Maniacmechanic1

solid fixture here in the forum

Trapped hidden steam pockets in the cylinder heads are another issue in many engines.

I think Rick was drinking again last night.ok, where are the clear detailed pictures RICK???

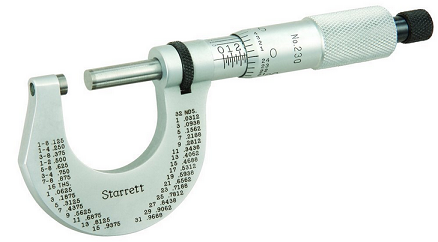

The gap was opposite the side of the spark plug hole so it made it hard to see. Also hard to getThat is the one I have - VERY pleased with it.

Its a Good idea I think Grumpy to a have a Pro Valve job done.yeah, it looks like, you avoided major damage,

you'll need a new valve and some lapping time,

check the seal with alcohol in the combustion chamber,

not draining past the valve seal,

youll need too carefully re-clean and re-spray the copper head gasket,

and re-assemble and you'll be back up and running

yes you might want to have a local machine shop clean inspect and install the new valve if you don,t feel comfortable doing the valve

The first step was trying to find the compression stroke with my finger over the spark plug holeDid you use a "home made" piston stop made of hard metal and screwed in too far? Maby it hit the valve and bent it?

Also the fact that the valve was hard to come out(stuck in the guide).

Wondering what the valve seat looks like.

So what is the R/S ratio of your 1965 Olds 425? And do you figure a high or low R/S ratio is better for detonation resistance?I really believe the Rod to Stroke ratio has a big factor with engine detonation resistance with crappy pump gas.

Mild detonation will cause Oily Sooty Residue in the combustion chamber & on the piston tops Mike.So what is the R/S ratio of your 1965 Olds 425? And do you figure a high or low R/S ratio is better for detonation resistance?

My 302 Chevy has a 1.9 R/S ratio.

About the same as a Pontiac 400.So what is the R/S ratio of your 1965 Olds 425? And do you figure a high or low R/S ratio is better for detonation resistance?

My 302 Chevy has a 1.9 R/S ratio.