NOT A TA

reliable source of info

I've been busy working on other peoples projects and some of my own other projects however it's time to get some work done on my bird and get it back together! The only part of the prizes I hadn't ordered yet were the Rushforth wheels.

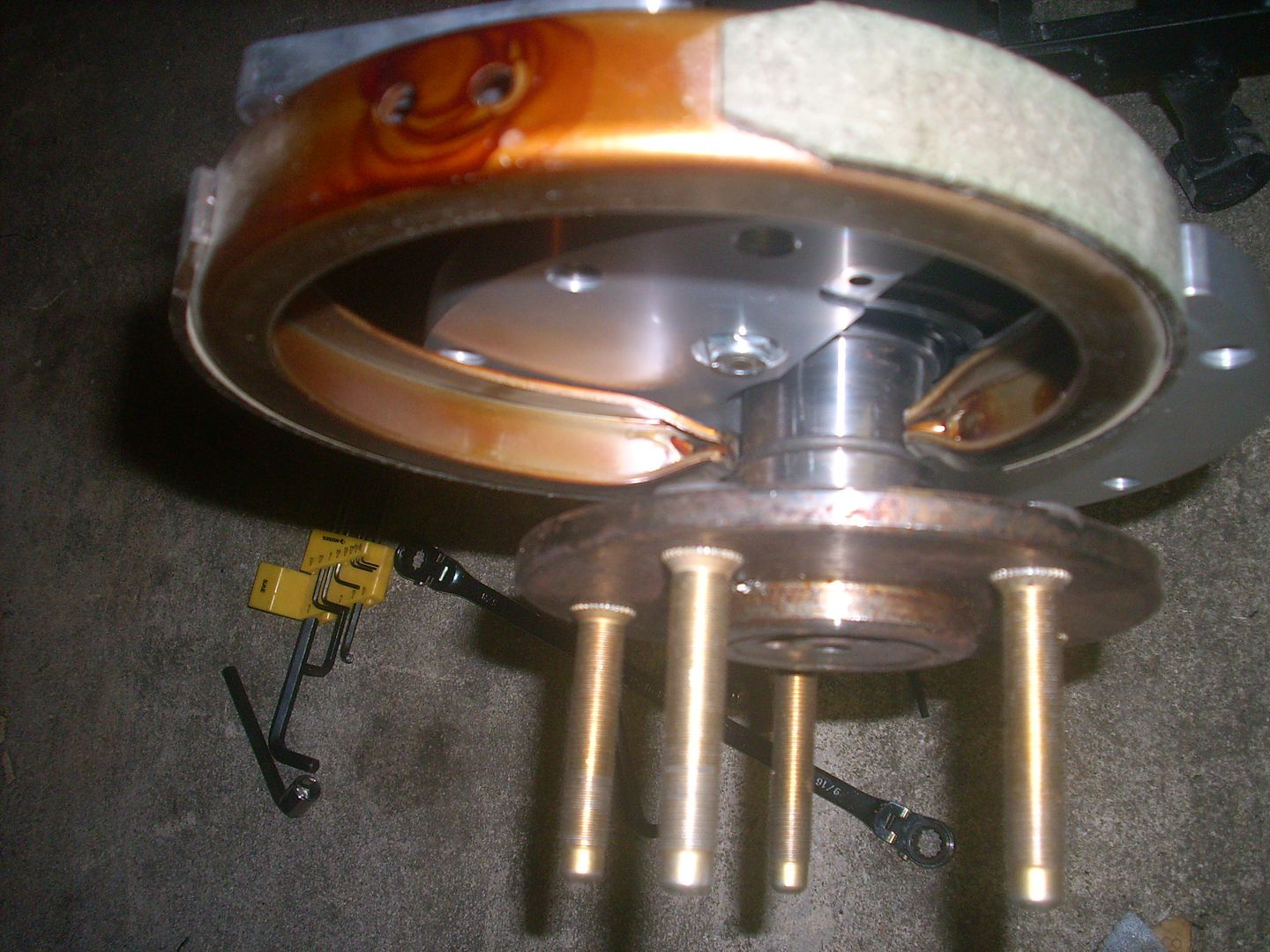

I decided that figuring out the backspacing I think will work for the new wheels and ordering them would give me incentive. So I ordered 18 X 10's with 6" backspacing up front and 5.5 backspacing in the rear. The 285/295 tires are Yokohama AO 48's which are a DOT legal race compound tire designed for track day use. I expected a wait time of 8-10 weeks which is not unusual for custom wheels and figured I'd use the time to start working on the car. Imagine my surprise when I got a tracking # within a week! I better get moving!

For those who've never bought custom aftermarket wheels like these Rushforth Night Trains there are other options besides the backspacing. You can get different finishes/colors, regular or hidden valve stems, exposed or hidden hardware etc. My wheels are the model shown below but will appear a bit different. Will post pics of mine when I get them.

I decided that figuring out the backspacing I think will work for the new wheels and ordering them would give me incentive. So I ordered 18 X 10's with 6" backspacing up front and 5.5 backspacing in the rear. The 285/295 tires are Yokohama AO 48's which are a DOT legal race compound tire designed for track day use. I expected a wait time of 8-10 weeks which is not unusual for custom wheels and figured I'd use the time to start working on the car. Imagine my surprise when I got a tracking # within a week! I better get moving!

For those who've never bought custom aftermarket wheels like these Rushforth Night Trains there are other options besides the backspacing. You can get different finishes/colors, regular or hidden valve stems, exposed or hidden hardware etc. My wheels are the model shown below but will appear a bit different. Will post pics of mine when I get them.