got asked recently what hydraulic roller cam ID suggest for a street/strip 383 combo?(obviously theres a wide selection that may work,)

theres at least a few hours of very worth while , and quite useful reading in this thread and links that will prevent you wasting time and money, keep in mind the sub links contain a huge wealth of additional info youll need

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

many guys ignore proven combos, because it may cost more than they want to spend, and either insist on using components they own currently or think they can buy far less expensively than the components, I know from experience will actually work.

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

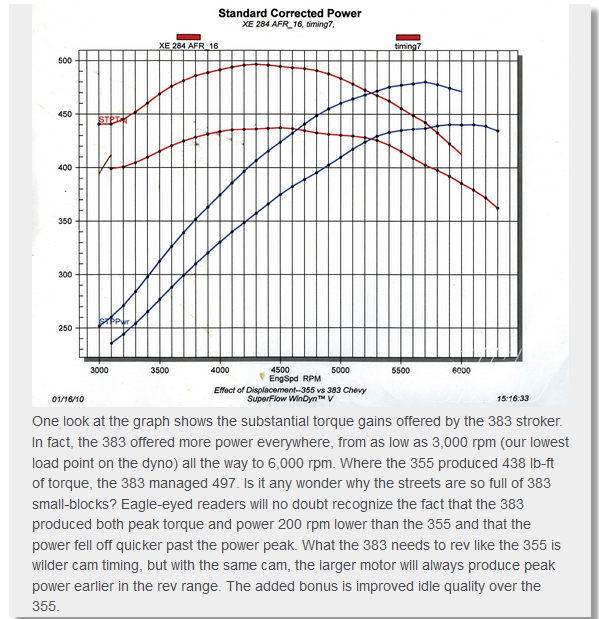

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

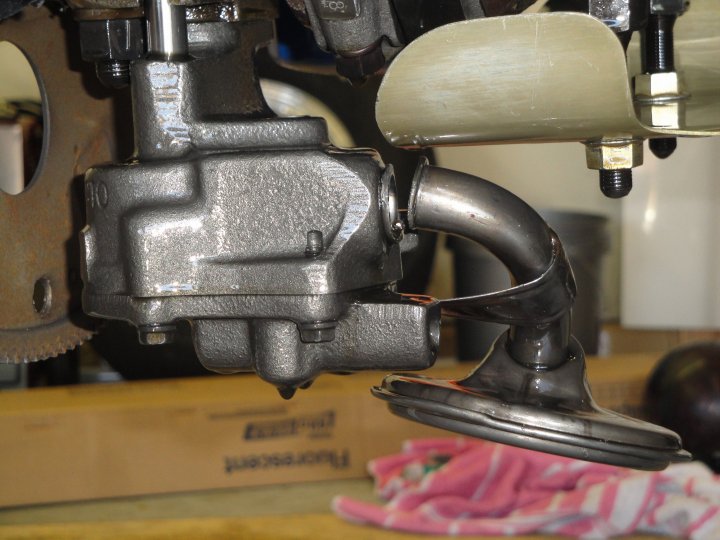

high volume oil pumps use is far more beneficial than high peak pressure in oil pumps,

remember peak pressure only happens at higher rpms and tests show,

no benefits in long term engine durability,

if peak oil pressure exceeds 65 psi or higher.

www.shafiroff.com

read links and sub links

www.shafiroff.com

read links and sub links

READ THESE LINK'S OVER CAREFULLY TWICE

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.co...lap-on-factory-headers.3155/page-2#post-66722

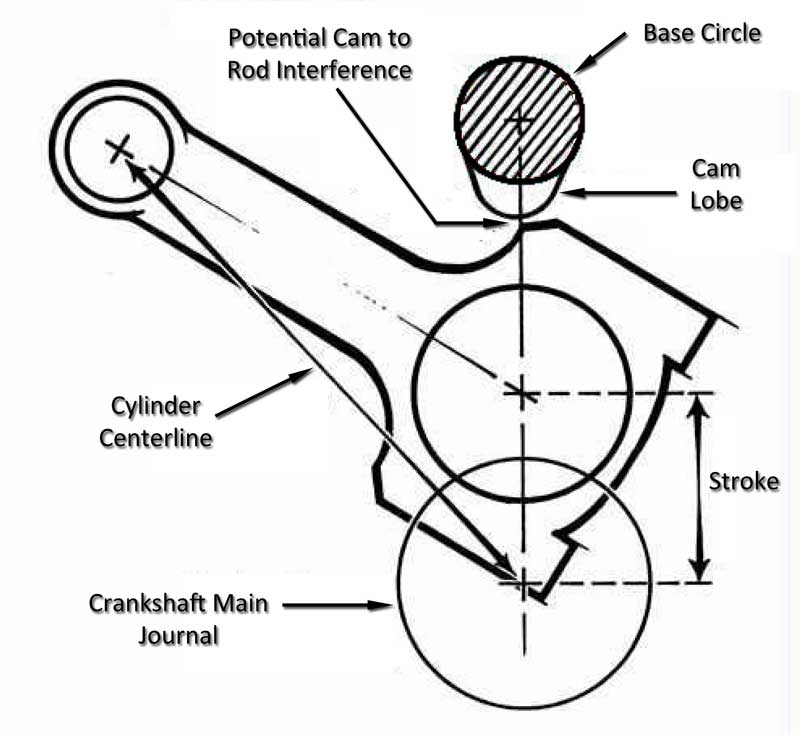

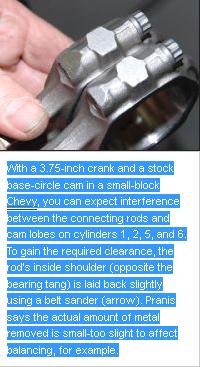

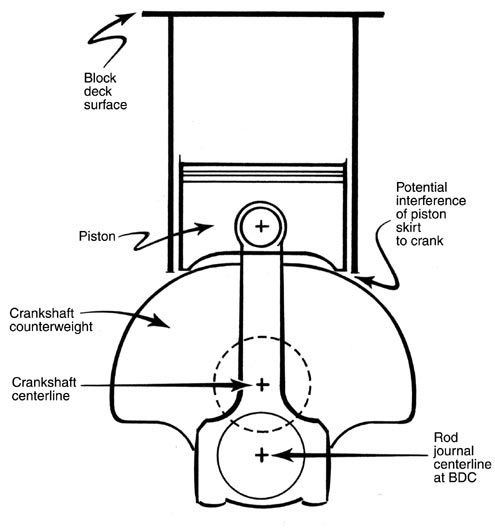

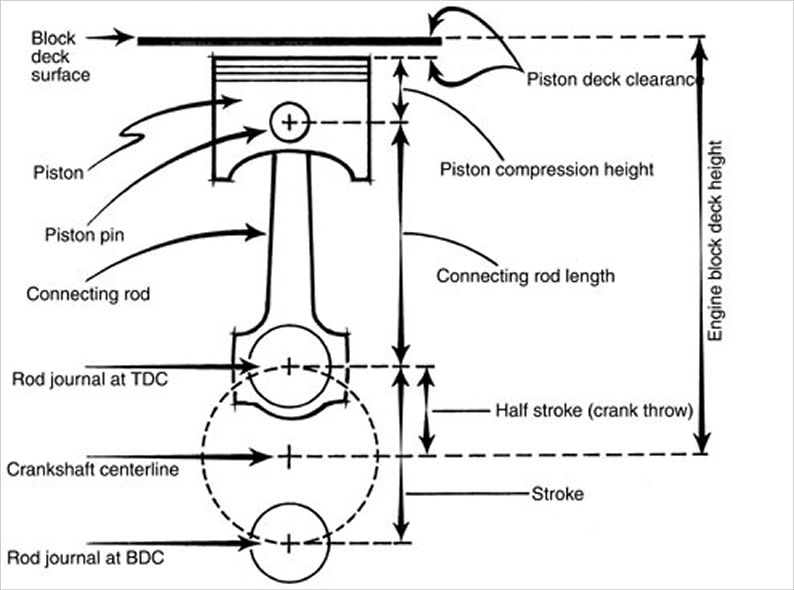

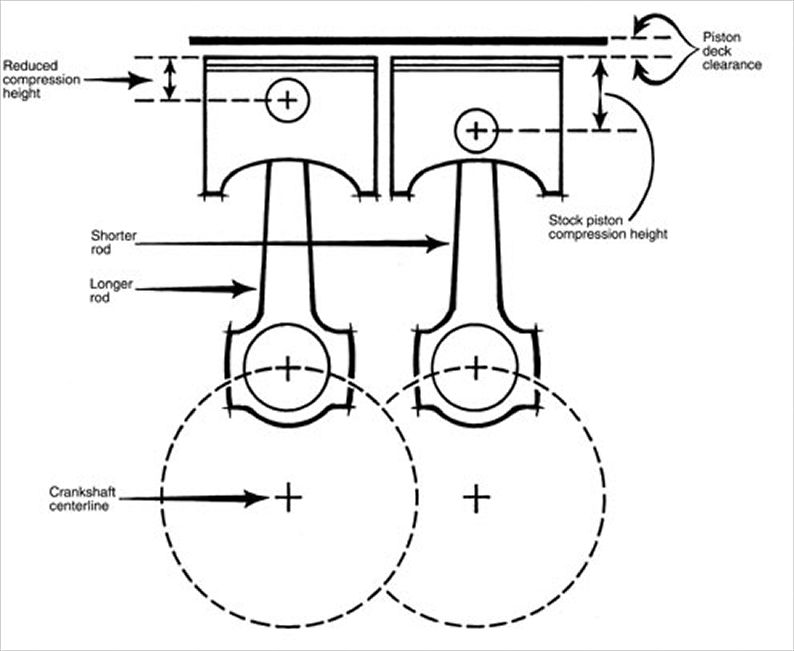

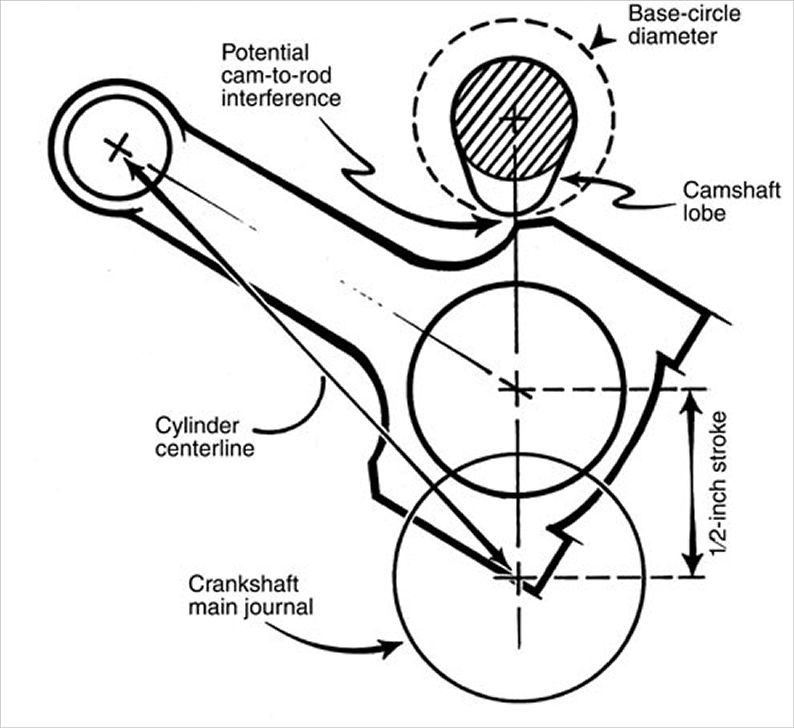

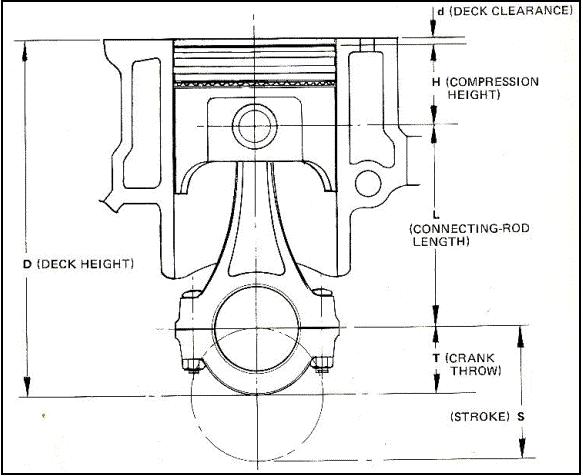

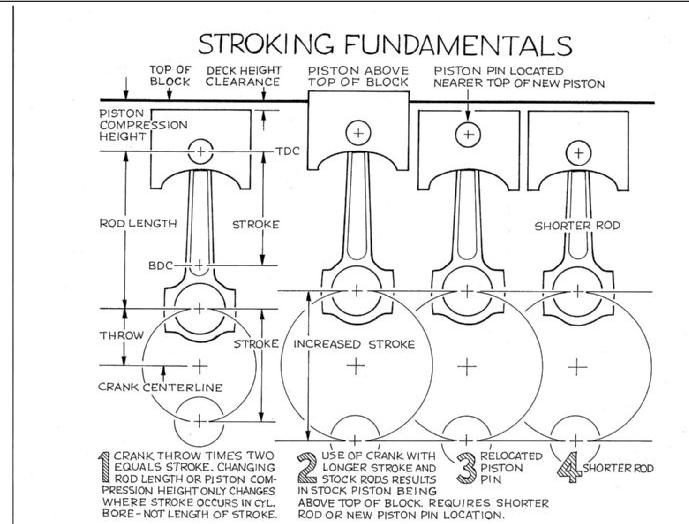

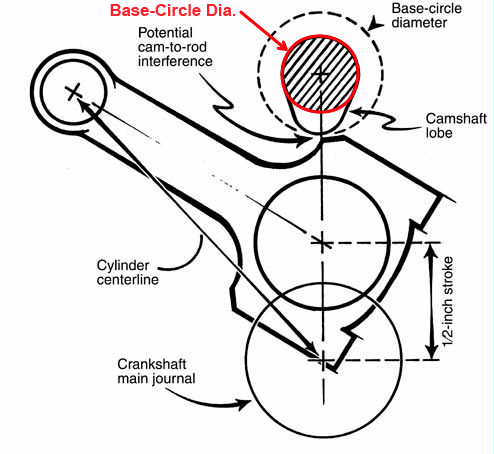

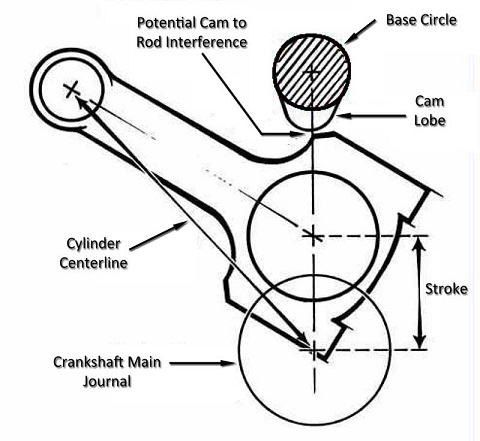

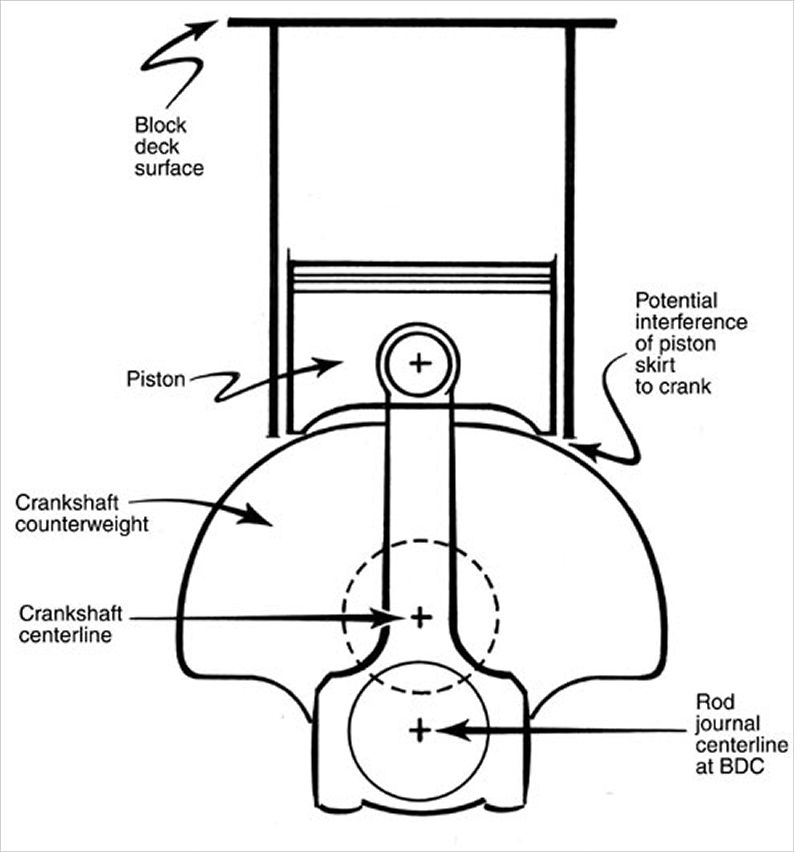

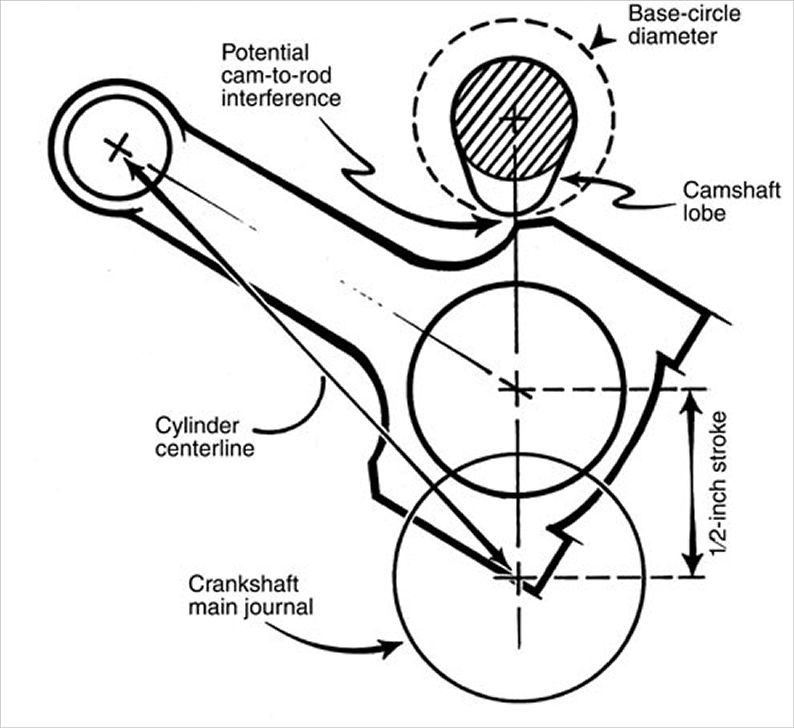

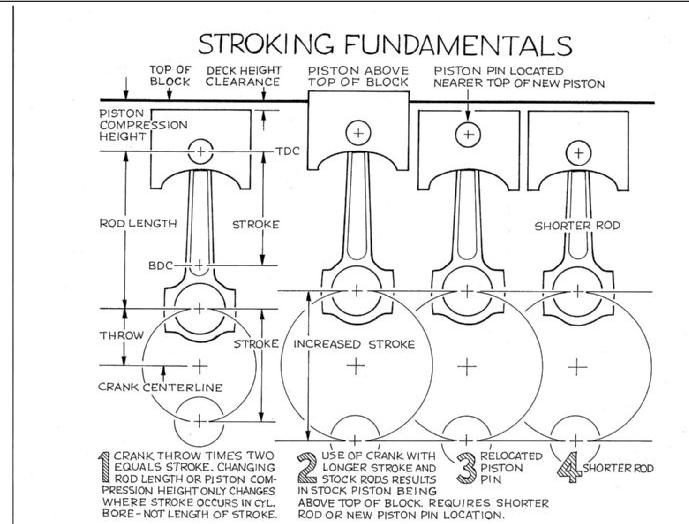

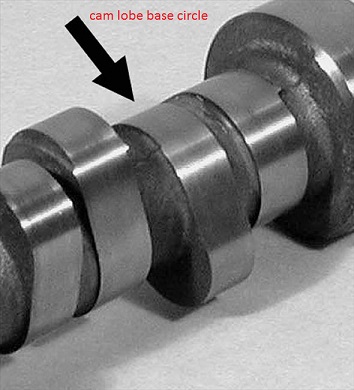

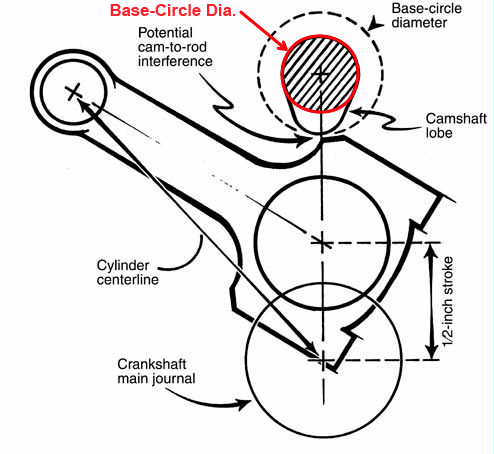

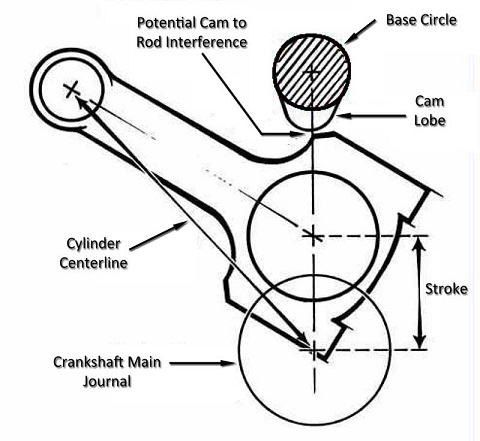

some of the newer stroker rods do in most cases let you avoid the use of a smaller base circle cam, but because there's dozens of different connecting rod designs and different types of rods and rod bolts clearances vary a good deal,

as alway you'll need to check & verify the clearances, once the cam is degreed in, and rods are installed in your particular engine.

www.chevydiy.com

www.chevydiy.com

www.chevydiy.com

www.chevydiy.com

www.motortrend.com

www.motortrend.com

ONE GENTLEMAN pointed out ,after shopping around one of the least expensive deals seems to be the EDELBROCK CAM BELOW

http://www.jegs.com/i/Edelbrock/350/22015/10002/-1#

https://garage.grumpysperformance.com/index.php?threads/redline.343/#post-419

http://www.hotrod.com/how-to/engine...-assembly-for-a-stroker-383-chevrolet-engine/

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

(hit cancel the info appears)

http://www.themotorbookstore.com/resmchstvi.html

http://www.amazon.com/Lingenfelter-Modi ... 82&sr=8-11"]Amazon.com: John Lingenfelter on Modifying Small-block Chevy Engines (0075478012381): John Lingenfelter: Books

http://www.amazon.com/Smokey-Yunicks-Po ... 809&sr=8-2"]Amazon.com: Smokey Yunick's Power Secrets (9780931472060): Smokey Yunick: Books

http://www.summitracing.com/popup/calcsandtools/stroker-combinations

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

(hit cancel the info appears)

http://www.airflowresearch.com/super-chevy-apr-2010-210cc-sbc.php

http://www.hotrod.com/how-to/engine...-assembly-for-a-stroker-383-chevrolet-engine/

buy these book/video's its probably the best money value you can get, you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

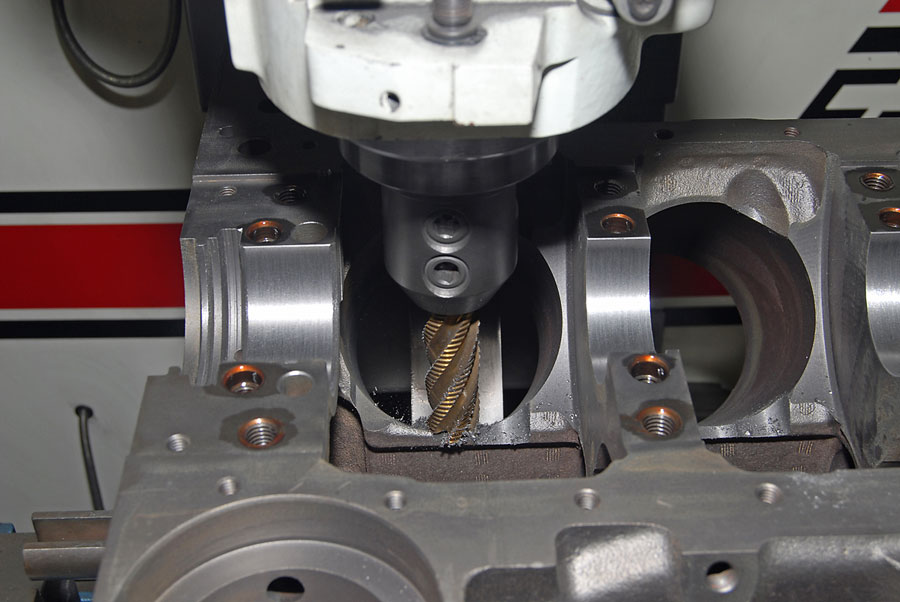

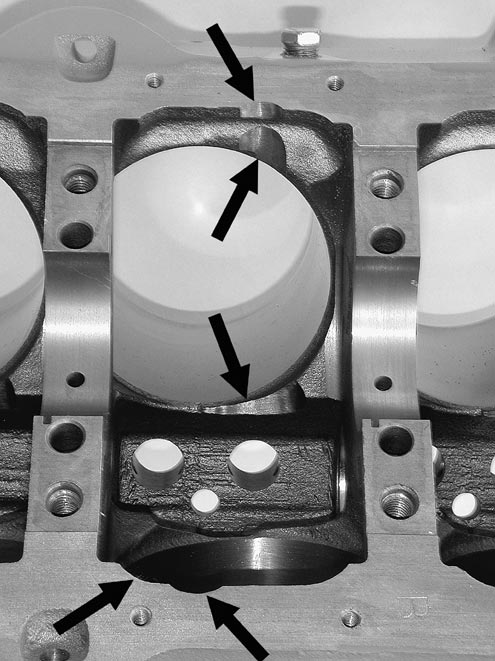

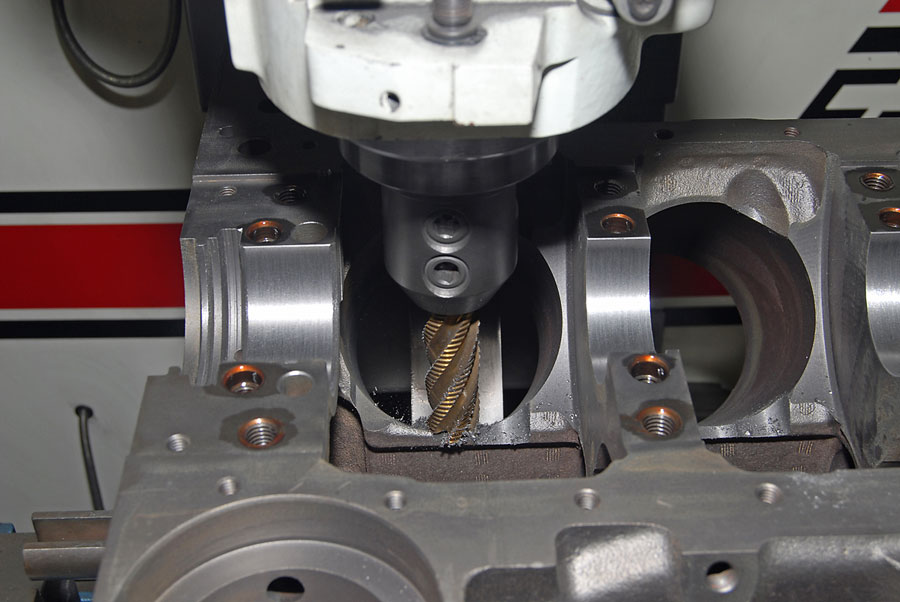

milling stroker clearance on 350/383

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://www.superchevy.com/how-to/engine ... shaft.html

http://www.flatlanderracing.com/probe-sportsbc04.html

http://www.maintenanceresources.com/ref ... alance.htm

http://www.circletrack.com/enginetech/c ... rminology/

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.summitracing.com/popup/calcsandtools/stroker-combinations

http://garage.grumpysperformance.co...ty-thats-key-in-building-a-good-engine.11682/

http://www.chevyhiperformance.com/techa ... ine_build/

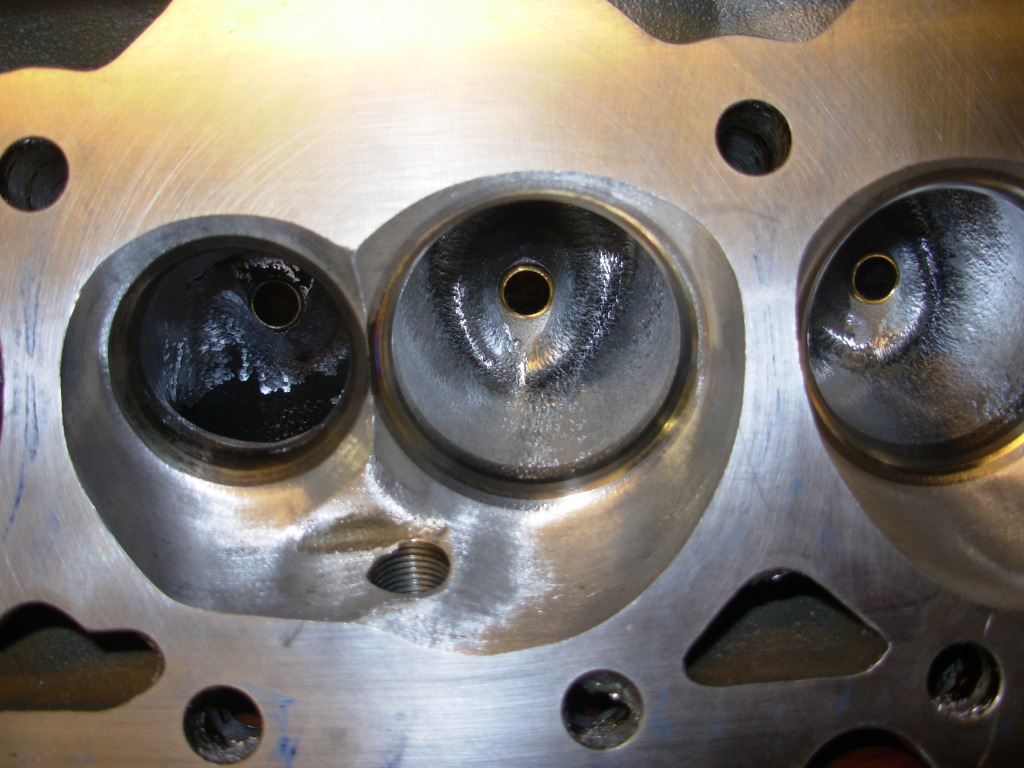

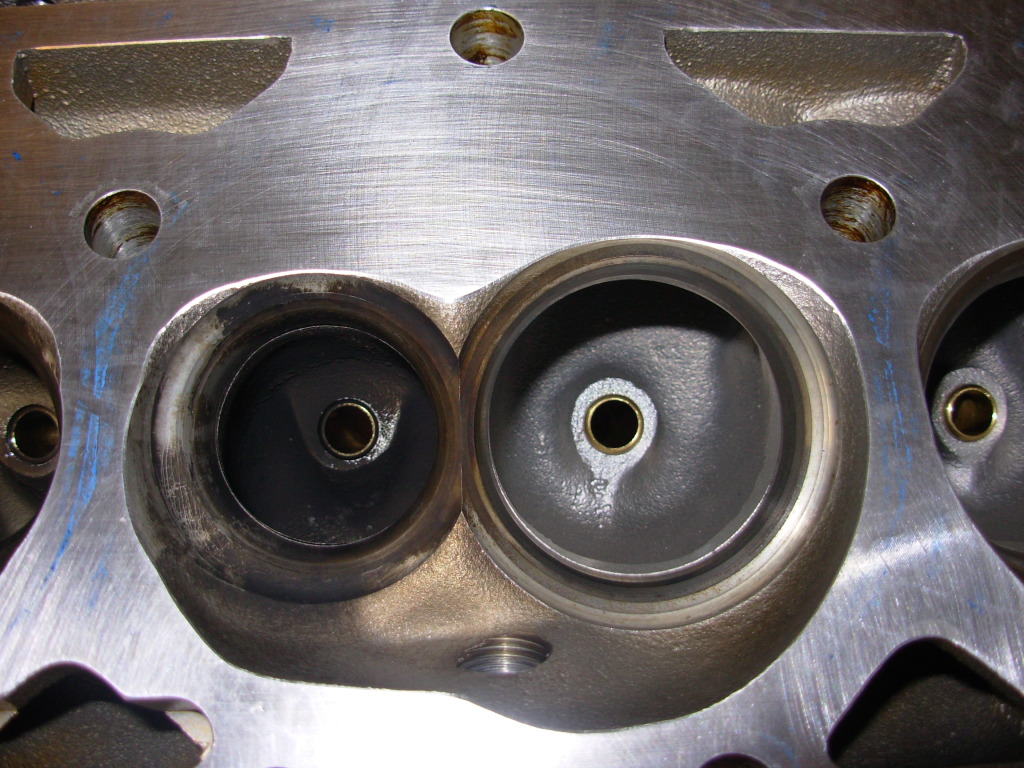

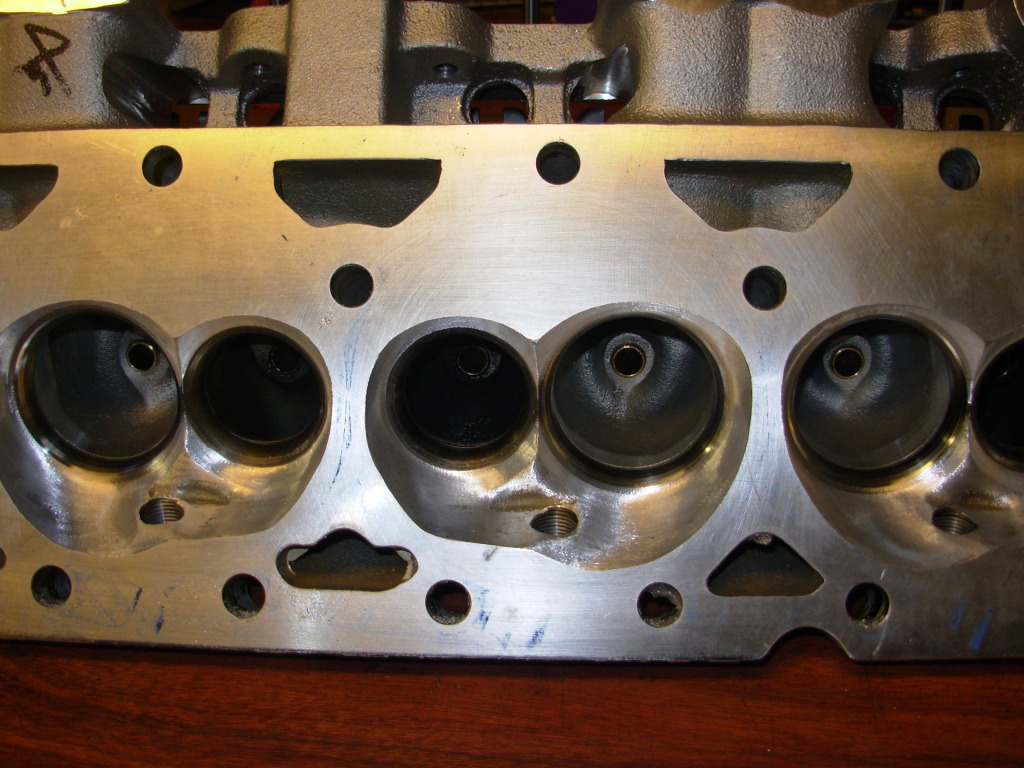

notice its right where the roller cams lobe design maximized the extra air flow potential that is the most effective flow area during the whole valve flow curve

and yes it frequently helps to match a roller cam to roller rockers as the reduced friction further helps the engines durability and ability to easily cope with faster valve train component acceleration, that tends to reduce heat and wear.

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches, thus it makes a great deal of sense to push the valve lift a bit over .500, and have an intake port that is at least 3.2 square inches in cross sectional area, if you want to maximize flow on a 2.02" intake valve

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

SB-Chevy 283-400 Hydraulic Roller Camshaft Kit

Duration Advertised 296° Intake/300° Exhaust

Duration @ .050'' 234° Intake/238° Exhaust

Lift @ Valve .539'' Intake/.548'' Exhaust

Lift @ Cam .359'' Intake/.365'' Exhaust

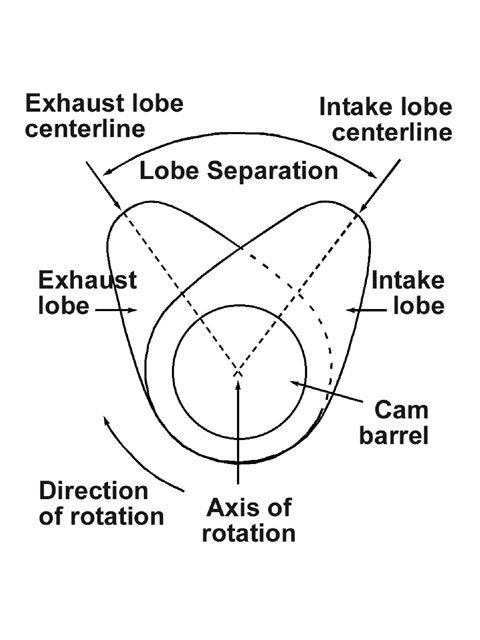

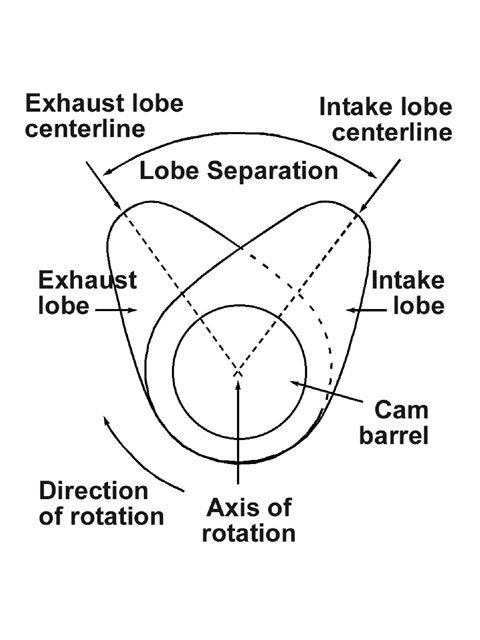

Lobe Separation Angle 112°

Intake Centerline 107°

Intake Timing @ .050" Open 10° BTDC

Close 44° ABDC

Exhaust Timing @ .050" Open 56° BBDC

Close 2° ATDC

A FEW HOURS OR EVEN DAYS ,SPENT READING LINKS AND SUB LINKS CAN SAVE YOU MONTHS OF WORK AND THOUSANDS OF DOLLARS

http://chevyhighperformance.automotive. ... index.html

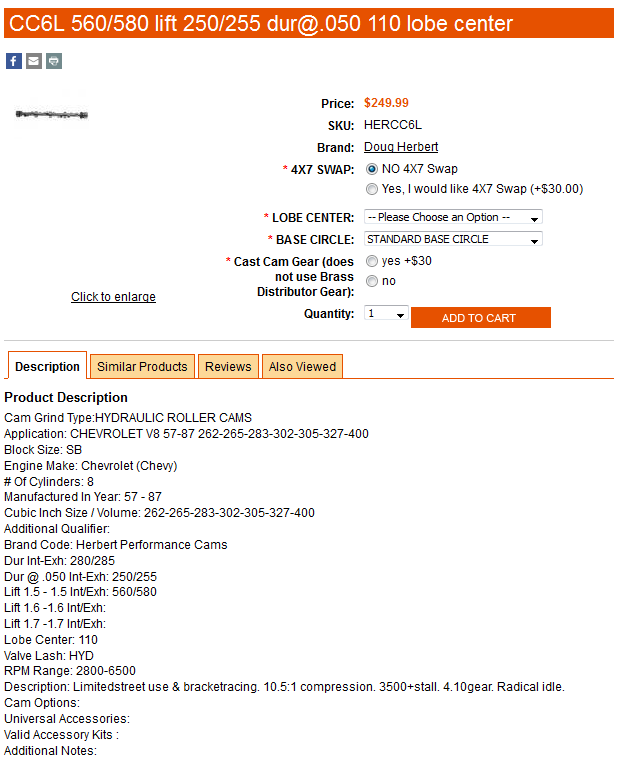

IVE used similar cam designs (serration/lift/)in the past with excellent results and $709 for the cam, roller lifters and push rods is a good value, naturally the REST of the components and the cars drive train and the cars intended use will effect the choice

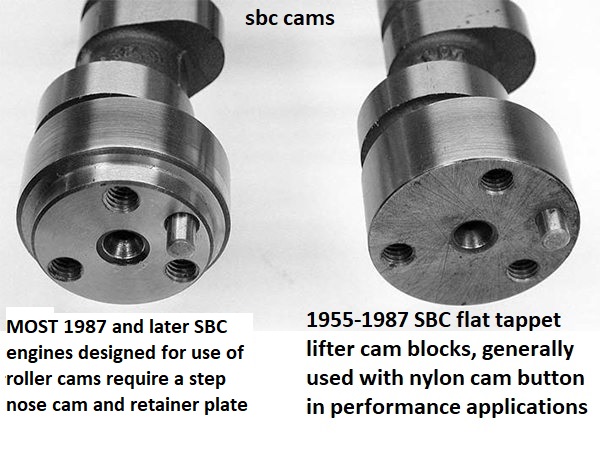

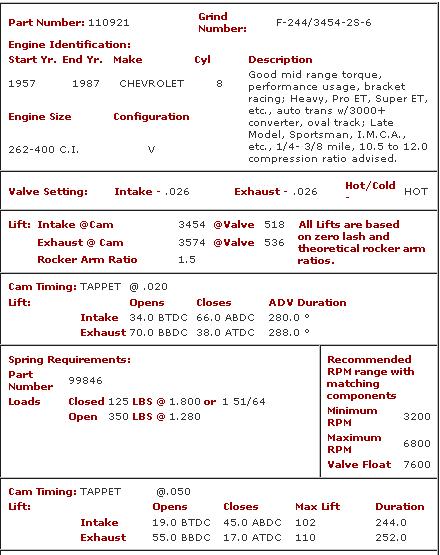

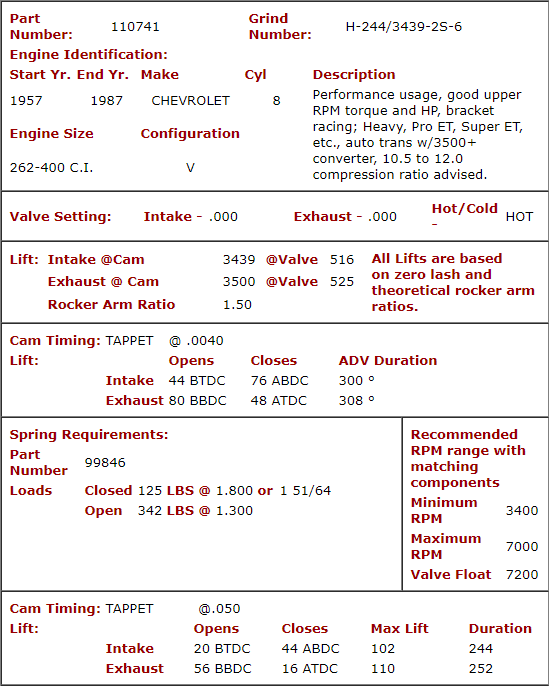

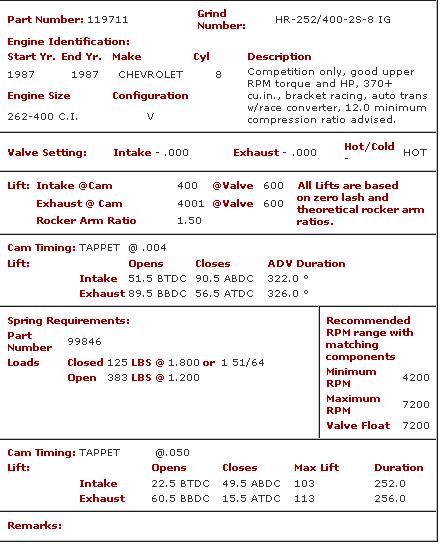

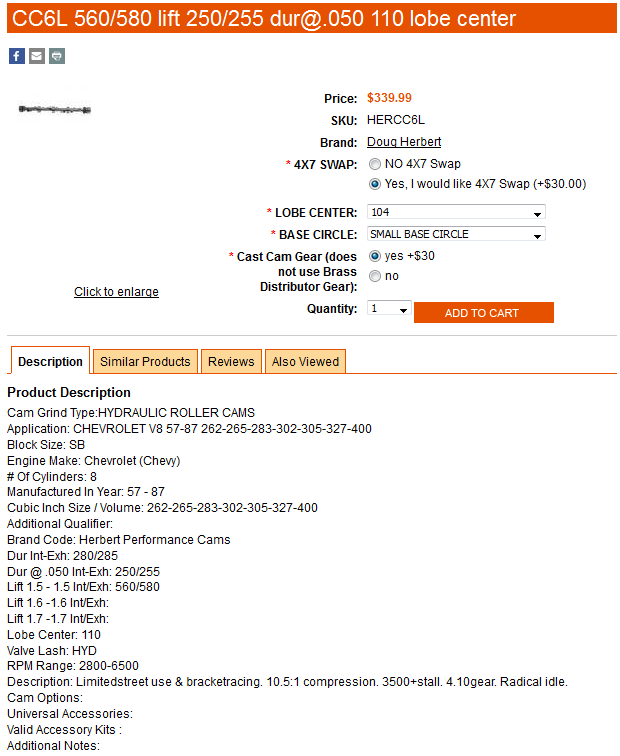

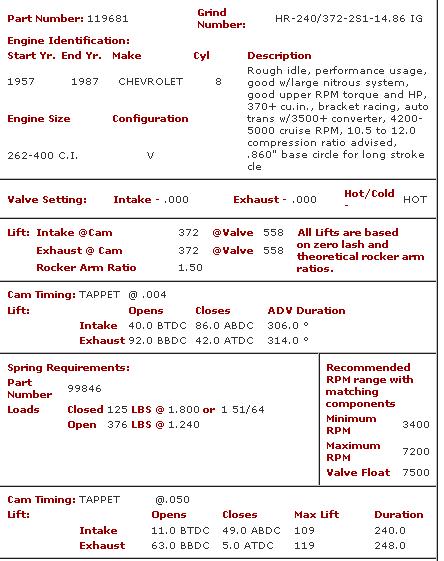

the only thing that makes me hesitate is the quality of edelbrocks cam cores.AS most IVE SEEN are not billet but cast cores which are less durable and on a 383, PLUS you want a small base circle cam......for rotating assembly clearance issues ,one reason I usually suggest this cam in similar combos

one very common mistake is selecting a cam duration, rear gear ratio, compression ratio or set of heads that can,t operate with the other components in the same power band efficiently

the best heads matched to a restrictive intake or the wrong cam will result in a DOG just as surely as a great intake and crappy heads with low compression, or any of a few dozen other miss-matched parts.

if you want impressive bragging level hp you need to design a combo capable of operating efficiently above 5800-6000rpm but thats NOT necessarily going to be a good street engine

example

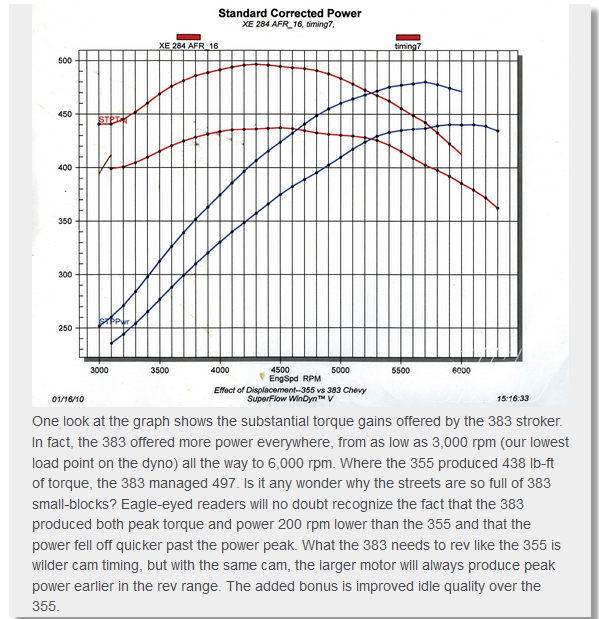

horsepower =torque times rpm divided by 5252

so 370ft lbs at 3700rpm=261hp

but 370ft lbs at 5700rpm=401hp

and the heads , rear gear ratio,and cam that operate effectively at 3700rpm wont be the same as those matched to 5700rpm, you might also keep in mind youll make approximately 1.1-1.2 hp per cubic inch of displacement and piston speeds below 4200fpm are strongly recommended for long term durability, and hydraulic lifter valve trains seldom do well over 6300rpm, and about 10.2:1 static compression is about the max crappy pump gas will tolerate IF MATCHED TO THE CORRECT COMBO

theres a HUGE MIS -CONCEPTION out there that its always the larger port cross sectional area on any engine that lacks low speed torque, thats responsible for a loss of low speed torque, in most cases it is the combo of a larger than ideal for the application cam duration and a single plane intake, and larger and shorter headers or a restrictive exhaust having been selected ,NOT the cylinder heads port size.

YES cylinder head port cross section will effect the port velocity, but in most cases if your building a performance street cars engine your better off going slightly larger on port size and slightly conservative on the cam duration.

READ THESE LINKS

http://airflowresearch.com/articles/article093/A-P1.htm

IF your having issues with low rpm torque with a 383-406 SBC youve built ask yourself some questions

WHAT CAM ARE YOU USING?

WHATS YOUR IGNITION ADVANCE CURVE?

WHATS YOUR FUEL/AIR RATIO AT PEAK TORQUE?

WHATS YOUR FUEL PRESSURE EVERY 1000,RPM

WHATS YOUR HEADERS BACK PRESSURE AT PEAK TORQUE?

WHAT INTAKE MANIFOLD ARE YOU USING?

whats the PLENUM VACUUM READ AT 2500RPM?, 4500RPM? 6000RPM?

ARE YOU RUNNING A WELL MATCHED REAR GEAR RATIO AND CONVERTER STALL SPEED?

DOES YOUR DRIVE TRAIN GEARING AND TIRE SIZE MATCH THE ENGINES POWER CURVE?

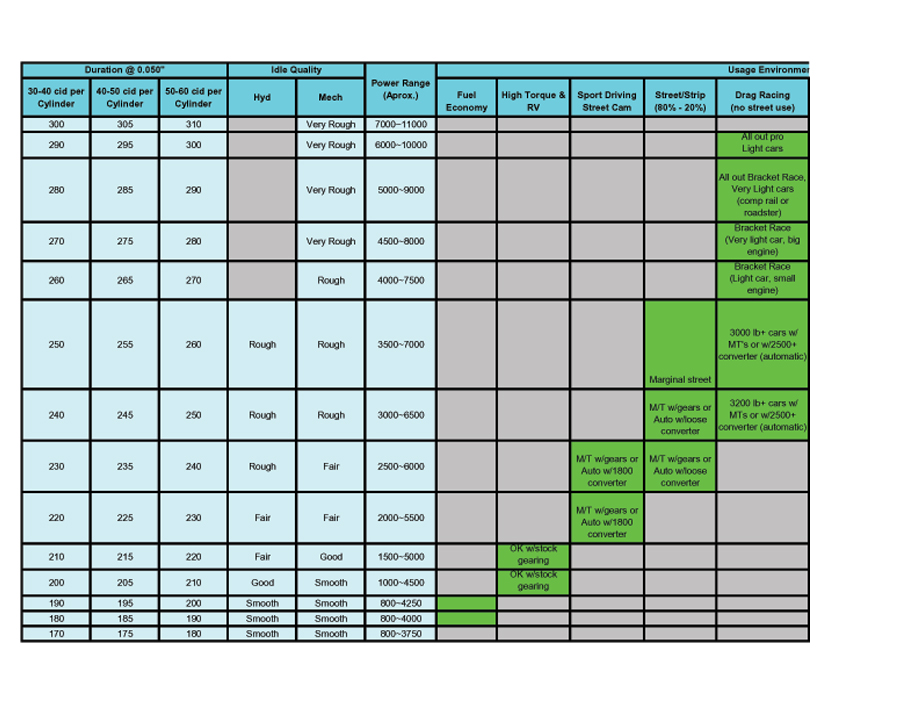

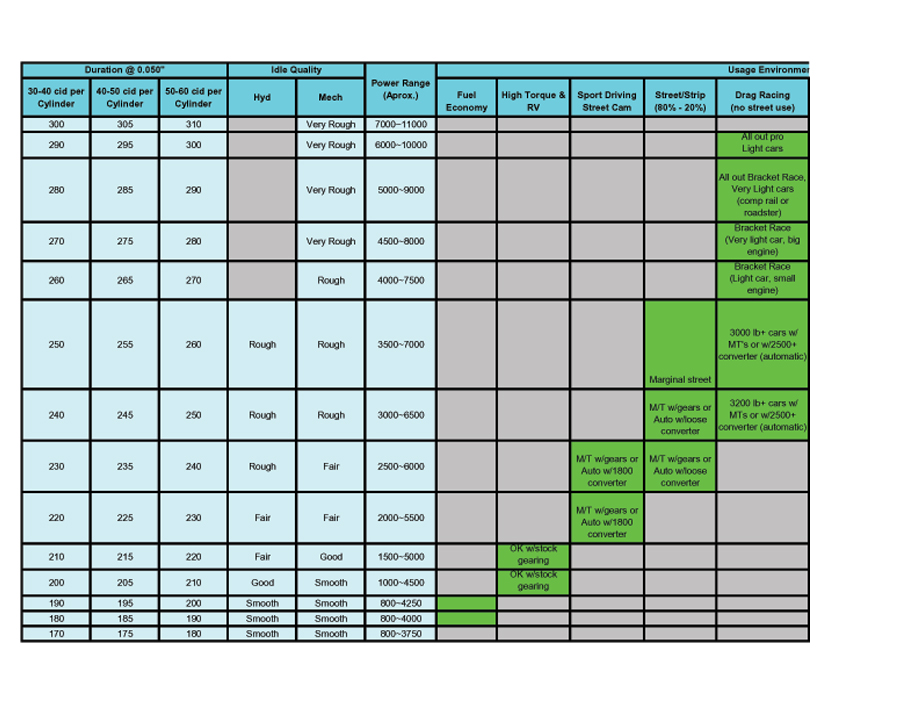

combining the info posted a 383 sbc has 47.8 cubic inches per cylinder divided by 2.02=23.7 on the chart above, so youll find cams in the correct duration range having a tight 105-108 lSA most efficient at filling the cylinders in many combos,

you WILL find these threads and sub linked info BELOW VERY useful, so skipping over them is not the best route to take here, yes I know you are most likely not into extensive reading, its worth the time

SAFE piston speeds are best restricted to 4000fpm for stock components and 4500fpm for the better common aftermarket components

viewtopic.php?f=53&t=343&p=16772&hilit=redline#p16772

viewtopic.php?f=53&t=341

viewtopic.php?f=54&t=2187&p=5890#p5890

http://garage.grumpysperformance.com/index.php?threads/sbc-spacer-bearings.3058/

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.airflowresearch.com/articles ... 1/A-P1.htm

http://www.skipwhiteperformance.com/det ... 3831P-1230

http://www.chevymania.com/tech/383.htm

viewtopic.php?f=71&t=741&p=1048#p1048

viewtopic.php?f=53&t=8685&p=30565#p30565

http://www.airflowresearch.com/articles ... A16-P1.htm

http://www.hotrod.com/techarticles/engi ... ewall.html

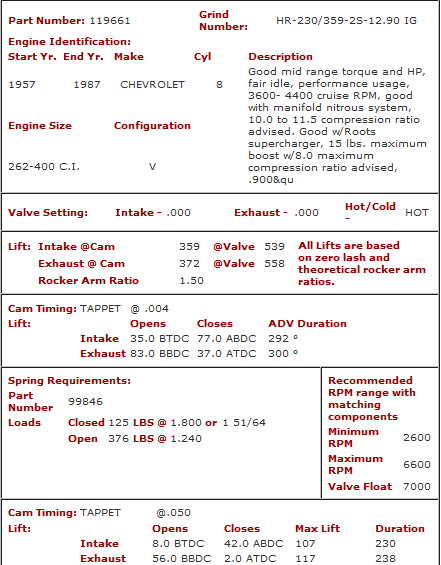

http://www.cranecams.com/index.php?s...61&lvl=2&prt=5

http://www.jegs.com/i/Crane/270/119661/10002/-1#

http://www.jegs.com/webapp/wcs/store...hTerm=11532-16

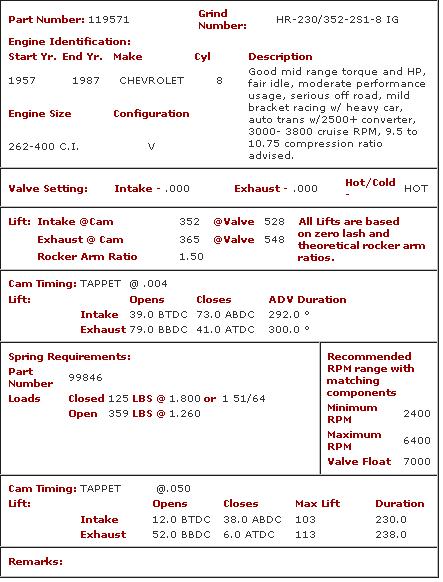

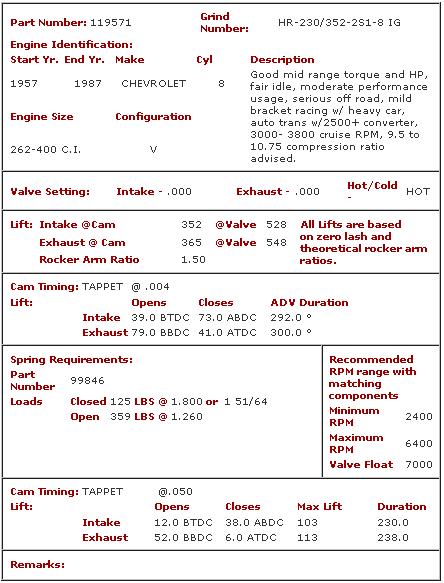

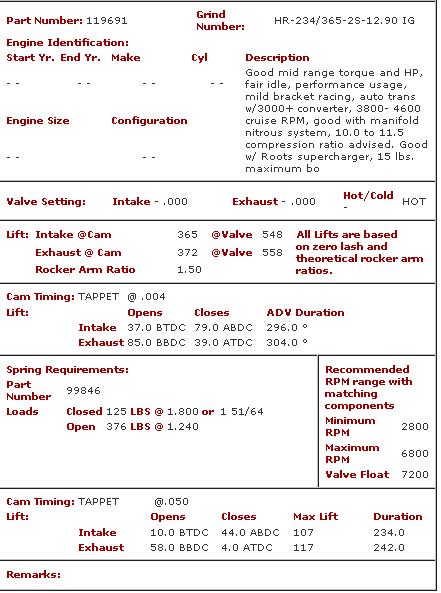

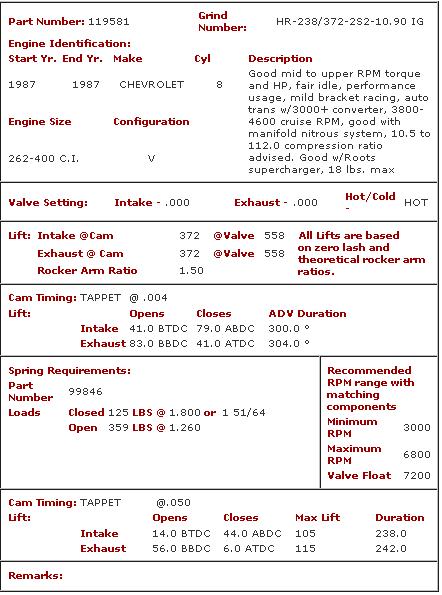

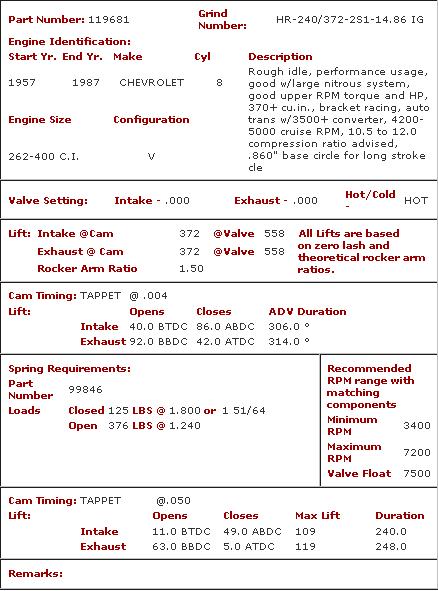

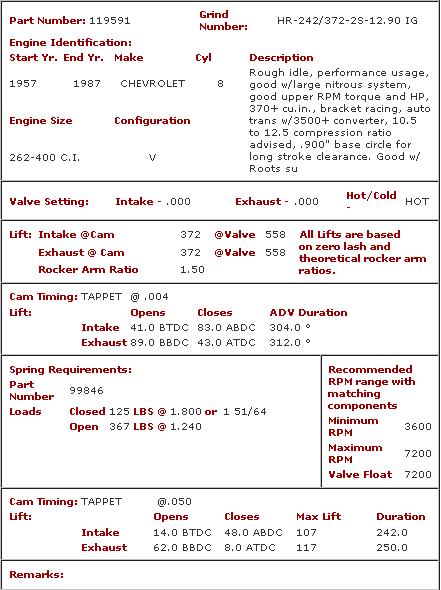

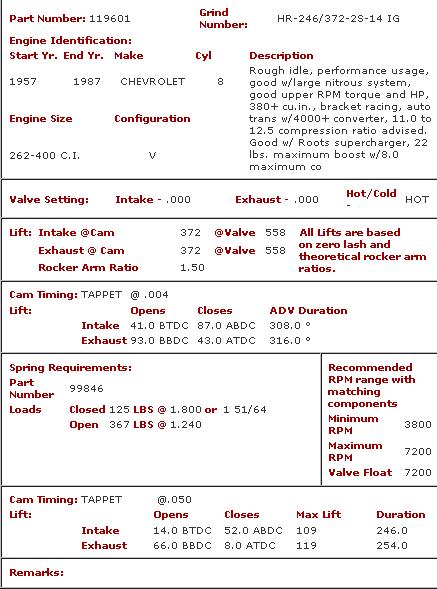

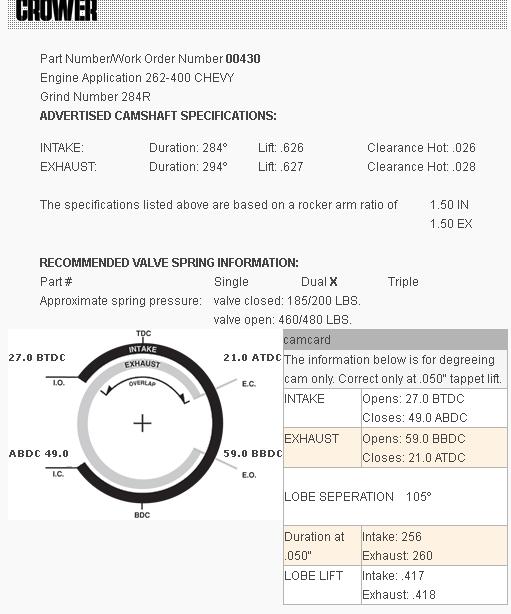

Grind Number: HR-230/359-2S-12.90 IG

Operating Range: 3000-6500 RPM

Duration Advertised: 292° Intake / 300° Exhaust

Duration @ .050'' Lift: 230° Intake / 238° Exhaust

Valve Lift w/1.5 Rockers: .539'' Intake / .558'' Exhaust

Lobe Separation Angle: 112°

Max Lift Angle: 107° ATDC Intake / 117° BTDC Exhaust

Open/Close @.050'' Cam Lift: Intake - 8° BTDC (opens) / 42° ABDC (closes)

Exhaust - 56° BBDC (opens) / 2° ATDC (closes)

with either cam youll want a 3000rpm stall converter , about 10.5:1 cpr and a 3.73-4.11:1 rear gear to maximize the performance and a low restriction exhaust, headers and a high flow intake

IM currently running the crane 119661 cam in MY 383 and Ive tested over a dozen cams in that engine, so if its a street/strip combo ID suggest going that route, SMALL BASE CIRCLE AND BILLET CORE.....yeah! YOU GET WHAT YOU PAY,FOR and DURABILITY FOR PARTS TENDS TO COST MORE

__________________

these related links and their sub links will help a good deal IF YOU TAKE THE TIME TO READ THRU THEM

YES IT WILL TAKE HOURS TO READ THRU THE LINKED INFO...IT WILL ALSO SAVE YOU HUNDREDS OF DOLLARS AND WEEKS OF WORK,

YOU CAN LEARN A GREAT DEAL, ABOUT COMBOS THAT WORK, IF YOU READ THRU ALL THE LINKS AND SUB LINKED INFO BELOW

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.brodix.com/heads/tonydyno.html

http://www.sporttruck.com/howto/40619/index.html

viewtopic.php?f=50&t=1249

viewtopic.php?f=51&t=125

viewtopic.php?f=50&t=1859

http://bracketmasters.com/small_block_s ... 383_cu.htm

http://www.summitracing.com/parts/SUM-150100/

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://www.vsihp.com/library/CleviteEng ... sGuide.pdf

http://www.chevyhiperformance.com/tech/ ... ewall.html

http://www.carcraft.com/techarticles/cc ... index.html

http://bracketmasters.com/small_block_s ... 383_cu.htm

http://www.compcams.com/catalog/COMP201 ... 010_10.pdf

http://garage.grumpysperformance.co...ber-of-people-that-don-t-use-resources.12125/

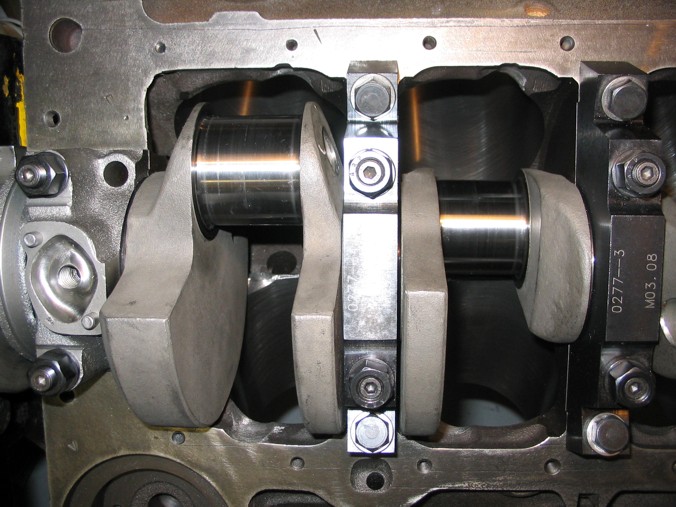

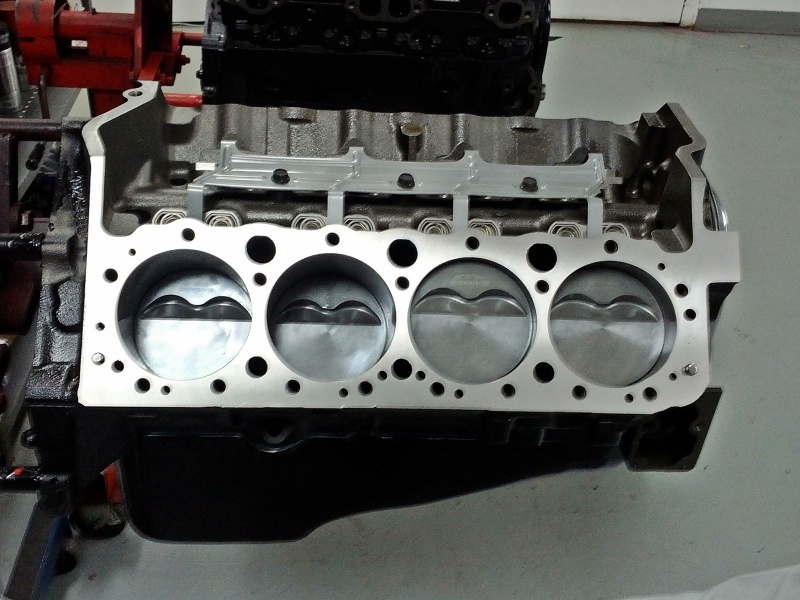

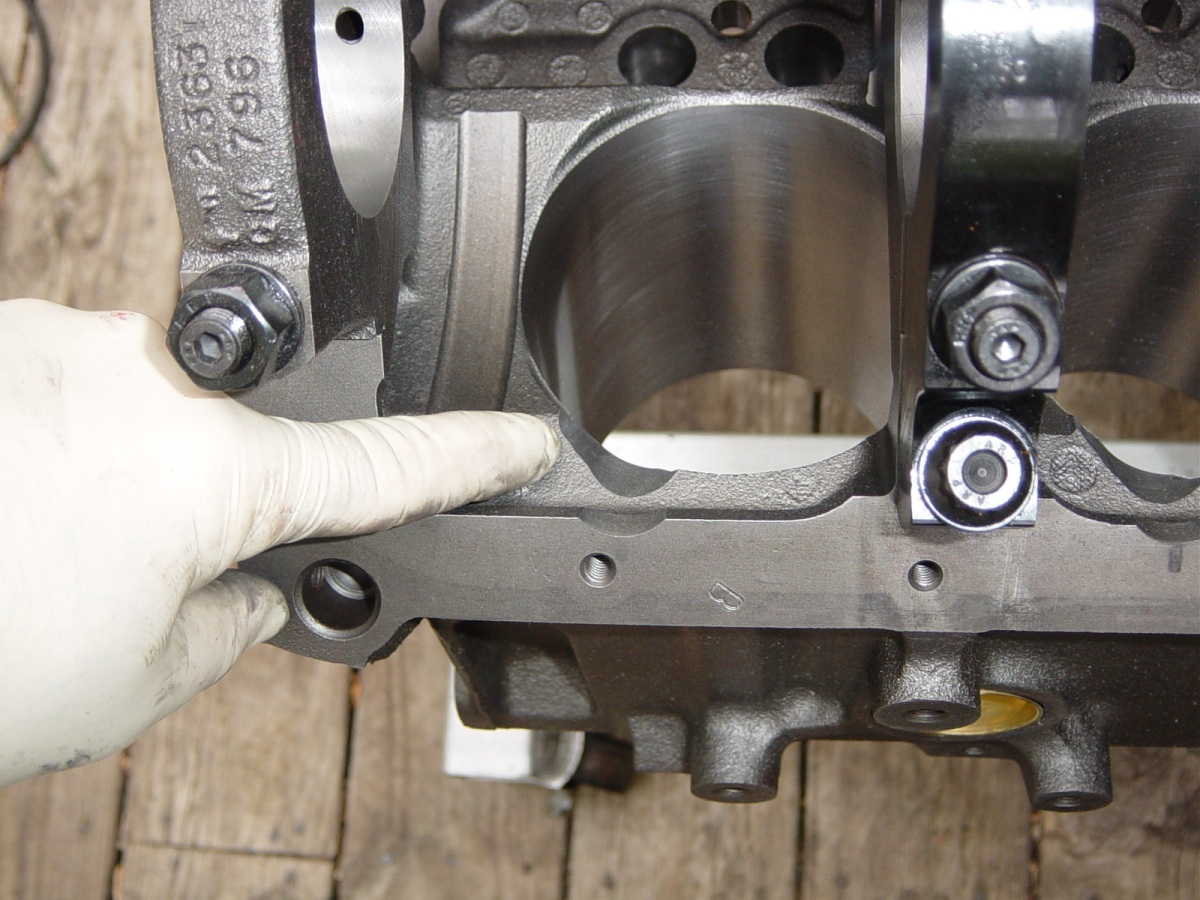

its really refreshing to see someone take the effort to do those clearance checks that are so critical to long term durability

for those just starting on their 383 build ups heres some very useful linked info

http://www.hotrod.com/howto/69883_strok ... to_07.html

http://www.superchevy.com/technical/eng ... index.html

http://www.carcraft.com/techarticles/cc ... index.html

BIGGER is NOT always BETTER, and since both the header primary diam. and length and the collectors , which have a huge effect on the resulting scavenging can,t be changed as we change engine rpms, we need to maximize the cylinder scavenging characteristics so as to maximize the cylinder filling and extend the rpm band of the torque curve but once your have the collectors and headers primary designed to maximize the scavenging in your chosen and intended rpm range and run the collectors to a (X) to induce both increased scavenging and lower restriction to flow theres not much that a larger exhaust past that point can do badly but increase the noise levels while it should be rather obvious that a smaller than ideal exhaust will hurt the upper rpm band as it tends to be a restriction

yes if you have a smaller exhaust diam. it tends to act like an extended collector and increase low rpm torque at the cost OF being A restriction ONCE THE RPMS BUILD PAST A CERTAIN POINT.

having both collectors empty into an (X) pipe EFFECTIVELY instantly doubles the cross sectional area of the exhaust pulse and significantly reduces the return reflected pressure wave, almost making the collectors act as if its running without any restriction compared to a true dual exhaust IF the exhaust pipes are large enough to provide a very low restriction at that point

as I POINTED OUT ABOVE...

theres plenty of fluid dynamics math and research out there to show that the distances the exhaust travels between exhaust pulses and the diam. and length are easily calculated, and past that length the second previous pulse has little effect compared to the current and previous pulse energy and reflective wave

and lets not forget the cam timing displacement and intake port all effect the cylinder scavenging the headers can effectively provide also

http://www.engr.colostate.edu/~allan...ngth/pipe.html

http://www.rbracing-rsr.com/runnertorquecalc.html

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.headerdesign.com/

http://www.pontiacracing.net/js_header_length1.htm

http://www.slowgt.com/Calc2.htm#Header

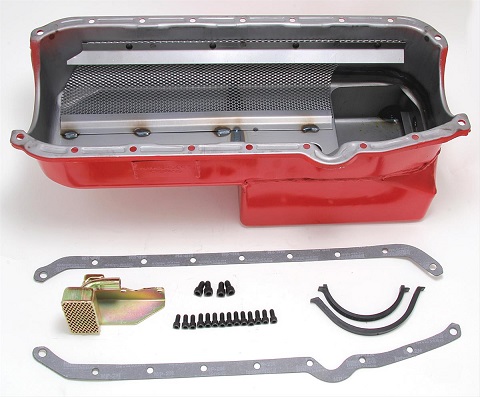

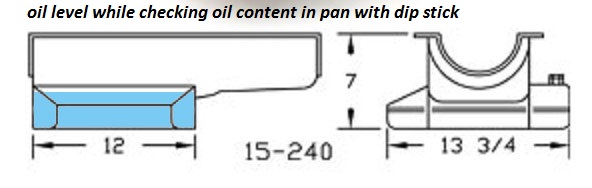

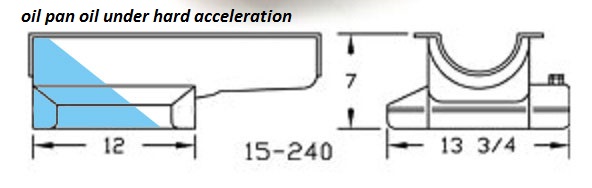

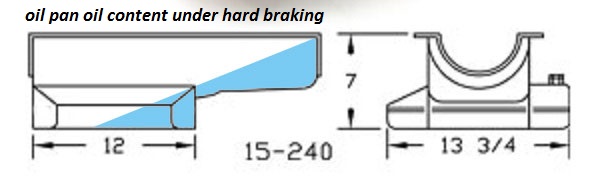

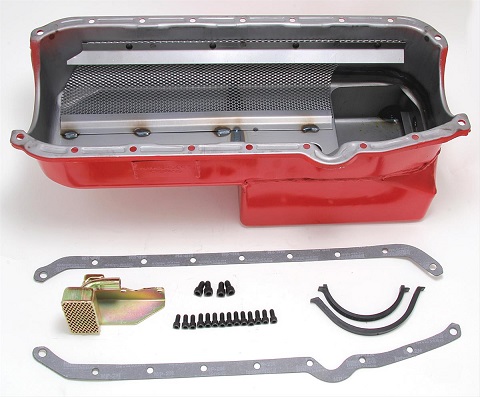

use a good 7-8 quart baffled oil pan, the added capacity and baffles add a good bit more durability

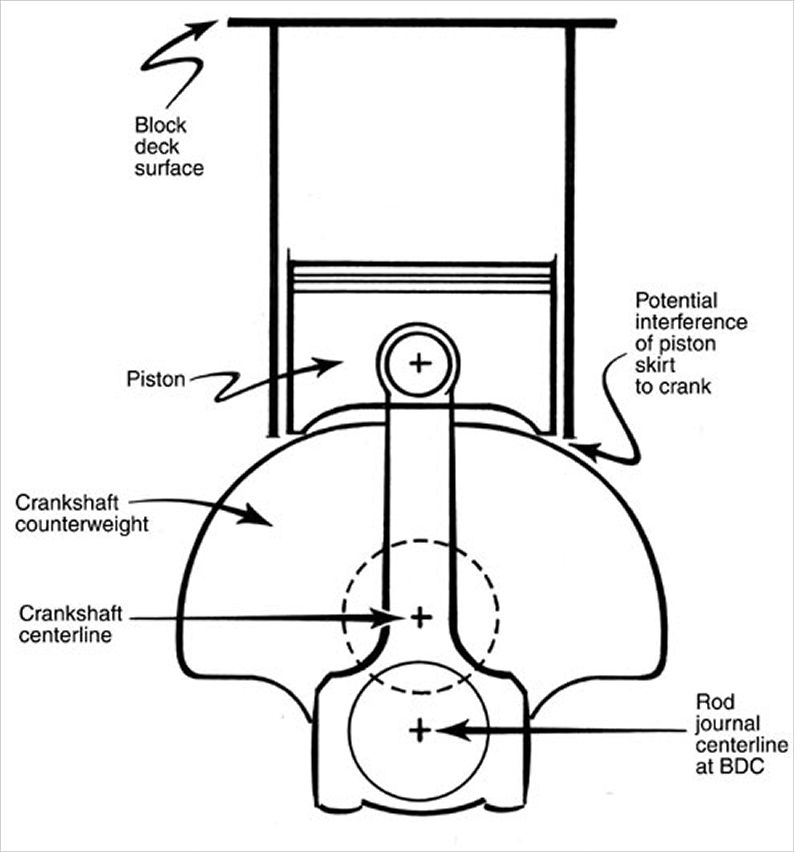

if you look very carefully at this canton oil pan youll notice the oil pan rail is dimpled outward to increase rod clearance on the longer 3.75" stroke cranks

most stock oil pans will require a bit of clearance work with a ball peen hammer near the oil pan rail, to move the wall near the seal rail where the gaskets seals,outward in a similar adjustment , to allow the longer stroker crank assembly to clear,but the MASSAGE WORK rarely requires more than a .080 outward adjustment on each side wall WHERE the rod cap rod bolts come the closest to the oil pan rail/wall, and most stock oil pans will accept that without issue!

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

Id say its a VERY bad idea personally , if you shop carefully you can find a reasonably priced 6- 7 quart oil pan that should help engine durability.

SHOP CAREFULLY ,

WHEN YOU GO TO BUY AN OIL PAN for your engine or transmission,

<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY,

AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

many guys ignore proven combos, because it may cost more than they want to spend, and either insist on using components they own currently or think they can buy far less expensively than the components, I know from experience will actually work.

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

http://www.shopmoroso.com/eb/catalog/navigationPath/1::Moroso Performance Products/1100001::Oil Pans/11005::Chevy Big Block, Gen VGen VI?resetOffset=true&entryId=catalog.productgroup.1110000111005&expand=true&menuId=main.menu

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

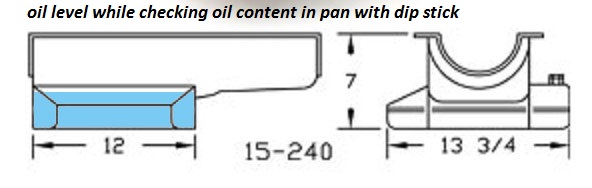

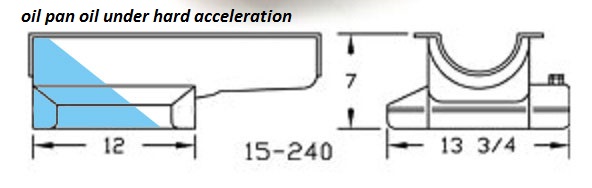

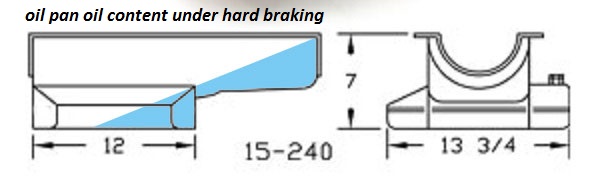

IF you've wondered why I suggest buying and using a well designed BAFFLED oil pan with 7-8 quart capacity its to prevent the oil from uncovering the oil pump pick-up under performance use.

without control baffles oil sloshes away from the oil pump pick-up

obviously you,ll want to ask specific questions as to the ,

ground clearance, starters that can be used,

oil filters, oil dip stick, location,

oil pan gasket matching both pan and lock used.

rear oil seal type,and frame and suspension clearance issues,

related to your car, before you purchase any oil pan

I think the hamburger oil pan is a better value At $242

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

http://garage.grumpysperformance.co...l-level-in-oil-pan-with-engine-running.11263/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-7231

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68206

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-64733

http://garage.grumpysperformance.co...es-engine-builders-magazine.11965/#post-57052

http://garage.grumpysperformance.co...te-filter-require-a-new-pump.3144/#post-16458

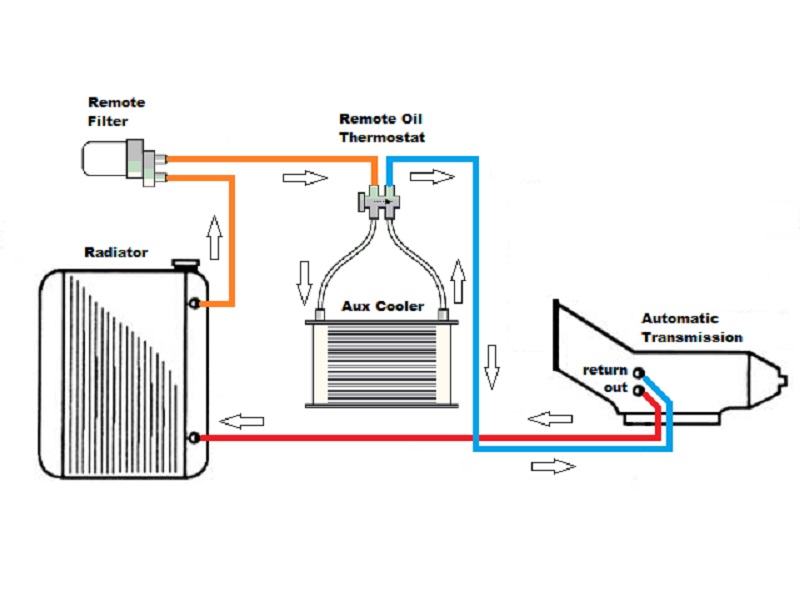

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-12473

http://garage.grumpysperformance.co...essure-bye-pass-circuit-works.3536/#post-9379

http://garage.grumpysperformance.com/index.php?threads/oil-system-basics.615/#post-1731

http://garage.grumpysperformance.com/index.php?threads/engine-oil-temps.296/#post-361

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

yeah it takes time and experience too get it done correctly but its just not that difficult to do with very little practice, you may also need to grind the block for rod clearance in some cases with some rods, but be aware that there are rods specifically designed to allow increased clearance that require little or now work to clear a stock block or oil pan

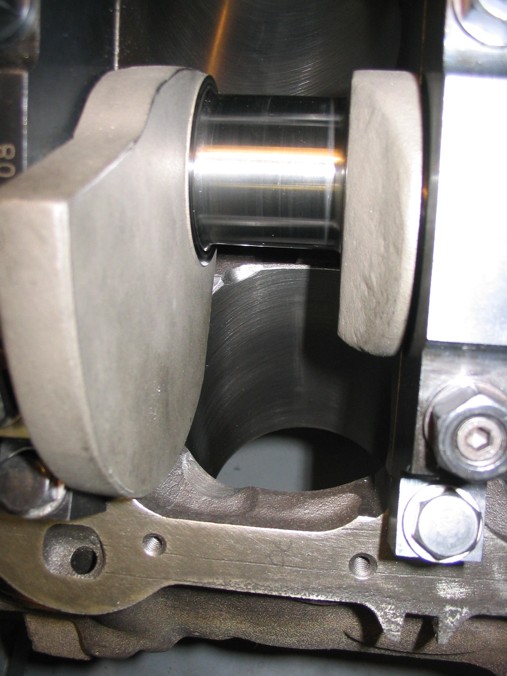

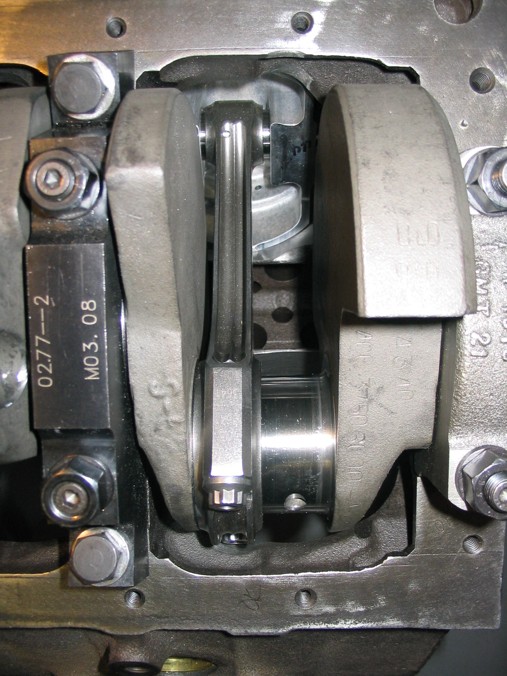

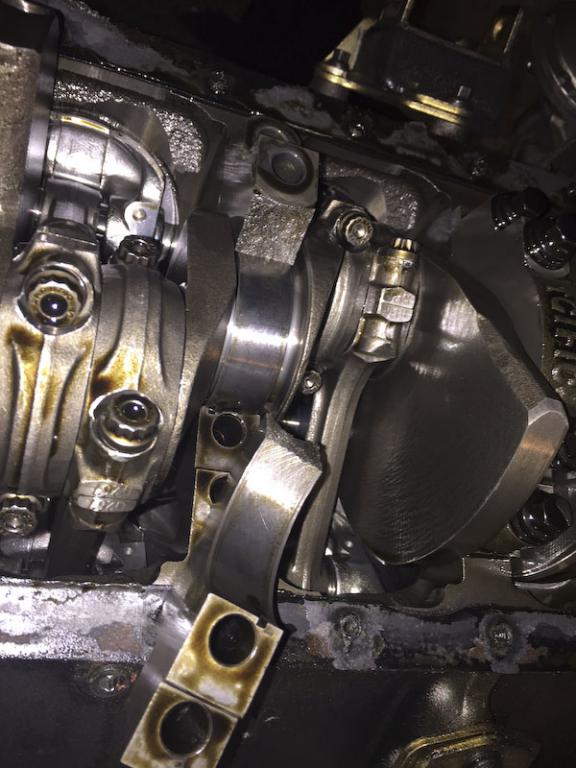

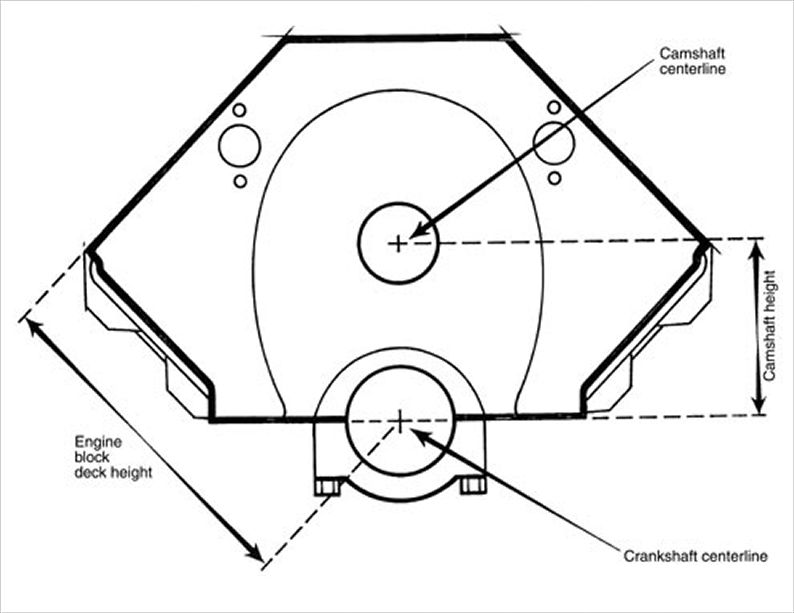

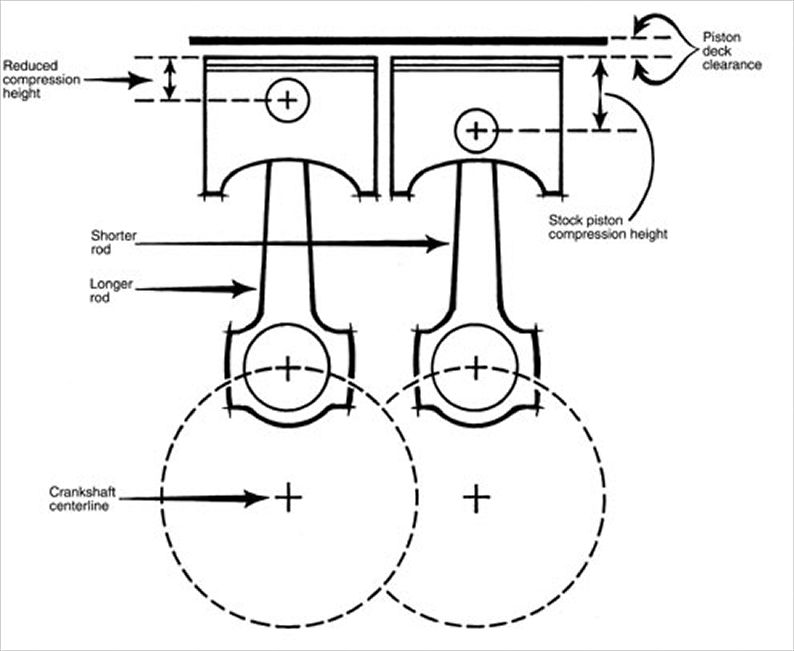

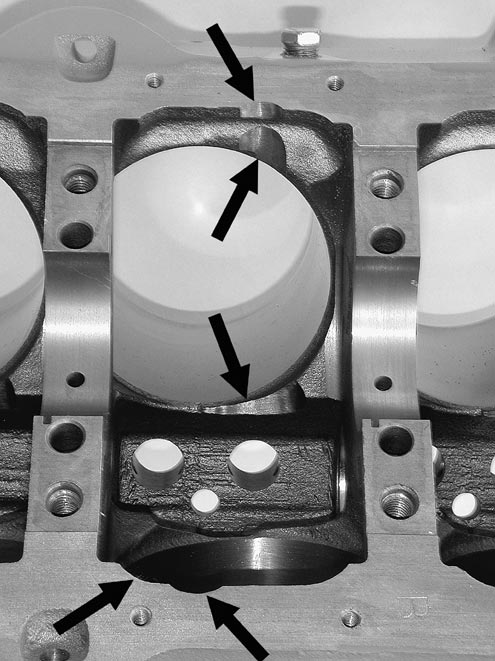

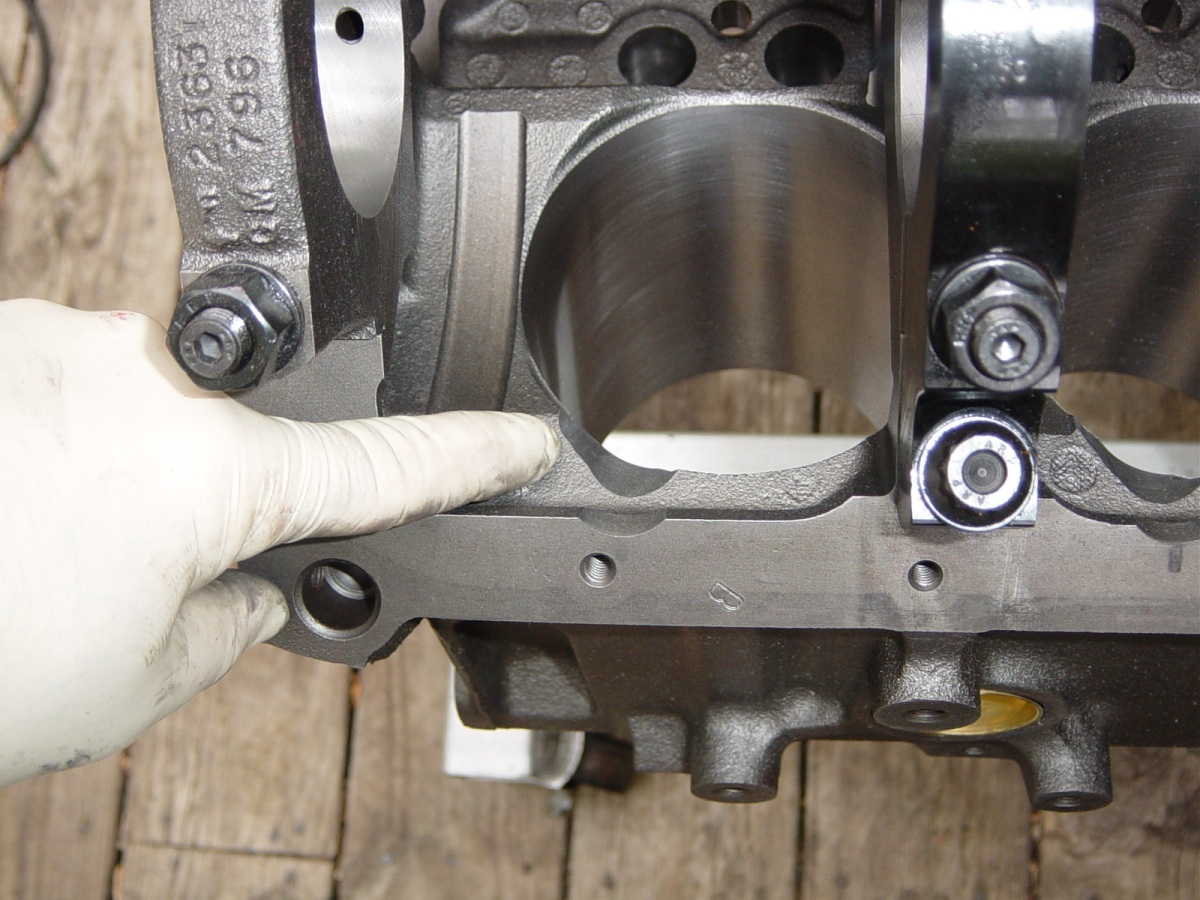

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

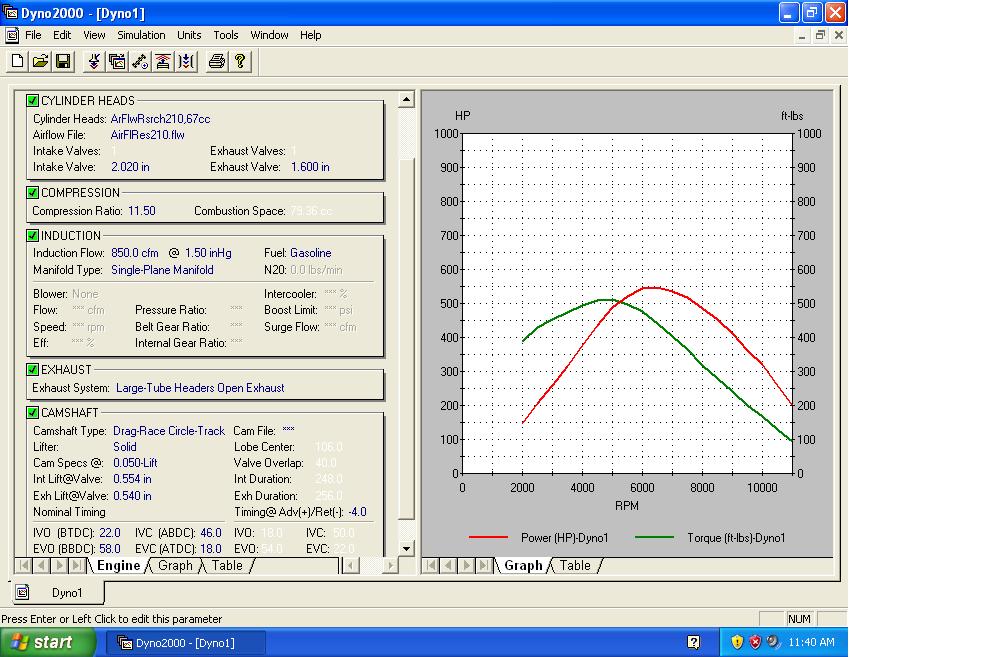

LETS ASSUME I WANT MY 383 TO MAKE MAX POWER IN THE 5000RPM-6300RPM BAND (mostly so I can run street gears and pump high test gas and a low maintenance hydraulic roller cam, and IM willing to sacrifice a good deal of street drive-ability to maximize my corvettes track potential)

using the above calculators we quickly find I should have about a 3 sq inch intake port cross sectional area, the exhaust should be about 39" long in the primary 1.825 diam,and about 18" -20" long in the collector, about 3"-3.5" diam.

a matching compression of about 10.5:1-11:1 and a cam in the 230-235 duration range at .050 lift, heads that have the same 3 sq inch port and flow about 280cfm this will tend to maximize the power at THAT rpm band, and ideally a 3.90:1-4.11:1 rear gear ratio and a 3000rpm-3500rpm stall converter

but that above will NOT work nearly as well as a smaller and less radical combo in the 1500rpm-4500rpm most cars spend 90% of their time in

its all a compromise and most people don,t realize how miserable that combo will make the daily driven car that rarely get above 4500rpm, where a smaller and longer exhaust would scavenge more effectively but give up some of the potential for max power when the cars raced

your 100% correct if you were looking to cruise at 2500rpm , the cams above will be a P.I.T.A. on a car designed mostly for mid rpm cruising, you could get good performance from them but the street manors in traffic will be less than ideal....certainly manageable but not exactly smooth

youll be far better off with something similar to these, if street manors and low to mid rpm cruising are a higher priority, but have a LONG talk with the manufacturer of your choice about your combo and expectations before selecting your cam and matching your combo gearing and compression, head lift restrictions and flow characteristics

http://www.tpis.com/index.php?module...draulic+Roller

ZZ-9 Hydraulic Roller:

Intake Exhaust This is an emission legal cam which makes

Advertised Duration 282/ 287 over 400HP with our CNC"D LT heads and

Duration at .050 212 /226 F-car headers. Great with an auto or six

Gross Lift .483/.520 speed.

Lobe Separation 112

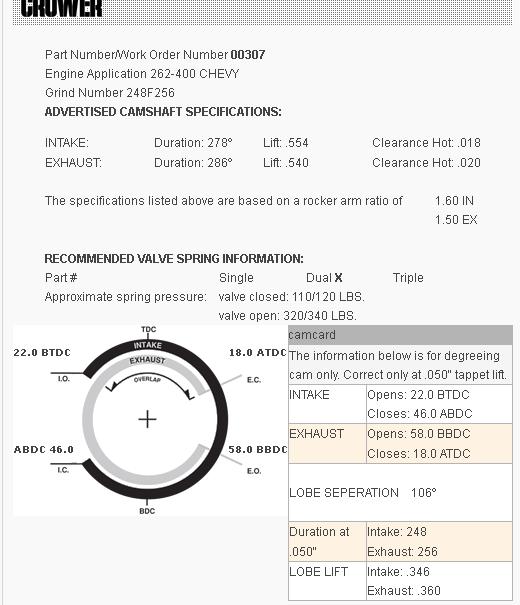

http://www.crower.com/misc/m_cat.shtml

http://www.crower.com/misc/cam_spec/...00466&x=38&y=9

http://www.cranecams.com/?show=brows...tType=camshaft

Im running that crane 119661 cam retarded 4 degrees BTW but detonation has not been a problem, remember that the coolant temp, air temps the engine sees, QUENCH distance, type of head gasket and its construction ,ignition advance,plug heat range,piston to bore clearance, exhaust valve seat width, and oil temp and pollishing your combustion chamber and piston domes, and your AIR/FUEL RATIO , and the effective DYNAMIC compression ratio, have a noticable effect on detonation

when you build an engine you generally have some idea as to its intended operational rpm range and the octane level of the fuel you want to use.

normal quality blended gasoline tends to produce its best power at about a 12.5:1 fuel/air ratio, and lowest exhaust emissions at about a 14.7:1 f/a ratio

the higher the effective compression ratio (up to about 13:1) the more torque you can expect to produce from an engine,if you use, high octane gas or race fuels, but the octane of the fuel currently available from pump gas drops the max effective dynamic compression ratio to about 8:1

obviously the components selected must work in the desired rpm and intended power range.

you need to select a cam duration and LSA , and static compression that BOTH matches the static compression ratio and your cars gearing so the effective dynamic compression ratio falls in that range, and intended rpm/power band

obviously if your willing to run race octane fuel and operate the engine at higher average rpms you can increase the cam duration and static compression ratio

BEFORE you buy connecting rods ,talk to SCAT tech guys, before you order connecting rods, and discuss what your doing,and your options and what parts you currently have and part compatibility.

the rods you link too use 3/8" rod bolts

either rod choice is a noticeable improvement over the stock connecting rods being rebuilt.

http://www.summitracing.com/parts/sca-25700p/overview/

here the rods (LINK BELOW)

I generally use on mild performance builds requiring 5.7" rods, but Id ask about the pistons because I generally use full float piston designs

the reason is that these are exceptionally strong rods with 7/16" arp rod bolts, the rod bolt size alone increases strength over 20% but the 200k psi steel is easily 30% stronger than most oem steel rod bolts, increasing the strength of the rotating assembly by easily 50%-70% over stock components

these rods use the stronger 7/16' and its a significantly stronger connecting rod, yes the cost is about $90 more a set, but thats peanuts in the total build cost and the strength is a good increase over both stock and the other rods

http://www.summitracing.com/parts/sca-2 ... /overview/

viewtopic.php?f=52&t=727

viewtopic.php?f=55&t=2718&p=12119&hilit=octane#p12119

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=82

viewtopic.php?f=71&t=741

viewtopic.php?f=52&t=4081&hilit=detonation

viewtopic.php?f=55&t=109

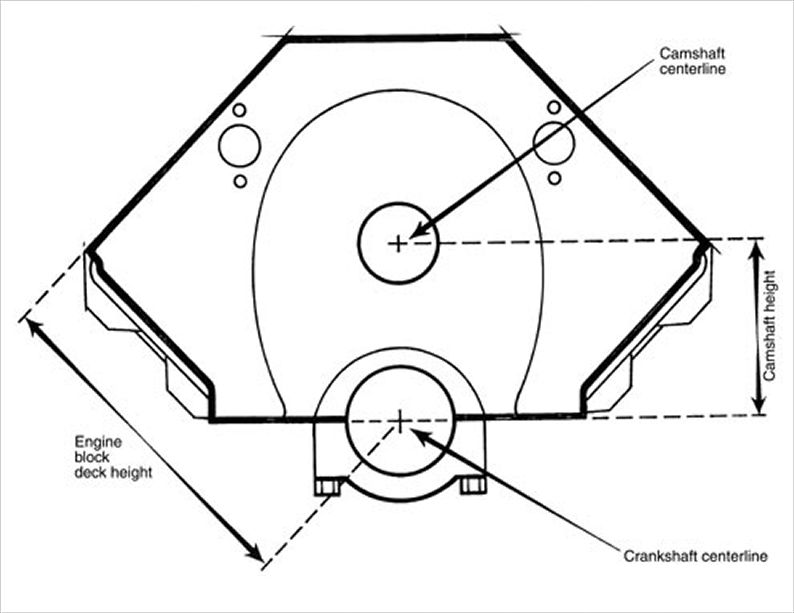

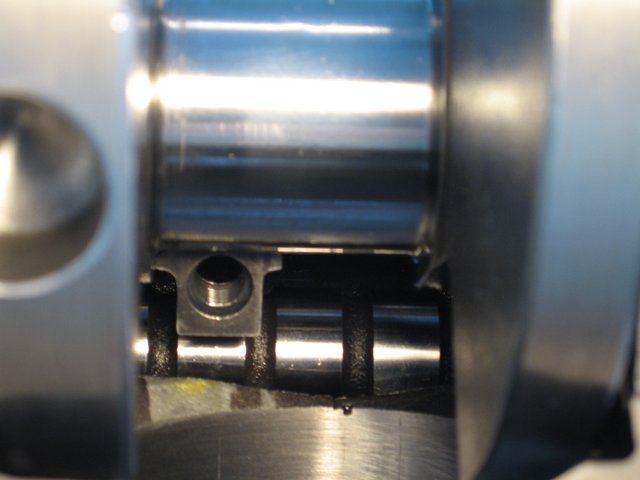

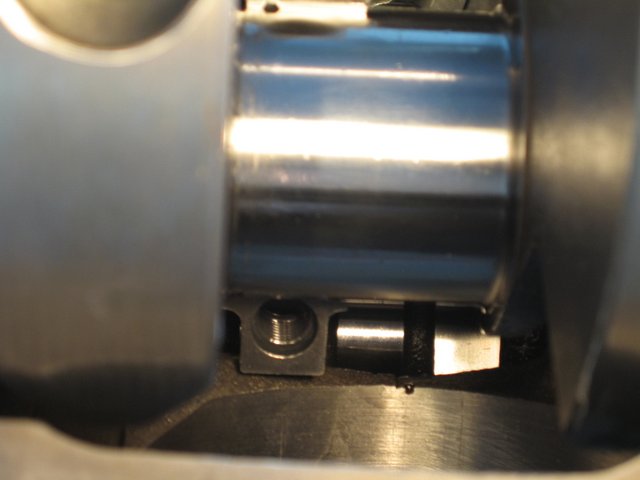

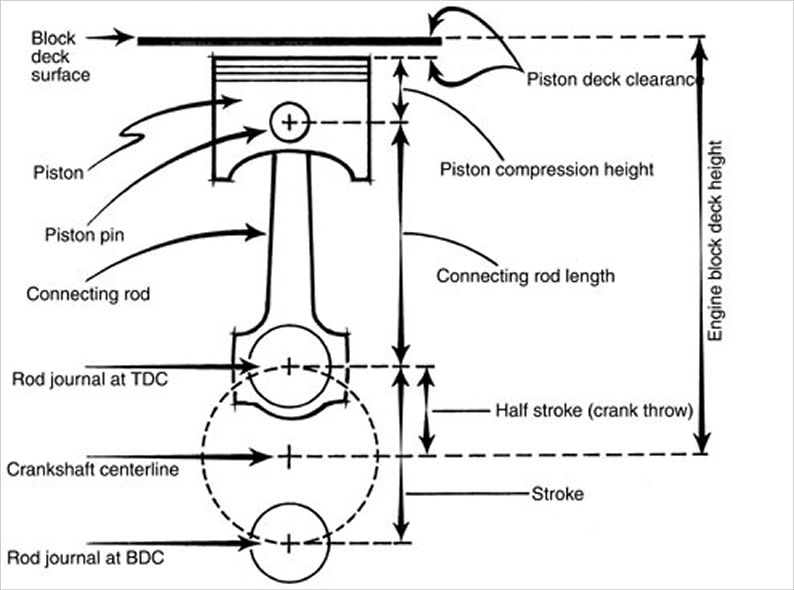

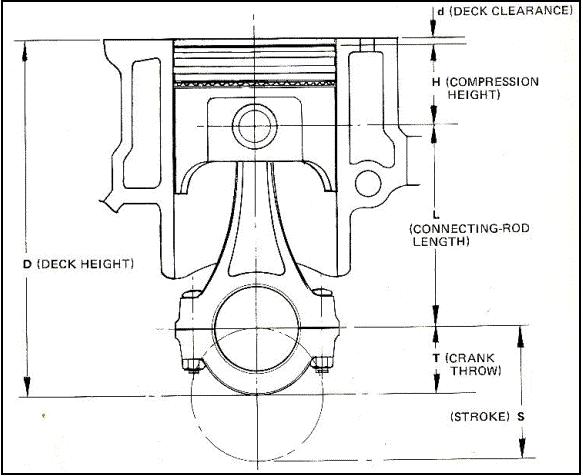

http://www.daytona-sensors.com/tech_tuning.html

yes the cam lobes can very easily contact the connecting rods when the cam index is out of its proper timing, on almost any chevy engine the cam lobe center lines will be spaced at between 103 and 116 degrees, with the piston at TDC theres SUPPOSED to be about .060 MINIMUM clearance between the connecting rod bolts and cam lobes, this is a mandatory clearance check point and a plastic cable tie can be used to gauge clearance, its best done on each individual connecting rod to cam lobe clearance point AFTER the cams been degreed into the block as each connecting rods being installed but Ive generally done it during the several trial assembly points where I check other clearances like block to connecting rod clearance.

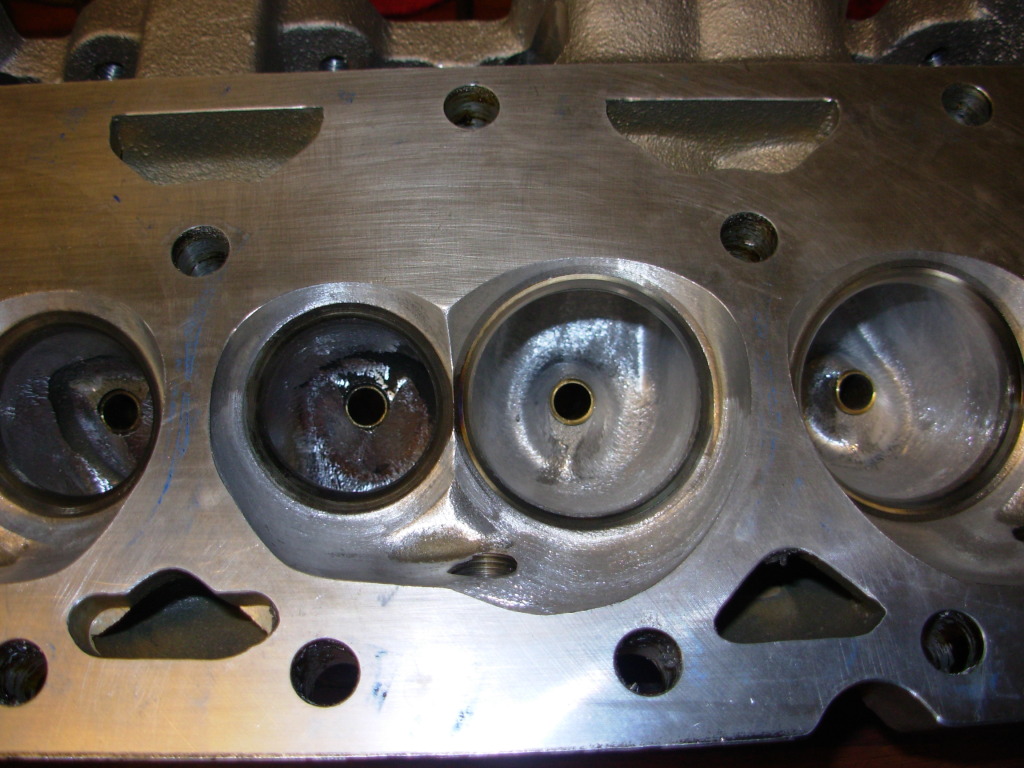

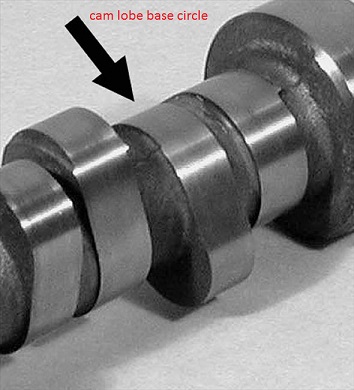

thats why on some stroker crank engines a SMALL BASE CIRCLE cam is used to MAXIMIZE CLEARANCE,between the two moving parts.

a cams lobe lift is the difference the lifter moves off the cams base circle between its base circle and its max lobe lift, thus a cam with a 1.1" diam base circle and a .400 lobe lift would have a , .400 lobe lift and if you had 1.5:1 ratio rockers a .600 valve lift, but if you wanted more clearance you could use a smaller base circle at .900, and a 400 lobe lift this would allow the connecting rod, to sweep by with an additional amount of cam lobe to connecting rod bolt clearance, the change in diameter generally requires a swap to a stronger cam billet core . vs cheaper cast core,to maintain cam strength

removing the rod caps during clearance checks while building your 383 ,does seem to allow you to see the clearance issues a bit easier

a fairly well known and rather successful 383 sbc combo thats fairly economical to build is The scat 9000 series crank for 6 inch rods will internally balance little problem,

The scat I beams with 7/16 bolts are the way to go, the Mahle or Wiseco, J&E, TRW and TRICKFLOW pistons all work with good results.

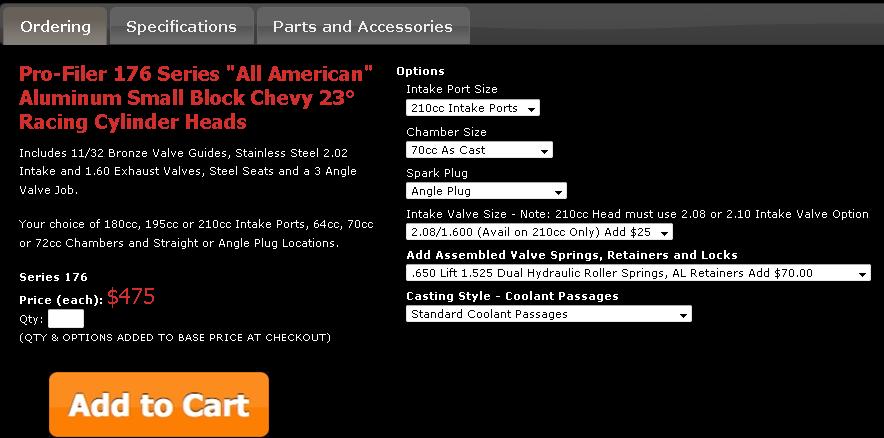

The Heads you select should flow at least 250 cfm at .600 lift minimum,

(250 CFM AT .500 lift is even better) if your using an dual plane Air Gap intake the Dart SHP 180 or 180cc AFR heads are a good choice, a 750cfm-to-850 cfm, works well.

If your using a single plane intake go with the Dart SHP 200, or BRODIX 200cc runner or 195 AFR heads, provided the cars drive train and gearing match the compression and cam timing,

for most applications a cam in the 230-240 intake duration at .050 lift and a fairly tight 106-108 LSA with a 9.5:1 -10.5:1 compression will meet the requirements,

generally youll want a dynamic compression near 8:1 and a quench distance in the .038-.044 range

the cam rotates while indexed by the timing chain at 1/2 crank shaft speed , there are connecting rods designed to provide additional clearance.

BTW I JUST TOOK THE TIME TO RE_READ THIS THREAD< ITS A VIRTUAL CLASS IN ENGINE ASSEMBLY THAT SHOULD BE READ BY EVERY LAST MEMBER

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

READ THESE THREAD's

and don,t skip the sub linked info

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-57940

http://garage.grumpysperformance.com/index.php?threads/redline.343/

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...s-to-casting-numbers-and-info.632/#post-53467

http://garage.grumpysperformance.com/index.php?threads/ballancing-the-components.141/#post-5391

THESE MAY HELP

http://www.airflowresearch.com/super-chevy-nov-2013-195cc-sbc.php

http://www.airflowresearch.com/super-chevy-sep-2013-195cc-sbc.php

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

http://airflowresearch.com/articles/article152/A-P1.html

http://airflowresearch.com/articles/article085/A-P1.htm

http://airflowresearch.com/articles/article031/A-P1.htm

http://www.airflowresearch.com/articles/SBC/lt1shootout/lt1shootout.php

theres at least a few hours of very worth while , and quite useful reading in this thread and links that will prevent you wasting time and money, keep in mind the sub links contain a huge wealth of additional info youll need

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

many guys ignore proven combos, because it may cost more than they want to spend, and either insist on using components they own currently or think they can buy far less expensively than the components, I know from experience will actually work.

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

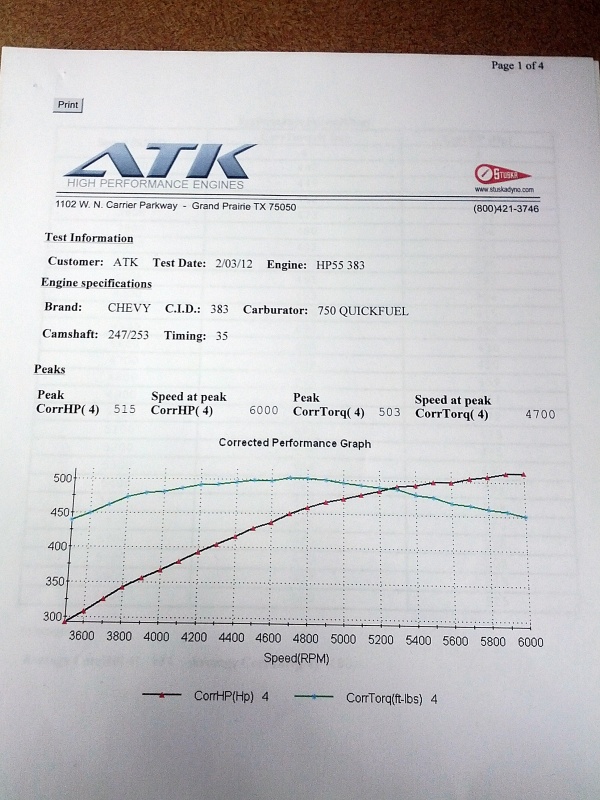

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

read the links and sub links below

a day or so spent doing reading and research,

(reading links and threads)

will frequently save you thousands of dollars and weeks of wasted work.

if you want a fast dependable car you will need to either do the research required to know exactly how and why things should work, or pay someone else to do the work that has taken that time and effort.

high volume oil pumps use is far more beneficial than high peak pressure in oil pumps,

remember peak pressure only happens at higher rpms and tests show,

no benefits in long term engine durability,

if peak oil pressure exceeds 65 psi or higher.

Small Block Chevy Balanced Rotating Assembly

Small Block Chevy Balanced Rotating Assembly. Many Crank, Rod, Piston and Ring Configurations Available. Priced From: $2,350. Custom Balanced by Scott Shafiroff Race Engines and Components.

how your oil pumps pressure bye-pass circuit works,

theres seems to be a lot of mis-information about , how the oil pump regulates its pressure curve, and the related subject of shimming oil pump springs and how your oil pumps pressure bye-pass circuit works. PRESSURE, that you see displayed on the oil pressure gauge is a measure of the...

garage.grumpysperformance.com

Oil Viscosity Question

You know how some newer motors require lighter weight oils such as my DD calls for 0w20 and my wife’s car needs 5w20. She has a load of miles on that car and has a history of letting her car go dry on a few occasions. * I made her be responsible to check and add her own oil in case anything...

garage.grumpysperformance.com

basic info on your v8 lube system

now think it thru, HERES SOME USEFUL INFO, that might help in this thread and the sub links http://garage.grumpysperformance.com/index.php?threads/crank-case-blow-bye-and-related-info.16790/ the first thing Id be doing here, if your not getting a strong oil flow at each rocker while your turn...

garage.grumpysperformance.com

oil pump bye-pass test issues

{quote]=AZUjMJsp1UQe6RLMcu7jViEbuqx87Z2V62Q8VlrlmAbAoCV84hOjxEwt44Za6O_Kr5lnWFVNWx2dN26wS7DK2M2L52os3SWipY1lqPXVHdyBjXSOuunUrv1XJYJ8Zp7ebPS1LmW3WYny2HLXDIuwxdzAY9V9fUAdjTQBl9CPs5H7iQ&__tn__=-UC%2CP-y-R']Carl Hinkson ptsSnordoe8Jgu155e21 i la5h93:u8mPac4cu2tM0nt t4 · The 383 I dynoed with...

garage.grumpysperformance.com

READ THESE LINK'S OVER CAREFULLY TWICE

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-55314

http://garage.grumpysperformance.co...lap-on-factory-headers.3155/page-2#post-66722

some of the newer stroker rods do in most cases let you avoid the use of a smaller base circle cam, but because there's dozens of different connecting rod designs and different types of rods and rod bolts clearances vary a good deal,

as alway you'll need to check & verify the clearances, once the cam is degreed in, and rods are installed in your particular engine.

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods- Step by Step How-To Instructions, Images, Examples, and Checklists

Chevy Small Block Cranks, Rods, and Piston Guide

Chevy Small Block Cranks, Rods, and Piston Guide- How to Build Max Performance Chevy Small Blocks on a Budget

383 Stroker Small Block Chevy - Car Craft Magazine

A 383 Stroker Small Block Chevy is analyzed, assembled and dynoed. Follow along and get every fact and trick you wanted to know about a 383 build. - Car Craft Magazine

should you re-use stock connecting rods?

I get asked all the time, "should you re-use those stock rods, when I rebuild my 350 or when I build my 383 stroker" or "Ive got a 325hp 396 BBC,Im rebuilding, should I upgrade or rebuild the connecting rods" most sbc and many BBC stock rods are designed to be cheap, and dependable in engines...

garage.grumpysperformance.com

http://www.jegs.com/i/Edelbrock/350/22015/10002/-1#

https://garage.grumpysperformance.com/index.php?threads/redline.343/#post-419

http://www.hotrod.com/how-to/engine...-assembly-for-a-stroker-383-chevrolet-engine/

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

(hit cancel the info appears)

http://www.themotorbookstore.com/resmchstvi.html

http://www.amazon.com/Lingenfelter-Modi ... 82&sr=8-11"]Amazon.com: John Lingenfelter on Modifying Small-block Chevy Engines (0075478012381): John Lingenfelter: Books

http://www.amazon.com/Smokey-Yunicks-Po ... 809&sr=8-2"]Amazon.com: Smokey Yunick's Power Secrets (9780931472060): Smokey Yunick: Books

http://www.summitracing.com/popup/calcsandtools/stroker-combinations

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

(hit cancel the info appears)

http://www.airflowresearch.com/super-chevy-apr-2010-210cc-sbc.php

http://www.hotrod.com/how-to/engine...-assembly-for-a-stroker-383-chevrolet-engine/

buy these book/video's its probably the best money value you can get, you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

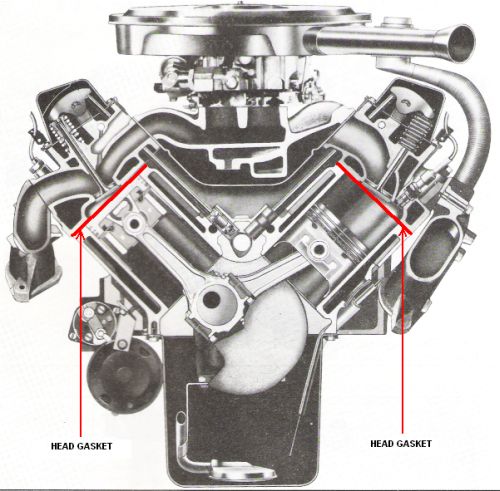

milling stroker clearance on 350/383

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

http://www.superchevy.com/how-to/engine ... m#cxrecs_s

http://www.superchevy.com/how-to/engine ... shaft.html

http://www.flatlanderracing.com/probe-sportsbc04.html

http://www.maintenanceresources.com/ref ... alance.htm

http://www.circletrack.com/enginetech/c ... rminology/

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.summitracing.com/popup/calcsandtools/stroker-combinations

http://garage.grumpysperformance.co...ty-thats-key-in-building-a-good-engine.11682/

http://www.chevyhiperformance.com/techa ... ine_build/

notice its right where the roller cams lobe design maximized the extra air flow potential that is the most effective flow area during the whole valve flow curve

and yes it frequently helps to match a roller cam to roller rockers as the reduced friction further helps the engines durability and ability to easily cope with faster valve train component acceleration, that tends to reduce heat and wear.

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches, thus it makes a great deal of sense to push the valve lift a bit over .500, and have an intake port that is at least 3.2 square inches in cross sectional area, if you want to maximize flow on a 2.02" intake valve

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

SB-Chevy 283-400 Hydraulic Roller Camshaft Kit

Duration Advertised 296° Intake/300° Exhaust

Duration @ .050'' 234° Intake/238° Exhaust

Lift @ Valve .539'' Intake/.548'' Exhaust

Lift @ Cam .359'' Intake/.365'' Exhaust

Lobe Separation Angle 112°

Intake Centerline 107°

Intake Timing @ .050" Open 10° BTDC

Close 44° ABDC

Exhaust Timing @ .050" Open 56° BBDC

Close 2° ATDC

A FEW HOURS OR EVEN DAYS ,SPENT READING LINKS AND SUB LINKS CAN SAVE YOU MONTHS OF WORK AND THOUSANDS OF DOLLARS

http://chevyhighperformance.automotive. ... index.html

IVE used similar cam designs (serration/lift/)in the past with excellent results and $709 for the cam, roller lifters and push rods is a good value, naturally the REST of the components and the cars drive train and the cars intended use will effect the choice

the only thing that makes me hesitate is the quality of edelbrocks cam cores.AS most IVE SEEN are not billet but cast cores which are less durable and on a 383, PLUS you want a small base circle cam......for rotating assembly clearance issues ,one reason I usually suggest this cam in similar combos

one very common mistake is selecting a cam duration, rear gear ratio, compression ratio or set of heads that can,t operate with the other components in the same power band efficiently

the best heads matched to a restrictive intake or the wrong cam will result in a DOG just as surely as a great intake and crappy heads with low compression, or any of a few dozen other miss-matched parts.

if you want impressive bragging level hp you need to design a combo capable of operating efficiently above 5800-6000rpm but thats NOT necessarily going to be a good street engine

example

horsepower =torque times rpm divided by 5252

so 370ft lbs at 3700rpm=261hp

but 370ft lbs at 5700rpm=401hp

and the heads , rear gear ratio,and cam that operate effectively at 3700rpm wont be the same as those matched to 5700rpm, you might also keep in mind youll make approximately 1.1-1.2 hp per cubic inch of displacement and piston speeds below 4200fpm are strongly recommended for long term durability, and hydraulic lifter valve trains seldom do well over 6300rpm, and about 10.2:1 static compression is about the max crappy pump gas will tolerate IF MATCHED TO THE CORRECT COMBO

theres a HUGE MIS -CONCEPTION out there that its always the larger port cross sectional area on any engine that lacks low speed torque, thats responsible for a loss of low speed torque, in most cases it is the combo of a larger than ideal for the application cam duration and a single plane intake, and larger and shorter headers or a restrictive exhaust having been selected ,NOT the cylinder heads port size.

YES cylinder head port cross section will effect the port velocity, but in most cases if your building a performance street cars engine your better off going slightly larger on port size and slightly conservative on the cam duration.

READ THESE LINKS

http://airflowresearch.com/articles/article093/A-P1.htm

IF your having issues with low rpm torque with a 383-406 SBC youve built ask yourself some questions

WHAT CAM ARE YOU USING?

WHATS YOUR IGNITION ADVANCE CURVE?

WHATS YOUR FUEL/AIR RATIO AT PEAK TORQUE?

WHATS YOUR FUEL PRESSURE EVERY 1000,RPM

WHATS YOUR HEADERS BACK PRESSURE AT PEAK TORQUE?

WHAT INTAKE MANIFOLD ARE YOU USING?

whats the PLENUM VACUUM READ AT 2500RPM?, 4500RPM? 6000RPM?

ARE YOU RUNNING A WELL MATCHED REAR GEAR RATIO AND CONVERTER STALL SPEED?

DOES YOUR DRIVE TRAIN GEARING AND TIRE SIZE MATCH THE ENGINES POWER CURVE?

combining the info posted a 383 sbc has 47.8 cubic inches per cylinder divided by 2.02=23.7 on the chart above, so youll find cams in the correct duration range having a tight 105-108 lSA most efficient at filling the cylinders in many combos,

you WILL find these threads and sub linked info BELOW VERY useful, so skipping over them is not the best route to take here, yes I know you are most likely not into extensive reading, its worth the time

SAFE piston speeds are best restricted to 4000fpm for stock components and 4500fpm for the better common aftermarket components

viewtopic.php?f=53&t=343&p=16772&hilit=redline#p16772

viewtopic.php?f=53&t=341

viewtopic.php?f=54&t=2187&p=5890#p5890

http://garage.grumpysperformance.com/index.php?threads/sbc-spacer-bearings.3058/

http://www.airflowresearch.com/articles ... 5/A-P1.htm

http://www.airflowresearch.com/articles ... 1/A-P1.htm

http://www.skipwhiteperformance.com/det ... 3831P-1230

http://www.chevymania.com/tech/383.htm

viewtopic.php?f=71&t=741&p=1048#p1048

viewtopic.php?f=53&t=8685&p=30565#p30565

http://www.airflowresearch.com/articles ... A16-P1.htm

http://www.hotrod.com/techarticles/engi ... ewall.html

http://www.cranecams.com/index.php?s...61&lvl=2&prt=5

http://www.jegs.com/i/Crane/270/119661/10002/-1#

http://www.jegs.com/webapp/wcs/store...hTerm=11532-16

Grind Number: HR-230/359-2S-12.90 IG

Operating Range: 3000-6500 RPM

Duration Advertised: 292° Intake / 300° Exhaust

Duration @ .050'' Lift: 230° Intake / 238° Exhaust

Valve Lift w/1.5 Rockers: .539'' Intake / .558'' Exhaust

Lobe Separation Angle: 112°

Max Lift Angle: 107° ATDC Intake / 117° BTDC Exhaust

Open/Close @.050'' Cam Lift: Intake - 8° BTDC (opens) / 42° ABDC (closes)

Exhaust - 56° BBDC (opens) / 2° ATDC (closes)

with either cam youll want a 3000rpm stall converter , about 10.5:1 cpr and a 3.73-4.11:1 rear gear to maximize the performance and a low restriction exhaust, headers and a high flow intake

IM currently running the crane 119661 cam in MY 383 and Ive tested over a dozen cams in that engine, so if its a street/strip combo ID suggest going that route, SMALL BASE CIRCLE AND BILLET CORE.....yeah! YOU GET WHAT YOU PAY,FOR and DURABILITY FOR PARTS TENDS TO COST MORE

__________________

these related links and their sub links will help a good deal IF YOU TAKE THE TIME TO READ THRU THEM

YES IT WILL TAKE HOURS TO READ THRU THE LINKED INFO...IT WILL ALSO SAVE YOU HUNDREDS OF DOLLARS AND WEEKS OF WORK,

YOU CAN LEARN A GREAT DEAL, ABOUT COMBOS THAT WORK, IF YOU READ THRU ALL THE LINKS AND SUB LINKED INFO BELOW

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.brodix.com/heads/tonydyno.html

http://www.sporttruck.com/howto/40619/index.html

viewtopic.php?f=50&t=1249

viewtopic.php?f=51&t=125

viewtopic.php?f=50&t=1859

http://bracketmasters.com/small_block_s ... 383_cu.htm

http://www.summitracing.com/parts/SUM-150100/

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://www.vsihp.com/library/CleviteEng ... sGuide.pdf

http://www.chevyhiperformance.com/tech/ ... ewall.html

http://www.carcraft.com/techarticles/cc ... index.html

http://bracketmasters.com/small_block_s ... 383_cu.htm

http://www.compcams.com/catalog/COMP201 ... 010_10.pdf

http://garage.grumpysperformance.co...ber-of-people-that-don-t-use-resources.12125/

its really refreshing to see someone take the effort to do those clearance checks that are so critical to long term durability

for those just starting on their 383 build ups heres some very useful linked info

http://www.hotrod.com/howto/69883_strok ... to_07.html

http://www.superchevy.com/technical/eng ... index.html

http://www.carcraft.com/techarticles/cc ... index.html

BIGGER is NOT always BETTER, and since both the header primary diam. and length and the collectors , which have a huge effect on the resulting scavenging can,t be changed as we change engine rpms, we need to maximize the cylinder scavenging characteristics so as to maximize the cylinder filling and extend the rpm band of the torque curve but once your have the collectors and headers primary designed to maximize the scavenging in your chosen and intended rpm range and run the collectors to a (X) to induce both increased scavenging and lower restriction to flow theres not much that a larger exhaust past that point can do badly but increase the noise levels while it should be rather obvious that a smaller than ideal exhaust will hurt the upper rpm band as it tends to be a restriction

yes if you have a smaller exhaust diam. it tends to act like an extended collector and increase low rpm torque at the cost OF being A restriction ONCE THE RPMS BUILD PAST A CERTAIN POINT.

having both collectors empty into an (X) pipe EFFECTIVELY instantly doubles the cross sectional area of the exhaust pulse and significantly reduces the return reflected pressure wave, almost making the collectors act as if its running without any restriction compared to a true dual exhaust IF the exhaust pipes are large enough to provide a very low restriction at that point

as I POINTED OUT ABOVE...

theres plenty of fluid dynamics math and research out there to show that the distances the exhaust travels between exhaust pulses and the diam. and length are easily calculated, and past that length the second previous pulse has little effect compared to the current and previous pulse energy and reflective wave

and lets not forget the cam timing displacement and intake port all effect the cylinder scavenging the headers can effectively provide also

http://www.engr.colostate.edu/~allan...ngth/pipe.html

http://www.rbracing-rsr.com/runnertorquecalc.html

http://victorylibrary.com/mopar/header-tech-c.htm

http://www.headerdesign.com/

http://www.pontiacracing.net/js_header_length1.htm

http://www.slowgt.com/Calc2.htm#Header

use a good 7-8 quart baffled oil pan, the added capacity and baffles add a good bit more durability

if you look very carefully at this canton oil pan youll notice the oil pan rail is dimpled outward to increase rod clearance on the longer 3.75" stroke cranks

most stock oil pans will require a bit of clearance work with a ball peen hammer near the oil pan rail, to move the wall near the seal rail where the gaskets seals,outward in a similar adjustment , to allow the longer stroker crank assembly to clear,but the MASSAGE WORK rarely requires more than a .080 outward adjustment on each side wall WHERE the rod cap rod bolts come the closest to the oil pan rail/wall, and most stock oil pans will accept that without issue!

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

Id say its a VERY bad idea personally , if you shop carefully you can find a reasonably priced 6- 7 quart oil pan that should help engine durability.

SHOP CAREFULLY ,

WHEN YOU GO TO BUY AN OIL PAN for your engine or transmission,

<AND ASK LOTS OF QUESTIONS ABOUT WHAT WILL FIT YOUR CAR CORRECTLY,

AND ASK FOR SUGGESTIONS ON MATCHING COMPONENTS OR PARTS THAT WON,T FIT

many guys ignore proven combos, because it may cost more than they want to spend, and either insist on using components they own currently or think they can buy far less expensively than the components, I know from experience will actually work.

MILODON,

http://www.milodon.com/

CHAMP

http://www.champpans.com/products/c/oil-pans/

CANTON,

https://www.cantonracingproducts.com/category/1501/Chevy-SS--Road-Race-Oil-Pans/1.html

MOROSO

http://www.moroso.com/

http://www.shopmoroso.com/eb/catalog/navigationPath/1::Moroso Performance Products/1100001::Oil Pans/11005::Chevy Big Block, Gen VGen VI?resetOffset=true&entryId=catalog.productgroup.1110000111005&expand=true&menuId=main.menu

AVIAID

http://aviaid.com/shopsite_sc/store/html/ws_oilpns_sbc.html

STEFS

http://www.stefs.com/products/oilpans/circletrackwetsump.htm

HAMBURGERPERFORMANCE

http://www.hamburgersperformance.com/

KEVKO

https://kevko.myshopify.com/

IF you've wondered why I suggest buying and using a well designed BAFFLED oil pan with 7-8 quart capacity its to prevent the oil from uncovering the oil pump pick-up under performance use.

without control baffles oil sloshes away from the oil pump pick-up

obviously you,ll want to ask specific questions as to the ,

ground clearance, starters that can be used,

oil filters, oil dip stick, location,

oil pan gasket matching both pan and lock used.

rear oil seal type,and frame and suspension clearance issues,

related to your car, before you purchase any oil pan

I think the hamburger oil pan is a better value At $242

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

http://garage.grumpysperformance.co...l-level-in-oil-pan-with-engine-running.11263/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/#post-7231

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68206

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-64733

http://garage.grumpysperformance.co...es-engine-builders-magazine.11965/#post-57052

http://garage.grumpysperformance.co...te-filter-require-a-new-pump.3144/#post-16458

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-12473

http://garage.grumpysperformance.co...essure-bye-pass-circuit-works.3536/#post-9379

http://garage.grumpysperformance.com/index.php?threads/oil-system-basics.615/#post-1731

http://garage.grumpysperformance.com/index.php?threads/engine-oil-temps.296/#post-361

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

yeah it takes time and experience too get it done correctly but its just not that difficult to do with very little practice, you may also need to grind the block for rod clearance in some cases with some rods, but be aware that there are rods specifically designed to allow increased clearance that require little or now work to clear a stock block or oil pan

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

LETS ASSUME I WANT MY 383 TO MAKE MAX POWER IN THE 5000RPM-6300RPM BAND (mostly so I can run street gears and pump high test gas and a low maintenance hydraulic roller cam, and IM willing to sacrifice a good deal of street drive-ability to maximize my corvettes track potential)

using the above calculators we quickly find I should have about a 3 sq inch intake port cross sectional area, the exhaust should be about 39" long in the primary 1.825 diam,and about 18" -20" long in the collector, about 3"-3.5" diam.

a matching compression of about 10.5:1-11:1 and a cam in the 230-235 duration range at .050 lift, heads that have the same 3 sq inch port and flow about 280cfm this will tend to maximize the power at THAT rpm band, and ideally a 3.90:1-4.11:1 rear gear ratio and a 3000rpm-3500rpm stall converter

but that above will NOT work nearly as well as a smaller and less radical combo in the 1500rpm-4500rpm most cars spend 90% of their time in

its all a compromise and most people don,t realize how miserable that combo will make the daily driven car that rarely get above 4500rpm, where a smaller and longer exhaust would scavenge more effectively but give up some of the potential for max power when the cars raced

your 100% correct if you were looking to cruise at 2500rpm , the cams above will be a P.I.T.A. on a car designed mostly for mid rpm cruising, you could get good performance from them but the street manors in traffic will be less than ideal....certainly manageable but not exactly smooth

youll be far better off with something similar to these, if street manors and low to mid rpm cruising are a higher priority, but have a LONG talk with the manufacturer of your choice about your combo and expectations before selecting your cam and matching your combo gearing and compression, head lift restrictions and flow characteristics

http://www.tpis.com/index.php?module...draulic+Roller

ZZ-9 Hydraulic Roller:

Intake Exhaust This is an emission legal cam which makes

Advertised Duration 282/ 287 over 400HP with our CNC"D LT heads and

Duration at .050 212 /226 F-car headers. Great with an auto or six

Gross Lift .483/.520 speed.

Lobe Separation 112

http://www.crower.com/misc/m_cat.shtml

http://www.crower.com/misc/cam_spec/...00466&x=38&y=9

http://www.cranecams.com/?show=brows...tType=camshaft

Im running that crane 119661 cam retarded 4 degrees BTW but detonation has not been a problem, remember that the coolant temp, air temps the engine sees, QUENCH distance, type of head gasket and its construction ,ignition advance,plug heat range,piston to bore clearance, exhaust valve seat width, and oil temp and pollishing your combustion chamber and piston domes, and your AIR/FUEL RATIO , and the effective DYNAMIC compression ratio, have a noticable effect on detonation

when you build an engine you generally have some idea as to its intended operational rpm range and the octane level of the fuel you want to use.

normal quality blended gasoline tends to produce its best power at about a 12.5:1 fuel/air ratio, and lowest exhaust emissions at about a 14.7:1 f/a ratio

the higher the effective compression ratio (up to about 13:1) the more torque you can expect to produce from an engine,if you use, high octane gas or race fuels, but the octane of the fuel currently available from pump gas drops the max effective dynamic compression ratio to about 8:1

obviously the components selected must work in the desired rpm and intended power range.

you need to select a cam duration and LSA , and static compression that BOTH matches the static compression ratio and your cars gearing so the effective dynamic compression ratio falls in that range, and intended rpm/power band

obviously if your willing to run race octane fuel and operate the engine at higher average rpms you can increase the cam duration and static compression ratio

BEFORE you buy connecting rods ,talk to SCAT tech guys, before you order connecting rods, and discuss what your doing,and your options and what parts you currently have and part compatibility.

the rods you link too use 3/8" rod bolts

either rod choice is a noticeable improvement over the stock connecting rods being rebuilt.

http://www.summitracing.com/parts/sca-25700p/overview/

here the rods (LINK BELOW)

I generally use on mild performance builds requiring 5.7" rods, but Id ask about the pistons because I generally use full float piston designs

the reason is that these are exceptionally strong rods with 7/16" arp rod bolts, the rod bolt size alone increases strength over 20% but the 200k psi steel is easily 30% stronger than most oem steel rod bolts, increasing the strength of the rotating assembly by easily 50%-70% over stock components

these rods use the stronger 7/16' and its a significantly stronger connecting rod, yes the cost is about $90 more a set, but thats peanuts in the total build cost and the strength is a good increase over both stock and the other rods

http://www.summitracing.com/parts/sca-2 ... /overview/

viewtopic.php?f=52&t=727

viewtopic.php?f=55&t=2718&p=12119&hilit=octane#p12119

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=82

viewtopic.php?f=71&t=741

viewtopic.php?f=52&t=4081&hilit=detonation

viewtopic.php?f=55&t=109

http://www.daytona-sensors.com/tech_tuning.html

yes the cam lobes can very easily contact the connecting rods when the cam index is out of its proper timing, on almost any chevy engine the cam lobe center lines will be spaced at between 103 and 116 degrees, with the piston at TDC theres SUPPOSED to be about .060 MINIMUM clearance between the connecting rod bolts and cam lobes, this is a mandatory clearance check point and a plastic cable tie can be used to gauge clearance, its best done on each individual connecting rod to cam lobe clearance point AFTER the cams been degreed into the block as each connecting rods being installed but Ive generally done it during the several trial assembly points where I check other clearances like block to connecting rod clearance.

thats why on some stroker crank engines a SMALL BASE CIRCLE cam is used to MAXIMIZE CLEARANCE,between the two moving parts.

a cams lobe lift is the difference the lifter moves off the cams base circle between its base circle and its max lobe lift, thus a cam with a 1.1" diam base circle and a .400 lobe lift would have a , .400 lobe lift and if you had 1.5:1 ratio rockers a .600 valve lift, but if you wanted more clearance you could use a smaller base circle at .900, and a 400 lobe lift this would allow the connecting rod, to sweep by with an additional amount of cam lobe to connecting rod bolt clearance, the change in diameter generally requires a swap to a stronger cam billet core . vs cheaper cast core,to maintain cam strength

removing the rod caps during clearance checks while building your 383 ,does seem to allow you to see the clearance issues a bit easier

a fairly well known and rather successful 383 sbc combo thats fairly economical to build is The scat 9000 series crank for 6 inch rods will internally balance little problem,

The scat I beams with 7/16 bolts are the way to go, the Mahle or Wiseco, J&E, TRW and TRICKFLOW pistons all work with good results.

The Heads you select should flow at least 250 cfm at .600 lift minimum,

(250 CFM AT .500 lift is even better) if your using an dual plane Air Gap intake the Dart SHP 180 or 180cc AFR heads are a good choice, a 750cfm-to-850 cfm, works well.

If your using a single plane intake go with the Dart SHP 200, or BRODIX 200cc runner or 195 AFR heads, provided the cars drive train and gearing match the compression and cam timing,

for most applications a cam in the 230-240 intake duration at .050 lift and a fairly tight 106-108 LSA with a 9.5:1 -10.5:1 compression will meet the requirements,

generally youll want a dynamic compression near 8:1 and a quench distance in the .038-.044 range

the cam rotates while indexed by the timing chain at 1/2 crank shaft speed , there are connecting rods designed to provide additional clearance.

BTW I JUST TOOK THE TIME TO RE_READ THIS THREAD< ITS A VIRTUAL CLASS IN ENGINE ASSEMBLY THAT SHOULD BE READ BY EVERY LAST MEMBER

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

READ THESE THREAD's

and don,t skip the sub linked info

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-57940

http://garage.grumpysperformance.com/index.php?threads/redline.343/

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/

http://garage.grumpysperformance.co...s-to-casting-numbers-and-info.632/#post-53467

http://garage.grumpysperformance.com/index.php?threads/ballancing-the-components.141/#post-5391

THESE MAY HELP

http://www.airflowresearch.com/super-chevy-nov-2013-195cc-sbc.php

http://www.airflowresearch.com/super-chevy-sep-2013-195cc-sbc.php

http://www.airflowresearch.com/articles/SBC/biggerbetter/big.php

http://airflowresearch.com/articles/article152/A-P1.html

http://airflowresearch.com/articles/article085/A-P1.htm

http://airflowresearch.com/articles/article031/A-P1.htm

http://www.airflowresearch.com/articles/SBC/lt1shootout/lt1shootout.php

Last edited by a moderator: