OLD POST COVERS THAT INFO

I can,t believe the stuff I see at times..in the car mags that are SUPPOSED to be articles composed by guys who know what they are doing!!!!!!!

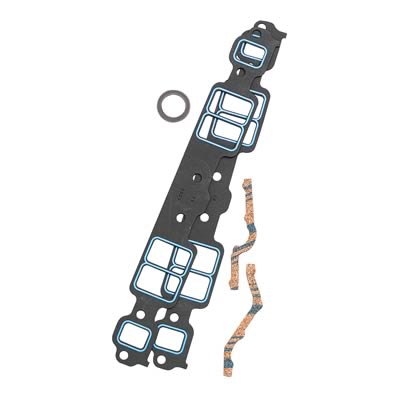

I picked up a copy of one of the more common, Chevy based magazines and theres PICTURES of a guy dipping head bolts in yellow weather strip adhesive to be used as a thread sealant on the bolt threads (its not designed to come in direct contact with oil and/or high heat coolant),and its not going to give the correct torque readings either, and on the next page the guys glopping, GOBS of clear silicone like you'll use to seal aquariums or bathroom fixtures 1/4 thick on/around the intake manifold ports, NEITHER SEALANT is DESIGNED FOR or is LIKELY to perform correctly IN EITHER APPLICATION, and WHERE does this guy think all that excess silicone will go once the intakes torqued down????

theres only two high probability's, it will flow into the port where it will eventually harden and get sucked into the cylinders or it may hang there causing a restriction in the port, or if it flows down, it gets into the lifter gallery where its eventually going to get into the oil pump pick up screen, restricting or blocking oil flow

I would not let these guys fix a flat tire let alone work on MY ENGINES all I can do is shake my head and wonder who if ANYONE screens these articles

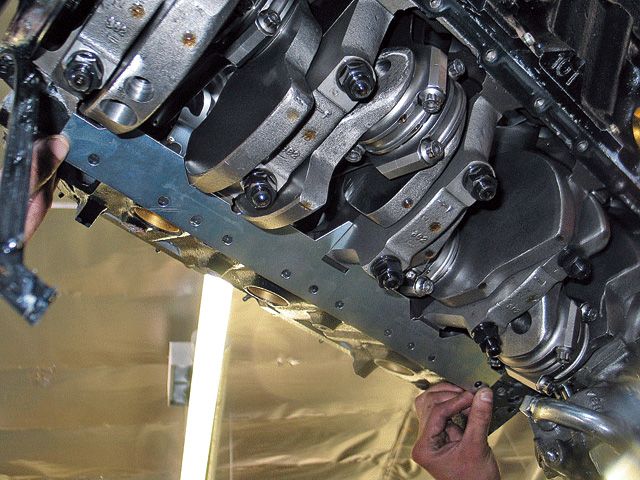

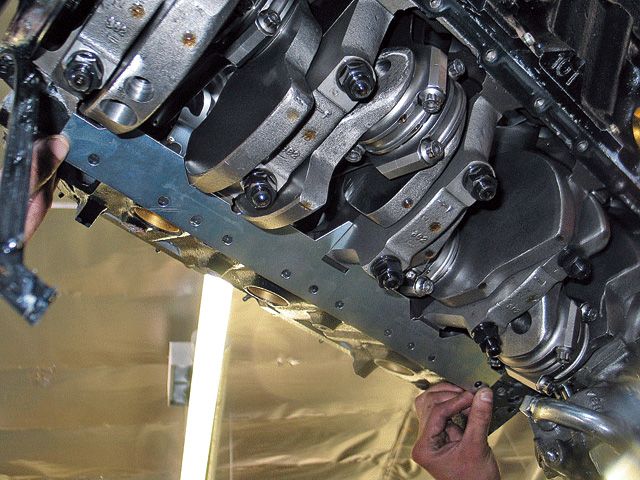

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

always use the manufacturers suggested installation instructions, as some applications or gasket types REQUIRE different lubes or sealants but heres a rough guide, you need to carefully clean and degrease any contact areas where sealants are to be used.

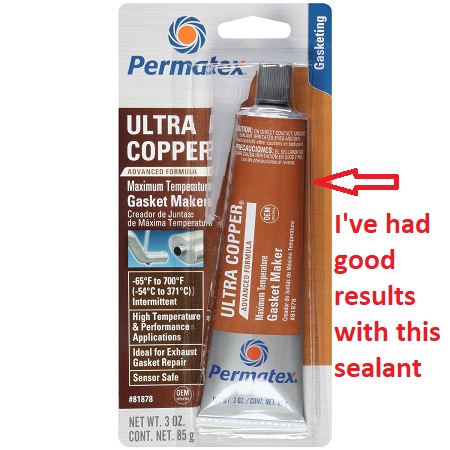

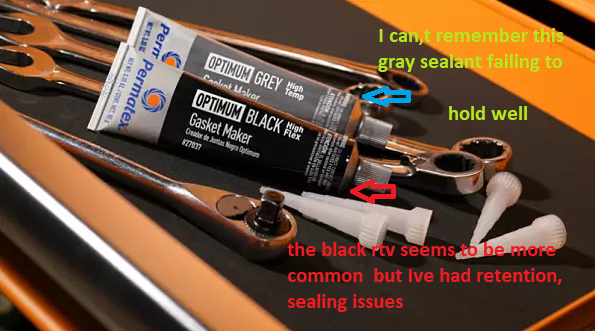

heres a rough guide to help select the correct sealants

yes any component needs to be properly installed, I've seen something similar happen a few times in the past, (persistent slow oil leaks) when guys were using a crank scraper sandwiched between the oil pan gasket and the block,

when guys simply forgot to spray both of the crank scraper surfaces and the block and gasket surface with some sealant like copper coat. hot oil is DESIGNED and formulated to seep into and through small cracks , and if there's no sealant blocking that hot liquid penetrating oil, it will eventually find its way through micro cracks in the area between two metal surfaces, so you,ll want to coat both sides of the gasket and crank scraper with a thin coat of spray sealant just prior to oil pan assembly

head bolts #5, dip clean dry thread in

http://www.devcon.com/devconfamilyproduct.cfm?familyid=386&catid=69

then insert and tq heads in place

http://www.summitracing.com/search/product-line/moroso-oil-pan-gaskets?SortBy=Default&SortOrder=Ascending&tw=moroso oil pan gaskets&sw=Moroso Oil Pan Gaskets

http://www.summitracing.com/search/part-type/transmission-pan-gaskets/brand/fel-pro?N=4294923830+400150&SortBy=Default&SortOrder=Ascending

head gaskets #3

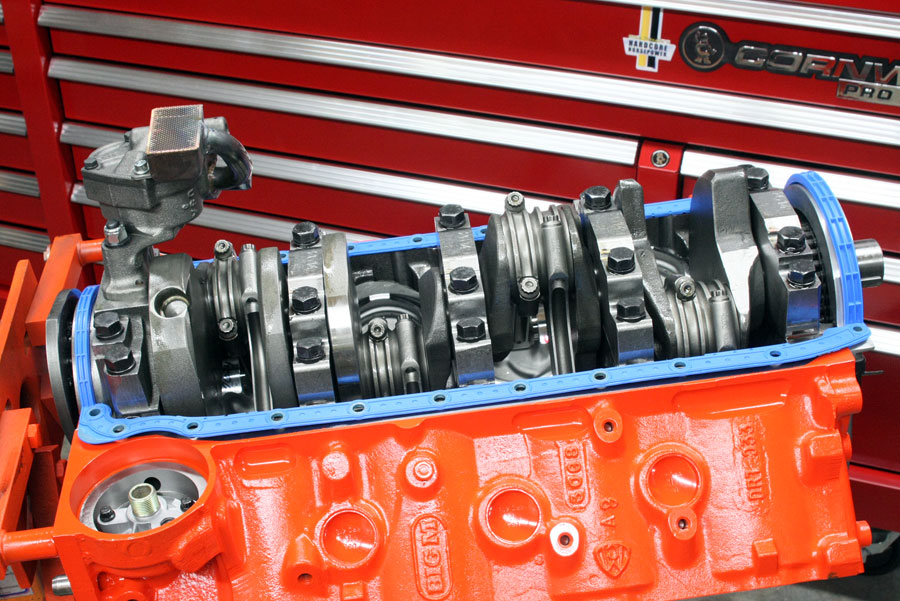

main bolts #2

rod bolts #2

oil pump stud and nut #4

oil pan bolts #5

oil pan gasket #6

cam sprocket bolts #4

timing cover gasket #6

timing cover bolts #1

intake bolts #1

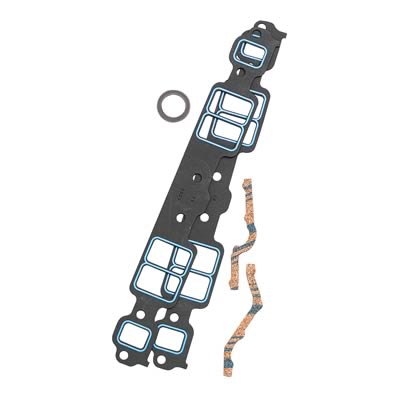

intake gasket AROUND WATER PORTS AND ON END WALLS #6

sensors #5

thermostat housing bolts #5

thermostat housing gasket (also do you really need it) usually yes #6

Exhaust manifold/header bolts #1

Exhaust manifold/header gaskets #3

Water pump bolts #5

water pump gaskets #6

fuel pump #6

crank/damper bolt #1

Torque converter bolts #4

flywheel/flexplate bolts #4

bellhousing bolts #2

head bolts #5

rocker stud threads into heads #5

(7)ANY SCREW THREAD FUEL LINE ADAPTER THREAD

sealant to use, use the number matched to application,

1 antiseize

2 oil or ARP thread lube

3 copper coat spray gasket sealer or apply dry in some cases (see manufactures suggestions)

4 loctite (red or blue depends on application ,read the labels)

5 http://www.devcon.com/devconfamilyproduct.cfm?familyid=386&catid=69

this works as a head bolt and rocker stud thread sealant, and sensor threads where they get screwed into the engine

don't forget the rear surface of the rear seal to block and main cap needs to be sealed, oil tight

both of these work great at sealing head bolt threads, and freeze plugs etc.

both of these work great at sealing head bolt threads, and freeze plugs etc.

6 black high temp RTV

use the correct stuff for the application, AND READ & FOLLOW THE DIRECTIONS it prevents PROBLEMS

a few things you should know

viewtopic.php?f=51&t=10464&p=43788#p43788

http://www.valvedirectory.com/valve_04122006.html

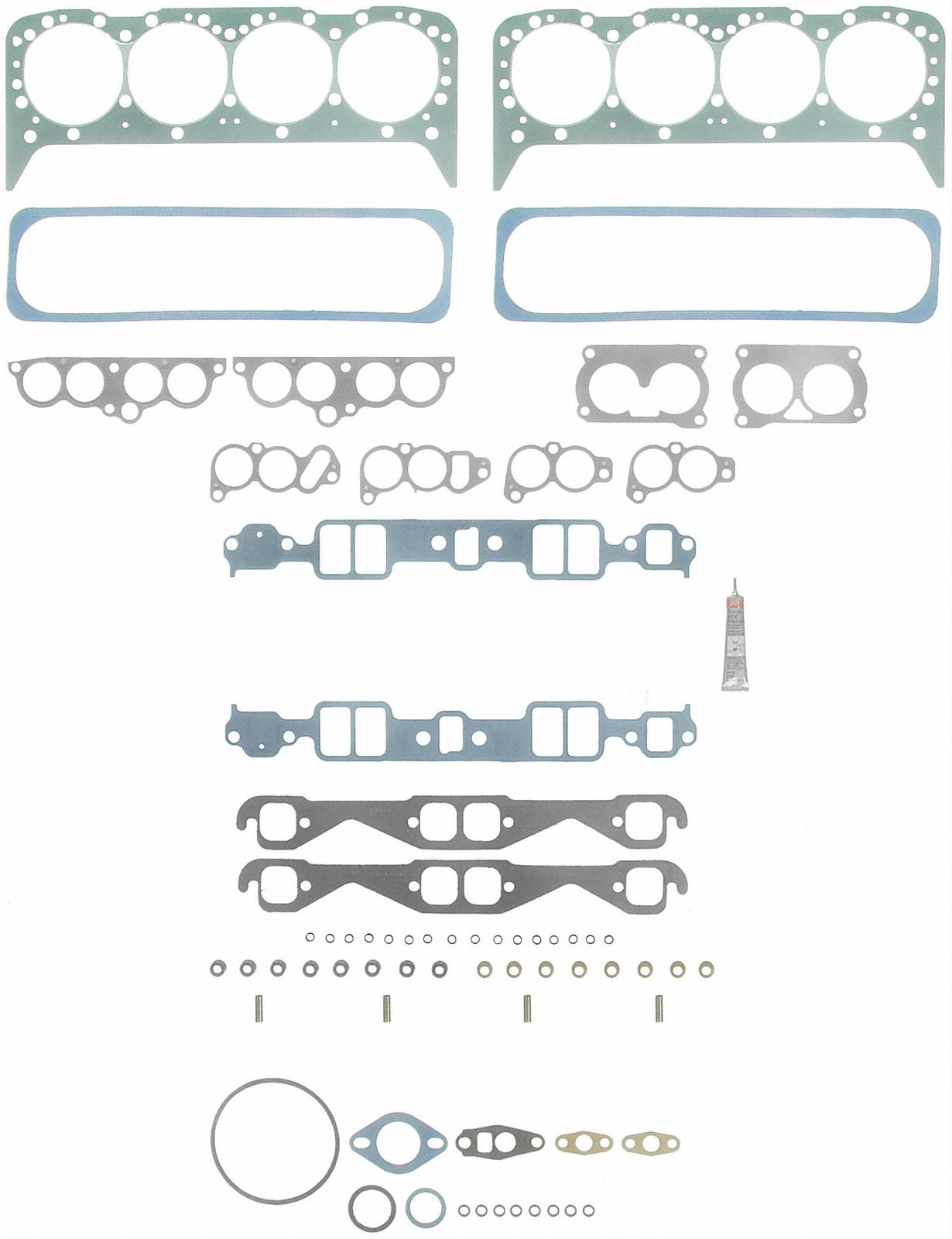

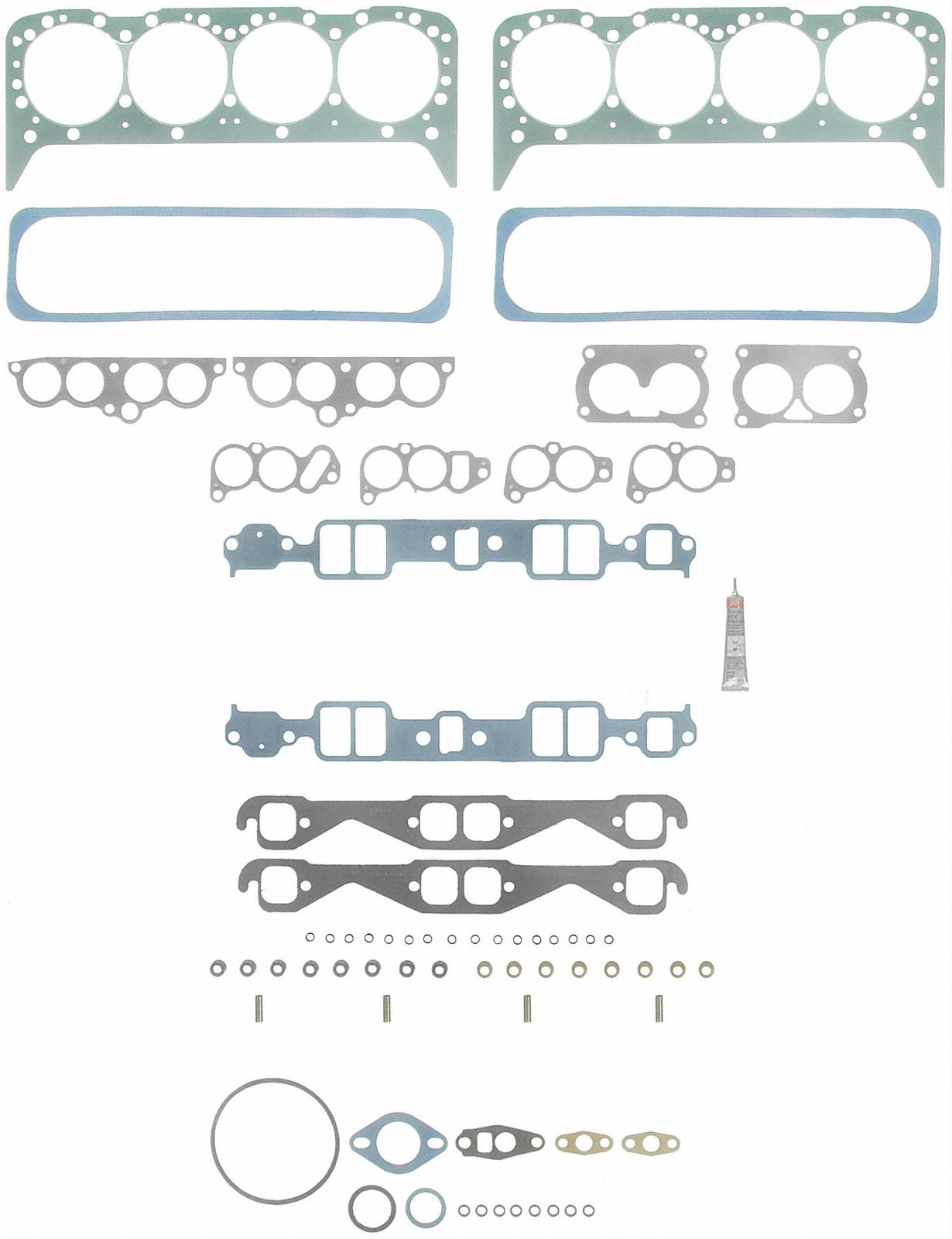

Ive had the best luck with the extra thick synthetic /cork composite mix gaskets, for valve covers, the fully synthetic one piece oil pan gaskets, and perma-seal, and felpro brand on many of the other gaskets, SCE makes real nice pure copper head gaskets but that's naturally not for all applications

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43842

http://www.summitracing.com/parts/FEL-1604/ SBC

http://www.summitracing.com/parts/FEL-1630/ BBC

IF YOUR SIMPLY TRYING TO GET A STOCK TPI CORVETTE ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

keep in mind coolant must have the anti-freeze ratio set at 50%water 50% antifreeze and be replaced at least every 4 years MAX to retain its anti corrosive additives

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

VALVE COVERS

[1] synthetic oil dissolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before gluing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night,depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

http://www.summitracing.com/search/part-type/oil-pan-gaskets?sortby=Default&sortorder=Ascending&keyword=oil Pan Gaskets&kr=oil Pan Gaskets

read this also

this looks like a darn bargain

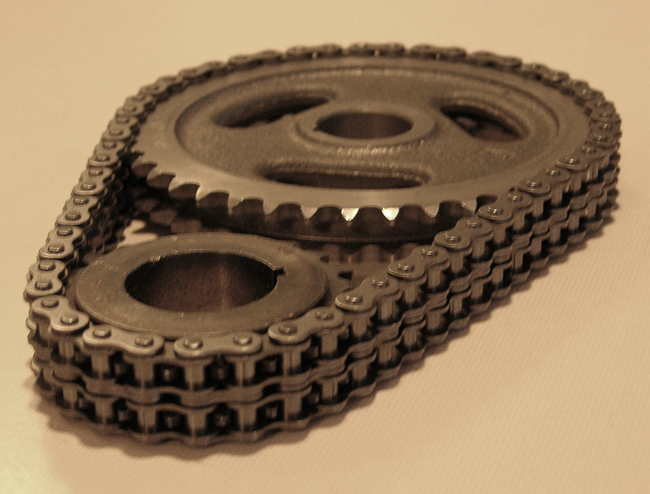

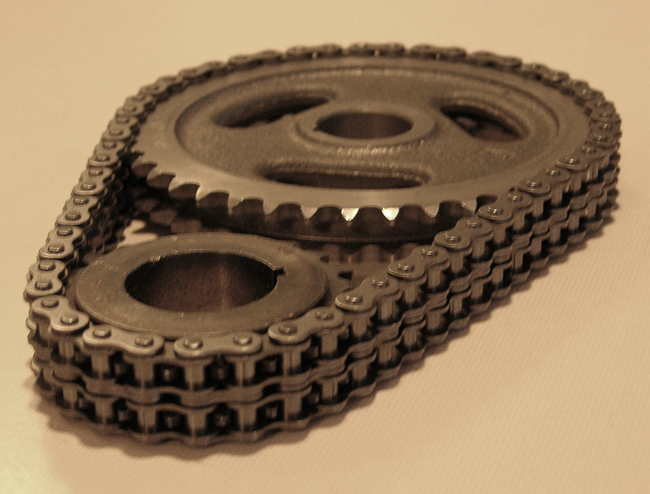

the double roller cloyes timing chains tend to last longer before they wear and have excess slack

and they can be used with the stock O.E.M timing chain cover

http://garage.grumpysperformance.com/index.php?threads/timing-tabs-and-indicators.1015/#post-49812

TRUE DOUBLE ROLLER TIMING CHAIN SETS FROM QUALITY MANUFACTURERS TEND TO BE MORE DURABLE

Last edited: 5 minutes ago

viewtopic.php?f=54&t=206&hilit=+gasket

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_25118_-1

yes you get a PAIR at that price

(7)

when installing an oil pan gasket its always preferable to install the front timing cover first if possible, as it makes sealing the oil pan to the block with the current one piece synthetic gaskets far easier

read these

viewtopic.php?f=54&t=2725&p=7076&hilit=synthetic+gasket#p7076

viewtopic.php?f=54&t=206&p=1154&hilit=+synthetic+gasket#p1154

the front timing cover seal, that provides the oil seal on the damper as it slides into the cover on the crank snout is pressed in from the front, most guys tap it in with a plastic mallet,after carefully cleaning and repainting the stock cover or buying a new chrome timing chain cover as they are fairly cheap,youll want to be coating the outside edge of the seal with a liquid sealant while the timing cover is supported from the rear on a block of wood,the seals knocked out from the rear with a flat blade screw driver and a small hammer , used at an angle on the inside lip, replace it so the inner seals lip angles in towards the crank not out toward the front damper

BUT most guys simply buy a new cover since they are cheap and don,t bother cleaning the old one if it looks damaged, at $8-$10, for a new cover its hardly worth taking a chance, with the old one if its damaged

http://www.summitracing.com/parts/SUM-G3200/

I can,t believe the stuff I see at times..in the car mags that are SUPPOSED to be articles composed by guys who know what they are doing!!!!!!!

I picked up a copy of one of the more common, Chevy based magazines and theres PICTURES of a guy dipping head bolts in yellow weather strip adhesive to be used as a thread sealant on the bolt threads (its not designed to come in direct contact with oil and/or high heat coolant),and its not going to give the correct torque readings either, and on the next page the guys glopping, GOBS of clear silicone like you'll use to seal aquariums or bathroom fixtures 1/4 thick on/around the intake manifold ports, NEITHER SEALANT is DESIGNED FOR or is LIKELY to perform correctly IN EITHER APPLICATION, and WHERE does this guy think all that excess silicone will go once the intakes torqued down????

theres only two high probability's, it will flow into the port where it will eventually harden and get sucked into the cylinders or it may hang there causing a restriction in the port, or if it flows down, it gets into the lifter gallery where its eventually going to get into the oil pump pick up screen, restricting or blocking oil flow

I would not let these guys fix a flat tire let alone work on MY ENGINES all I can do is shake my head and wonder who if ANYONE screens these articles

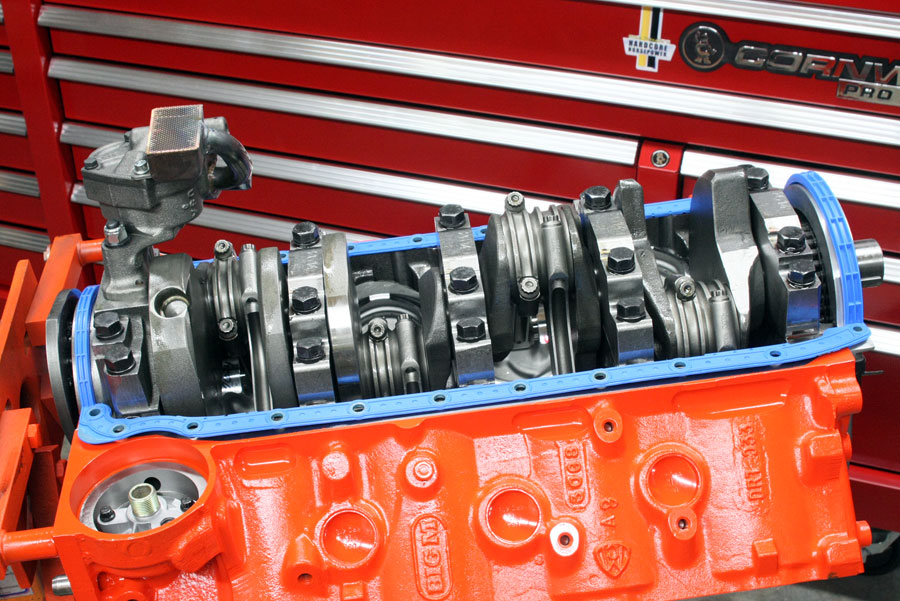

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

always use the manufacturers suggested installation instructions, as some applications or gasket types REQUIRE different lubes or sealants but heres a rough guide, you need to carefully clean and degrease any contact areas where sealants are to be used.

heres a rough guide to help select the correct sealants

yes any component needs to be properly installed, I've seen something similar happen a few times in the past, (persistent slow oil leaks) when guys were using a crank scraper sandwiched between the oil pan gasket and the block,

when guys simply forgot to spray both of the crank scraper surfaces and the block and gasket surface with some sealant like copper coat. hot oil is DESIGNED and formulated to seep into and through small cracks , and if there's no sealant blocking that hot liquid penetrating oil, it will eventually find its way through micro cracks in the area between two metal surfaces, so you,ll want to coat both sides of the gasket and crank scraper with a thin coat of spray sealant just prior to oil pan assembly

head bolts #5, dip clean dry thread in

http://www.devcon.com/devconfamilyproduct.cfm?familyid=386&catid=69

then insert and tq heads in place

http://www.summitracing.com/search/product-line/moroso-oil-pan-gaskets?SortBy=Default&SortOrder=Ascending&tw=moroso oil pan gaskets&sw=Moroso Oil Pan Gaskets

http://www.summitracing.com/search/part-type/transmission-pan-gaskets/brand/fel-pro?N=4294923830+400150&SortBy=Default&SortOrder=Ascending

head gaskets #3

main bolts #2

rod bolts #2

oil pump stud and nut #4

oil pan bolts #5

oil pan gasket #6

cam sprocket bolts #4

timing cover gasket #6

timing cover bolts #1

intake bolts #1

intake gasket AROUND WATER PORTS AND ON END WALLS #6

sensors #5

thermostat housing bolts #5

thermostat housing gasket (also do you really need it) usually yes #6

Exhaust manifold/header bolts #1

Exhaust manifold/header gaskets #3

Water pump bolts #5

water pump gaskets #6

fuel pump #6

crank/damper bolt #1

Torque converter bolts #4

flywheel/flexplate bolts #4

bellhousing bolts #2

head bolts #5

rocker stud threads into heads #5

(7)ANY SCREW THREAD FUEL LINE ADAPTER THREAD

sealant to use, use the number matched to application,

1 antiseize

2 oil or ARP thread lube

3 copper coat spray gasket sealer or apply dry in some cases (see manufactures suggestions)

4 loctite (red or blue depends on application ,read the labels)

5 http://www.devcon.com/devconfamilyproduct.cfm?familyid=386&catid=69

this works as a head bolt and rocker stud thread sealant, and sensor threads where they get screwed into the engine

don't forget the rear surface of the rear seal to block and main cap needs to be sealed, oil tight

both of these work great at sealing head bolt threads, and freeze plugs etc.

both of these work great at sealing head bolt threads, and freeze plugs etc.

6 black high temp RTV

use the correct stuff for the application, AND READ & FOLLOW THE DIRECTIONS it prevents PROBLEMS

a few things you should know

viewtopic.php?f=51&t=10464&p=43788#p43788

http://www.valvedirectory.com/valve_04122006.html

Ive had the best luck with the extra thick synthetic /cork composite mix gaskets, for valve covers, the fully synthetic one piece oil pan gaskets, and perma-seal, and felpro brand on many of the other gaskets, SCE makes real nice pure copper head gaskets but that's naturally not for all applications

http://garage.grumpysperformance.co...oving-gaskets-the-wrong-way.10464/#post-43842

http://www.summitracing.com/parts/FEL-1604/ SBC

http://www.summitracing.com/parts/FEL-1630/ BBC

IF YOUR SIMPLY TRYING TO GET A STOCK TPI CORVETTE ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

keep in mind coolant must have the anti-freeze ratio set at 50%water 50% antifreeze and be replaced at least every 4 years MAX to retain its anti corrosive additives

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

VALVE COVERS

[1] synthetic oil dissolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before gluing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night,depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

http://www.summitracing.com/search/part-type/oil-pan-gaskets?sortby=Default&sortorder=Ascending&keyword=oil Pan Gaskets&kr=oil Pan Gaskets

read this also

this looks like a darn bargain

the double roller cloyes timing chains tend to last longer before they wear and have excess slack

and they can be used with the stock O.E.M timing chain cover

http://garage.grumpysperformance.com/index.php?threads/timing-tabs-and-indicators.1015/#post-49812

TRUE DOUBLE ROLLER TIMING CHAIN SETS FROM QUALITY MANUFACTURERS TEND TO BE MORE DURABLE

Last edited: 5 minutes ago

viewtopic.php?f=54&t=206&hilit=+gasket

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_25118_-1

yes you get a PAIR at that price

(7)

when installing an oil pan gasket its always preferable to install the front timing cover first if possible, as it makes sealing the oil pan to the block with the current one piece synthetic gaskets far easier

read these

viewtopic.php?f=54&t=2725&p=7076&hilit=synthetic+gasket#p7076

viewtopic.php?f=54&t=206&p=1154&hilit=+synthetic+gasket#p1154

the front timing cover seal, that provides the oil seal on the damper as it slides into the cover on the crank snout is pressed in from the front, most guys tap it in with a plastic mallet,after carefully cleaning and repainting the stock cover or buying a new chrome timing chain cover as they are fairly cheap,youll want to be coating the outside edge of the seal with a liquid sealant while the timing cover is supported from the rear on a block of wood,the seals knocked out from the rear with a flat blade screw driver and a small hammer , used at an angle on the inside lip, replace it so the inner seals lip angles in towards the crank not out toward the front damper

BUT most guys simply buy a new cover since they are cheap and don,t bother cleaning the old one if it looks damaged, at $8-$10, for a new cover its hardly worth taking a chance, with the old one if its damaged

http://www.summitracing.com/parts/SUM-G3200/

Last edited by a moderator: