you really should read all the links and sub-links below to maximize your understanding of the concepts, in the thread

READ THE LINKS AND SUB LINKS

www.randysworldwide.com

www.randysworldwide.com

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://www.wallaceracing.com/calc-rpm-drop-shift.php

http://www.zealautowerks.com/transcalc.php

http://garage.grumpysperformance.co...ear-axles-and-differentials.11848/#post-99450

https://www.silveradosierra.com/threads/all-in-one-final-drive-gear-calculator.616410/

http://www.grimmjeeper.com/gears.html

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

http://garage.grumpysperformance.com/index.php?threads/tires-and-tire-compounds.1676/#post-63907

http://garage.grumpysperformance.co...asonably-fast-in-street-trim.3404/#post-33377

do a few calculations, think about the rpm band

YOUR engine makes its best power in,

and YOUR tire diameter

and YOUR cars weight

and YOUR rear gearing,

and YOUR trans GEARING

as a general rule if your looking for brisk street performance,

(especially with an over drive transmission)

youll want the transmission first gear . multiplied times the rear gear ratio to fall in the 10:1-10.6:1 range

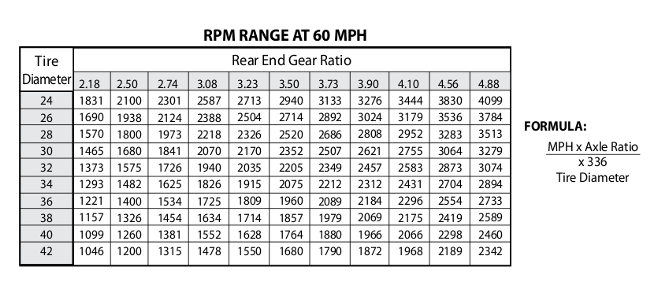

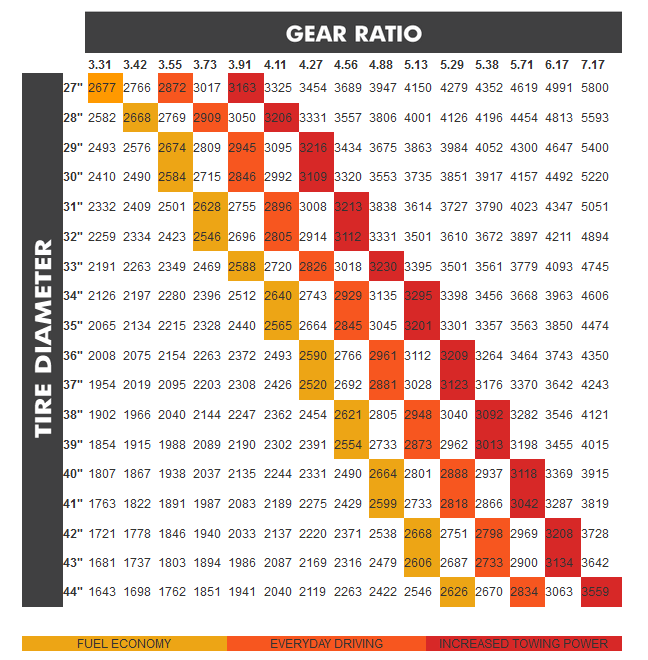

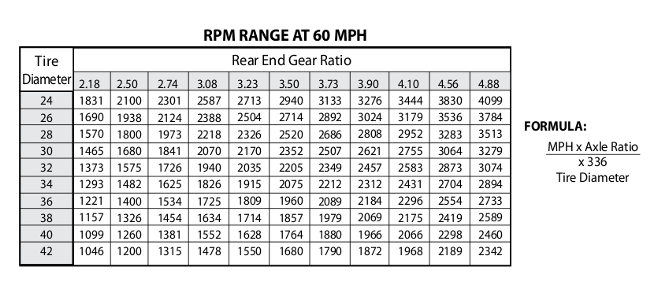

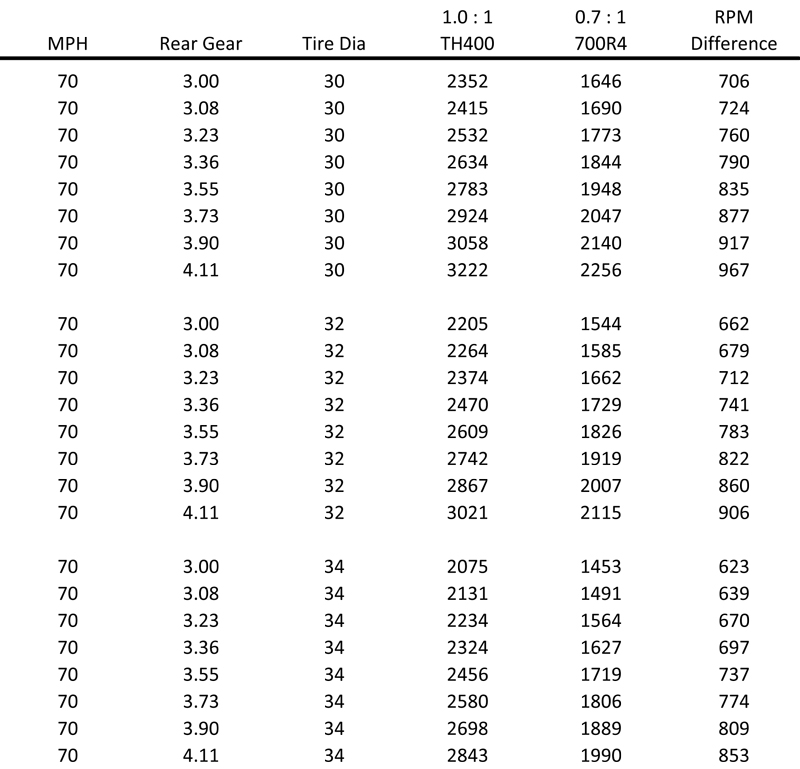

and youll want the engine to cruse at 70 mph in the lower end of the engines effective torque curve

if we assume your looking at maximizing a performance cars acceleration while maintaining a reasonable cruise rpm for mileage, and you have a tire diam range of between 26-29" tall as, most muscle cars have, you can just find the ratio that multiplied times your transmissions first gear ratio falls in the 10:1-10.6:1 range and you'll find it works out rather well, especially with the OVER DRIVE TOP GEAR TRANSMISSIONS

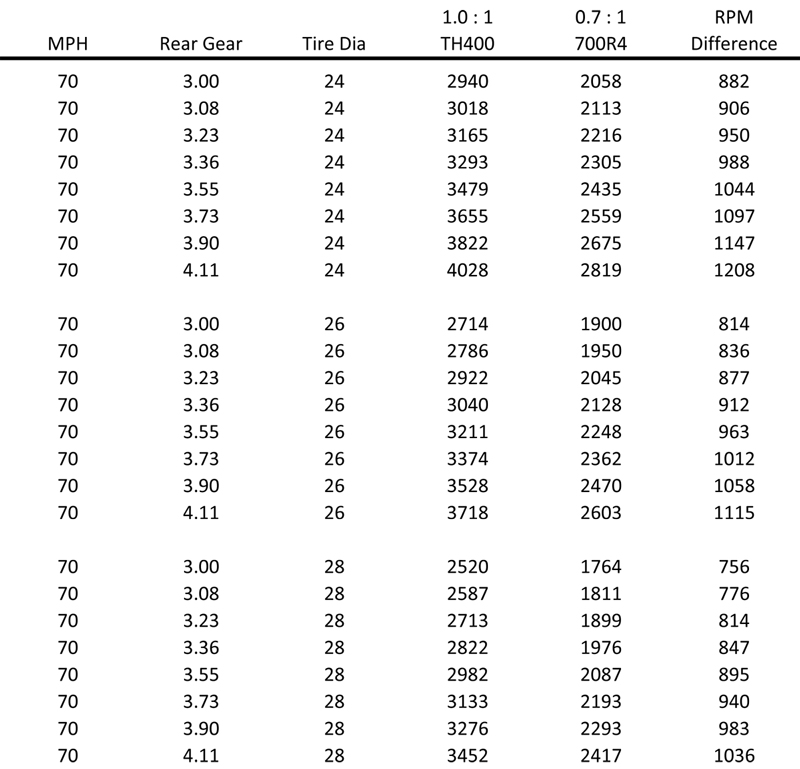

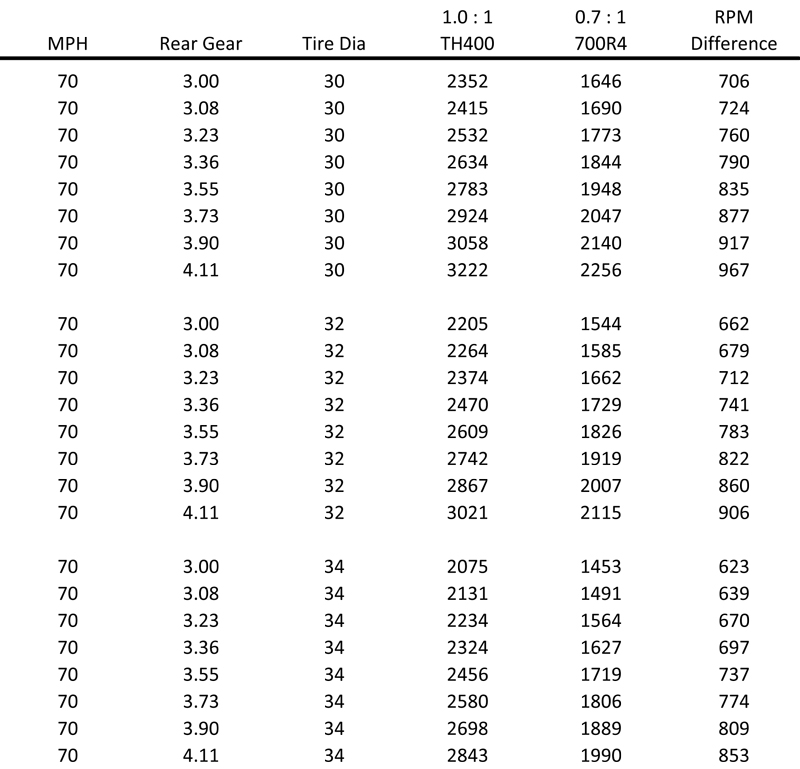

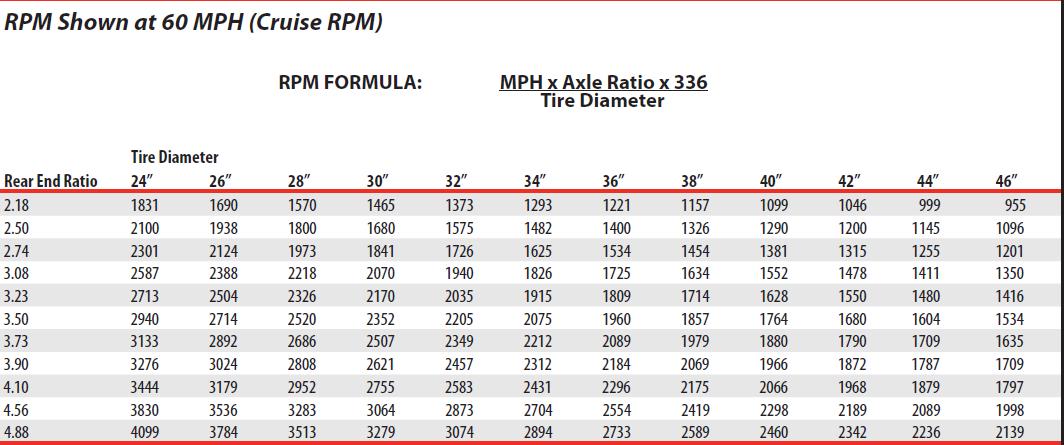

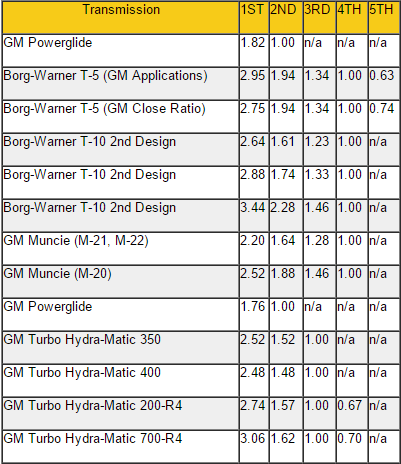

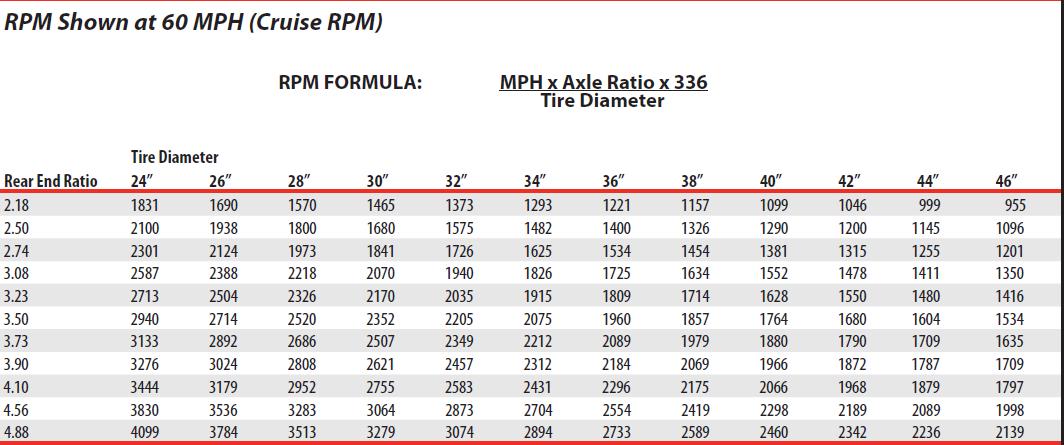

if you don,t have an over drive transmission most guys just select the gear ratio that when matched to their tire diam. that will have the engine rpm range fall in the 2400rpm-2600rpm, or the lower edge of the engine torque curve, range at 70mph

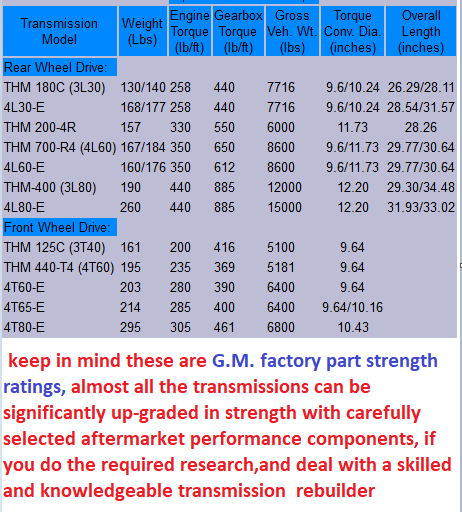

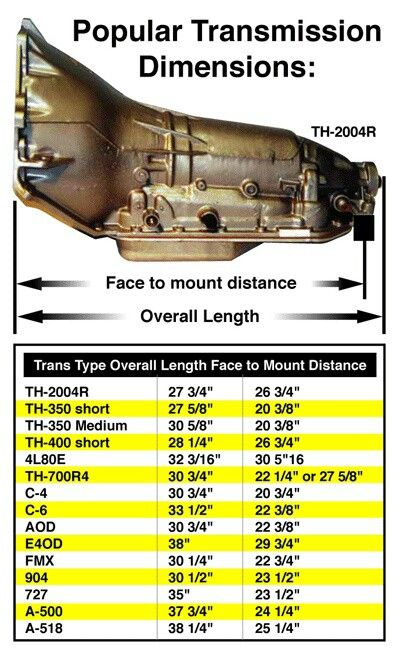

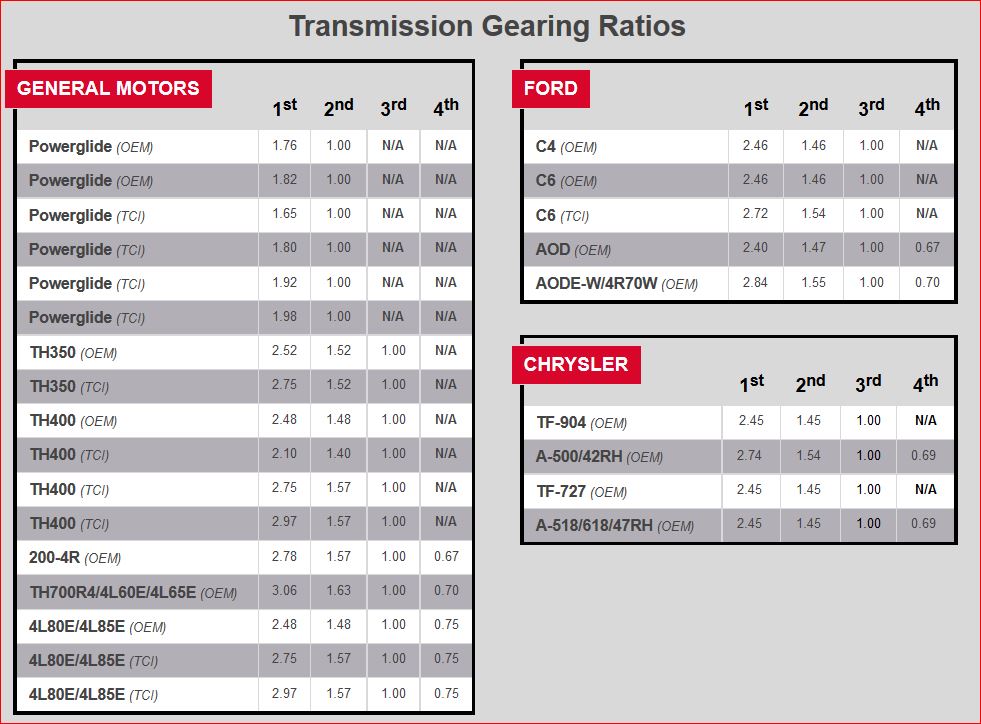

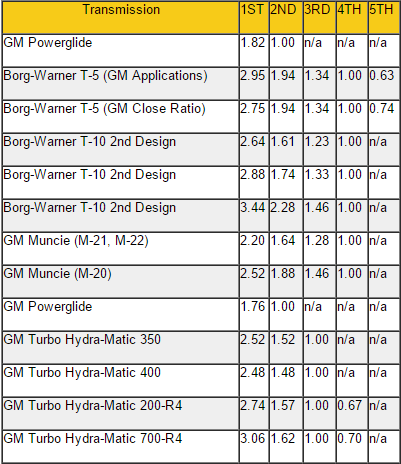

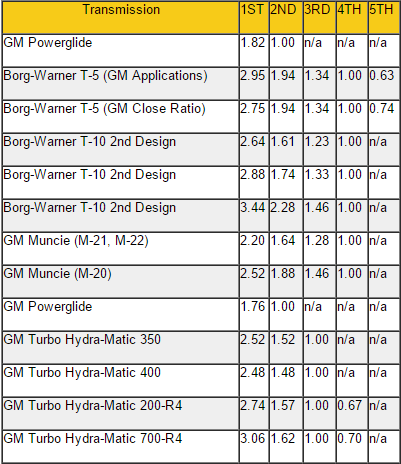

Gear comparisons for 700R4 vs. other GM Transmissions:

.............................1st.......2nd....3rd....4th

Power Glide..............1.76......1.0

TH350 .....................2.52.....1.52....1.0

TH400......................2.48.....1.48....1.0

700-R4/4L60..............3.06.....1.63....1.0.....70

200-R4.....................2.74.....1.57....1.0.....67

4L80E......................2.48.....1.48....1.0.....75

EXAMPLE

I know some people would rather gargle flaming broken glass than use info in links and sub-links but theres a great deal of useful info you can use

CALCULATORS CAN BE USEFUL

http://www.vibratesoftware.com/

http://www.blocklayer.com/Rpm-GearEng.aspx

http://glennmessersmith.com/shiftpt.html

http://www.5speeds.com/ratios.html

http://www.f-body.org/gears/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://purplesagetradingpost.com/sumner ... index.html

http://www.jegs.com/p/Richmond-Gear/Ric ... 3/10002/-1

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://tire-size-conversion.com/tire-height-calculator/

http://www.summitracing.com/expertadvic ... calculator

http://www.wallaceracing.com/gearcalc.php

http://www.wallaceracing.com/gear-speed.php

http://www.offroaders.com/info/tech-cor ... ph-rpm.htm

http://www.prosystemsracing.com/calculate.html

http://www.fatboyraceworks.com/gears/

http://garage.grumpysperformance.com/index.php?threads/matching-the-combo.11020/#post-48707

http://www.wallaceracing.com/RPM%20Drop ... ulator.php

http://www.wallaceracing.com/gear-speed.php

http://www.wallaceracing.com/gearcalc.php

http://wallaceracing.com/Calculators.htm

http://robrobinette.com/et.htm

http://tire-size-conversion.com/tire-size-chart/

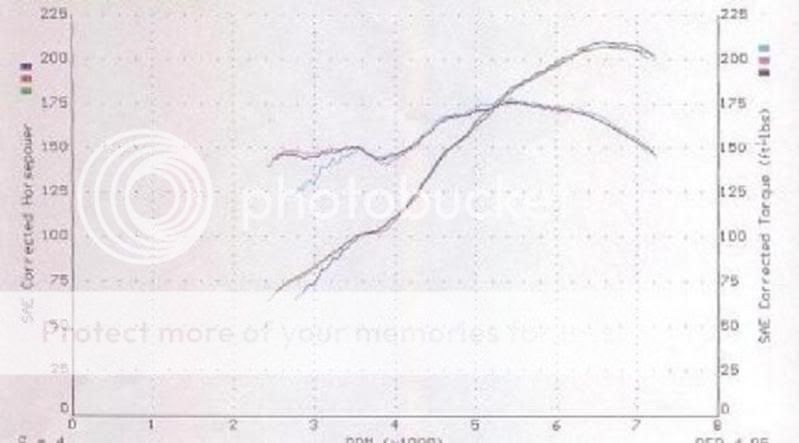

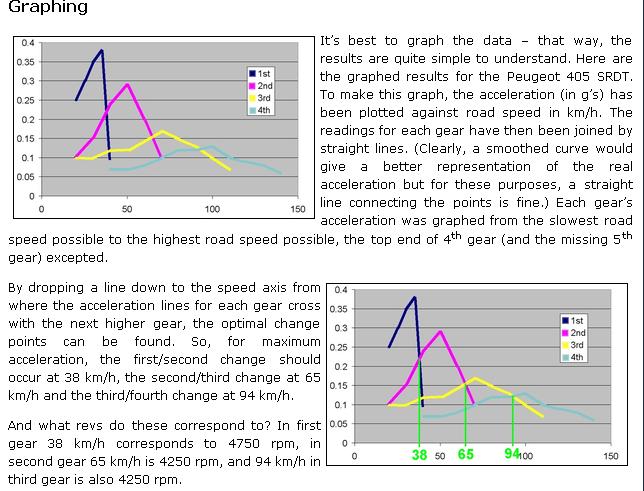

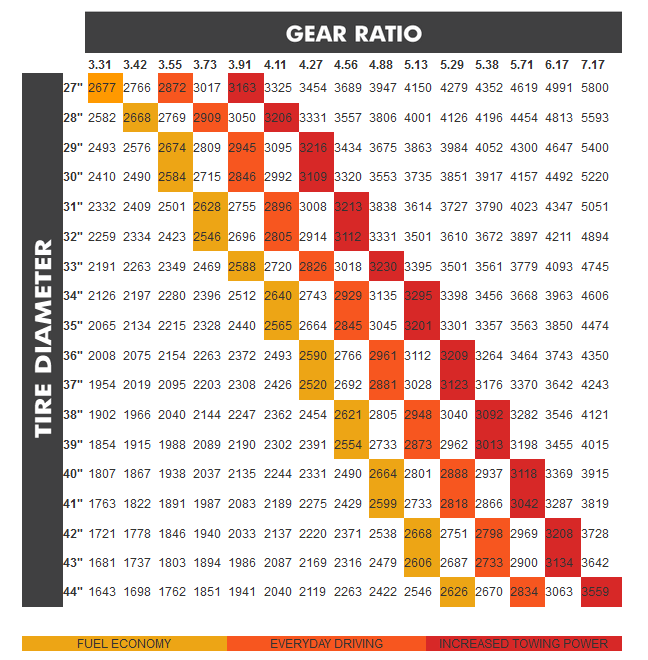

you should ideally select a cam , tire diam. converter stall speed and differential gearing, THE CARS WEIGHT AND,AT WHAT RPM THE TRANSMISSION WILL SHIFT TO THE NEXT GEAR UNDER WOT RACING CONDITIONS, that put the engine rpm MOST EFFECTIVELY MATCHED TOO<or in your engines most effective power range, so your maximizing the torque in your power curve about 90% of the time

if your first gear ratio in your 4l80e transmission were to be a 2.48:1 you divide 10.25/2.48 and you find the closest ratio is a 4.11:1, if your more concerned with mileage than brute acceleration ,you should drop back to a 3.73:1 or a compromise 3.90:1 ratio

you get the advantage of reasonably low gears and highway drive ability if you install the correct over drive transmission, and reasonably low rear gearing, everything's a compromise but its easily possible to get a decent combo, lets say you want want to cruise at 2500-2800rpm and a top speed in excess of 120mph at a reasonable 6000rpm and a good launch with torque, and you multiplication that low gears provide, your running lets assume a 24"-26" tire

you want the first gear ratio times the rear gear ratio to fall in the 10:1-11:1 range

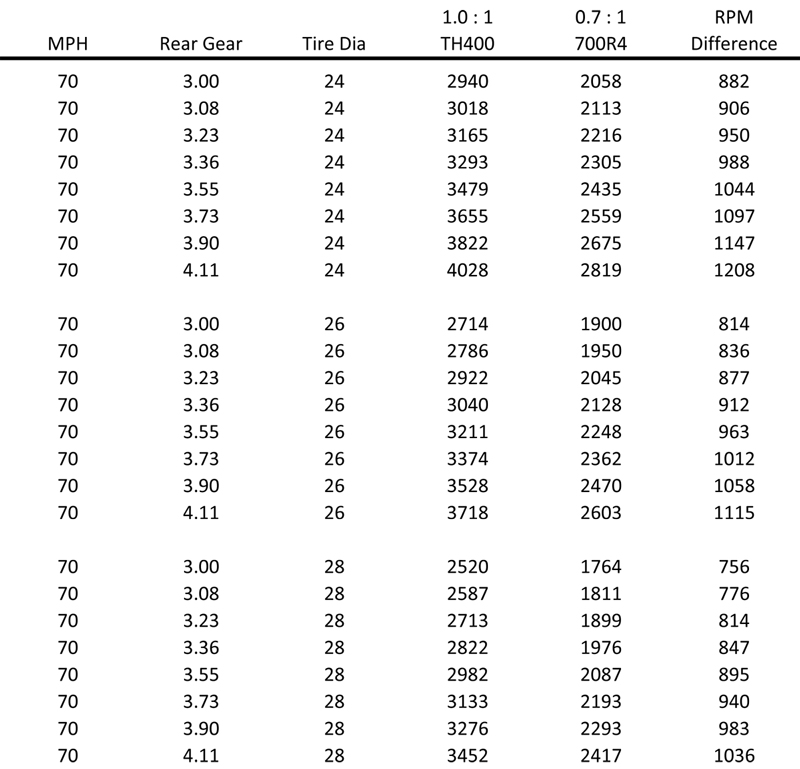

lets assume your dealing with a th400 and 2.73 rear gears you fall into the 2.48/2.73=6.77:1 range killing fast acceleration

swap to a 5.13 rear gear with that 2.48 th400 trans gear and you fall in the 12.73 range killing cruising speed, as well as top speed, which would be around 80mph in top gear.

but lets swap that 5.13 rear gear into a car with a 4l80e TRANSMISSION with its overdrive gearing, its 0.75 brings you a top speed of near 117mph , and a launch ratio of 12.7:1, not bad with big sticky slicks on a light weight car, but not ideal on the street

now lets try to get both a great top speed and a great launch plus a decent cruise rpm,

with a 26" tire

(obviously youll need to measure and calculate your particular needs)

we start with the 4l80e trans first gear divided into 10:1-11:1 and find a 4.11:1-4.33:1 ratio is a great choice, a 4.11:1-4.33:1 ratio gives you a 140mph-150mph theoretical top speed, and a cruise speed near 65mph, a 3.73-3.90:1 rear gear would probably be better on a car used mostly for cruising as it will drop the cruise rpm several hundred rpm

trans gearing

http://vexer.com/automotive-tools/speed-rpm-calculator

http://www.vibratesoftware.com/

http://www.stl-vettes.com/65Vette/Trans ... earing.htm

http://purplesagetradingpost.com/sumner ... index.html

http://purplesagetradingpost.com/sumner ... index.html

http://www.drivetrain.com/autotranscrossref.html

http://www.bgsoflex.com/rpmmph.html

http://700r4.com/speedoCalc/rpmgearscalc.shtml

http://www.chevyhiperformance.com/techa ... index.html

http://www.tciauto.com/tc/trans-dim

http://www.tciauto.com/tc/gear-ratios

impalla65ss posted this link below

This is pretty extensive. Everyone will learn a lot from it.

get this excel-file downloaded and play with it <<<<<CLICK ON LINK

youll find what you want here

https://www.google.com/search?q=how%2Bt ... ar%2Bratio

http://www.btc-bci.com/~billben/reargear.htm

http://www.thirdgen.org/calculations

http://www.geocities.com/z_design_studi ... zx_tt.html

http://www.datsuns.com/Tech/whentoshift.htm

FIRST, THANK YOU IFATGMC!!!

THATS VERY USEFUL, IF YOU DON,T MIND ILL MAKE THIS A STICKY :grin:

http://purplesagetradingpost.com/sumner/bvillecar/bville-spreadsheet-index.html

HERES OTHER INFO LINKS

http://www.xracingsports.com/tirecalc.html

http://www.secondstrike.com/Technical/GearCalc.asp

http://www.5speedtransmissions.com/calculators.html

http://www.geocities.com/z_design_studi ... zx_tt.html

http://www.datsuns.com/Tech/whentoshift.htm

http://www.corvetteactioncenter.com/tec ... scalc.html

http://www.wallaceracing.com/reargear.htm

http://users.erols.com/srweiss/calcmph.htm

http://www.tciauto.com/Products/TechInf ... tors.asp#8

http://www.grimmjeeper.com/gears.html

http://users.erols.com/srweiss/calcrpm.htm

http://users.erols.com/srweiss/calcrgr.htm

http://users.erols.com/srweiss/transc.htm#tabtop

http://users.erols.com/srweiss/transc.htm#Auto

http://www.gmtuners.com/gmtransinfo.htm

heres some calculators to play with

http://robrobinette.com/et.htm

http://www.wallaceracing.com/et-hp-mph.php

http://www.competitiondiesel.com/Phil/bg/

http://www.stealth316.com/2-calc-hp-et-mph.htm

http://drag-zone.com/calculators.html#1

http://www.leeracingteam.com/et.htm

if your looking for a 3.73-4.11 rear gear for your corvette,and can,t find a 4.11 gear,the reason is that the highest COMMON gear ratio is 3.73:1 in that differential for that C4 corvette, but heres a link, btw you do realize that 4.09, 4.10, 4.11:1 rear gears are all the same exact SAME ratio and the difference is in how they were calculated

the RATIO IS CALCULATED BY COUNTING THE NUMBER gear teeth on the RING GEAR are divided by the NUMBER OF TEETH ON THE PINION GEAR

btw, for anyone reading thru this thread,

if you've got a transmission without an over drive top gear ratio like a th400, th350, etc I would consider ,STRONGLY CONSIDER something in the 3.07-3.31 rear gear ratio range, if you have an over drive top gear, like a 700r4, 4l80e, 200r4 the same criteria apply but youll find , a 3.54.-3.90:1 rear gear as a good choice

remember this is for effectively gearing a mixed performance/transportation street/strip car, combo and

Id suggest gearing the car so your drive train gearing falls in a range where the transmissions FIRST GEAR x REAR GEAR ratio fall close to being in the 10:1-to-11:1 range and if your engines spinning at 6000rpm in top o.d. gear places the car speed no higher than 135 mph, the closer you can get the gearing to fall in that gearing range the more responsive most cars will be,get the rear gear ratio low enough that the rear gear ratio times first gear is over 11:1 and your first two gears become far less useful without major suspension mods and SLICKS, and truthfully, how many times do you need to exceed 135mph?

http://www.datsuns.com/Tech/whentoshift.htm

http://www.welltall.com/ymc/discovery/car/shiftpt.html

http://www.bgsoflex.com/shifter.html

http://autospeed.com/cms/title_Finding- ... ticle.html

READ THE LINKS AND SUB LINKS

Transmission Ratio RPM Calculator | RANDYS Worldwide

By entering your R&P Ratio, Tire Height, Speed (mph), and Transmission Ratio, you can quickly calculate RPM

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://www.wallaceracing.com/calc-rpm-drop-shift.php

http://www.zealautowerks.com/transcalc.php

http://garage.grumpysperformance.co...ear-axles-and-differentials.11848/#post-99450

https://www.silveradosierra.com/threads/all-in-one-final-drive-gear-calculator.616410/

http://www.grimmjeeper.com/gears.html

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

http://garage.grumpysperformance.com/index.php?threads/tires-and-tire-compounds.1676/#post-63907

http://garage.grumpysperformance.co...asonably-fast-in-street-trim.3404/#post-33377

do a few calculations, think about the rpm band

YOUR engine makes its best power in,

and YOUR tire diameter

and YOUR cars weight

and YOUR rear gearing,

and YOUR trans GEARING

as a general rule if your looking for brisk street performance,

(especially with an over drive transmission)

youll want the transmission first gear . multiplied times the rear gear ratio to fall in the 10:1-10.6:1 range

and youll want the engine to cruse at 70 mph in the lower end of the engines effective torque curve

if we assume your looking at maximizing a performance cars acceleration while maintaining a reasonable cruise rpm for mileage, and you have a tire diam range of between 26-29" tall as, most muscle cars have, you can just find the ratio that multiplied times your transmissions first gear ratio falls in the 10:1-10.6:1 range and you'll find it works out rather well, especially with the OVER DRIVE TOP GEAR TRANSMISSIONS

if you don,t have an over drive transmission most guys just select the gear ratio that when matched to their tire diam. that will have the engine rpm range fall in the 2400rpm-2600rpm, or the lower edge of the engine torque curve, range at 70mph

Gear comparisons for 700R4 vs. other GM Transmissions:

.............................1st.......2nd....3rd....4th

Power Glide..............1.76......1.0

TH350 .....................2.52.....1.52....1.0

TH400......................2.48.....1.48....1.0

700-R4/4L60..............3.06.....1.63....1.0.....70

200-R4.....................2.74.....1.57....1.0.....67

4L80E......................2.48.....1.48....1.0.....75

EXAMPLE

I know some people would rather gargle flaming broken glass than use info in links and sub-links but theres a great deal of useful info you can use

CALCULATORS CAN BE USEFUL

http://www.vibratesoftware.com/

http://www.blocklayer.com/Rpm-GearEng.aspx

http://glennmessersmith.com/shiftpt.html

http://www.5speeds.com/ratios.html

http://www.f-body.org/gears/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://purplesagetradingpost.com/sumner ... index.html

http://www.jegs.com/p/Richmond-Gear/Ric ... 3/10002/-1

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://tire-size-conversion.com/tire-height-calculator/

http://www.summitracing.com/expertadvic ... calculator

http://www.wallaceracing.com/gearcalc.php

http://www.wallaceracing.com/gear-speed.php

http://www.offroaders.com/info/tech-cor ... ph-rpm.htm

http://www.prosystemsracing.com/calculate.html

http://www.fatboyraceworks.com/gears/

http://garage.grumpysperformance.com/index.php?threads/matching-the-combo.11020/#post-48707

http://www.wallaceracing.com/RPM%20Drop ... ulator.php

http://www.wallaceracing.com/gear-speed.php

http://www.wallaceracing.com/gearcalc.php

http://wallaceracing.com/Calculators.htm

http://robrobinette.com/et.htm

http://tire-size-conversion.com/tire-size-chart/

you should ideally select a cam , tire diam. converter stall speed and differential gearing, THE CARS WEIGHT AND,AT WHAT RPM THE TRANSMISSION WILL SHIFT TO THE NEXT GEAR UNDER WOT RACING CONDITIONS, that put the engine rpm MOST EFFECTIVELY MATCHED TOO<or in your engines most effective power range, so your maximizing the torque in your power curve about 90% of the time

if your first gear ratio in your 4l80e transmission were to be a 2.48:1 you divide 10.25/2.48 and you find the closest ratio is a 4.11:1, if your more concerned with mileage than brute acceleration ,you should drop back to a 3.73:1 or a compromise 3.90:1 ratio

you get the advantage of reasonably low gears and highway drive ability if you install the correct over drive transmission, and reasonably low rear gearing, everything's a compromise but its easily possible to get a decent combo, lets say you want want to cruise at 2500-2800rpm and a top speed in excess of 120mph at a reasonable 6000rpm and a good launch with torque, and you multiplication that low gears provide, your running lets assume a 24"-26" tire

you want the first gear ratio times the rear gear ratio to fall in the 10:1-11:1 range

lets assume your dealing with a th400 and 2.73 rear gears you fall into the 2.48/2.73=6.77:1 range killing fast acceleration

swap to a 5.13 rear gear with that 2.48 th400 trans gear and you fall in the 12.73 range killing cruising speed, as well as top speed, which would be around 80mph in top gear.

but lets swap that 5.13 rear gear into a car with a 4l80e TRANSMISSION with its overdrive gearing, its 0.75 brings you a top speed of near 117mph , and a launch ratio of 12.7:1, not bad with big sticky slicks on a light weight car, but not ideal on the street

now lets try to get both a great top speed and a great launch plus a decent cruise rpm,

with a 26" tire

(obviously youll need to measure and calculate your particular needs)

we start with the 4l80e trans first gear divided into 10:1-11:1 and find a 4.11:1-4.33:1 ratio is a great choice, a 4.11:1-4.33:1 ratio gives you a 140mph-150mph theoretical top speed, and a cruise speed near 65mph, a 3.73-3.90:1 rear gear would probably be better on a car used mostly for cruising as it will drop the cruise rpm several hundred rpm

trans gearing

http://vexer.com/automotive-tools/speed-rpm-calculator

http://www.vibratesoftware.com/

http://www.stl-vettes.com/65Vette/Trans ... earing.htm

http://purplesagetradingpost.com/sumner ... index.html

http://purplesagetradingpost.com/sumner ... index.html

http://www.drivetrain.com/autotranscrossref.html

http://www.bgsoflex.com/rpmmph.html

http://700r4.com/speedoCalc/rpmgearscalc.shtml

http://www.chevyhiperformance.com/techa ... index.html

http://www.tciauto.com/tc/trans-dim

http://www.tciauto.com/tc/gear-ratios

impalla65ss posted this link below

This is pretty extensive. Everyone will learn a lot from it.

get this excel-file downloaded and play with it <<<<<CLICK ON LINK

youll find what you want here

https://www.google.com/search?q=how%2Bt ... ar%2Bratio

http://www.btc-bci.com/~billben/reargear.htm

http://www.thirdgen.org/calculations

http://www.geocities.com/z_design_studi ... zx_tt.html

http://www.datsuns.com/Tech/whentoshift.htm

FIRST, THANK YOU IFATGMC!!!

THATS VERY USEFUL, IF YOU DON,T MIND ILL MAKE THIS A STICKY :grin:

http://purplesagetradingpost.com/sumner/bvillecar/bville-spreadsheet-index.html

HERES OTHER INFO LINKS

http://www.xracingsports.com/tirecalc.html

http://www.secondstrike.com/Technical/GearCalc.asp

http://www.5speedtransmissions.com/calculators.html

http://www.geocities.com/z_design_studi ... zx_tt.html

http://www.datsuns.com/Tech/whentoshift.htm

http://www.corvetteactioncenter.com/tec ... scalc.html

http://www.wallaceracing.com/reargear.htm

http://users.erols.com/srweiss/calcmph.htm

http://www.tciauto.com/Products/TechInf ... tors.asp#8

http://www.grimmjeeper.com/gears.html

http://users.erols.com/srweiss/calcrpm.htm

http://users.erols.com/srweiss/calcrgr.htm

http://users.erols.com/srweiss/transc.htm#tabtop

http://users.erols.com/srweiss/transc.htm#Auto

http://www.gmtuners.com/gmtransinfo.htm

heres some calculators to play with

http://robrobinette.com/et.htm

http://www.wallaceracing.com/et-hp-mph.php

http://www.competitiondiesel.com/Phil/bg/

http://www.stealth316.com/2-calc-hp-et-mph.htm

http://drag-zone.com/calculators.html#1

http://www.leeracingteam.com/et.htm

if your looking for a 3.73-4.11 rear gear for your corvette,and can,t find a 4.11 gear,the reason is that the highest COMMON gear ratio is 3.73:1 in that differential for that C4 corvette, but heres a link, btw you do realize that 4.09, 4.10, 4.11:1 rear gears are all the same exact SAME ratio and the difference is in how they were calculated

the RATIO IS CALCULATED BY COUNTING THE NUMBER gear teeth on the RING GEAR are divided by the NUMBER OF TEETH ON THE PINION GEAR

btw, for anyone reading thru this thread,

if you've got a transmission without an over drive top gear ratio like a th400, th350, etc I would consider ,STRONGLY CONSIDER something in the 3.07-3.31 rear gear ratio range, if you have an over drive top gear, like a 700r4, 4l80e, 200r4 the same criteria apply but youll find , a 3.54.-3.90:1 rear gear as a good choice

remember this is for effectively gearing a mixed performance/transportation street/strip car, combo and

Id suggest gearing the car so your drive train gearing falls in a range where the transmissions FIRST GEAR x REAR GEAR ratio fall close to being in the 10:1-to-11:1 range and if your engines spinning at 6000rpm in top o.d. gear places the car speed no higher than 135 mph, the closer you can get the gearing to fall in that gearing range the more responsive most cars will be,get the rear gear ratio low enough that the rear gear ratio times first gear is over 11:1 and your first two gears become far less useful without major suspension mods and SLICKS, and truthfully, how many times do you need to exceed 135mph?

http://www.datsuns.com/Tech/whentoshift.htm

http://www.welltall.com/ymc/discovery/car/shiftpt.html

http://www.bgsoflex.com/shifter.html

http://autospeed.com/cms/title_Finding- ... ticle.html

Last edited by a moderator: