Ive always been rather amazed that there seems to be far more SBC powered t-buckets than almost all the other engine choices COMBINED

yes you occasionally see a few 426 HEMIs, LS and the new hemis

but they seem to be far rarer,

and a couple big block chevys , occasionally

when I was younger, hell one guy I had classes with in engineering school had a t-bucket with a CHRYSLER SLANT 6 with a push button automatic trans

I remember far more guys building the T-buckets (KITS WERE CHEAP AND MOST OF THE GUYS COULD BUY ECONOLINE VAN FRONT STRAIT AXLES AND FORD 9" or BUICK REAR DIFFERENTIALS with a much more varied list of ,

power plant and drive train choices

the Buick 455,

caddy 500,

Pontiac 389-455

Chrysler 383-440 wedge

Chrysler 354-392 hemis

and ford 429-460 engines

were hardly rare choices

keep in mind most guys had fairly easy access to larger car power plants and drive train components back in the 1960s-1980s but I still find the lack of variation rather odd?

Id also add that most of the guys would not even consider use of anything but a 4 speed manual transmission when I was younger, but I have to admit that by the mid 80s or so most of the guys I knew had swapped to built up automatics with a high stall converter and there were far more guys who had upgraded to DISC BRAKES, while when I was in high school back in the mid 1960s the large aluminum drum brakes from the fords and buicks were seemingly the hot ticket, especially if you had the large aluminum drum brakes of the buicks

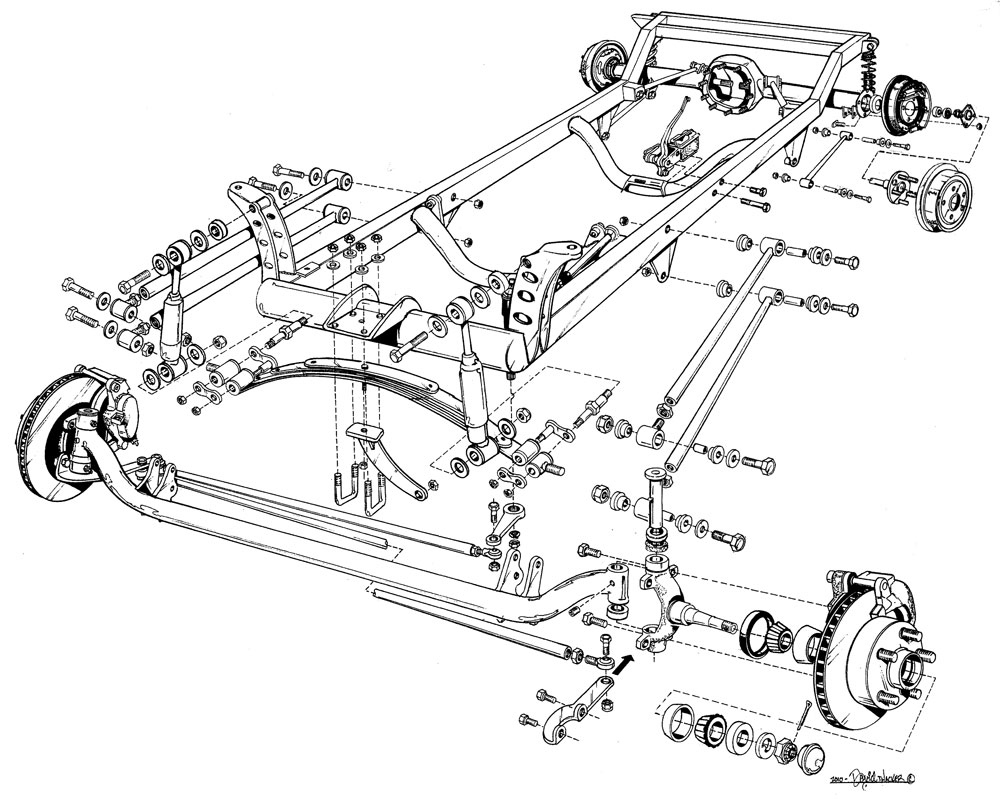

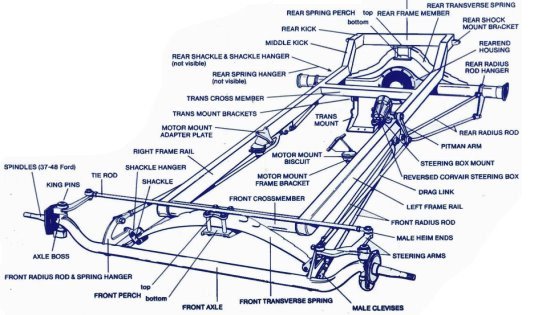

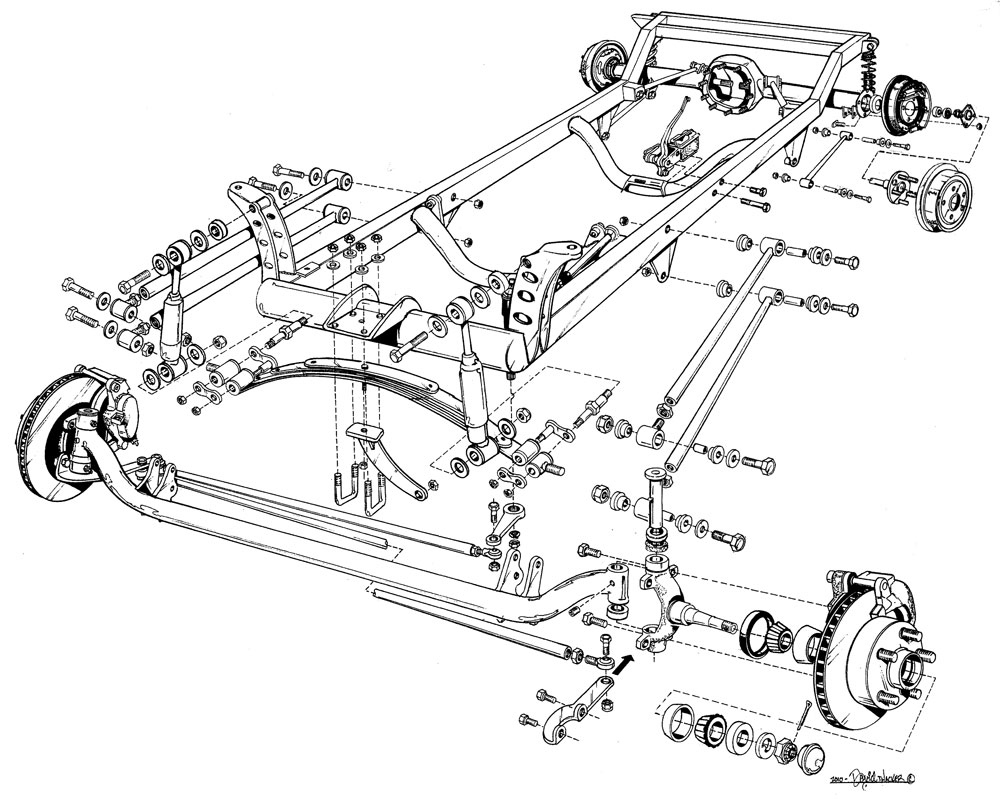

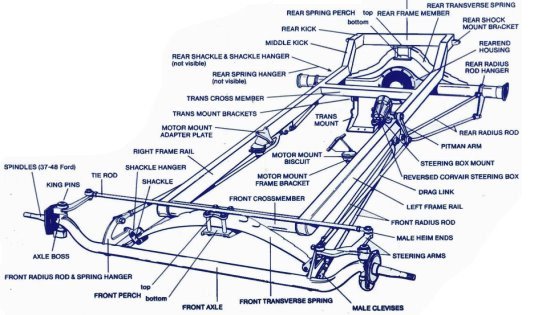

are you working to a set of blue-print style plans, assembling a kit from some supplier, with matching components, or just winging the construction of the tee bucket?

NOW don,t get me wrong, theres not a thing wrong with "WINGING IT" provided you have extensive experience building those cars,

but if not your FAR BETTER OFF following a well designed set of plans, or selecting a prepackaged kit, as purchasing components and assembling them from different sources can pose some problems with parts that won,t fit together easily

a few t-bucket frame and related linked info

http://www.hotrod.com/how-to/chassi...notching-rails-from-art-morrison-enterprises/

http://www.speedwaymotors.com/Speedway-Tribute-T-Bucket-Kit-Car,46194.html

http://www.up22.com/t_bucket.htm

http://www.speedwaymotors.com/Deluxe-1927-T-Bucket-Frame-Kit,24789.html

http://www.tbucketplans.com/t-bucket-kits/

http://www.welderseries.com/hardcopy/webcatalog.pdf

https://www.olddogstreetrods.com/Chassis.pdf

http://www.hotrod.com/cars/featured/0707sr-1923-ford-t-bucket/

www.tbuckets.com

www.spiritindustries.com

www.speedwaymotors.com

www.californiacustomroadsters.com

http://www.tbucketplans.com/the-youngster-free-t-bucket-frame-plans/

http://www.speedwaymotors.com/Nosta...0&cadevice=c&gclid=CKD64pa31McCFQyoaQod0s4AFg

http://www.tbucketplans.com/t-bucket-kits/

http://www.tbucketplans.com/

http://www.streetrodplans.com/91-2/

When the Mark IV was installed in production vehicles for the first time in 1965, it carried the Turbo-Jet name on the air cleaner, displaced 396 cubic inches, and was rated at a maximum of 425 horsepower in the Corvettes.

Here’s a quick look at milestones in the big-block’s expanding and contracting history of displacement:

396 cid – introduced in 1965, with 4.094-in. x 3.760-in. bore and stroke (first production Mark IV engine).

427 cid – introduced in 1966, with 4.250-in. x 3.760-in. bore and stroke (aluminum versions used in COPO supercars).

366 cid – introduced in 1968, with 3.935-in. x 3.760-in. bore and stroke (tall-deck; used in truck applications).

402 cid – introduced in 1970, with 4.125-in. x 3.760-in. bore and stroke (advertised as 396 cid).

454 cid – introduced in 1970, with 4.250-in. x 4.000-in. bore and stroke.

502 cid – introduced in 1988, with 4.466-in. x 4.000-in. bore and stroke (Gen V block, originally developed for non-automotive applications; adapted later by Chevrolet Performance).

572 cid – introduced in 2003, with 4.560-in. x 4.375-in. bore and stroke (developed by Chevrolet Performance; no production vehicle applications).

http://www.tooltopia.com/fowler-72-646-300.aspx

yes you occasionally see a few 426 HEMIs, LS and the new hemis

but they seem to be far rarer,

and a couple big block chevys , occasionally

when I was younger, hell one guy I had classes with in engineering school had a t-bucket with a CHRYSLER SLANT 6 with a push button automatic trans

I remember far more guys building the T-buckets (KITS WERE CHEAP AND MOST OF THE GUYS COULD BUY ECONOLINE VAN FRONT STRAIT AXLES AND FORD 9" or BUICK REAR DIFFERENTIALS with a much more varied list of ,

power plant and drive train choices

the Buick 455,

caddy 500,

Pontiac 389-455

Chrysler 383-440 wedge

Chrysler 354-392 hemis

and ford 429-460 engines

were hardly rare choices

keep in mind most guys had fairly easy access to larger car power plants and drive train components back in the 1960s-1980s but I still find the lack of variation rather odd?

Id also add that most of the guys would not even consider use of anything but a 4 speed manual transmission when I was younger, but I have to admit that by the mid 80s or so most of the guys I knew had swapped to built up automatics with a high stall converter and there were far more guys who had upgraded to DISC BRAKES, while when I was in high school back in the mid 1960s the large aluminum drum brakes from the fords and buicks were seemingly the hot ticket, especially if you had the large aluminum drum brakes of the buicks

are you working to a set of blue-print style plans, assembling a kit from some supplier, with matching components, or just winging the construction of the tee bucket?

NOW don,t get me wrong, theres not a thing wrong with "WINGING IT" provided you have extensive experience building those cars,

but if not your FAR BETTER OFF following a well designed set of plans, or selecting a prepackaged kit, as purchasing components and assembling them from different sources can pose some problems with parts that won,t fit together easily

a few t-bucket frame and related linked info

http://www.hotrod.com/how-to/chassi...notching-rails-from-art-morrison-enterprises/

http://www.speedwaymotors.com/Speedway-Tribute-T-Bucket-Kit-Car,46194.html

http://www.up22.com/t_bucket.htm

http://www.speedwaymotors.com/Deluxe-1927-T-Bucket-Frame-Kit,24789.html

http://www.tbucketplans.com/t-bucket-kits/

http://www.welderseries.com/hardcopy/webcatalog.pdf

https://www.olddogstreetrods.com/Chassis.pdf

http://www.hotrod.com/cars/featured/0707sr-1923-ford-t-bucket/

www.tbuckets.com

www.spiritindustries.com

www.speedwaymotors.com

www.californiacustomroadsters.com

http://www.tbucketplans.com/the-youngster-free-t-bucket-frame-plans/

http://www.speedwaymotors.com/Nosta...0&cadevice=c&gclid=CKD64pa31McCFQyoaQod0s4AFg

http://www.tbucketplans.com/t-bucket-kits/

http://www.tbucketplans.com/

http://www.streetrodplans.com/91-2/

When the Mark IV was installed in production vehicles for the first time in 1965, it carried the Turbo-Jet name on the air cleaner, displaced 396 cubic inches, and was rated at a maximum of 425 horsepower in the Corvettes.

Here’s a quick look at milestones in the big-block’s expanding and contracting history of displacement:

396 cid – introduced in 1965, with 4.094-in. x 3.760-in. bore and stroke (first production Mark IV engine).

427 cid – introduced in 1966, with 4.250-in. x 3.760-in. bore and stroke (aluminum versions used in COPO supercars).

366 cid – introduced in 1968, with 3.935-in. x 3.760-in. bore and stroke (tall-deck; used in truck applications).

402 cid – introduced in 1970, with 4.125-in. x 3.760-in. bore and stroke (advertised as 396 cid).

454 cid – introduced in 1970, with 4.250-in. x 4.000-in. bore and stroke.

502 cid – introduced in 1988, with 4.466-in. x 4.000-in. bore and stroke (Gen V block, originally developed for non-automotive applications; adapted later by Chevrolet Performance).

572 cid – introduced in 2003, with 4.560-in. x 4.375-in. bore and stroke (developed by Chevrolet Performance; no production vehicle applications).

http://www.tooltopia.com/fowler-72-646-300.aspx

Last edited by a moderator:

![7620_2[583x].jpg](/proxy.php?image=http%3A%2F%2Fwww.grumpysperformance.com%2Fjuly2017%2F7620_2%5B583x%5D.jpg&hash=5931892943d24f9505466692c10aa541)