I was curious how much difference changing only the cylinder head from OEM to AFR 205 would

make. So I used Sim01, changed the heads and nothing else. Below is that comparison graph.

Do you have the part number ? AFR typically has a street version and a competition version, which head

are you using ? This will help me keep my documentation of my library head flow valid, thanks !

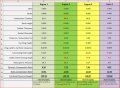

Then I made the rest of the requested changes shown below on the Highlighted lines. This new simulation will be called Sim05.

Below is the new graph for Sim05 with all the changes compared to Sim01.

Daniel, I see where you are showing a DCR of 8.3 after the changes made above, I get 7.75. Assuming that you

wanted more low rpm torque, I advanced the came 2° and 4°, which shows a DCR of 7.91 and 8.07. Either one

of these have a decent chance of working with a 91-octane fuel.

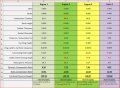

The RED characters denote a change from the previous engine calculations.

With the camshaft numbers provided by Summit, Dynomation was able to calculate the IVC of 79°. Now

I’ve never used the “Rocker Math Calculator” RMC on any forum before, but when you changed from

Rocker Ratio RR of 1.7 to 1.8 the event timing number changed slightly. Changes are noted in the

graphic below. This is why you see in the Excel calculator an IVC of “79.3°”. The duration of the intake

valve increased by 0.6° total . You will want to review my numbers and let me know if you see something.

make. So I used Sim01, changed the heads and nothing else. Below is that comparison graph.

Do you have the part number ? AFR typically has a street version and a competition version, which head

are you using ? This will help me keep my documentation of my library head flow valid, thanks !

Then I made the rest of the requested changes shown below on the Highlighted lines. This new simulation will be called Sim05.

Below is the new graph for Sim05 with all the changes compared to Sim01.

Daniel, I see where you are showing a DCR of 8.3 after the changes made above, I get 7.75. Assuming that you

wanted more low rpm torque, I advanced the came 2° and 4°, which shows a DCR of 7.91 and 8.07. Either one

of these have a decent chance of working with a 91-octane fuel.

The RED characters denote a change from the previous engine calculations.

With the camshaft numbers provided by Summit, Dynomation was able to calculate the IVC of 79°. Now

I’ve never used the “Rocker Math Calculator” RMC on any forum before, but when you changed from

Rocker Ratio RR of 1.7 to 1.8 the event timing number changed slightly. Changes are noted in the

graphic below. This is why you see in the Excel calculator an IVC of “79.3°”. The duration of the intake

valve increased by 0.6° total . You will want to review my numbers and let me know if you see something.