Thanks for the input everyone!

Yes, I have been reading lots and am leaning more to a forged crank now, I'd rather build the bottom end once instead of shredding it to pieces. Also, for the cost of balancing and machine work I intend to do, I might as well do it right. I see there is a forged 3.900" crank I can get from K1 technologies. I know a lot of guys use the 4.000" crank but I would do well to bore the cylinders out to 3.905 and I thought bore stroke ratios were supposed to be greater than 1. However, I will poke around the site about what I can see here about bore-stroke ratios.

I know that at 1.2 to 1.4 hp per cubic inch for and NA engine I should expect between 375 and 438 hp (hence my leaning to a stroker crank to increase displacement). This also brings me back to the turbo question, but I think I need to take a step back and think about how I am going to use this vehicle.

This truck is being built as something that is driven regularly, but it is not my daily driver.

I will never take it down the 1/4 mile track, but I want to be able to put a big stupid grin on my face whenever I want.

I will not use the truck for towing.

I also need to be able to run pump gas (I have 91 octane available where I am but if 87 works then that's what I will do).

I need to keep 4x4 as we get plenty of snow up here in Sault Ste Marie.

It needs to be able to idle and I do not need it to scream to 7000 rpm.

The truck could go on a 3 hour drive to Costco (the wife will gladly load up the truck at Costco), but we would cruise there at 75 mph (120km/hr) because if I go any faster then that I will meet my friendly neighborhood police man

Last time I build a truck it was a 75 c10 with a 350 4 bolt. It had:

- Stock rotating assembly

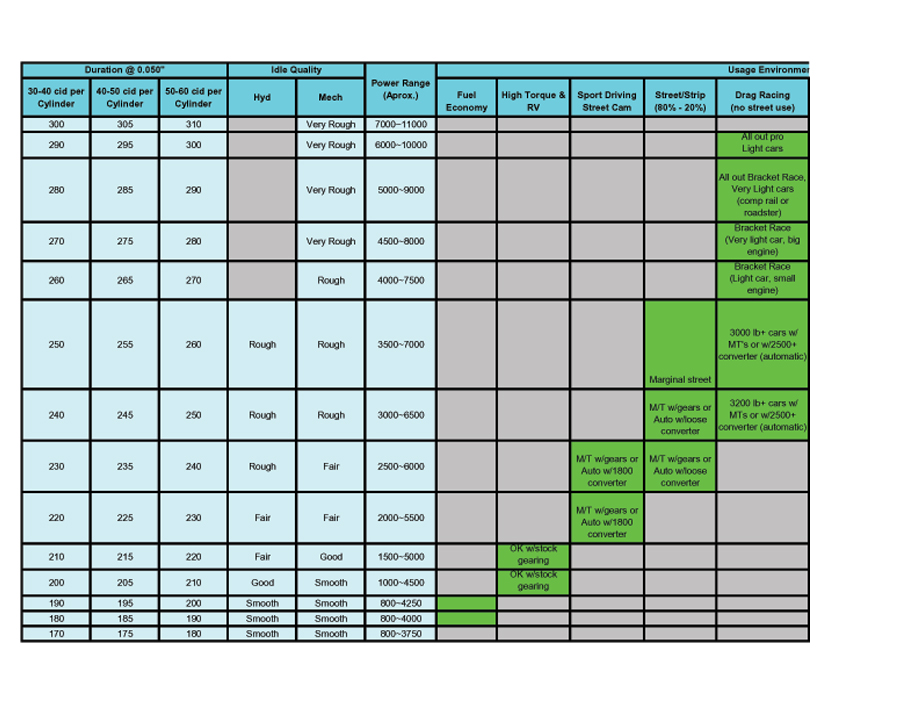

- Summit 1102 camshaft 204/214 with .422/.444 lift running a 4 deg advance https://www.summitracing.com/parts/sum-1102

- 190cc heads with 64cc combustion chamber and a

- 1.5 roller rockers

- 600cfm 4 barrel carb

- Edelbrock dual plane intake

- 1 5/8" headers with 2.5" exhaust (with some cheap high flow mufflers from summit)

- I also had a 2400 rpm stall converter.

- 3.73 gears with stock 27.5 inch tires

I think I regret my camshaft selection, the truck was too tame, I wanted more. The old girl drove well and could keep up with any new truck no problem, but it just didn't get up and go (never felt myself getting pushed into my seat). IT was awesome how I could just lightly touch the throttle and it would glide up 10 to 15 mph so I think I had the torque I wanted, but gave up too much on the top end.

When I built the C10 I just kinda did it as I went a long. This time I want to make a parts list and actually plan out the engine to match what I want. A lot of the info on other sites is about engine building based around peak hp and high rpms for lighter cars. How do I take that info and build a power curve for a heavier truck? (I do find TONS of helpful info on this sight).

So to re-cap:

How do I determine a desired power curve based on what I want?

What considerations do I need to make for bore stroke ratios?

How will the extra weight of the truck come into play during component selection?