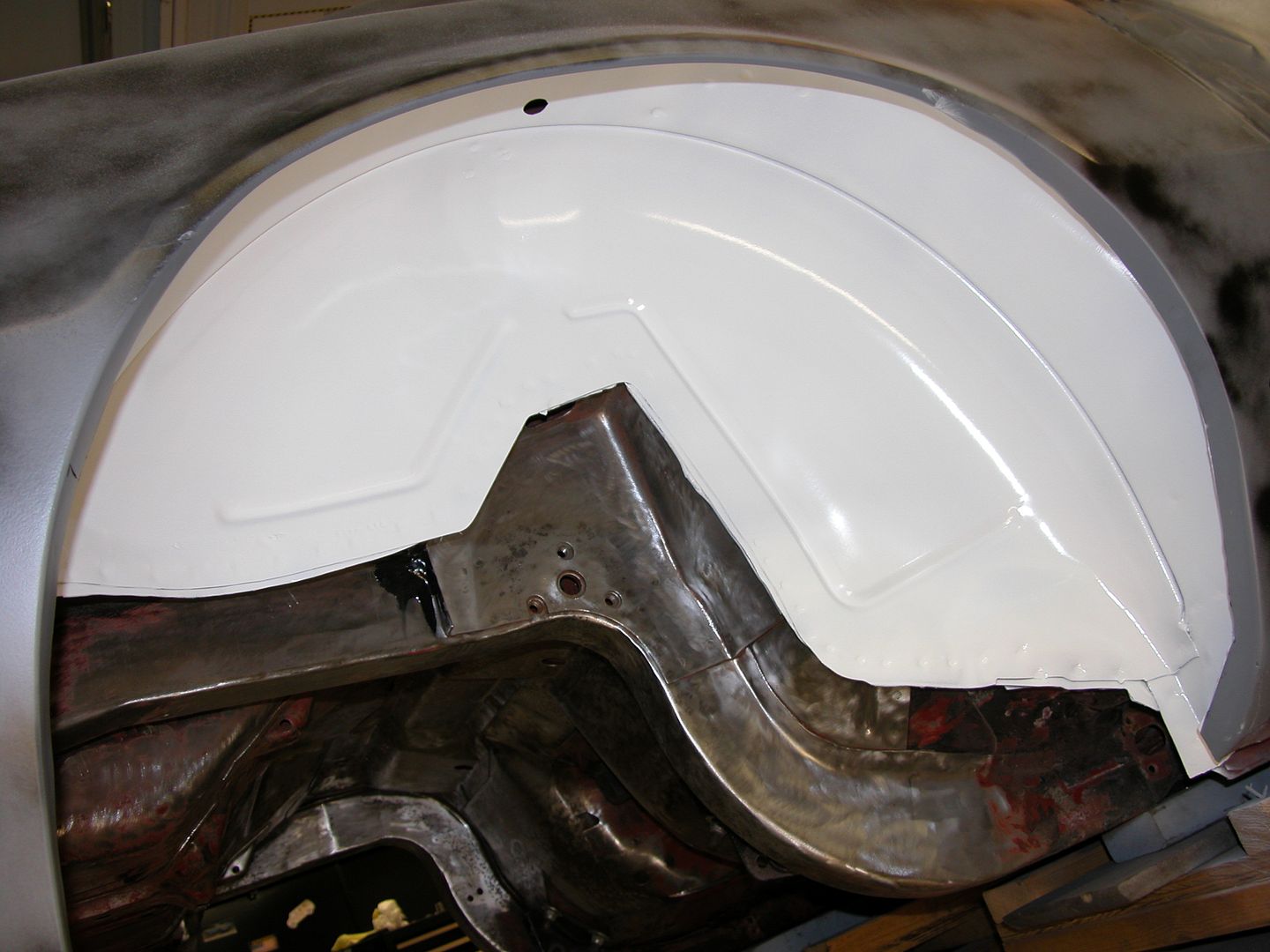

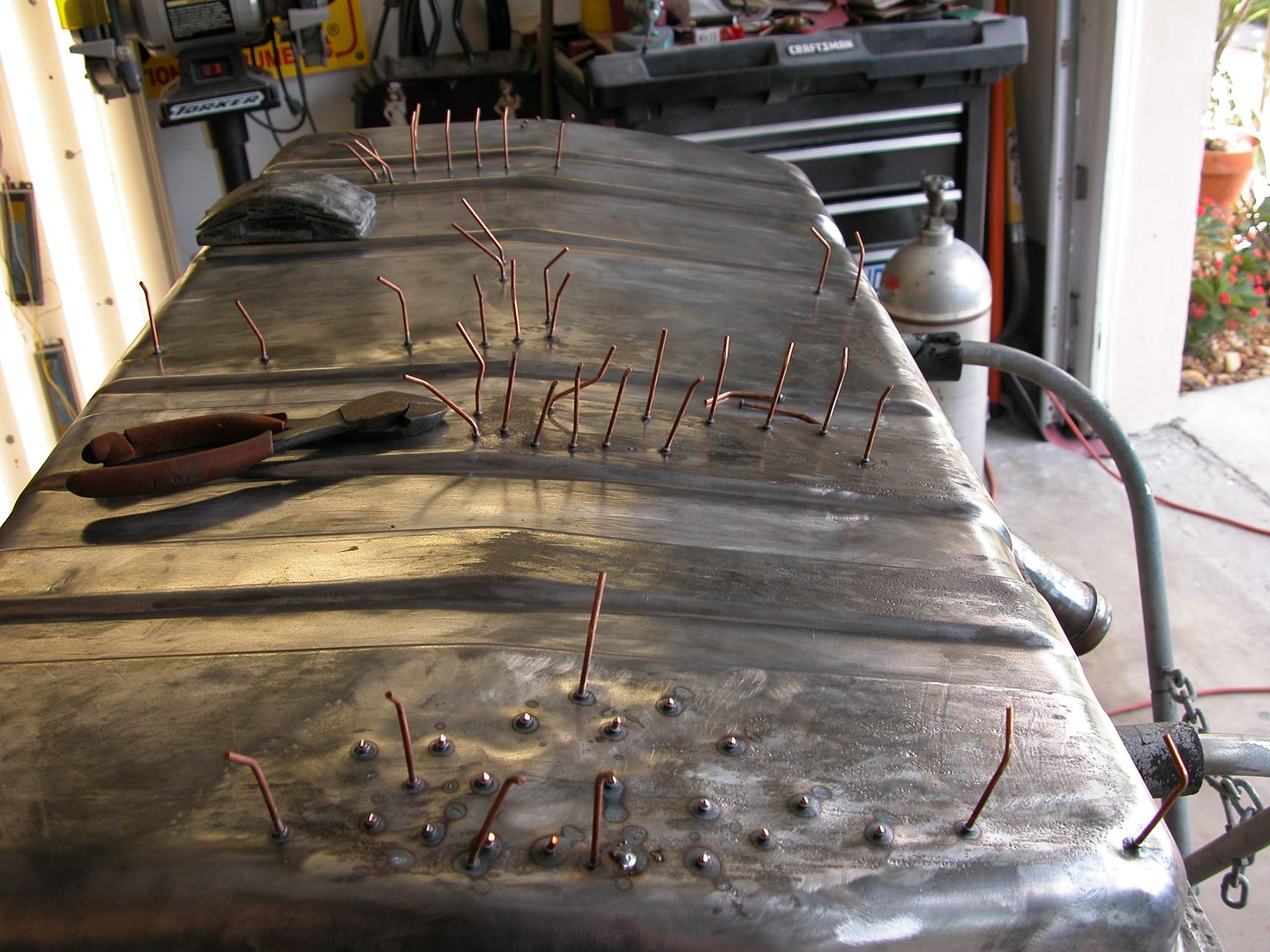

WOW NOW THAT,S DAMN IMPRESSIVE!

Ive seen lots of "professional" body repair shops do far lower quality repair work!

and is it not amazing how indispensable , near instant access to a good welder, or drill press,or compressor with air tools is to a shop once you learn how to use them?, tools like a decent compressor and a drill press with a vise , or a mig or tig welder,well,, you feel seriously lost without access to those tools, and their common accessories, I know if I go out to the shop, and find I'm out of argon, or tig rods or mig wire , or the compressors broke, or some other supply I need is missing thats needed that day, I feel like I MIGHT AS WELL EITHER JUMP IN THE CAR AND GO GET WHATS REQUIRED OR JUST GO TAKE A LONG NAP, BECAUSE I KNOW NOT MUCH OF VALUES GOING TO BE ACCOMPLISHED UNTIL I GET THE TOOLS FIXED OR SUPPLIES I NEED and theres few things more frustrating than knowing exactly how to fix things correctly and having the correct tool and supplies but finding the tools missing a small consumable component part or a critical supply is lacking, or some one used up the last (fill in the blank) and left the empty container which you thought was 3/4-to-9/10ths full) like when morons leave the argon shield gas tank on the TIG WELDER , valve open and it drains over the week since they used the TIG welder for a 5 minute job, and a tank you thought was full because you filled it a week ago is now empty.