You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Cam Research for the Experts Eye

- Thread starter TXChevy

- Start date

Next steps related to bearing selection.....I've been through many info links on this as well.

Crank mains/journals measured well within spec so there's no need to turn it. Its currently .010 under on mains/journals. I had also made a "story board" where I placed (hot glued) all the bearings face up in order of mains and rods. This was simply to see the overall picture, not to take the place of any measurements.

The bearings used were clevite P series that looked very good. What was interesting is that the mains showed a bit more wear on the bottom saddles than the tops. I think this was due to the long periods that the car sat and the crank settled onto the lower half, then when first starting it was hard on the lower half until oil pressure "floated" the crank off the bearing. Hope I explained that ok. In all cases the wear was not severe but you could see a difference.

From what I understand about P vs H clevites, I think it will be fine to use P new bearings with this stock cast crank.

New ARP studs are being used for the main caps and therefore the mains were sized and the block has been line bored. I'll measure the main cap bores to verify bearing size needed, and I'll also measure centerline of cam to crank to verify timing chain length.

On the rods, I'm re-using the pistons as they measured within spec. Block is currently 30 over and the bores were fine therefore just a fresh hone for new rings. The stock rods have been replaced with scat rods (same length) with ARP bolts. Rods have been sized and pistons/rods balanced.

So I'll measure everything (I have mics/bore gauge/etc) to verify what bearing sizes I need but for questions:

1. Is there a reason that I shouldn't use P series bearings? Their performance was excellent in the engine.

2. I'll double check but I believe the bores were honed for moly rings. If memory serves me right that's what was in the engine (Hastings) and these also performed great. Same type of question, is there a reason not to use this material?

Edit - I'd better research this more, I also see plasma-moly but also variances of the shape/edge of the rings. I'm in over my head but happy to continue the learning curve...

Crank mains/journals measured well within spec so there's no need to turn it. Its currently .010 under on mains/journals. I had also made a "story board" where I placed (hot glued) all the bearings face up in order of mains and rods. This was simply to see the overall picture, not to take the place of any measurements.

The bearings used were clevite P series that looked very good. What was interesting is that the mains showed a bit more wear on the bottom saddles than the tops. I think this was due to the long periods that the car sat and the crank settled onto the lower half, then when first starting it was hard on the lower half until oil pressure "floated" the crank off the bearing. Hope I explained that ok. In all cases the wear was not severe but you could see a difference.

From what I understand about P vs H clevites, I think it will be fine to use P new bearings with this stock cast crank.

New ARP studs are being used for the main caps and therefore the mains were sized and the block has been line bored. I'll measure the main cap bores to verify bearing size needed, and I'll also measure centerline of cam to crank to verify timing chain length.

On the rods, I'm re-using the pistons as they measured within spec. Block is currently 30 over and the bores were fine therefore just a fresh hone for new rings. The stock rods have been replaced with scat rods (same length) with ARP bolts. Rods have been sized and pistons/rods balanced.

So I'll measure everything (I have mics/bore gauge/etc) to verify what bearing sizes I need but for questions:

1. Is there a reason that I shouldn't use P series bearings? Their performance was excellent in the engine.

2. I'll double check but I believe the bores were honed for moly rings. If memory serves me right that's what was in the engine (Hastings) and these also performed great. Same type of question, is there a reason not to use this material?

Edit - I'd better research this more, I also see plasma-moly but also variances of the shape/edge of the rings. I'm in over my head but happy to continue the learning curve...

piston rings & related info

step ONE if the bores not concentric, and bore walls parallel and the bore surface consistent in its surface Finish or if you had the bore honed without the use of torque plates simulating a cylinder heads bolted in place, the rings WILL NOT SEAL as effectively , as they would if you had...

garage.grumpysperformance.com

Last edited:

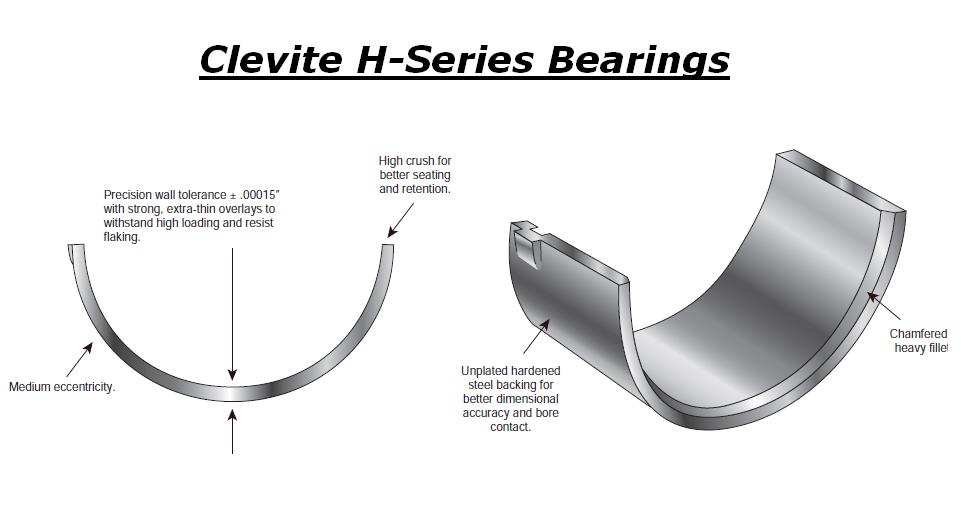

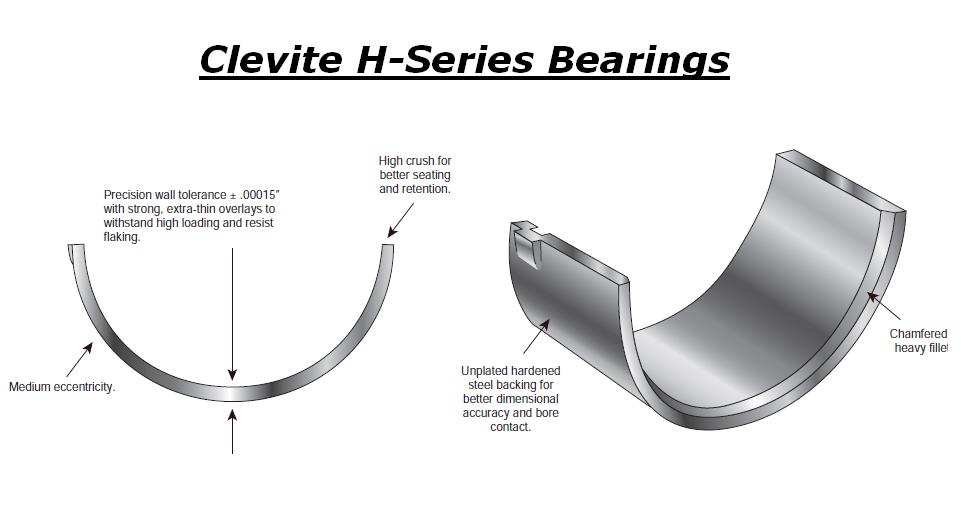

P-series bearings are standard duty & softer thus have a bit better embeddability for micro trash in the oil,

and lack the edge radius clearance of the h series bearings, h series bearings have more clearance on some cranks journals

https://www.enginebuildermag.com/2016/04/high-performance-engine-bearings/

yeah read the links and sub links as usual

https://www.motortrend.com/how-to/select-install-high-performance-engine-bearings/

and lack the edge radius clearance of the h series bearings, h series bearings have more clearance on some cranks journals

https://www.enginebuildermag.com/2016/04/high-performance-engine-bearings/

yeah read the links and sub links as usual

bearing clearances

Understanding Today’s Bearing Clearance Recipe ■Tech Center by Engine Builder Staff - Feb 6, 2015 0 3928 Print Email What’s needed to keep the rotating assembly rotating? It’s a recipe that includes three key ingredients: the bearing, the crankshaft and the oil. But understanding the...

garage.grumpysperformance.com

https://www.motortrend.com/how-to/select-install-high-performance-engine-bearings/

don,t guess on clearances and journal surface

So I decided to buy a couple of worthless old 283s to learn how to build engines. If I acquire the appropriate skills, I'm going to build a torquey 383 out of the anemic '77 350 in my C30. It tows cars, but it doesn't exactly set the road on fire, if you know what I mean. Anyway, I bought two...

garage.grumpysperformance.com

engine assembly tips

the first few rule's of GRUMPY'S engine assembly (1) THINK THINGS THROUGH CAREFULLY , WRITE DOWN A LIST OF COMPONENTS , MAKE DARN SURE THE LIST IS COMPATIBLE WITH, and AT LEAST SEMI-REASONABLY PRICED WITHIN YOUR BUDGET. FOR WHAT YOU INTEND TO BUILD AND RESEARCH THE RELATED MACHINE WORK...

garage.grumpysperformance.com

assembling and installing connecting rods/pistons

He Measured .0004" - 4/10,000 th of an inch #5 MAIN CAP BORE DISTORTION TORQUED DOWN TO SPECS WITH THE OIL PUMP ON. I DON'T.LIKE IT. IT SHOULD BE +/- .0001" TOLERANCE. +/- .0002" INCH MAX.

garage.grumpysperformance.com

rotating assembly bearings

hi grumpy had a question , im rebuilding a 350 chevy. the crank readings are main bearing journal is 2.448 and rod journals read 2.098 so does this mean that I would need standard sized bearings? and also when installing new bearing from the box , do I need to clean them and if so with what ...

garage.grumpysperformance.com

bearings and oil flow

Bearings and oil flow, some of the most important processes in engine assembly are related to getting the bearing clearances and oil flow and pressure rates set up to provide the correct oil flow rates and pressure for cooling and preventing direct surface to surface contact on the rotating...

garage.grumpysperformance.com

lining up oil feed holes in bearings shells

I just got an e-mail asking what to do if you find that the blocks oil feed passage holes don,t line up exactly right with the holes in the oil feed holes in bearings shells? http://garage.grumpysperformance.com/index.php?threads/viscosity-centistoke.15612/ paint, marker etc. tends to...

garage.grumpysperformance.com

Bearing Clearances-Engine Builders Magazine

https://www.enginebuildermag.com/2016/04/high-performance-engine-bearings/ http://garage.grumpysperformance.com/index.php?threads/testing-high-volume-vs-standard-chevy-oil-pumps.15902/#post-95621

garage.grumpysperformance.com

tips on building a peanut port big block combo

PEANUT PORT HEADS WITH RECTANGLE PORT GASKET ABOVE 346236 1975-87 454 Open 113cc .PEANUT SLIGHTLY LARGER, COMMON EARLY OVAL PORT HEADS WITH RECTANGLE PORT GASKET BELOW polishing and smoothing these combustion chambers,surfaces, removing the sharp ridges etc, has shown noticeable benefits in...

garage.grumpysperformance.com

more related info

that might come in very useful

that might come in very useful

can I get it polished

"HEY grumpy I got a good deal on a new forged 454 crank, but the guy I bought it from purchased it for a project and had it sitting on a shelf for over 5 years and its got a few rusty finger prints on the journals, can it be used?" Since its a FORGED crank, Id bring it to a good machine shop...

garage.grumpysperformance.com

Tools Needed For 383 Sbc or almost any engine Assembly

I’ve been picking up tools and engine components for my build a little at a time. Among what I’ve picked up so far are a couple of Starrett micrometers in sizes 0-1” and 2-3”. Other than a 4-5”, what sizes would be required to assemble a 383? Does anyone have a comprehensive list of tools needed...

garage.grumpysperformance.com

Assembly lube summary

Maybe I missed it on the forum but is there a list describing what type of assembly lube to use and where, when building an engine? While doing research on this site and reading through a few engine build books, here’s what I have been able to determine. Am I missing anything? Crank...

garage.grumpysperformance.com

cam wear,articles you need to read

before, you start reading through the thread and links below, Ill point out that I've done the forensics on quite a few failed cams over the years, that guys have brought to my shop and Id say about 60% of the failed cam lobe & lifter problems were traced to a failure to check clearances or...

garage.grumpysperformance.com

I picked up my pistons installed on the new scat rods today. A quick check of piston and rod orientation looked ok.

I considered the P series bearings again as they worked very well before on my stock cast crank but per clevite:

"On the street, step up from P- to H-series Clevite-77 trimetal bearings when horsepower output is roughly 50-percent more than the stock power." —Bill McKnight

The average 1979 454 put out about 245 hp. This build simulations are showing peak 482 hp (with some assumptions). But I don't think that there's any significant changes to be made, so even a ballpark 450-480 hp would appear to move consideration to H series bearings.

But, I see where the P series have worked fine in engines in the 500hp range.....a dilemma lol

The shop told me my consideration of Mahle iron rings was fine, they had honed for iron rings. My initial selection:

So for now its check check check and measure everything before going further. I'll get my fuel system done in the meantime.

We're heading out in a few days for a Thanksgiving RV trip which will be a good break from the car stuff. I like to take a break and then come back fresh, as I usually see things I've missed.

I considered the P series bearings again as they worked very well before on my stock cast crank but per clevite:

"On the street, step up from P- to H-series Clevite-77 trimetal bearings when horsepower output is roughly 50-percent more than the stock power." —Bill McKnight

The average 1979 454 put out about 245 hp. This build simulations are showing peak 482 hp (with some assumptions). But I don't think that there's any significant changes to be made, so even a ballpark 450-480 hp would appear to move consideration to H series bearings.

But, I see where the P series have worked fine in engines in the 500hp range.....a dilemma lol

The shop told me my consideration of Mahle iron rings was fine, they had honed for iron rings. My initial selection:

- Material: UCR: Cast Iron; LCR: Cast Iron; OCR: Stainless Steel

- Facing: UCR: Plasma-Moly; LCR: N/A; OCR: Chrome

- UCR = Upper Compression Ring (Top Ring)

- LCR = Lower Compression Ring (Second Ring)

- OCR = Oil Control Ring (Bottom Ring)

So for now its check check check and measure everything before going further. I'll get my fuel system done in the meantime.

We're heading out in a few days for a Thanksgiving RV trip which will be a good break from the car stuff. I like to take a break and then come back fresh, as I usually see things I've missed.

Last edited:

"Keep it under a 100 !" That's what I would always tell my teenagers as they left the house, I was prettyWe're heading out in a few days for a Thanksgiving RV trip which will be a good break from the car stuff.

sure they would follow those instructions !!!

Anything else would be ignored !

Don't worry your pretty little head, either one is going to work just fine ! LOL !But, I see where the P series have worked fine in engines in the 500hp range.....a dilemma lol

Personally I would go with the H series bearings, but that's just me. Again you can't really go wrong.

Last edited:

Wish I had one !You know how it is when you are constantly running everything thru your brain!

This thread has sat for a bit but I'll be coming back to it as holiday stuff permits, or when they are over.

Not much happened as I've only washed the block, applied anti corrosive spray and wrapped it. Still have measurements to do before ordering rings and bearings.

Cam is still on order, I knew it was going to be 1-2 more weeks before cam is ground and shipped. I elected to have cam, lifters, rockers etc all shipped at the same time.

I don't mind the break, gives me a chance to catch up on vehicle maintenance and things around the house.

Not much happened as I've only washed the block, applied anti corrosive spray and wrapped it. Still have measurements to do before ordering rings and bearings.

Cam is still on order, I knew it was going to be 1-2 more weeks before cam is ground and shipped. I elected to have cam, lifters, rockers etc all shipped at the same time.

I don't mind the break, gives me a chance to catch up on vehicle maintenance and things around the house.

Last edited:

In addition to getting the supply/return fuel lines done, as a next engine step I want to get the block measurements verified, painted and the crank in the block. As I do these projects it's easier to set numerous mini goals along the way

So I think this thread will evolve into an overall engine build rather than focus only on cam/valvetrain.

Although for my records I take pics of everything, I'll not get too picture heavy here, just to highlight some main points.

Besides measuring, I had made a story board of the bearings, it let me look at the bigger picture.

This is after 34 years in the engine, but with low miles. Overall not too bad with the exception of #2 main that had more wear. I see indication of debris in the bearings, not unexpected since the engine sat for long periods, months - up to a year, something I don't intend to repeat.

The rods are new SCAT rods that were resized to get them all at 2.325 at the big end. Old rods were also at 2.325.

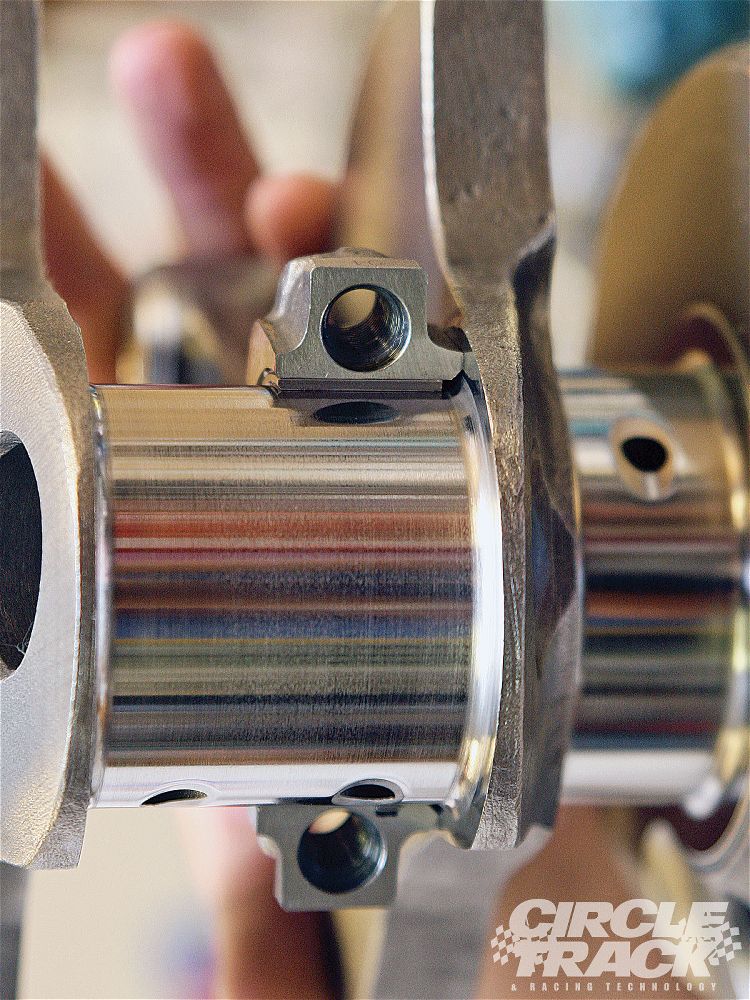

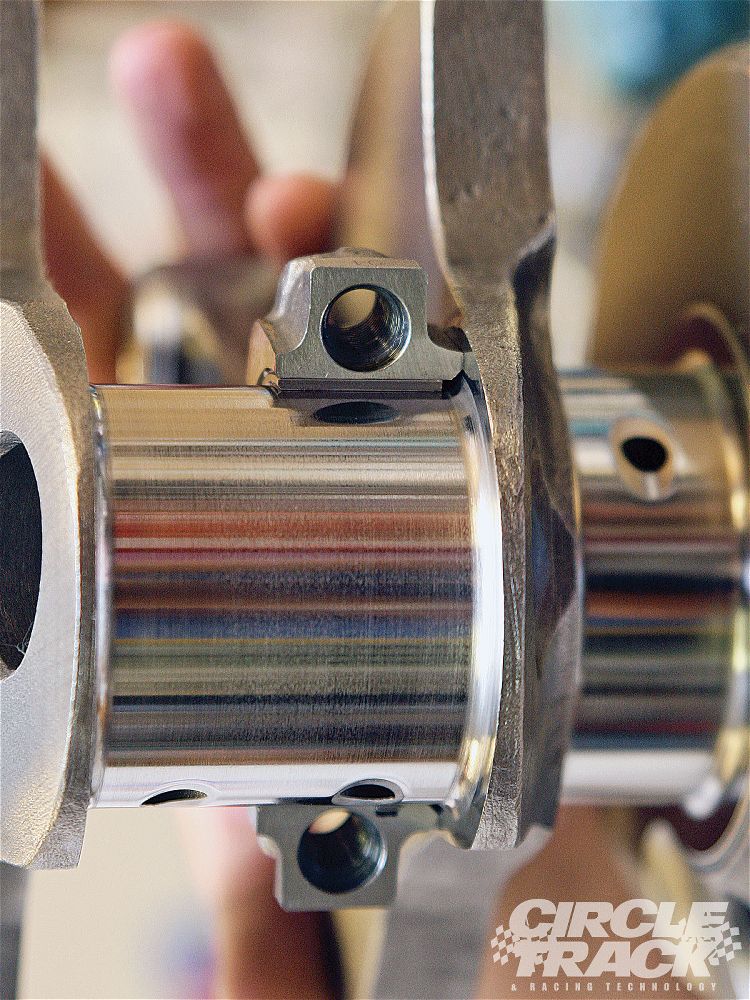

I went from bolts to ARP studs on the mains, but haven't measure the main cap bores yet. The block was also align honed. I think this may address the #2 main wear. I've already measured the crank journals in several axis to verify size/round/taper, everything was within spec. Crank was turned .010 when I first built the engine. Before disassembly it turned very smoothly within rotational spec. All I plan to do at this point is a very slight clean/polish on the journals.

This is typical of main/rod journals:

Rather than just get new .010 bearings and slap them in, I'm verifying initial measurements. I think I'm looking at this right just to verify that another .010 set is to be ordered? I'll also remeasure when I have new bearings.

Example:

- New SCAT rod bore = 2.325 (ARP bolts torqued)

- #3 rod journal measured average = 2.18867 (.010 over)

- Clevite 77 CB743P bearing thickness = .0620 x 2 (upper and lower shells) = .1240

- Add to bearing thickness for crank turned .010 = .1340

- Total to be subtracted from rod bore = 2.18867 + .1340 = 2.32267

Rod bore 2.325 subtract 2.32276 = .00233 clearance. Spec is .002 to .0025.

Do you agree with this initial figuring? This is what I plan to do for every main/rod.

So I think this thread will evolve into an overall engine build rather than focus only on cam/valvetrain.

Although for my records I take pics of everything, I'll not get too picture heavy here, just to highlight some main points.

Besides measuring, I had made a story board of the bearings, it let me look at the bigger picture.

This is after 34 years in the engine, but with low miles. Overall not too bad with the exception of #2 main that had more wear. I see indication of debris in the bearings, not unexpected since the engine sat for long periods, months - up to a year, something I don't intend to repeat.

The rods are new SCAT rods that were resized to get them all at 2.325 at the big end. Old rods were also at 2.325.

I went from bolts to ARP studs on the mains, but haven't measure the main cap bores yet. The block was also align honed. I think this may address the #2 main wear. I've already measured the crank journals in several axis to verify size/round/taper, everything was within spec. Crank was turned .010 when I first built the engine. Before disassembly it turned very smoothly within rotational spec. All I plan to do at this point is a very slight clean/polish on the journals.

This is typical of main/rod journals:

Rather than just get new .010 bearings and slap them in, I'm verifying initial measurements. I think I'm looking at this right just to verify that another .010 set is to be ordered? I'll also remeasure when I have new bearings.

Example:

- New SCAT rod bore = 2.325 (ARP bolts torqued)

- #3 rod journal measured average = 2.18867 (.010 over)

- Clevite 77 CB743P bearing thickness = .0620 x 2 (upper and lower shells) = .1240

- Add to bearing thickness for crank turned .010 = .1340

- Total to be subtracted from rod bore = 2.18867 + .1340 = 2.32267

Rod bore 2.325 subtract 2.32276 = .00233 clearance. Spec is .002 to .0025.

Do you agree with this initial figuring? This is what I plan to do for every main/rod.

Last edited:

Where did you get the .0620" number ?- Clevite 77 CB743P bearing thickness = .0620 x 2 (upper and lower shells) = .1240

- Add to bearing thickness for crank turned .010 = .1340

Mahle/Clevite catalog for the specific bearing part numbers I used (and plan to use again as new replacements). I've also got the spec for mains 1-4 and 5.Where did you get the .0620" number ?

I can't get to it at the moment but I'll follow later with a link to their catalogs, includes P, H etc bearing info.I was not aware that they published those dimensions ..... thanks !

Bores measure out to 4.277, I assume I'll buy rings for 4.28 and gap accordingly? Can't remember what I did in the first build. Since getting older I try to document my install info much more.

Last edited: