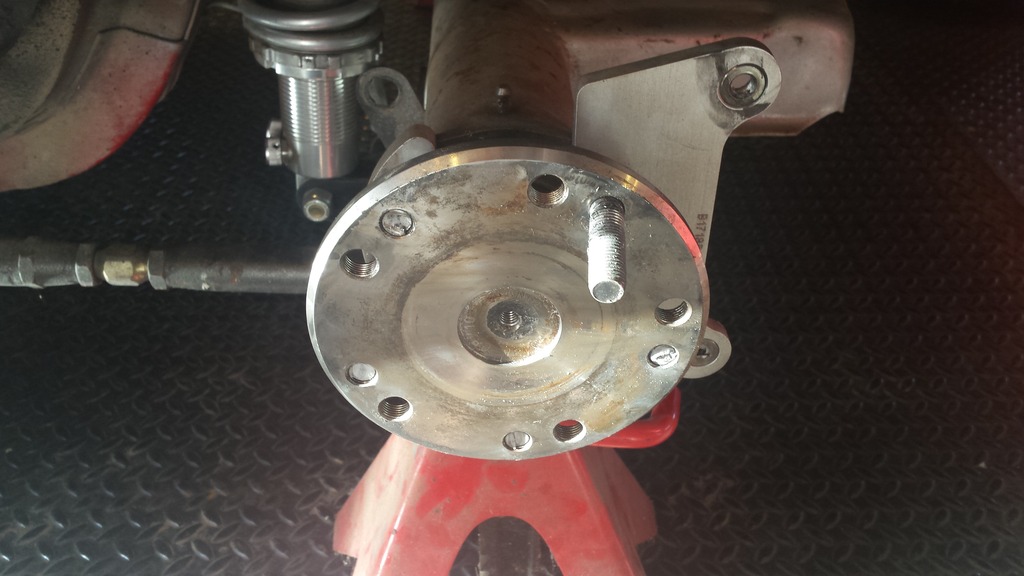

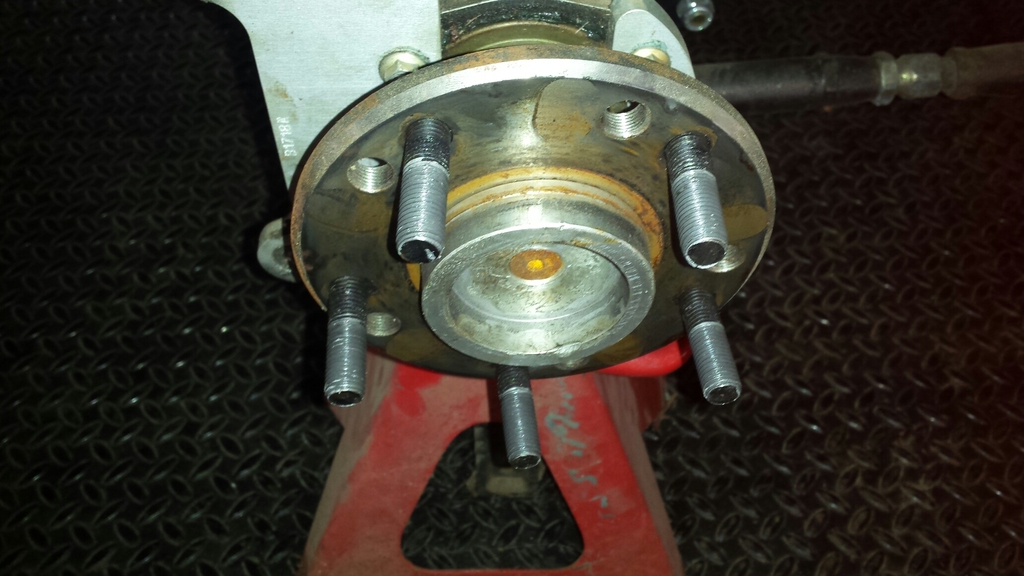

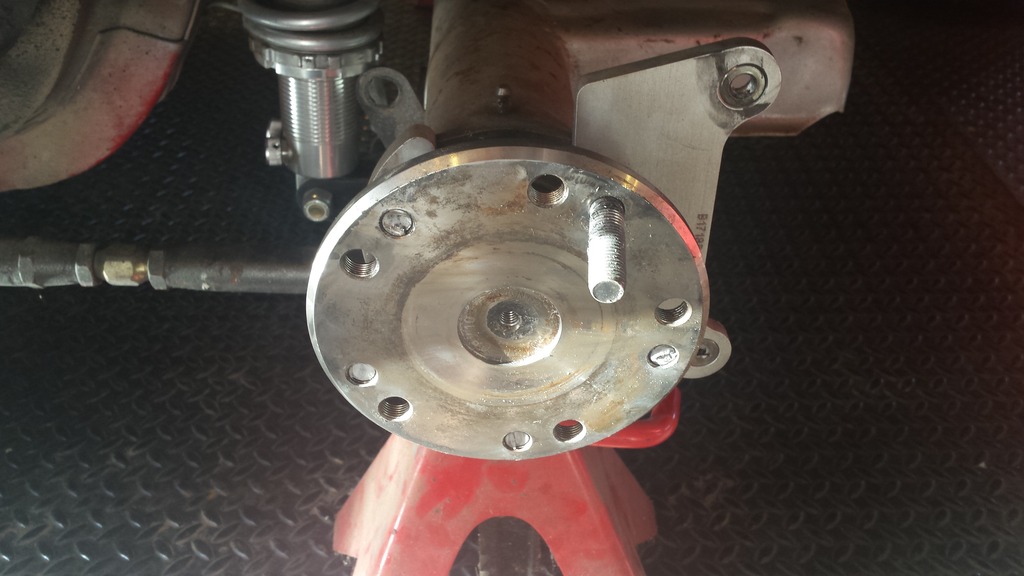

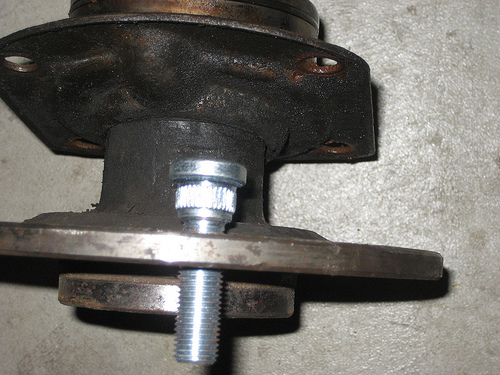

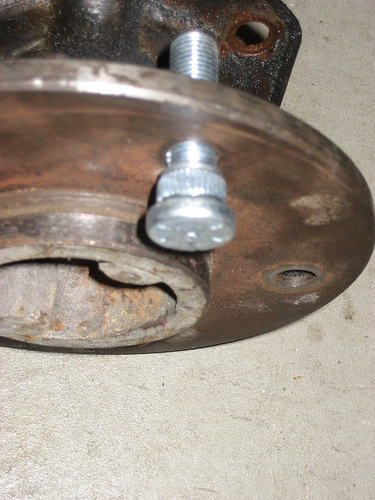

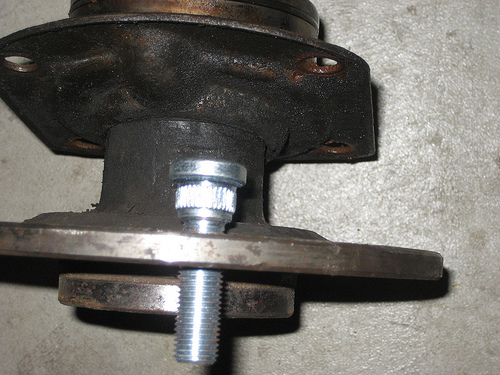

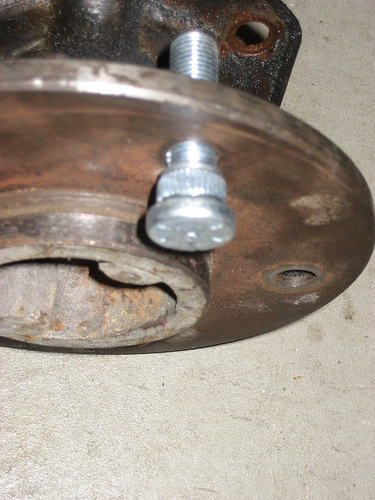

but the picture SHOWS THE WRONG REPLACEMENT AXLE STUDS, the correct axle studs will have the splined portion thats pulled into the flange be only a few thousandths of an inch larger in diam. than the hole in the flange they are drawn into, obviously smaller than the pictures.

parts store morons, will frequently tell you to just press in or use a lug nut to draw in the wrong studs, that will in most cases result in either a stripped stud or cracked axle flange , use a caliper and measure the studs and holes they are going into the correct interference fit is rarely more than a few thousands difference in size

read these related links

http://www.ehow.com/how_4686767_replace ... studs.html

http://www.classiccarauto.com/impala/ho ... stud.shtml

http://garage.grumpysperformance.com/index.php?threads/torquing-lug-nuts.15409/#post-90716

http://www.pavementsucks.com/tech-article-36.html

http://www.ehow.com/how_4508393_replace ... vette.html

http://www.mfavp.com/wheelstud/index.htm

these three pictures above show an obviously incorrect wheel stud , for the application, which is far too large in splined diam. section to be correctly installed in the wheel/axle flange

http://autorepair.about.com/od/fixityou ... d_repl.htm

use the correct size replacement stud, they should extend to the outer end of the lug nut, or slightly beyond

drive out the old stud

insert the new replacement stud

A stack of washers can be used in some cases to allow the lug nut to draw in , and seat the new stud, in the axle flange

harbor freight sells a cheap torque multiplier, if you find the nuts are hard to remove, and using an air tool to start and seat the lug nuts is frequently a great way to screw up the stud threads.

http://www.harborfreight.com/torque-mul ... 93645.html

you may want to read this thread, and MANY RACING ASSOCIATIONS REQUIRE 5/8" DIAM. wheel studs and wheel lock nuts that allow the studs to protrude, or extend thru the nuts

http://www.chevytalk.org/fusionbb/showt ... id/209918/

but the picture SHOWS THE WRONG REPLACEMENT AXLE STUDS, the correct axle studs will have the splined portion thats pulled into the flange be only a few thousandths of an inch larger in diam. than the hole in the flange they are drawn into, obviously smaller than the pictures.

parts store morons, will frequently tell you to just press in or use a lug nut to draw in the wrong studs, that will in most cases result in either a stripped stud or cracked axle flange , use a caliper and measure the studs and holes they are going into the correct interference fit is rarely more than a few thousands difference in size

read these related links

http://www.ehow.com/how_4686767_replace ... studs.html

http://www.classiccarauto.com/impala/ho ... stud.shtml

http://garage.grumpysperformance.com/index.php?threads/torquing-lug-nuts.15409/#post-90716

http://www.pavementsucks.com/tech-article-36.html

http://www.ehow.com/how_4508393_replace ... vette.html

http://www.mfavp.com/wheelstud/index.htm

these three pictures above show an obviously incorrect wheel stud , for the application, which is far too large in splined diam. section to be correctly installed in the wheel/axle flange

http://autorepair.about.com/od/fixityou ... d_repl.htm

use the correct size replacement stud, they should extend to the outer end of the lug nut, or slightly beyond

drive out the old stud

insert the new replacement stud

A stack of washers can be used in some cases to allow the lug nut to draw in , and seat the new stud, in the axle flange

Last edited by a moderator: