Indycars said:

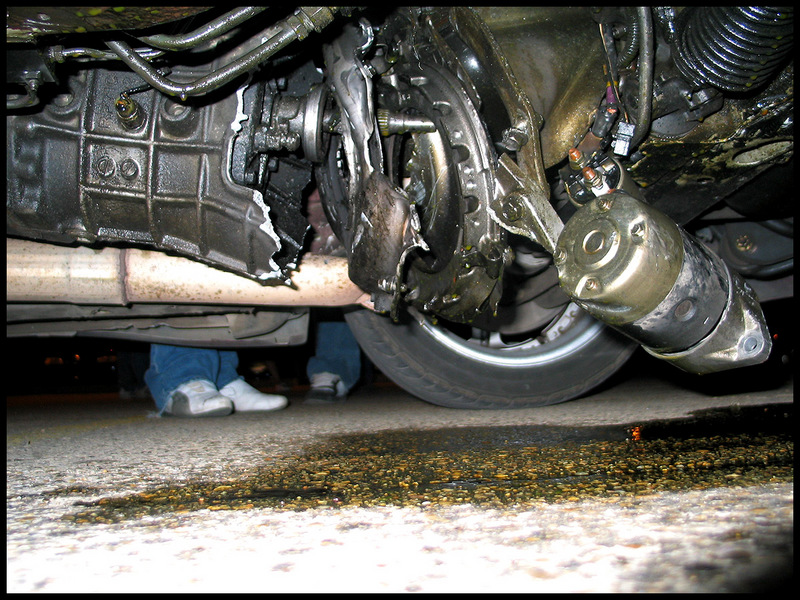

Grumpy, does it look like those rods got very hot in the big end?

its hard to tell from the pictures but the rod bearings, in those connecting rods, sure look well worn,and grooved from what looks like metallic contaminants, like a failed cam lobe might produce , and the resulting bearing over heating could easily result, thats one reason Im fairly sure the rods in the pictures, would be better off if replaced, while it might be superficial,damage and the rods could be re-sized and fitted with new rod bolts and bearings, if it was my engine the rods would go in the dumpster.

links worth reading

viewtopic.php?f=51&t=2919

viewtopic.php?f=53&t=6909&p=22571&hilit=pressed+float#p22571

viewtopic.php?f=53&t=6834&p=22136&hilit=pressed+float#p22136

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=509&p=28226&hilit=hone+plate#p28226

viewtopic.php?f=53&t=978&p=1725&hilit=pressed+float#p1725

http://www.maintenanceresources.com/ref ... alance.htm

http://www.circletrack.com/enginetech/c ... rminology/

viewtopic.php?f=53&t=110&p=137&hilit=pressed+float#p137

viewtopic.php?f=53&t=852