You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unforgiven Project

- Thread starter Unforgiven

- Start date

Loves302Chevy

"One test is worth a thousand expert opinions."

You intake can be drilled and tapped in the corners. You have to see what will work best, either perpendicular to the intake (same as the bolts),

or at an angle (which would be straight up when installed). The 2nd option is trickier because the hole and threads are cut in at an angle.

The hardest corner is by the distributor hold-down. I have a crappy digital camera, but I will see if I can get you a few pics tonight.

If your pistons stick out of the hole a few thousandths, no big deal. Just run a thicker head gasket, like Brian said.

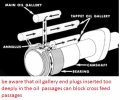

Oh yeah, the gallery threads do end up shallow. Just set the plugs flush, and make sure the back of the plug is not cutting off any oil flow.

RED Loctite them in and you will never have to worry about them coming out.

To clean your block, take it to the local quarter coin-op car wash at 2 am. Leave the mess there. Bring a can of WD-40 to coat the machined surfaces immediately.

or at an angle (which would be straight up when installed). The 2nd option is trickier because the hole and threads are cut in at an angle.

The hardest corner is by the distributor hold-down. I have a crappy digital camera, but I will see if I can get you a few pics tonight.

If your pistons stick out of the hole a few thousandths, no big deal. Just run a thicker head gasket, like Brian said.

Oh yeah, the gallery threads do end up shallow. Just set the plugs flush, and make sure the back of the plug is not cutting off any oil flow.

RED Loctite them in and you will never have to worry about them coming out.

To clean your block, take it to the local quarter coin-op car wash at 2 am. Leave the mess there. Bring a can of WD-40 to coat the machined surfaces immediately.

Loves302Chevy

"One test is worth a thousand expert opinions."

Now is the time to think about adding some magnets. Ask Grumpy.

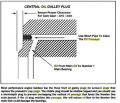

I assume your cam bearings are NOT installed yet. Do you or your machinist know where to "clock" the oil holes? Here is the answer to save you a bunch of time. From my 334 SBC build:

Cam bearings "clocked" to 2 o'clock on positions 2,3,4

3 o'clock on position 5 (rear) and 10 & 2 o’clock on position 1 (front)

countersunk back side of oil holes

The best placement is 1) 10 & 2 o’clock, and 2 to 3 o’clock for the rest.

GM factory placement is 1) 1 & 5 o’clock, 2,3 & 4) 5 o’clock, 5) 12 o’clock

By placing the bearing's oil hole at roughly the 2:00 position (anywhere between 2:00 and 3:00 is fine), oil is fed into the clearance between the cam journal and cam bearing as the cam rotates clockwise, creating an oil wedge that travels down and supports the cam much better during cam rotation. This forces a superior oil wedge under the cam, to provide oil support at the bottom (6:00) position.

Have him leave the rear cam plug out for now so you can easily measure the cam end play later.

I assume your cam bearings are NOT installed yet. Do you or your machinist know where to "clock" the oil holes? Here is the answer to save you a bunch of time. From my 334 SBC build:

Cam bearings "clocked" to 2 o'clock on positions 2,3,4

3 o'clock on position 5 (rear) and 10 & 2 o’clock on position 1 (front)

countersunk back side of oil holes

The best placement is 1) 10 & 2 o’clock, and 2 to 3 o’clock for the rest.

GM factory placement is 1) 1 & 5 o’clock, 2,3 & 4) 5 o’clock, 5) 12 o’clock

By placing the bearing's oil hole at roughly the 2:00 position (anywhere between 2:00 and 3:00 is fine), oil is fed into the clearance between the cam journal and cam bearing as the cam rotates clockwise, creating an oil wedge that travels down and supports the cam much better during cam rotation. This forces a superior oil wedge under the cam, to provide oil support at the bottom (6:00) position.

Have him leave the rear cam plug out for now so you can easily measure the cam end play later.

Last edited:

busterrm

solid fixture here in the forum

That’s a good point, that is a critical oil passage, if I am correct that npt plug can go no farther than 1/2 inch into the block before it starts to disrupt oil flow. Again my block is a Dart block and has priority main oiling first, that passage is farther back about another 3/8 of an inch and the oil flow is opposite from the mains to the cam bearing. Don’t go any deeper than 1/2 inch and your ok. Also, don’t forget the plug that goes in from the bottom of the block, it blocks of oil flow and you’ll lose oil pressure if it’s not installed.You intake can be drilled and tapped in the corners. You have to see what will work best, either perpendicular to the intake (same as the bolts),

or at an angle (which would be straight up when installed). The 2nd option is trickier because the hole and threads are cut in at an angle.

The hardest corner is by the distributor hold-down. I have a crappy digital camera, but I will see if I can get you a few pics tonight.

If your pistons stick out of the hole a few thousandths, no big deal. Just run a thicker head gasket, like Brian said.

Oh yeah, the gallery threads do end up shallow. Just set the plugs flush, and make sure the back of the plug is not cutting off any oil flow.

RED Loctite them in and you will never have to worry about them coming out.

To clean your block, take it to the local quarter coin-op car wash at 2 am. Leave the mess there. Bring a can of WD-40 to coat the machined surfaces immediately.

View attachment 11824

Loves302Chevy

"One test is worth a thousand expert opinions."

Loves302Chevy

"One test is worth a thousand expert opinions."

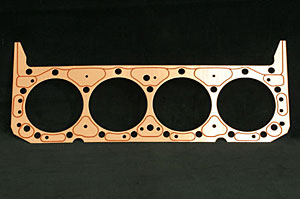

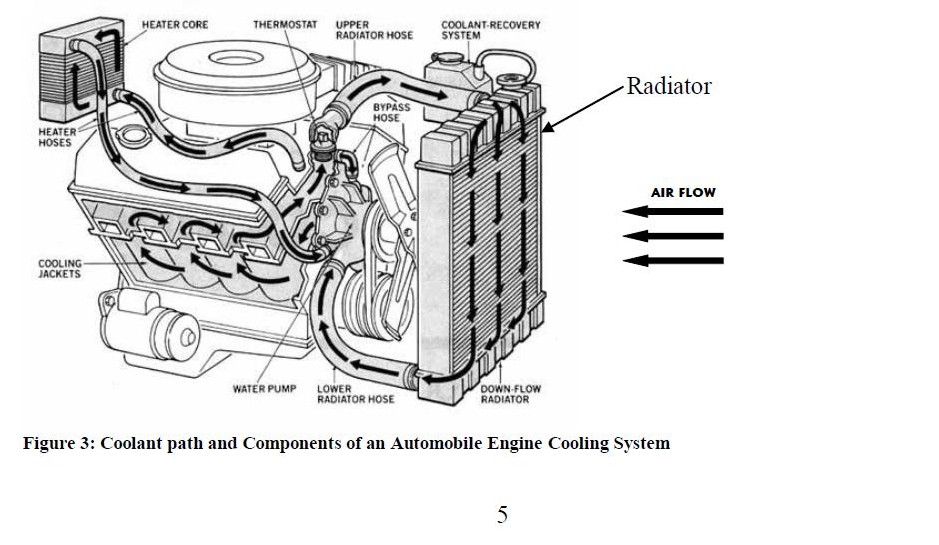

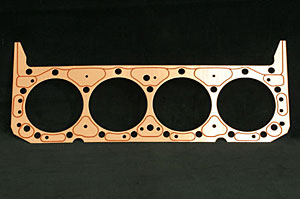

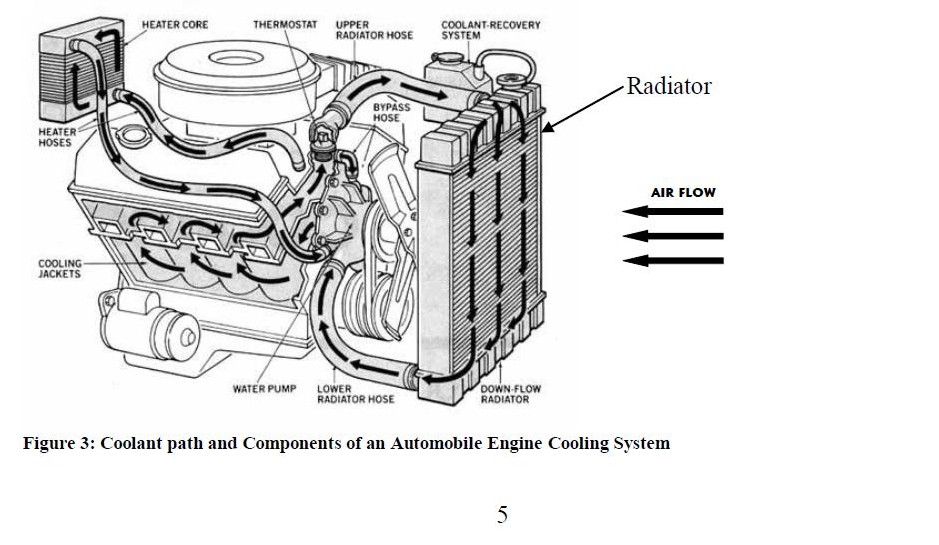

I forgot - the deck plug mod is to strengthen the decks - A LITTLE. If you look at your head gasket, there is only a small hole there to pass coolant.

This is from an era when circle track racers would do anything in search of even a tenth of a HP to get to the winners circle.

If you don't have time for it, don't sweat it. Like Grumpy said - marginal at best.

This is from an era when circle track racers would do anything in search of even a tenth of a HP to get to the winners circle.

If you don't have time for it, don't sweat it. Like Grumpy said - marginal at best.

Maniacmechanic1

solid fixture here in the forum

His Engine is Bit different from typical low po street builds done here.I forgot - the deck plug mod is to strengthen the decks - A LITTLE. If you look at your head gasket, there is only a small hole there to pass coolant.

This is from an era when circle track racers would do anything in search of even a tenth of a HP to get to the winners circle.

If you don't have time for it, don't sweat it. Like Grumpy said - marginal at best.

When Boost is on its like it has 15.0 to 18.0:1 static compression.

When You Hardblock Fill a block you take away alot of the cooling capacity around the cylinder bores.

Boost adds tremendous Heat loads to be expelled.

Tiny steam pockets form in near all engines.

The Only true way to eliminate all of them is To use a Reverse cooling system like Pontiac used 1955-1959.

And 2nd Gen LT1 SBC 1992-1996.

The deck plugs add stiffness yes.

Not what I am after.

Your resizing restricting the coolant some to get the steam pockets out by slowing down the coolant a bit.

Works like ultrasonic cleaners those steam pockets. Slowly errode away cast iron & aluminum internal in cooling passages.

Chevrolet conducted extensive research on this topic.

Finially made a changle come the 1985 Corvette.

They added a hidden steam pipe few know about on the L98 TPI 350.

Its on my 1987 Corvette Convertible that steam pipe.

Leave those plugs out I want in & this engine will likely overheat bad at the worst time.

Lockup.

Maniacmechanic1

solid fixture here in the forum

New parts look nice Unforgiven !

deck plugs marginally help reduce the bore wall and deck flex,

thus ring seal and head gasket seal,

they have no real positive effect on cooling

http://www.jegs.com/i/SCE-Gaskets/829/T ... tId=753475

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

thus ring seal and head gasket seal,

they have no real positive effect on cooling

http://www.jegs.com/i/SCE-Gaskets/829/T ... tId=753475

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

Last edited:

Unforgiven

solid fixture here in the forum

The deck plugs add stiffness yes.

Not what I am after.

Your resizing restricting the coolant some to get the steam pockets out by slowing down the coolant a bit.

But The head gaskets already restricted down the size of those water passage holes Brian.

I think the coolant mod that removes heated water from the rear would be a better way to go.

I really really like that concept!

Brian , also remember that I have increased my coolant capacity by about two gallons.

I realize that the hard block took about a gallon away, but I think I will be OK.

I do appreciate the passion you have for my motor too!

Unforgiven

solid fixture here in the forum

my machinist texted me today with a progress report. He says bores are almost done and is getting ready to send to the hone department.

I told him about the deck mod that I did NOT have enough time to do, and how a certain man (Brian ) seemed upset by me proceeding without it being done.

I just ran out of time period. So.... he sent me this pic below

I think he felt Brian's tears all the way over here near Detriot! LOL

I told him about the deck mod that I did NOT have enough time to do, and how a certain man (Brian ) seemed upset by me proceeding without it being done.

I just ran out of time period. So.... he sent me this pic below

I think he felt Brian's tears all the way over here near Detriot! LOL

Unforgiven

solid fixture here in the forum

New you would like that!

Loves302Chevy

"One test is worth a thousand expert opinions."

And they are even installed with RED Loctite!

Wow, I had to zoom in to make sure, but there is something red on the perimeter of those pipeAnd they are even installed with RED Loctite!

plugs .... how do you know it's RED Loctite ???

Loves302Chevy

"One test is worth a thousand expert opinions."

Well, I certainly HOPE it is. Red Loctite is what should be used there.

Unforgiven

solid fixture here in the forum

My friend knows better. They are a high performance shop . Besides.. he told me he used red loctite..

I just can't believe he went out of his way and did this mod for me... at no charge !

But ... Im at least going to buy him a case of beer. Nobody should work for free.

I just can't believe he went out of his way and did this mod for me... at no charge !

But ... Im at least going to buy him a case of beer. Nobody should work for free.

you do realize the installation of those block deck with the added plugs,

must now be followed by the block deck surface, being milled,

its milled to provide a flat level surface for the head gasket,

and the plugs will cause the bore walls to be very slightly out of round until the bores are honed.

this is one of several reasons , the considerably thicker castings used on the aftermarket blocks like DART sells,

with the much thicker decks and blind head bolt holes that don,t allow the head bolts to enter the coolant jacket,

are preferred on serious performance SBC builds

Loctite Threadlocker Red 271 is designed for the permanent locking and sealing of threaded fasteners. The product cures when confined in the absence of air between close fitting metal surfaces. It protects threads from rust and corrosion and prevents loosening from shock and vibration. It is only removable once cured by heating up parts to 500°F (260°C).

Prevents rusting of threads

Permanent seal, prevents tampering

Prevents loosening of metal fasteners caused by vibrations

Protects threads

High strength

Locks threads

must now be followed by the block deck surface, being milled,

its milled to provide a flat level surface for the head gasket,

and the plugs will cause the bore walls to be very slightly out of round until the bores are honed.

this is one of several reasons , the considerably thicker castings used on the aftermarket blocks like DART sells,

with the much thicker decks and blind head bolt holes that don,t allow the head bolts to enter the coolant jacket,

are preferred on serious performance SBC builds

Loctite Threadlocker Red 271 is designed for the permanent locking and sealing of threaded fasteners. The product cures when confined in the absence of air between close fitting metal surfaces. It protects threads from rust and corrosion and prevents loosening from shock and vibration. It is only removable once cured by heating up parts to 500°F (260°C).

Prevents rusting of threads

Permanent seal, prevents tampering

Prevents loosening of metal fasteners caused by vibrations

Protects threads

High strength

Locks threads

Last edited:

Maniacmechanic1

solid fixture here in the forum

3k Grumpy.

BHJ Blueprint be 3500-4 k

BHJ Blueprint be 3500-4 k

Unforgiven

solid fixture here in the forum

you do realize the installation of those block deck with the added plugs,

must now be followed by the block deck surface, being milled

Yes Sir.

The picture my machinist sent was to show me an added surprise that he did for me. At the time, he said he wanted to let the loctite set up

for awhile , and was going to mill the deck after he bored the cylinders to the required size for honing. He is also aware that my new stroke.rod and piston height is 9.015 so he will shoot for that number if possible. If the deck has to go under ( which I think it will) I will use a thicker head gasket.

The pistons asked for a .004 clearance.... I asked him to call wiesco and explain to them that the motor has a 1/2 fill and it will have a blower on top.

I am thinking that they are going to want a .005-.006 clearance in this application.

They are a professional race shop so I have full confidence in them.

They actually built the motor for "GAS MONKEY GARAGE" which I thought was pretty cool! Even though I don't care much for Richard Rawlins.

I still got me some of that! LOL

one more reason purchase of a DART block makes a great deal of sense,

why put more money into trying to get an O.E.M. block up to nearly the strength of a DART BLOCK,

a level it can NEVER obtain, when the much stronger DART blocks made with thicker bore walls, main cap webs etc.

costs less. and will be out of the box over 50% stronger in many areas and over 150% stronger in some critical areas

for less total cost?

yes we all want to save money, and you already own a O.E.M. block, but that block was never designed to handle the stress of racing and once you exceed about 450 hp,

on a regular basis stress is cumulative, you are exceeding the blocks original intended stress limitations.

we all know a few guys that have built impressive high horsepower engines on O.E.M. blocks, some live, many don,t

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/grinding-block-for-stroker-assembly.2855/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/

http://garage.grumpysperformance.co...eventing-engine-block-main-cap-movement.6162/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://dartheads.com/product-category/big-block-chevy/blocks/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

https://www.summitracing.com/parts/...MI-rSjpqed4QIVElcMCh2p6AcZEAQYBCABEgJ5J_D_BwE

why put more money into trying to get an O.E.M. block up to nearly the strength of a DART BLOCK,

a level it can NEVER obtain, when the much stronger DART blocks made with thicker bore walls, main cap webs etc.

costs less. and will be out of the box over 50% stronger in many areas and over 150% stronger in some critical areas

for less total cost?

yes we all want to save money, and you already own a O.E.M. block, but that block was never designed to handle the stress of racing and once you exceed about 450 hp,

on a regular basis stress is cumulative, you are exceeding the blocks original intended stress limitations.

we all know a few guys that have built impressive high horsepower engines on O.E.M. blocks, some live, many don,t

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/grinding-block-for-stroker-assembly.2855/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/

http://garage.grumpysperformance.co...eventing-engine-block-main-cap-movement.6162/

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://dartheads.com/product-category/big-block-chevy/blocks/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

https://www.summitracing.com/parts/...MI-rSjpqed4QIVElcMCh2p6AcZEAQYBCABEgJ5J_D_BwE