the old advice, about questionable parts, in any engine build-up would be

"if in doubt ,change it out!"

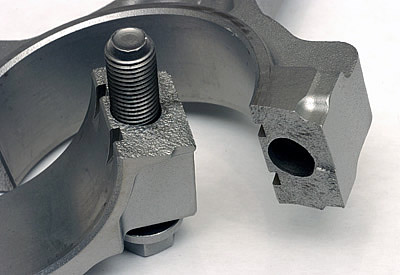

but Id sure visually check it out very carefully and swap it with the adjacent set of roller lifters to see, if the problem follows the lifters or the problem remains with the lifter bore location, if its the lifter bores, lifters or some other valve train component that's the problem, you need to correct it before proceeding in the build-up or it could cascade into something far more expensive later, if ignored.

I had a friend that chipped a lifter bore one time , forcing a busted lifter up out of a lifter bore, he failed to examine the damage carefully, he had in fact cracked the lifter gallery and ruined the block (I,m not saying that's probable in your case) but his lack of careful examination resulted in blowing the engine shortly after it was built costing him far more than just a replacement block, some welding metal stitching or re-sleeving a lifter bore ETC. which may have been the case if caught during the first assembly

http://www.sorenspecialties.com/cylinde ... epair.html

viewtopic.php?f=50&t=1926&p=5104&hilit=lifters+tube#p5104

http://www.hotrod.com/techarticles/buil ... index.html

"if in doubt ,change it out!"

but Id sure visually check it out very carefully and swap it with the adjacent set of roller lifters to see, if the problem follows the lifters or the problem remains with the lifter bore location, if its the lifter bores, lifters or some other valve train component that's the problem, you need to correct it before proceeding in the build-up or it could cascade into something far more expensive later, if ignored.

I had a friend that chipped a lifter bore one time , forcing a busted lifter up out of a lifter bore, he failed to examine the damage carefully, he had in fact cracked the lifter gallery and ruined the block (I,m not saying that's probable in your case) but his lack of careful examination resulted in blowing the engine shortly after it was built costing him far more than just a replacement block, some welding metal stitching or re-sleeving a lifter bore ETC. which may have been the case if caught during the first assembly

http://www.sorenspecialties.com/cylinde ... epair.html

viewtopic.php?f=50&t=1926&p=5104&hilit=lifters+tube#p5104

http://www.hotrod.com/techarticles/buil ... index.html