one of my neighbors kids is rebuilding a fairly mild 396 BBC, and after he got it assembled and installed in the car (a 1971 chevelle) he started it up after priming the engine with a priming tool that he used to verify that he was getting oil to all the rockers, and after cold setting the valves , and hes got 35 -40 psi of oil pressure at idle with 10w40 oil in the oil pan.

Now I got called over to trouble shoot, as his issue is that as long as the cars engine runs between about 900rpm where it idles and about 1500rpm his oil pressure stays at that 35 -40 psi range, and oil flows from every rocker, it looks like its well set up, yet if he blips the throttle the oil pressure rapidly FALLS as the RPMS increase past 2000rpm!

now he started talking about a new oil pump, and the bearing clearances and several other things like perhaps the oil pump pick-up weld to the oil pump had failed,And one of his friends kept telling him, that old MYTH,that it was the high volume performance oil pump ,sucking the oil pan dry! but after questioning him a bit I was rather convinced I knew what the issue and its cause was as I'd seen similar problems in the past.

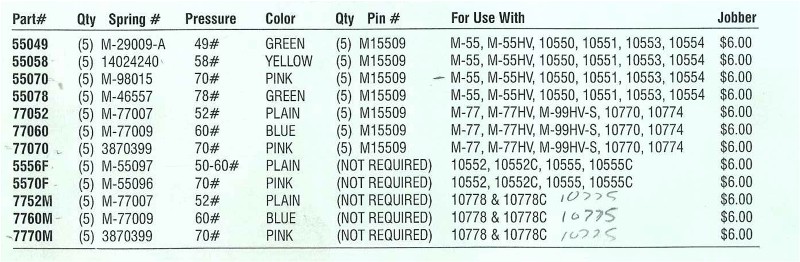

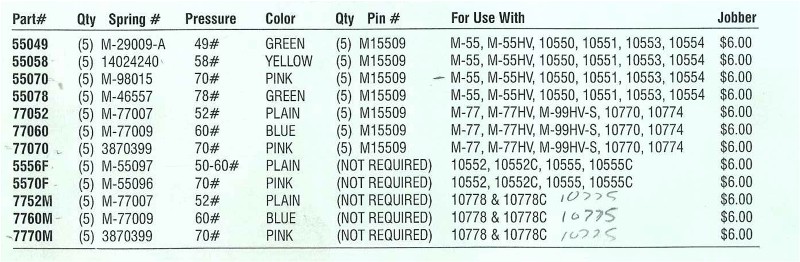

the K frame or cross member on a chevelle of that generation fits rather closely under the block,and rather far back restricting the stock oil pan voluum, as does the suspension, and he installed the stock 4-5 quart oil pan,to get clearance, with the melling m77hv oil pump.

keep in mind both engine oil temps and trans fluid temps seldom reach operational temps,fluid

and stabilize , for semi consistent data,in under 12-15 minutes of drive time,temps have a huge effect on lubricant viscosity and durability. .

while helical cut gears will run smoother ,

( ESPECIALLY WITH THE STOCK 7 tooth SBC oil pump)

as you potentially have 2 or three gear teeth in various stages of gear tooth contact

(depends on the angle of tooth engagement)

and yes the design will reduce a tendency to produce a pressure pulse, I have not seen this as a major issue.

simply swapping to the standard volume and pressure BIG BLOCK 12 tooth oil pump in a SBC engine all but eliminates the pulse and pressure and volume issues a sbc oil pump has.

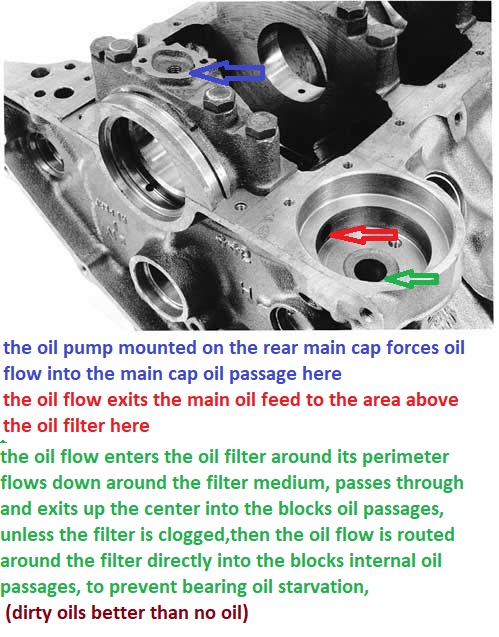

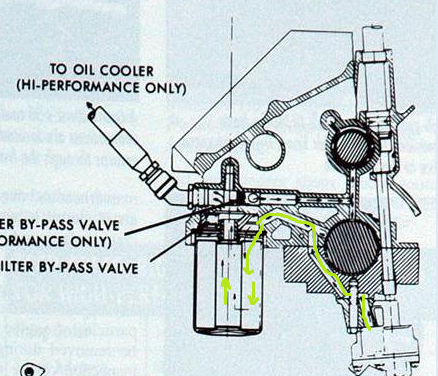

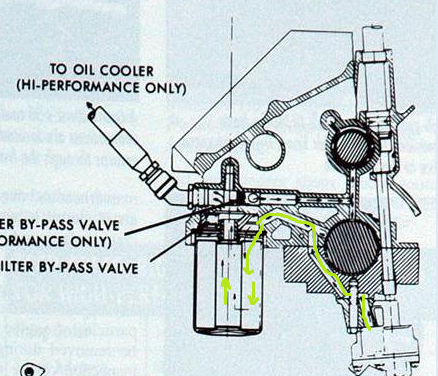

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

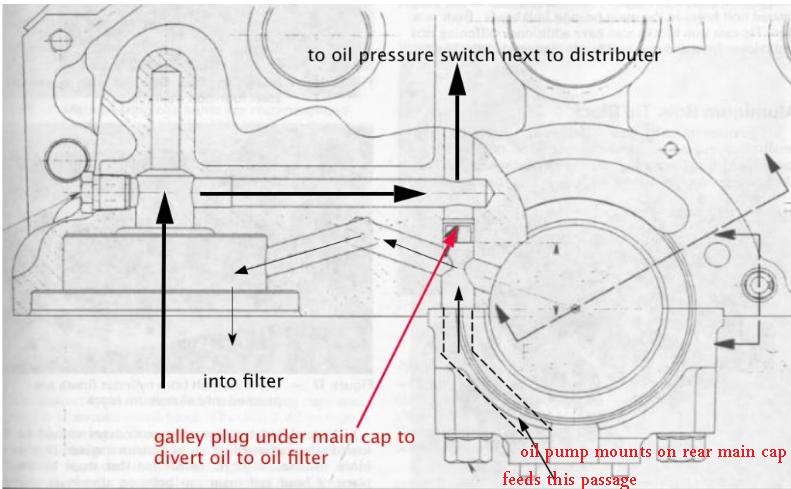

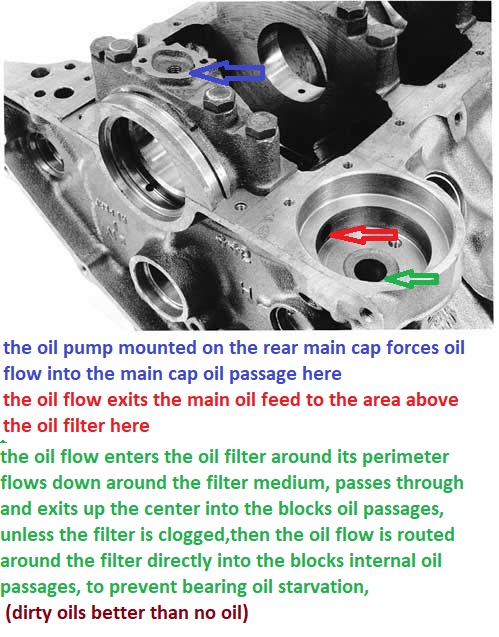

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

both G.M. engineering and smokey yunick working for NASCAR and G.M. ENGINEERING,

did extensive testing on engine longevity, and bearing durability in relation to oil pressure

there was no measurable improvement in bearing protection once oil pressure reached 70 psi.

there was an improvement if the volume of oil flow was increased but not pressure,

pressure is simply a measurement of RESISTANCE to flow.

MORE USEFUL INFO

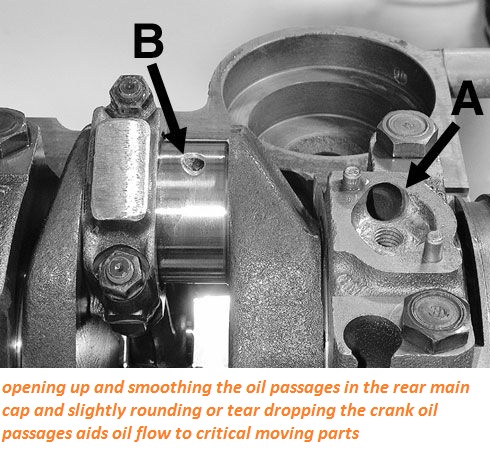

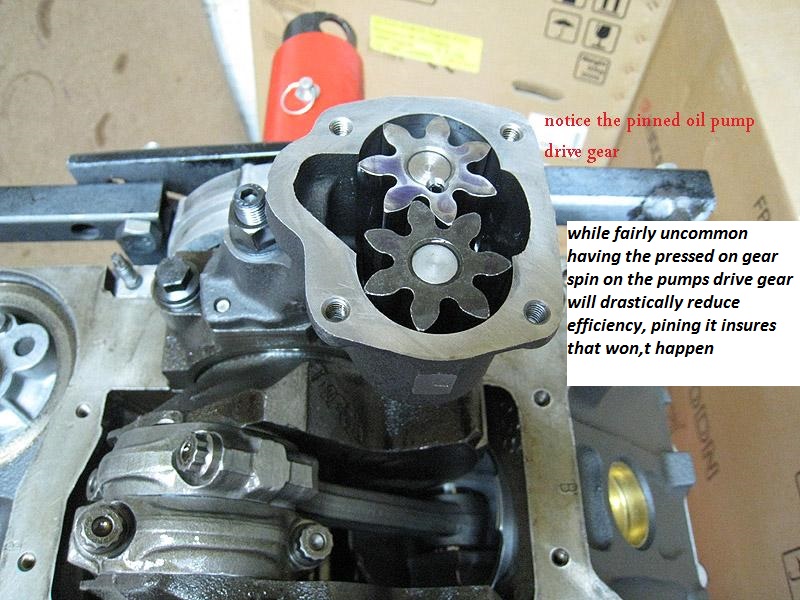

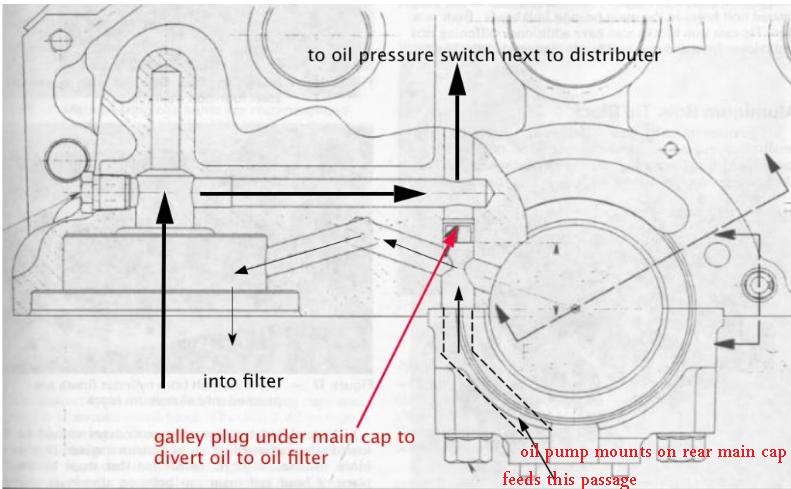

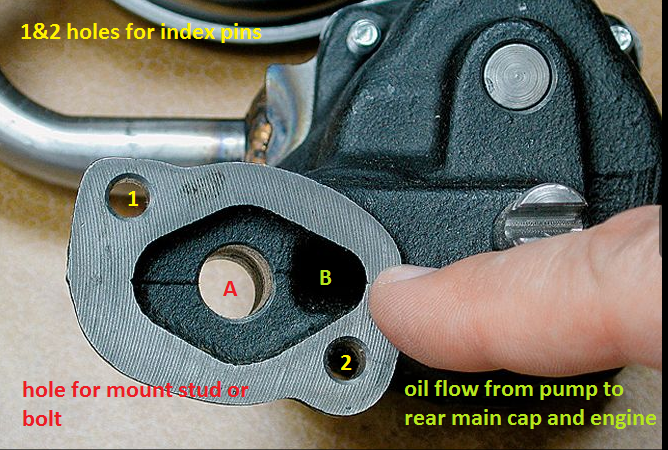

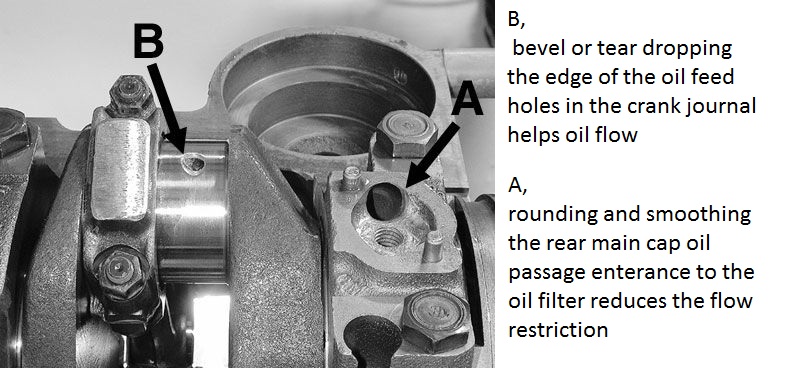

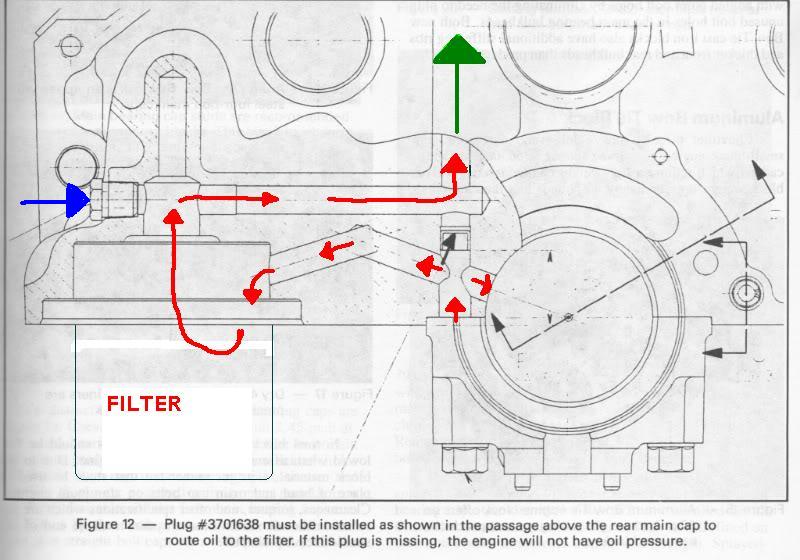

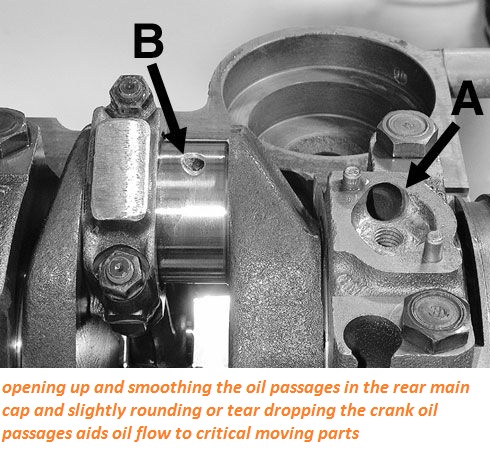

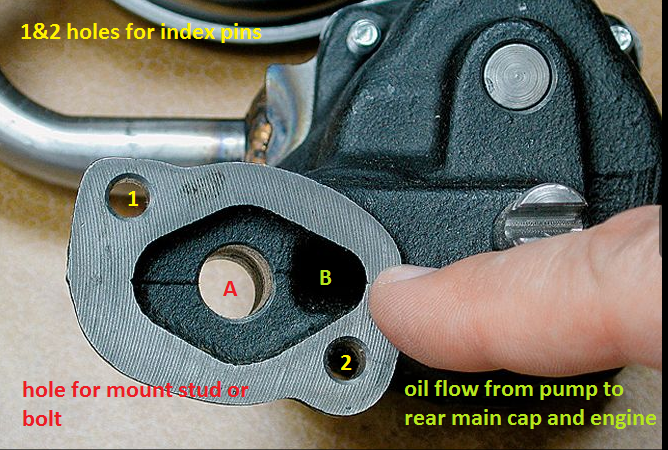

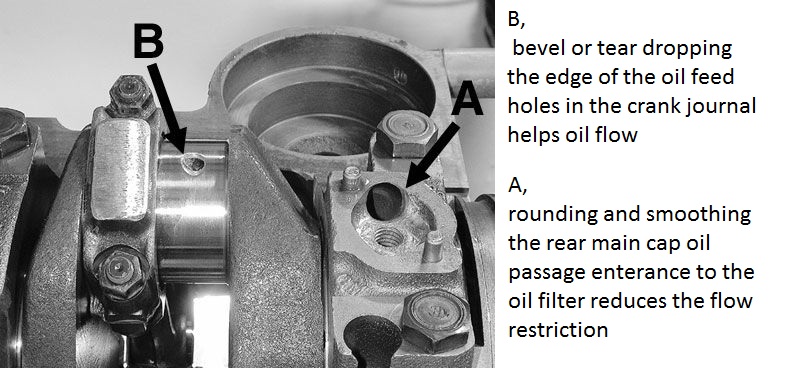

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

obviously the first two steps in diagnosing any oil pressure problem you suspect is to check your dipstick for the proper oil level in the engine and then test the pressure with an independent test gauge to verify your cars gauge is correct, and you do have a problem , not a defective sensor or gauge

the oil pressure sensor location, is next to the distributor base,on most sbc engines on the rear of the block, but if your trying to track down an oil pressure issue it could be either a bad sensor, bad connection on the sensor or gauge, or a defective gauge, causing the high pressure reading OR it may be a defective oil pump, or bearing clearances or an oil passage plug, or the wrong oil viscosity, or a busted oil pump pick-up or incorrect installation of the oil pump or pick-up,defective oil filter or several other potential sources if its a low pressure issue as previously mentioned.

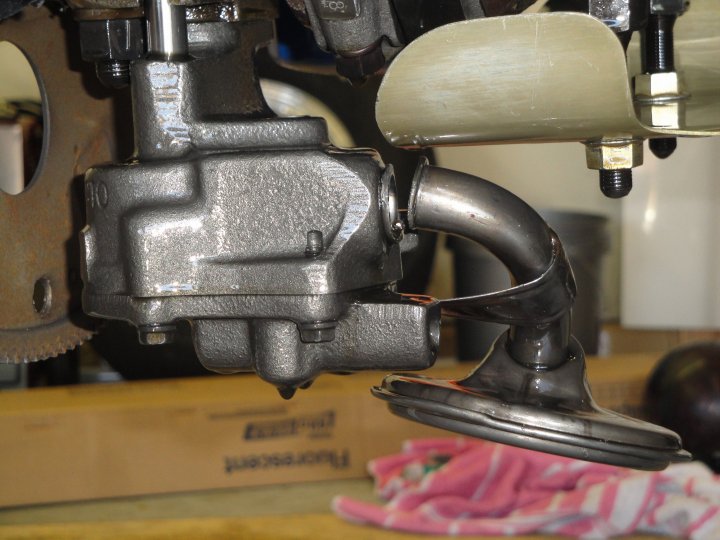

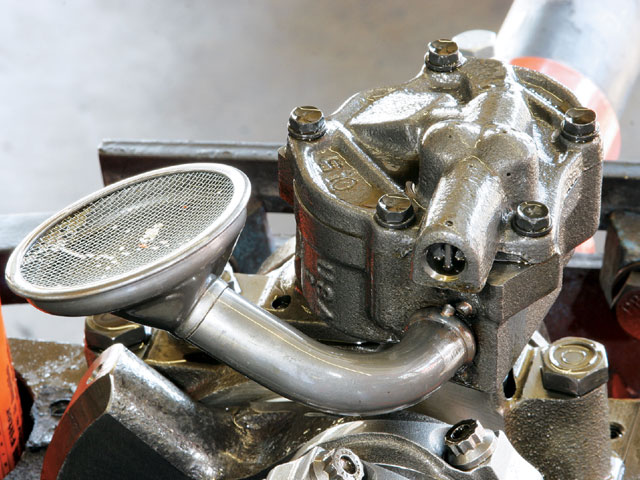

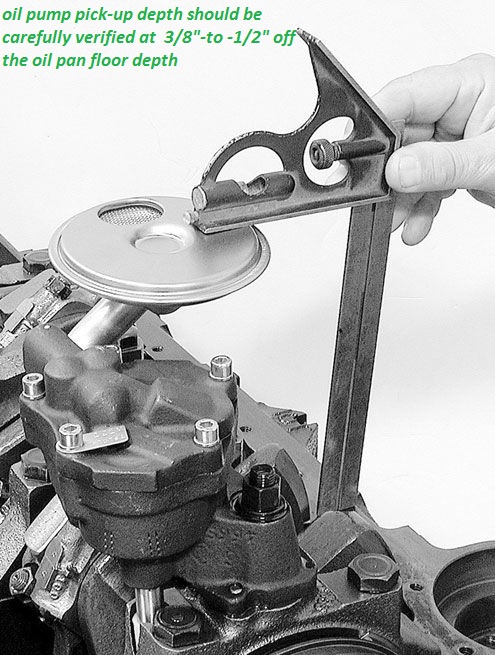

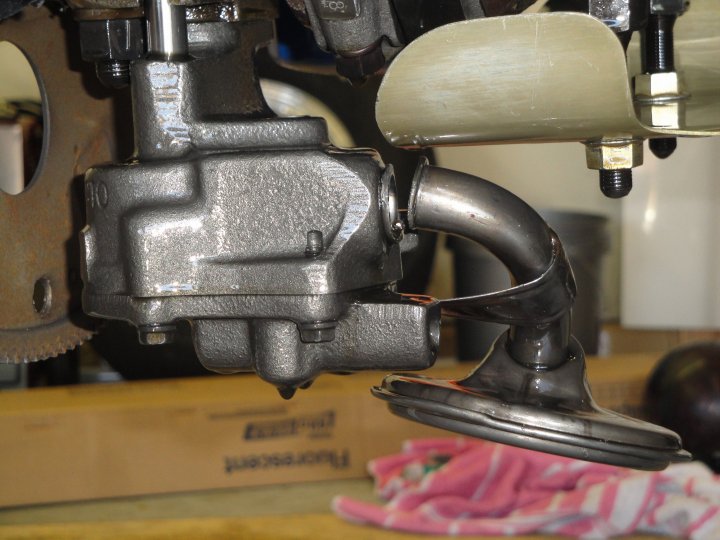

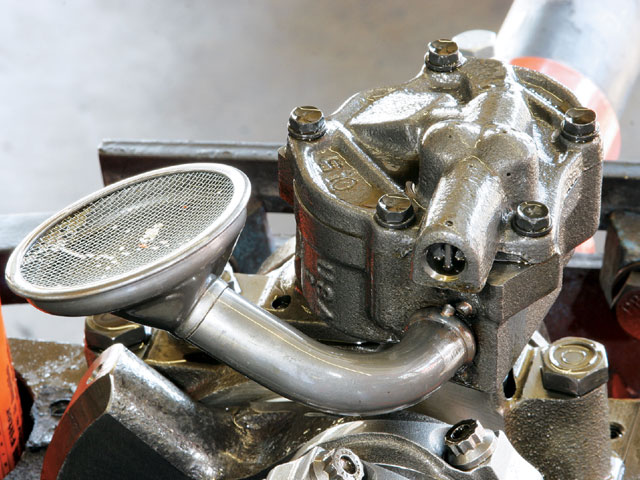

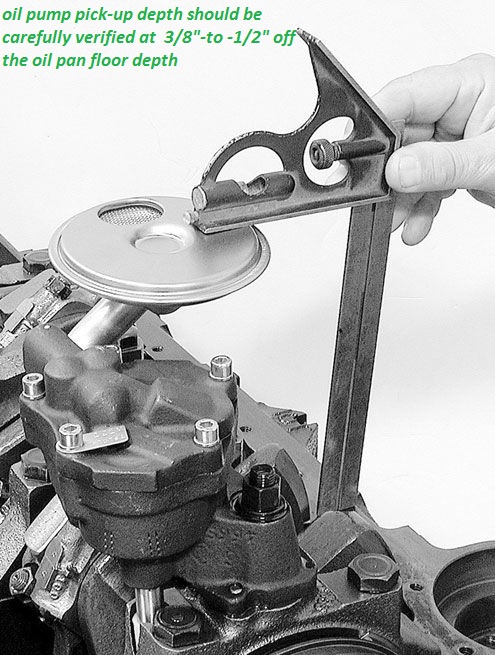

broken , or improperly installed oil pump pick-ups can cause several major oil pressure issues

almost every mechanics tool box needs a few basic measuring tools and supplies

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

https://www.amazon.com/Claytoon-Set...d=1466872286&sr=8-17&keywords=plastilina+clay

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

https://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

adding "ST" to the end of the existing melling SBC OIL PUMP part number denotes the helical gear set option

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

in my opinion , and experience and from lots of G.M. engine, race testing.

theres no need for oil pressure to exceed about 65 psi,

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces,if your engine shows more than about 70 psi, you should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

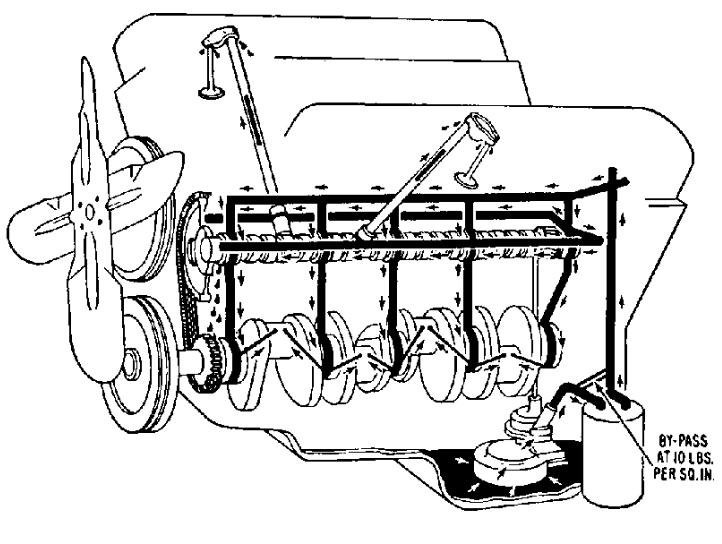

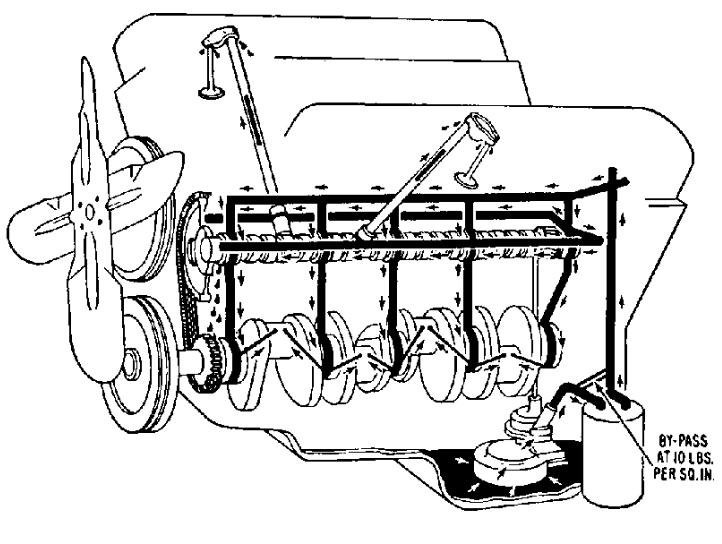

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

SHOP CAREFULLY , WHEN YOU GO TO BUY AN OIL PAN<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

read these related links it will provide a great many answers

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://www.ecklerschevelle.com/chevelle ... -1977.html

after quite a bit of discussion I convinced him to unbolt the exhaust and motor mounts ,pull the distributor, starter etc,and hook up the engine crane too lift the engine about 4" higher so we could remove the oil pan without removing the engine totally from the car, and found what I thought we would find, the oil pump pick-up was sitting about 1/16"=to-1/8"th inch off the oil pan floor, severely restricting oil flow into the oil pump.

I proved that with a strip of modeling clay and a quick test fit,so now hes looking for a 6-7 quart oil pan with a slightly deeper sump that will work with his existing oil pump and cars frame,suspension etc.

if any of you guys happen to know who makes that oil pan, for a 1971 BBC and its part number please post the info, yes I could custom weld up an oil pan, but I know he would rather just buy one

Now I got called over to trouble shoot, as his issue is that as long as the cars engine runs between about 900rpm where it idles and about 1500rpm his oil pressure stays at that 35 -40 psi range, and oil flows from every rocker, it looks like its well set up, yet if he blips the throttle the oil pressure rapidly FALLS as the RPMS increase past 2000rpm!

now he started talking about a new oil pump, and the bearing clearances and several other things like perhaps the oil pump pick-up weld to the oil pump had failed,And one of his friends kept telling him, that old MYTH,that it was the high volume performance oil pump ,sucking the oil pan dry! but after questioning him a bit I was rather convinced I knew what the issue and its cause was as I'd seen similar problems in the past.

the K frame or cross member on a chevelle of that generation fits rather closely under the block,and rather far back restricting the stock oil pan voluum, as does the suspension, and he installed the stock 4-5 quart oil pan,to get clearance, with the melling m77hv oil pump.

keep in mind both engine oil temps and trans fluid temps seldom reach operational temps,fluid

and stabilize , for semi consistent data,in under 12-15 minutes of drive time,temps have a huge effect on lubricant viscosity and durability. .

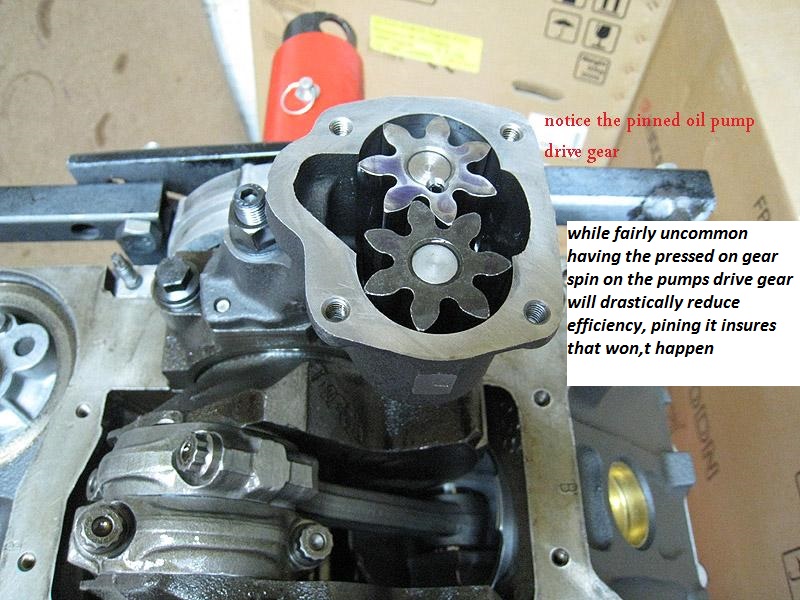

while helical cut gears will run smoother ,

( ESPECIALLY WITH THE STOCK 7 tooth SBC oil pump)

as you potentially have 2 or three gear teeth in various stages of gear tooth contact

(depends on the angle of tooth engagement)

and yes the design will reduce a tendency to produce a pressure pulse, I have not seen this as a major issue.

simply swapping to the standard volume and pressure BIG BLOCK 12 tooth oil pump in a SBC engine all but eliminates the pulse and pressure and volume issues a sbc oil pump has.

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

both G.M. engineering and smokey yunick working for NASCAR and G.M. ENGINEERING,

did extensive testing on engine longevity, and bearing durability in relation to oil pressure

there was no measurable improvement in bearing protection once oil pressure reached 70 psi.

there was an improvement if the volume of oil flow was increased but not pressure,

pressure is simply a measurement of RESISTANCE to flow.

MORE USEFUL INFO

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

obviously the first two steps in diagnosing any oil pressure problem you suspect is to check your dipstick for the proper oil level in the engine and then test the pressure with an independent test gauge to verify your cars gauge is correct, and you do have a problem , not a defective sensor or gauge

the oil pressure sensor location, is next to the distributor base,on most sbc engines on the rear of the block, but if your trying to track down an oil pressure issue it could be either a bad sensor, bad connection on the sensor or gauge, or a defective gauge, causing the high pressure reading OR it may be a defective oil pump, or bearing clearances or an oil passage plug, or the wrong oil viscosity, or a busted oil pump pick-up or incorrect installation of the oil pump or pick-up,defective oil filter or several other potential sources if its a low pressure issue as previously mentioned.

broken , or improperly installed oil pump pick-ups can cause several major oil pressure issues

almost every mechanics tool box needs a few basic measuring tools and supplies

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

https://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

adding "ST" to the end of the existing melling SBC OIL PUMP part number denotes the helical gear set option

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

in my opinion , and experience and from lots of G.M. engine, race testing.

theres no need for oil pressure to exceed about 65 psi,

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces,if your engine shows more than about 70 psi, you should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

SHOP CAREFULLY , WHEN YOU GO TO BUY AN OIL PAN<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

read these related links it will provide a great many answers

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://www.ecklerschevelle.com/chevelle ... -1977.html

after quite a bit of discussion I convinced him to unbolt the exhaust and motor mounts ,pull the distributor, starter etc,and hook up the engine crane too lift the engine about 4" higher so we could remove the oil pan without removing the engine totally from the car, and found what I thought we would find, the oil pump pick-up was sitting about 1/16"=to-1/8"th inch off the oil pan floor, severely restricting oil flow into the oil pump.

I proved that with a strip of modeling clay and a quick test fit,so now hes looking for a 6-7 quart oil pan with a slightly deeper sump that will work with his existing oil pump and cars frame,suspension etc.

melling oil pumps said:That is what a high volume pump will do. Now lets consider what it will not do.

1. it will not replace a rebuild in a worn out engine. It may increase pressure but the engine is still worn out.

2. It will not pump the pan dry. Both solid and hydraulic lifters have metering valves to limit flow of the oil to the top of the engine. If a pan is pumped dry it is because the holes that drain oil back to the pan are very restricted or plugged. If the high volume pump is also high pressure, there will also be a slight increase in flow to the top.

3. it will not wear out the distributor gears. The load on the gear is directly related to the resistance to flow. Oil pressure is the measure or resistance to flow. The 427 fe side oiler uses a pump with the relief valve set at 125 psi and it uses a standard distributor gear. Distributor gear failures are usually caused by a worn gear on a new cam gear and/or worn bearings allowing misalignment.

if any of you guys happen to know who makes that oil pan, for a 1971 BBC and its part number please post the info, yes I could custom weld up an oil pan, but I know he would rather just buy one

Last edited by a moderator: