- Home

- Forums

- Technical Articles/muscle cars

- Engine & transmission Swaps, related info

- Engine: Selection and Modification

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ZZ4 upgrades

- Thread starter ZZ71s

- Start date

did you mean 00551 or 00331?

there's no #00531 listed I can find

catalog

http://www.crower.com/misc/m_cat.shtml

00551

http://www.crower.com/misc/cam_spec/cam ... 1&x=51&y=9

00331

http://www.crower.com/misc/cam_spec/cam ... 1&x=51&y=9

there's no #00531 listed I can find

catalog

http://www.crower.com/misc/m_cat.shtml

00551

http://www.crower.com/misc/cam_spec/cam ... 1&x=51&y=9

00331

http://www.crower.com/misc/cam_spec/cam ... 1&x=51&y=9

Oh man now you got me questioning my self but I think it was a 00531 .grumpyvette said:did you mean 00551 or 00331?

What is there no cam 00531 I could have sworn that is what they said.

YOU obviously need to verify clearances and spring load rates before selecting either cam, but ID go CROWER, if it will work, because of the slightly more lift,that will allow greater port flow with similar duration and IVE had far better results with durability with CROWER cams over the years

The stock zz4 head has a 58 cc chamber which gives the zz4 a 10 to 1 compression ratio the AFR 180 eliminators come with 65 cc chambers should I have them milled down to keep to zz4s 10 to 1 comp/ratio?

AFR claims that if you mill the heads it will change the air flow spects.

Heres what I am thinking about doing is spliting the difference between the zz4s 58 cc and the AFR 65 cc and mill them to 62 cc chambers.

The zz430 uses the GM fast burns which have a 62 cc chamber which gives the zz430 9.5 to 1 comp/ratiowhich is the same cop/ratio that the engine in the AFR 355 450hp build has.

What do you all think

AFR claims that if you mill the heads it will change the air flow spects.

Heres what I am thinking about doing is spliting the difference between the zz4s 58 cc and the AFR 65 cc and mill them to 62 cc chambers.

The zz430 uses the GM fast burns which have a 62 cc chamber which gives the zz430 9.5 to 1 comp/ratiowhich is the same cop/ratio that the engine in the AFR 355 450hp build has.

What do you all think

IF its going to be a STREET DRIVEN CAR I would not bother even milling the heads, at all simply because you gain about 3% in torque for every point in compression gained,

since torque x rpm/5252 =hp, that torque increase will give a minor give a hp boost,

example

if nearly identical engines were built one with 9.5:1 cpr and one with a 10.5:1 cpr and the 10.5:1 cpr engine made 450hp the 9.5:1 combo should make 436hp and have noticeably less tendency to get into detonation with crappy pump gas.

keep in mind the 180cc heads, and the mild cams your looking at are HARDLY designed for race car horsepower levels and on the street you'll spend a great deal of the engines time at or well below 5000 rpm, where the resulting drive ability is far more important than PEAK HP, which your OBVIOUSLY NOT REALLY CONCERNED WITH, OR YOU WOULD HAVE SELECTED TOTALLY DIFFERENT HEAD,INTAKE,CAM,GEARING AND ADDED A HIGH COMPRESSION RATIO STROKER KIT.

lets look at the difference, given the average 3600 lb corvette with a driver in it ,your talking less than 1 mph or 1/10 second

viewtopic.php?f=69&t=1814

http://www.stealth316.com/2-calc-hp-et-mph.htm

and theres not a thing limiting you to 450 hp at 9:1 or 9.5:1 or 10.5:1 compression.

viewtopic.php?f=69&t=519

if your serious about making more HP, a larger displacement,engine with better large port heads, a more radical cam, a drive train geared to run at higher average rpms or use of NITROUS OR a SUPERCHARGER would be a good route, short version, you need to set goals, and on a street car, trading a slight loss of a few peak hp for better drive ability and octane tolerance is a good trade off.

since torque x rpm/5252 =hp, that torque increase will give a minor give a hp boost,

example

if nearly identical engines were built one with 9.5:1 cpr and one with a 10.5:1 cpr and the 10.5:1 cpr engine made 450hp the 9.5:1 combo should make 436hp and have noticeably less tendency to get into detonation with crappy pump gas.

keep in mind the 180cc heads, and the mild cams your looking at are HARDLY designed for race car horsepower levels and on the street you'll spend a great deal of the engines time at or well below 5000 rpm, where the resulting drive ability is far more important than PEAK HP, which your OBVIOUSLY NOT REALLY CONCERNED WITH, OR YOU WOULD HAVE SELECTED TOTALLY DIFFERENT HEAD,INTAKE,CAM,GEARING AND ADDED A HIGH COMPRESSION RATIO STROKER KIT.

lets look at the difference, given the average 3600 lb corvette with a driver in it ,your talking less than 1 mph or 1/10 second

viewtopic.php?f=69&t=1814

http://www.stealth316.com/2-calc-hp-et-mph.htm

and theres not a thing limiting you to 450 hp at 9:1 or 9.5:1 or 10.5:1 compression.

viewtopic.php?f=69&t=519

if your serious about making more HP, a larger displacement,engine with better large port heads, a more radical cam, a drive train geared to run at higher average rpms or use of NITROUS OR a SUPERCHARGER would be a good route, short version, you need to set goals, and on a street car, trading a slight loss of a few peak hp for better drive ability and octane tolerance is a good trade off.

This car has always been planned as a fast street car.

My goals have been to be able to stomp a few Hondas and be crushed into the seat from stop light to stop light and to break the tires loose with a quick stab of the throttle .

So,give me a honest opinion of my combo as it relates to my goals.

1971 corvette,Autogear m22w 2.52 first gear,355s,ZZ4 short block,Afr 180 eliminators,Edlebrock Performer RPM,Crower 00469lm 230 236 .545 .555 110 ,Hooker 1 5/8 headers and true duals,Holley 770 street aven and a Maloury uni light with 36 mech adv.

My goals have been to be able to stomp a few Hondas and be crushed into the seat from stop light to stop light and to break the tires loose with a quick stab of the throttle .

So,give me a honest opinion of my combo as it relates to my goals.

1971 corvette,Autogear m22w 2.52 first gear,355s,ZZ4 short block,Afr 180 eliminators,Edlebrock Performer RPM,Crower 00469lm 230 236 .545 .555 110 ,Hooker 1 5/8 headers and true duals,Holley 770 street aven and a Maloury uni light with 36 mech adv.

http://airflowresearch.com/articles/article032/A-P1.htm

sure you can , build something like this with that combo, it will not have the same peak hp but it should have a much lower rpm and similar torque curve for street use with the milder crower 00469 cam and slightly less cpr

sure you can , build something like this with that combo, it will not have the same peak hp but it should have a much lower rpm and similar torque curve for street use with the milder crower 00469 cam and slightly less cpr

+++450 or 520 hp at what level does traction become a problem.

I have been trying to find out where the limit of traction and HP and torque is to be found hence my combo m22w and 355s,can I really use 520 hp on the street or is 430ish or 450ish easier to handle.

What good is that blown big block if the only thing that happens when you stomp the throttle is the wheels turn to smoke.

You hear the saying torque wins races and HP sells engines is there any truth to this ?

I have given rides to two guys that have hot rod experience one thought the car was a 12.5 second car with the stock zz4 and hot cam and 1.6 rockers and the other said why in the world would you want to change that engine.

The problem is I have always had the more power sickness.

I have been trying to find out where the limit of traction and HP and torque is to be found hence my combo m22w and 355s,can I really use 520 hp on the street or is 430ish or 450ish easier to handle.

What good is that blown big block if the only thing that happens when you stomp the throttle is the wheels turn to smoke.

You hear the saying torque wins races and HP sells engines is there any truth to this ?

I have given rides to two guys that have hot rod experience one thought the car was a 12.5 second car with the stock zz4 and hot cam and 1.6 rockers and the other said why in the world would you want to change that engine.

The problem is I have always had the more power sickness.

you can easily handle 400-450 hp after learning how to drive without just stomping the accelerator pedal to the floor when you want the car to accelerate, I drove a 700hp plus corvette, on the street on occasion in the past, and while street tires were a joke if you wanted to race, on them, they were just fine if you added a bit of driving skill to your gas petal technique.

yes traction can be an issue, but only as much of an issue as you make it to be.

viewtopic.php?f=80&t=906&p=1493&hilit=+learning#p1493

viewtopic.php?f=7&t=489

viewtopic.php?f=7&t=486

yes traction can be an issue, but only as much of an issue as you make it to be.

viewtopic.php?f=80&t=906&p=1493&hilit=+learning#p1493

viewtopic.php?f=7&t=489

viewtopic.php?f=7&t=486

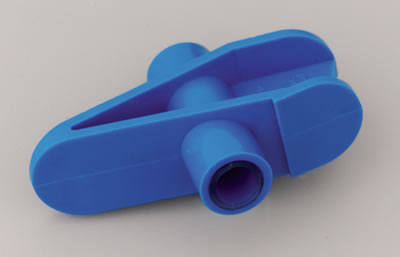

the COMP CAMS or CROWER roller rockers like THESE(below) are a good value , I use on most engine builds

http://www.summitracing.com/parts/CCA-1302-16/

these, or similar lifters

http://www.iskycams.com/pdf/1-ISKYCatal ... 028%29.pdf

http://www.summitracing.com/parts/CCA-1302-16/

these, or similar lifters

http://www.iskycams.com/pdf/1-ISKYCatal ... 028%29.pdf

ZZ71s said:Piston to valve clearance what is min safe distance and what size cam would you start really worrying about P/C?

minimum safe clearance?

that depends on the quench distance deck height and cam lift duration and lsa , how the cams degreed in and your rocker ratio

but

about .100 on the exhaust and about .080 on the intake valve to piston will normally be about MINIMUM required clearance and at lifts over about .480 and duration over about 220 degs @ .050 lift you better start checking carefully, and remember the valves come closest to the piston NEAR 10-20 degrees before and after TDC, not AT TDC

reading thru these threads should help

viewtopic.php?f=50&t=501&p=619#p619

viewtopic.php?f=52&t=1769

viewtopic.php?f=52&t=528

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=399&p=1043&hilit=+notches#p1043

interesting,(strange actually....)

every machinist I know has a few oz of non-hardening modeling clay to verify oil pump pick-up to oil pan floor and valve to piston, and piston dome to combustion chamber clearances.

but a bit of WD 40 sprayed on modeling clay strips ( about 1" wide and 1/4" thick and 3" long ),keeps them from sticking. and a razor can cut the valve indentation at its deepest point, cutting it cross wise, a dial caliper

http://store.summitracing.com/partdetai ... toview=sku

can measure, that thickness and youve got the correct info in about 3 minutes.

http://www.amaco.com/prod-plast-i-clay-332.html

once EITHER the duration exceeds about 225 @ .050 or the lift exceeds about .480 in a 383 SBC youll probably have clearance issues with stock connecting rods,and the cam lobes, aftermarket (H) or SOME (I) style stroker rods with 7/16" capscrew bolts are stronger and profiled to clear and use of both a small base billet roller cam and stroker profile rods will usually prevent that

Grompy

I am having a problem getting the truth about push rod measuring.

It seems to me if I use a hyd roller lifter to measure for push rod length the pressure will bleed off and I will get the wrong measurement.

I have heard that you can use a solid lifter but the zz4 has stock roller lifters in it now and the guy at Jegs claimed there are no solid lifters that are the same size as the stock GM roller lifters.

What is urban ledgen and what is the truth about push rod measuring.

BTW how do you keep up with all those links?

I am having a problem getting the truth about push rod measuring.

It seems to me if I use a hyd roller lifter to measure for push rod length the pressure will bleed off and I will get the wrong measurement.

I have heard that you can use a solid lifter but the zz4 has stock roller lifters in it now and the guy at Jegs claimed there are no solid lifters that are the same size as the stock GM roller lifters.

What is urban ledgen and what is the truth about push rod measuring.

BTW how do you keep up with all those links?

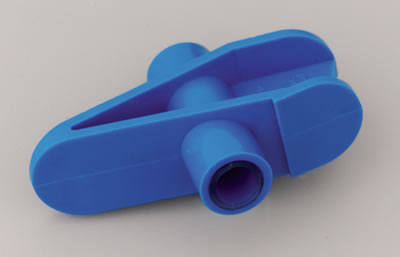

you use an adjustable

push rod , on the lifters you will use,

(theres no pressure on the lifter push rod seat during the geometry check, with the plastic check tool)

and a valve train geometry test checker, after the rockers removed and follow the linked info in the threads listed below

you then retest with the majic marker on the valve tip rotating the engine by hand after carefully reading and understanding the links

viewtopic.php?f=52&t=181&p=6764&hilit=geometry#p6764

viewtopic.php?f=52&t=697

viewtopic.php?f=52&t=553

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=528

push rod , on the lifters you will use,

(theres no pressure on the lifter push rod seat during the geometry check, with the plastic check tool)

and a valve train geometry test checker, after the rockers removed and follow the linked info in the threads listed below

you then retest with the majic marker on the valve tip rotating the engine by hand after carefully reading and understanding the links

viewtopic.php?f=52&t=181&p=6764&hilit=geometry#p6764

viewtopic.php?f=52&t=697

viewtopic.php?f=52&t=553

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=528

viewtopic.php?f=50&t=2883&start=0&st=0&sk=t&sd=a&view=viewpoll

I am going to replace the number 7 piston.

So,do I need to also replace the rings and bearing and is there any other thing I should think about when replacing just one piston ?

I am going to replace the number 7 piston.

So,do I need to also replace the rings and bearing and is there any other thing I should think about when replacing just one piston ?