76GrayVette

Member

Hey,

I just did my introduction post as I'm new to the forums but I figured I'd go ahead and jump right in. Forgive me for the questions, I have been doing lots of reading and research but it's hard to get a clear, specific answer for what I'm looking for so I'm hoping some of you guys can give me some tips and advice.

Anyway, like I said in my introduction post, I have a 76 L82 Corvette 4-speed that I'm fixing up and I have the engine tore down for rebuilding.

My goal for this engine is to make it a nice reliable street engine that makes decent power(maybe 300-350hp/torque?) with more focus on lower end torque as I don't plan to spin more than 5500rpm very often, if at all.

So I had to have the engine bored 0.030'' over because of pitting in the cylinders and the block was decked 0.012'' to fix a nick in the surface.

Here are my specs so far:

355 cubic inch

4-bolt main (I know not necessary for my 5500rpm limit but cool to have, especially because it's the original block for the car)

Forged steel crank (turned 0.010'')

Stock 5.7 rods (supposed to be forged)

Forged Speed Pro flat top four valve relief pistons (part# KL2256F30)

Vehicle weight is about 3600lbs I think

It's a 4-speed car with the Borg-Warner T-10

Tire diameter is about 27in I think. They are BF's 255/60R15

I'm not sure about the rear end ratio (I haven't been able to find the stamp yet) but I was running about 3000rpm or a little over at 55-60mph in 4th gear

so probably 3.50 or 3.70

That's pretty much the basic specs.

I have a limited budget so I was thinking some mild heads, cam, and intake.

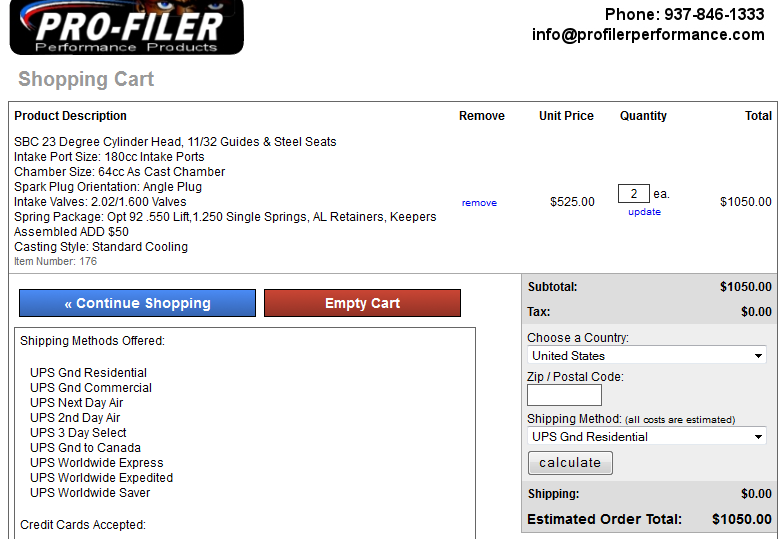

I had Edlebrocks E-street heads(5089/5073) in mind with their Performer Q-jet intake (2101) because they are in my price (and I think power) range and I've heard they are pretty good for the money. Again, I'm talking a mild build here. Not looking for wild HP numbers just some solid, very street-able power.

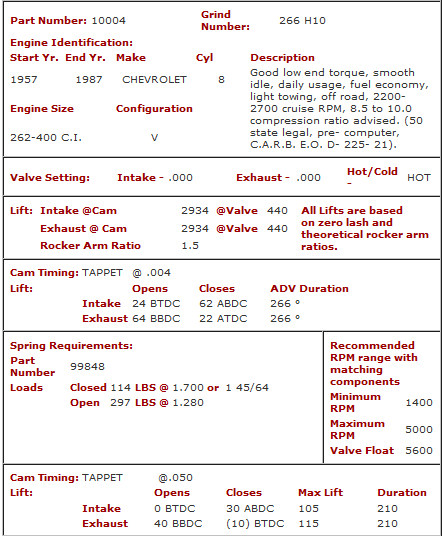

Okay, so the main questions/concerns are about matching my SCR and DCR with a cam that works with those heads and is in my rpm range (under about 5500rpm)

My first thoughts were to get the 64cc E-streets.

My SCR(according to RSR and other online calculators) would be about 9.98:1

Bore: 4.030''

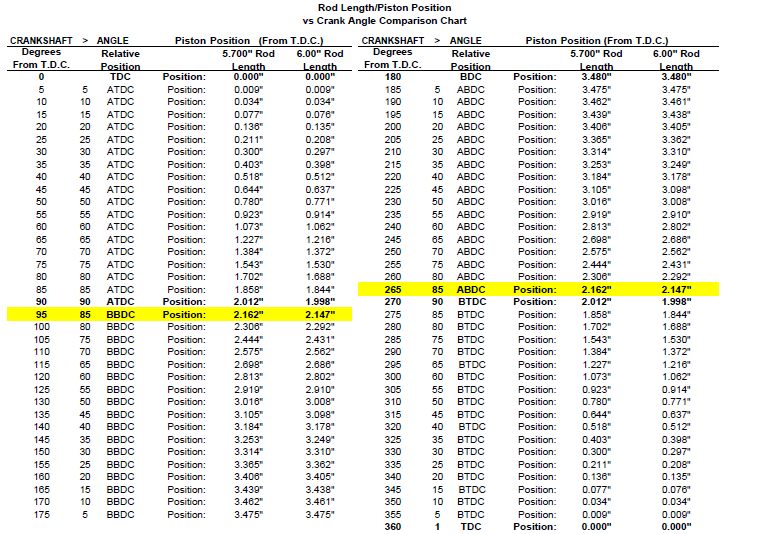

Stroke: 3.48''

Head Gasket Thickness: Probably 0.039'' compressed as I'd probably be using Fel-pro recommended by Edelbrock for the heads.

Deck Height: 0.013'' (assuming a stock 0.025'' minus a shaving of 0.012'')

Piston top volume: ad for speed pro's say 6.1cc

Combustion Chamber: 64cc

Quench is 0.052'' with that gasket and deck height. I know it's not ideal but I don't want to go much tighter in fear of having problems. (Edelbrock recommends 0.050'' piston to head clearance with the E-streets) (Could I go tighter or no?)

When I plug that SCR into some DCR calculators I find that to get a DCR under 8.0:1 (I'd feel safer at 7.5-7.8) I have to use some fairly large, longer duration cams

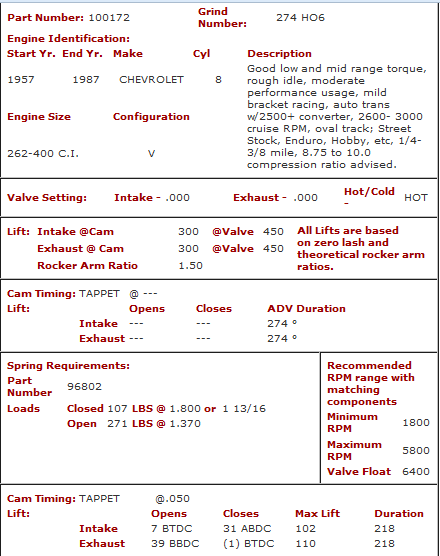

such as 7.81:1 with the Lunati 10001(Adv. 280/290, 0.050. 214/224, 0.443/0.465, LSA. 112)

I tried the Edelbrock Performer Plus which has a bit less duration, and it was about 7.87:1. I don't really want a DCR that high and the lift is not as high as the stock cam.

So the concern here is if I try and bump SCR up too high for more power and then have to pick a bigger cam to avoid a high DCR and detonation, will I loose my bottom end power?

Or is it better to get the 70cc Edelbrock heads and have a SCR of about 9.3:1 and get a smaller cam with a DCR of about 7.7:1

Whew! I think that was the major stuff. Sorry about the overload. I don't expect you all to have all the answers for me and I know all these numbers are just estimates, that's why I'd like to err on the lower side to be safe and I'll measure what I can but I'm hoping you can tell me if I'm on the right track or if I'm way off.

Thanks again,

Hayden

Here's a picture to make up for all the words

I just did my introduction post as I'm new to the forums but I figured I'd go ahead and jump right in. Forgive me for the questions, I have been doing lots of reading and research but it's hard to get a clear, specific answer for what I'm looking for so I'm hoping some of you guys can give me some tips and advice.

Anyway, like I said in my introduction post, I have a 76 L82 Corvette 4-speed that I'm fixing up and I have the engine tore down for rebuilding.

My goal for this engine is to make it a nice reliable street engine that makes decent power(maybe 300-350hp/torque?) with more focus on lower end torque as I don't plan to spin more than 5500rpm very often, if at all.

So I had to have the engine bored 0.030'' over because of pitting in the cylinders and the block was decked 0.012'' to fix a nick in the surface.

Here are my specs so far:

355 cubic inch

4-bolt main (I know not necessary for my 5500rpm limit but cool to have, especially because it's the original block for the car)

Forged steel crank (turned 0.010'')

Stock 5.7 rods (supposed to be forged)

Forged Speed Pro flat top four valve relief pistons (part# KL2256F30)

Vehicle weight is about 3600lbs I think

It's a 4-speed car with the Borg-Warner T-10

Tire diameter is about 27in I think. They are BF's 255/60R15

I'm not sure about the rear end ratio (I haven't been able to find the stamp yet) but I was running about 3000rpm or a little over at 55-60mph in 4th gear

so probably 3.50 or 3.70

That's pretty much the basic specs.

I have a limited budget so I was thinking some mild heads, cam, and intake.

I had Edlebrocks E-street heads(5089/5073) in mind with their Performer Q-jet intake (2101) because they are in my price (and I think power) range and I've heard they are pretty good for the money. Again, I'm talking a mild build here. Not looking for wild HP numbers just some solid, very street-able power.

Okay, so the main questions/concerns are about matching my SCR and DCR with a cam that works with those heads and is in my rpm range (under about 5500rpm)

My first thoughts were to get the 64cc E-streets.

My SCR(according to RSR and other online calculators) would be about 9.98:1

Bore: 4.030''

Stroke: 3.48''

Head Gasket Thickness: Probably 0.039'' compressed as I'd probably be using Fel-pro recommended by Edelbrock for the heads.

Deck Height: 0.013'' (assuming a stock 0.025'' minus a shaving of 0.012'')

Piston top volume: ad for speed pro's say 6.1cc

Combustion Chamber: 64cc

Quench is 0.052'' with that gasket and deck height. I know it's not ideal but I don't want to go much tighter in fear of having problems. (Edelbrock recommends 0.050'' piston to head clearance with the E-streets) (Could I go tighter or no?)

When I plug that SCR into some DCR calculators I find that to get a DCR under 8.0:1 (I'd feel safer at 7.5-7.8) I have to use some fairly large, longer duration cams

such as 7.81:1 with the Lunati 10001(Adv. 280/290, 0.050. 214/224, 0.443/0.465, LSA. 112)

I tried the Edelbrock Performer Plus which has a bit less duration, and it was about 7.87:1. I don't really want a DCR that high and the lift is not as high as the stock cam.

So the concern here is if I try and bump SCR up too high for more power and then have to pick a bigger cam to avoid a high DCR and detonation, will I loose my bottom end power?

Or is it better to get the 70cc Edelbrock heads and have a SCR of about 9.3:1 and get a smaller cam with a DCR of about 7.7:1

Whew! I think that was the major stuff. Sorry about the overload. I don't expect you all to have all the answers for me and I know all these numbers are just estimates, that's why I'd like to err on the lower side to be safe and I'll measure what I can but I'm hoping you can tell me if I'm on the right track or if I'm way off.

Thanks again,

Hayden

Here's a picture to make up for all the words