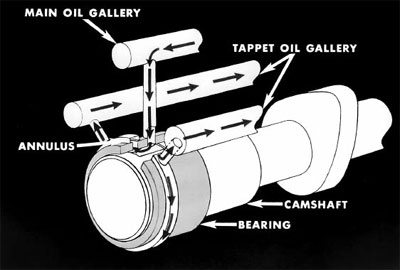

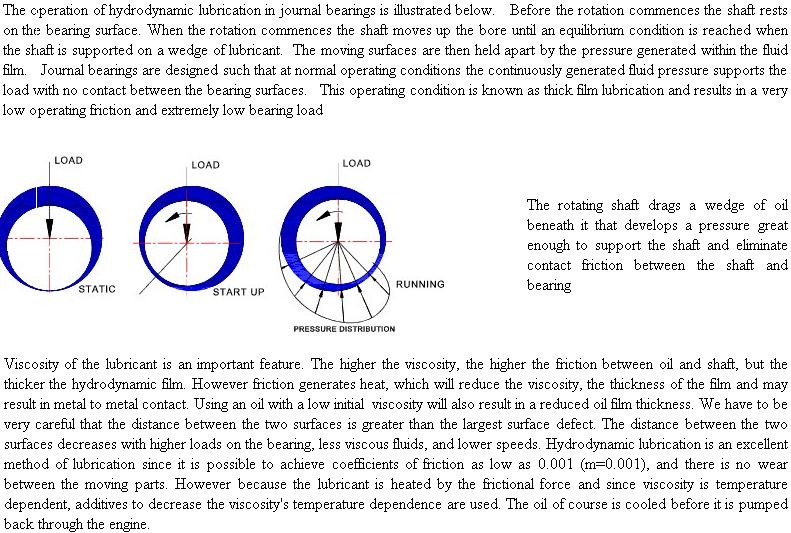

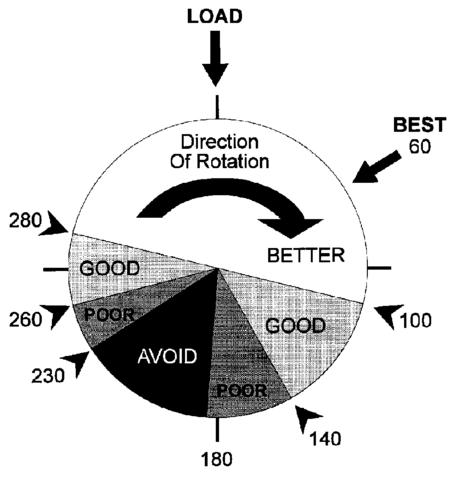

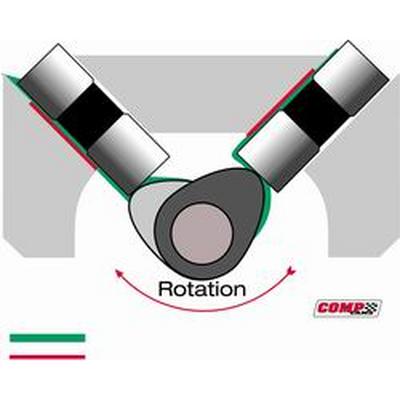

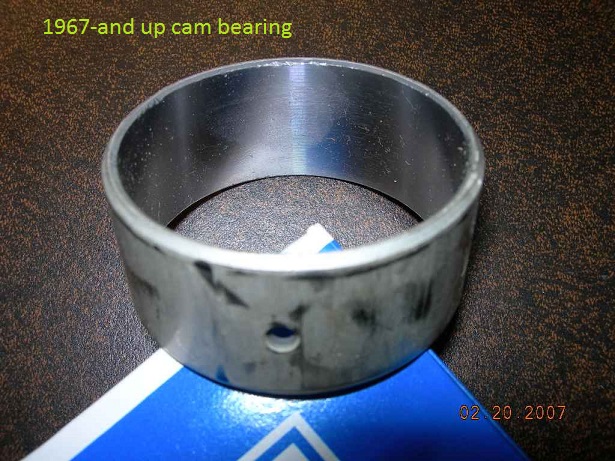

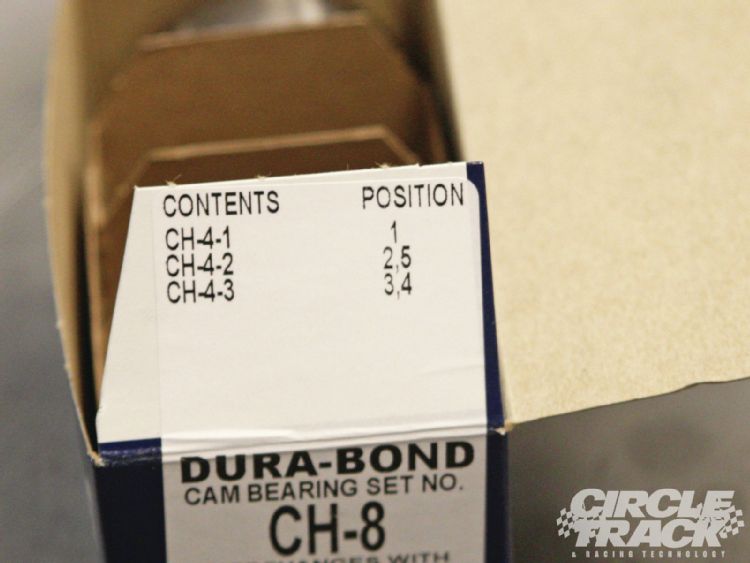

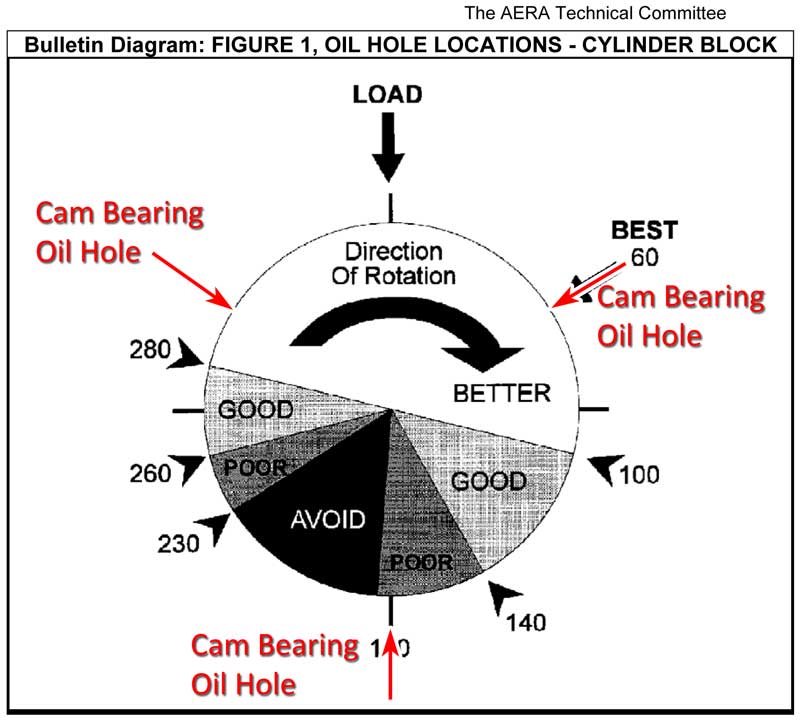

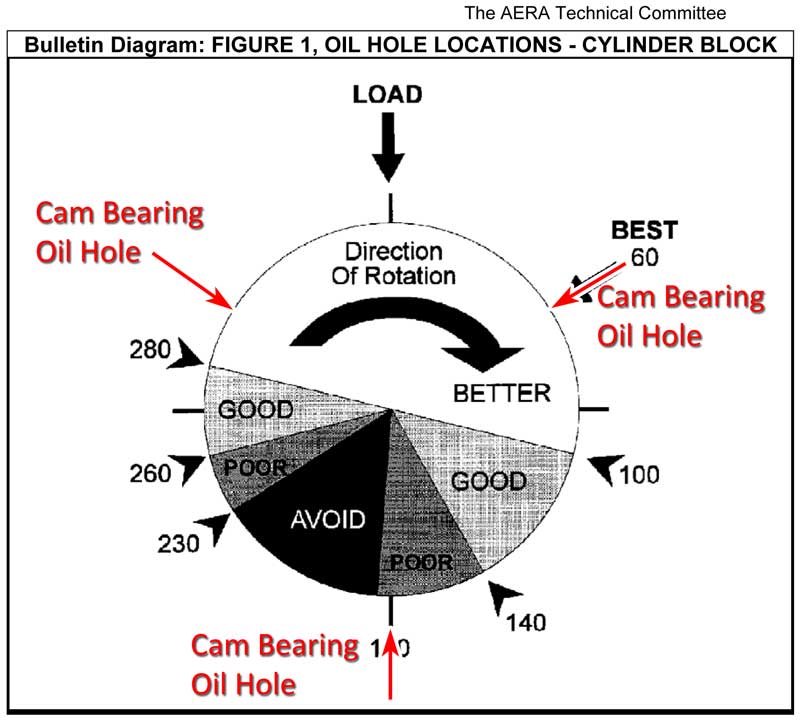

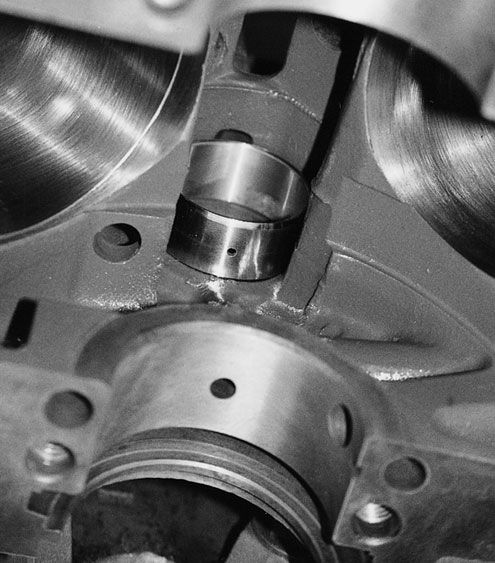

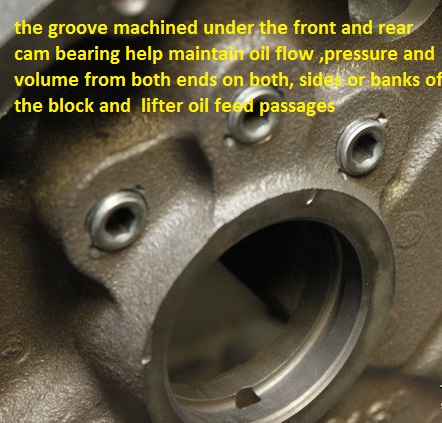

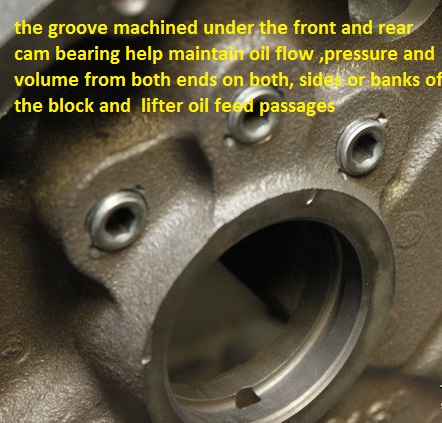

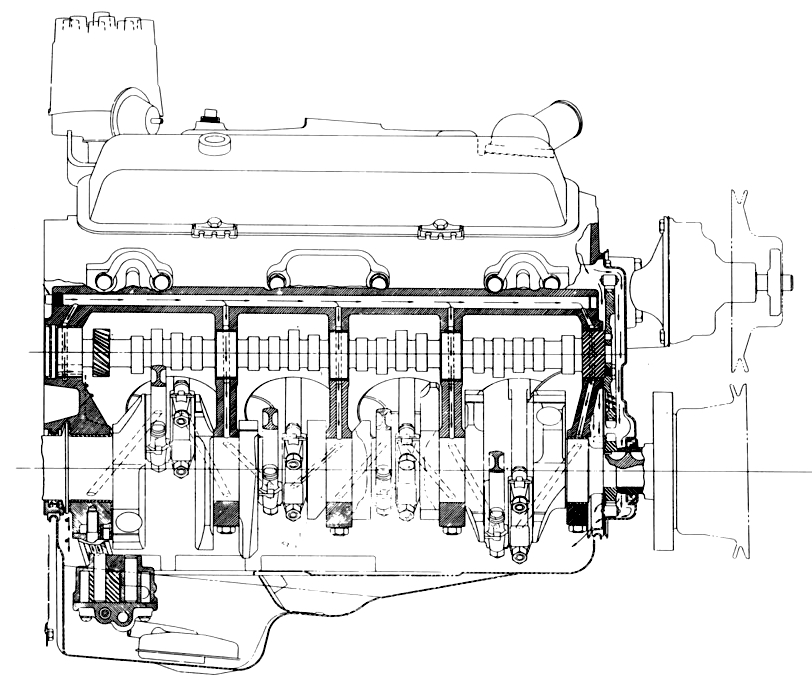

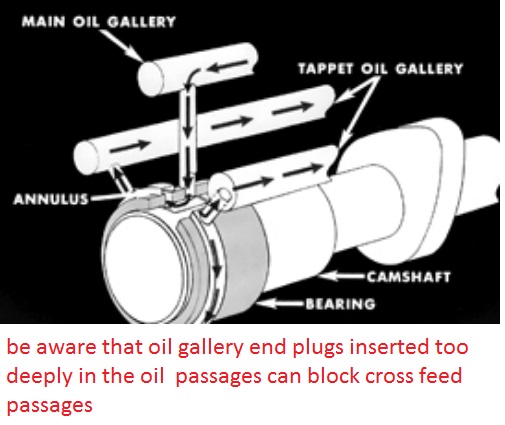

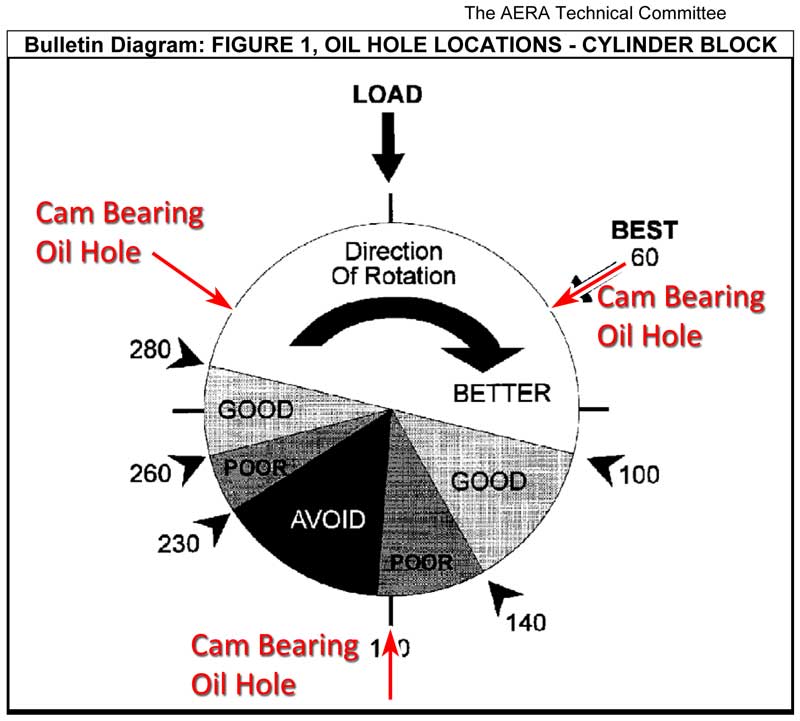

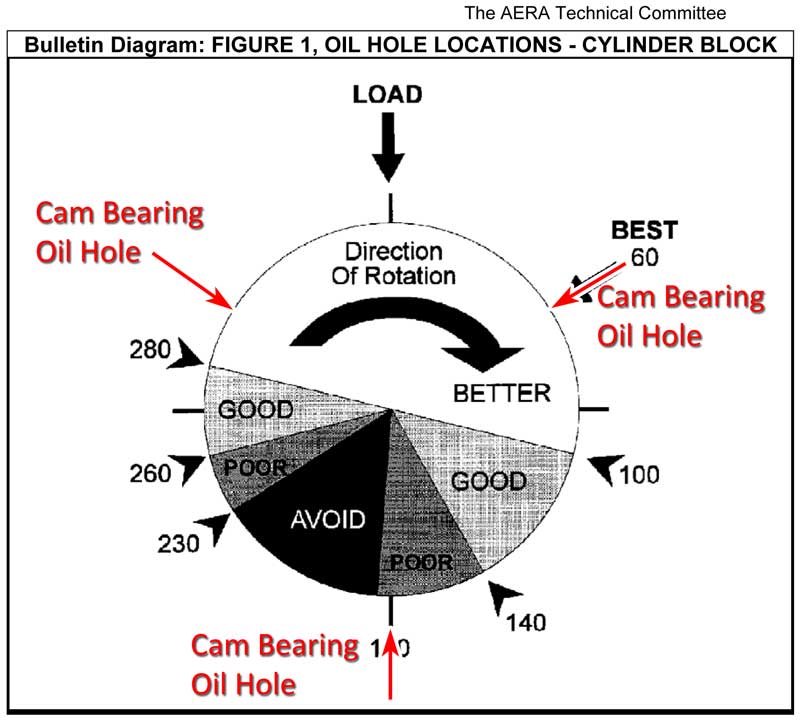

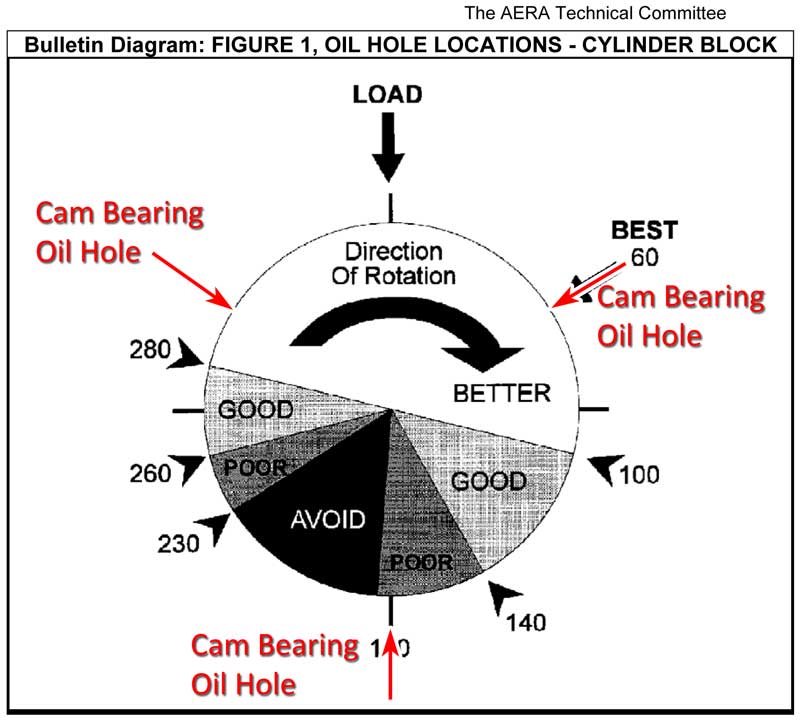

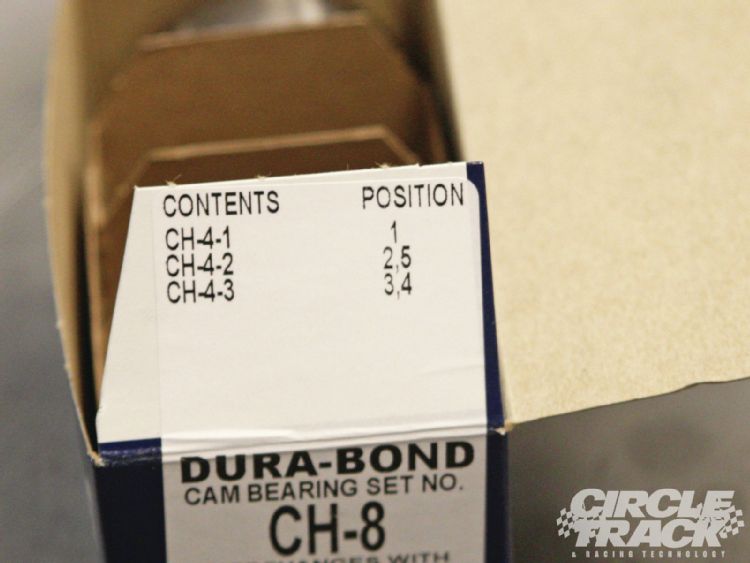

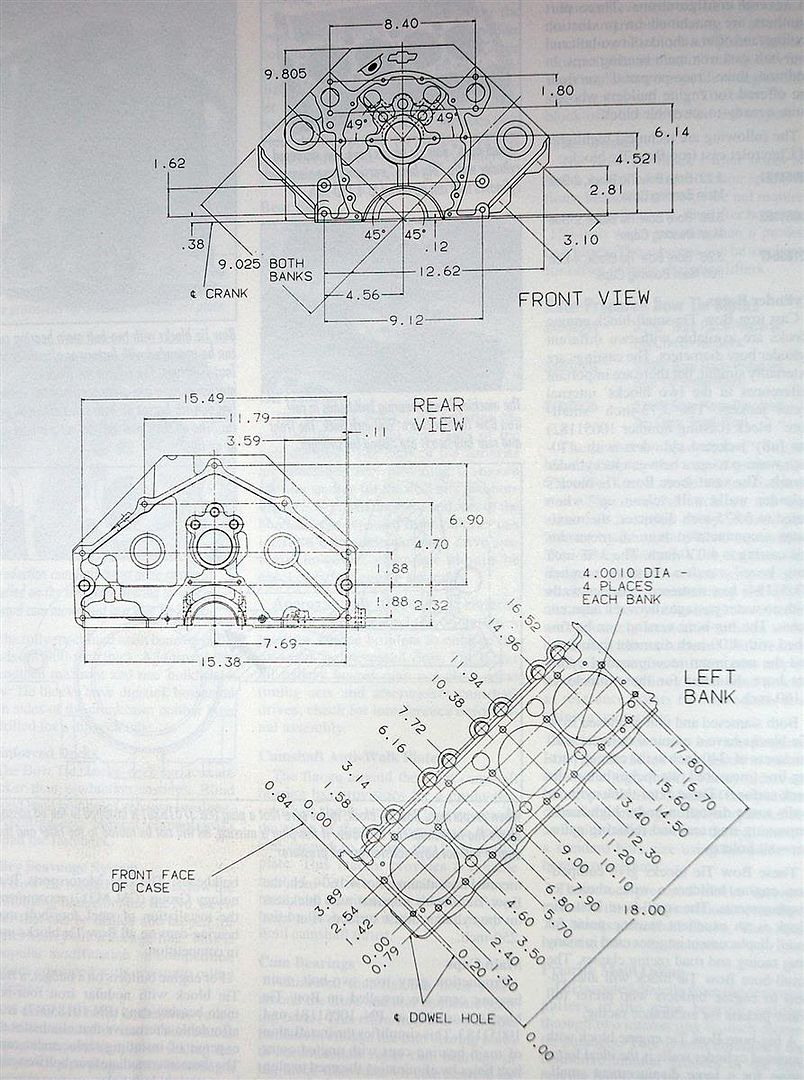

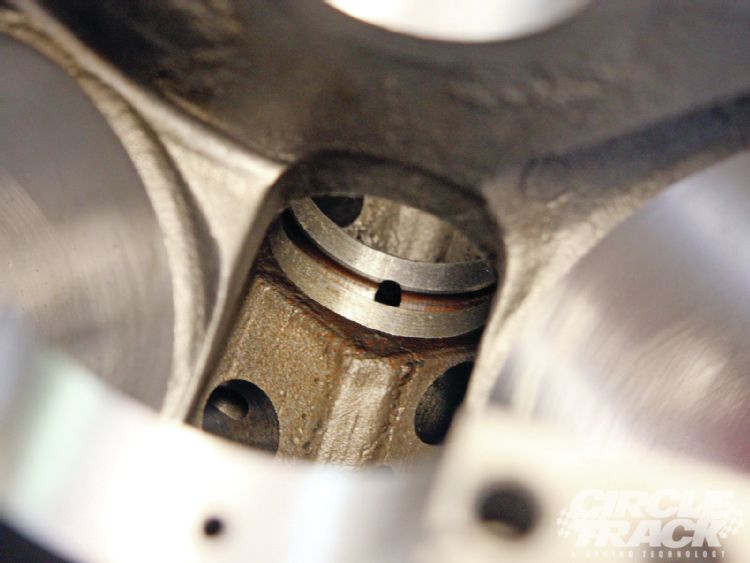

Youll need a cam bearing installation tool or your local machine shop can install the bearings for you, if your not doing this regularly, have them do it, as its cheaper and easier,on a one time install basis, but if you are doing it frequently GET a decent tool and learn how to use it, keep in mind its MANDATORY that the oil feed holes in the block align with the feed holes in the cam bearings once they are installed,but theres an oil feed groove that is machined in the block under some bearings and may not be under others, be observant, think things through,that must be lined up with the oil feed hole,from an engineering perspective the ideal location for the oil feed holes to provide the max cam journal support are indicated in the diagram posted below and most cam bearing sets come with instructions, in most cases that locates the cam bearing feed hole in the 12o,clock to -2 o,clock location with the block in its normal orientation,THIS IS WHERE THE CAM BEARING MANUFACTURERS SUGGEST YOU INSTALL THE BEARINGS FOR MAXIMUM CAM JOURNAL SUPPORT AND DURABILITY ,AS THIS LOCATION ALLOWS THE MAX OIL WEDGE SUPPORT TO BE FORMED AND MAINTAINED, AS THE ENGINE RUNS, you certainly don,t want the oil feed hole located where the max oil film support needs to be or in a location restricting flow to the bearing, but read thru the links provided, and be aware that the cam bearings are FREQUENTLY a different diam. for at least one and frequently several locations in the block so they must be located in the matched locations

engine building is about 75% technology and science and 10% art, and 15% skill gained through experience,over time.

doing it successfully mandates the person involved, in the process, can accurately observe, think, and recognize problems,

and if required, stop and think up solutions.

yes it involves knowing how components are intended to function and accurate precision measurement and access to some specific tools and a skilled well equiped machine shop you can trust, is a mandatory factor and skill set.

so many guys seem to be under the absurd impression that any and all solutions,

to any and all problems,

invariably involve, throwing away some component,

and installing some new out of the box part,

instead of acting logically and actually measuring,

thinking and potentially custom clearancing or at least reading the instructions,

and as most experienced engine builders will tell you ,

almost nothing you can buy fits and functions correctly in out-of-the-box, condition

,too near its true potential.after its ,

carefully, inspected, and correctly clearanced, and fitted.

www.youtube.com

www.youtube.com

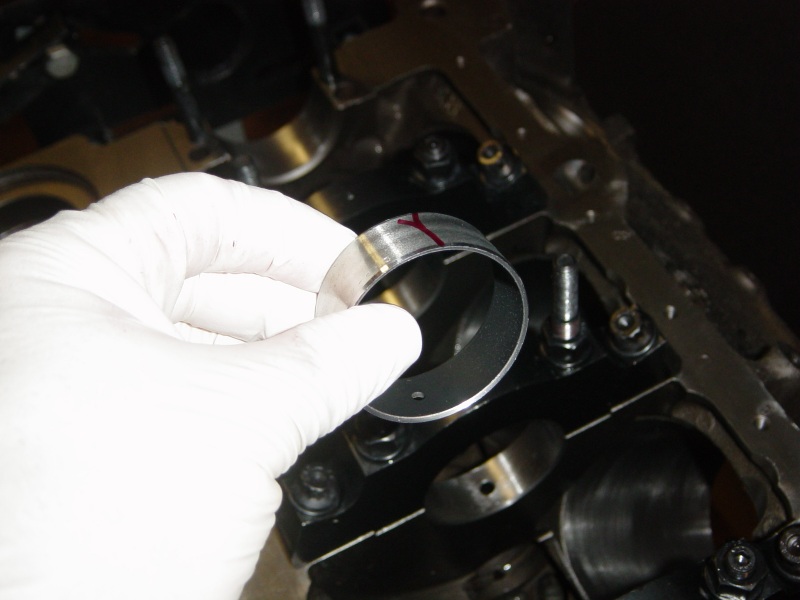

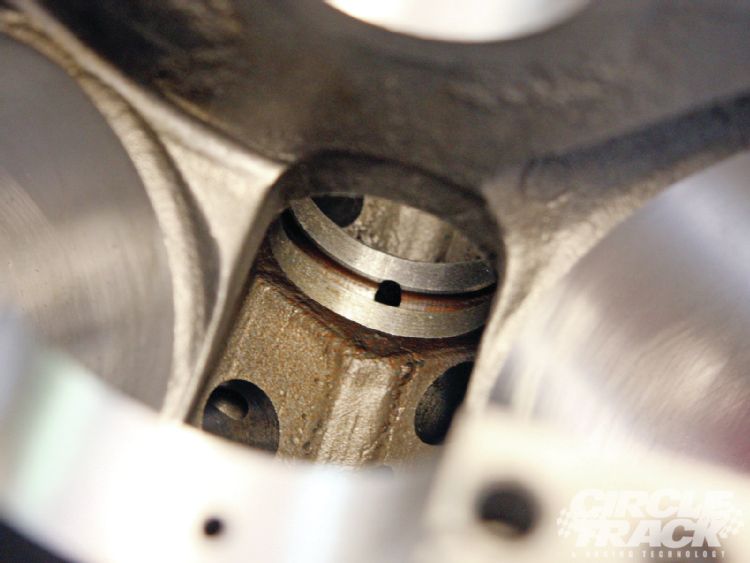

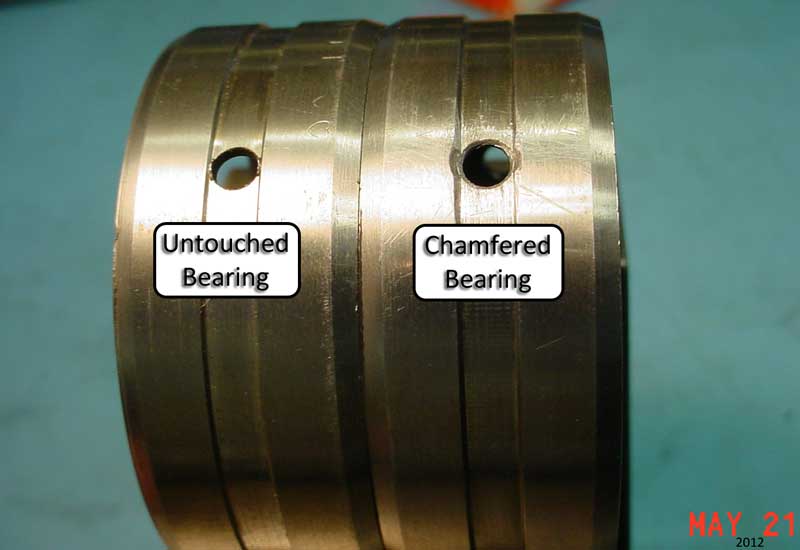

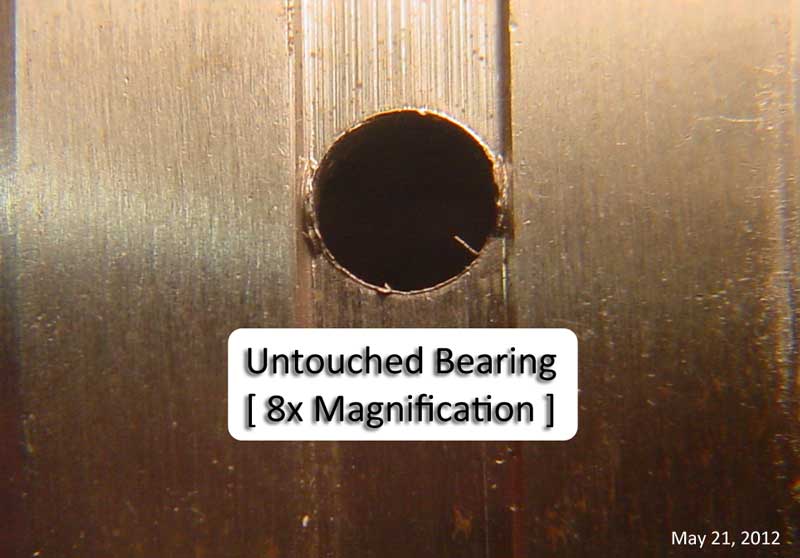

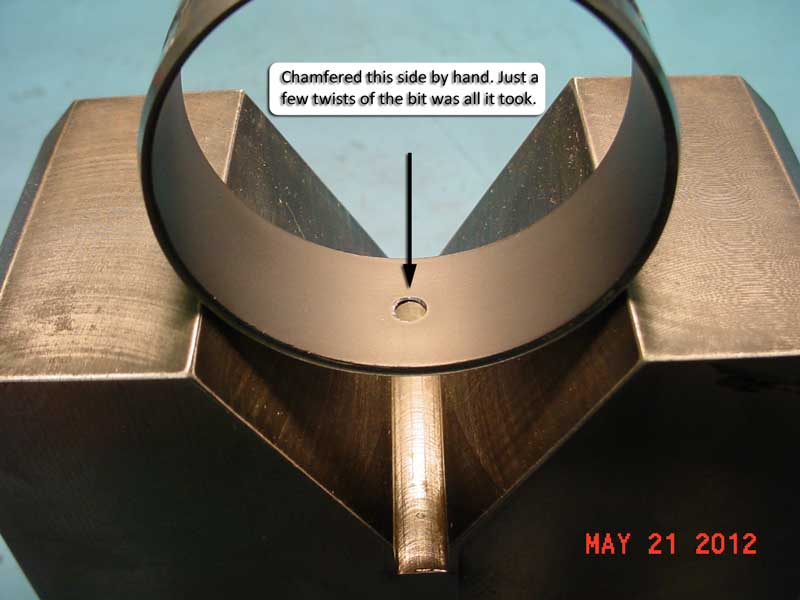

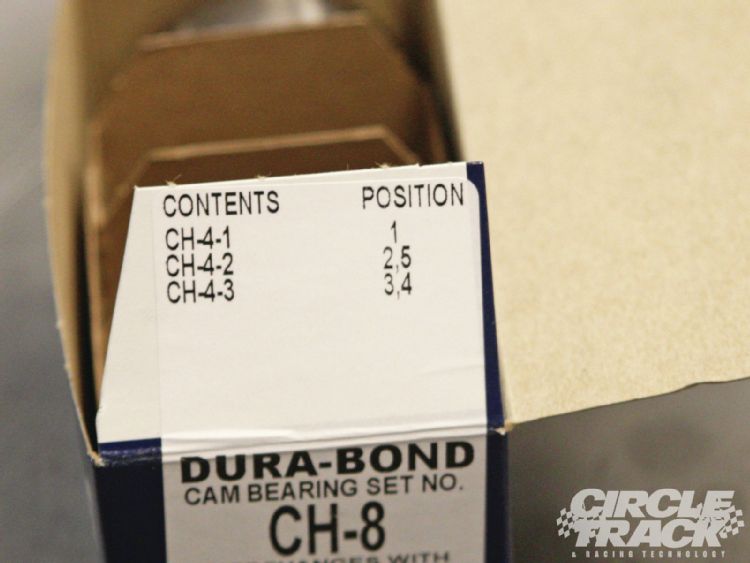

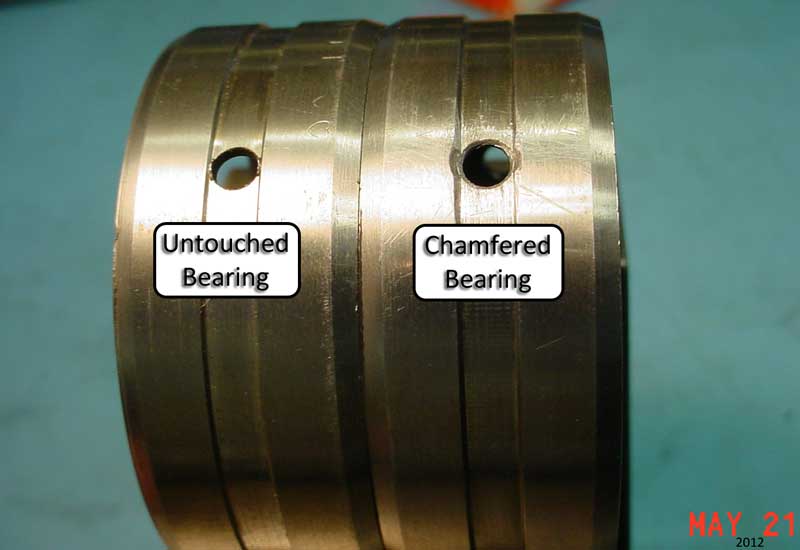

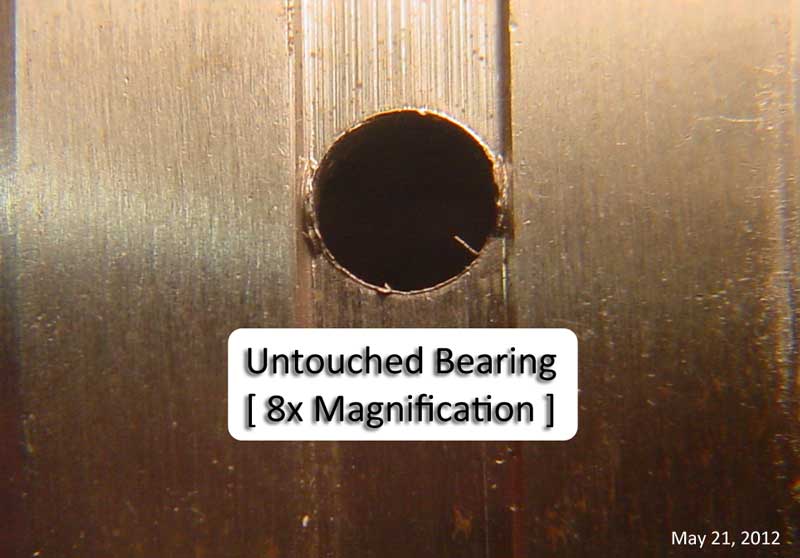

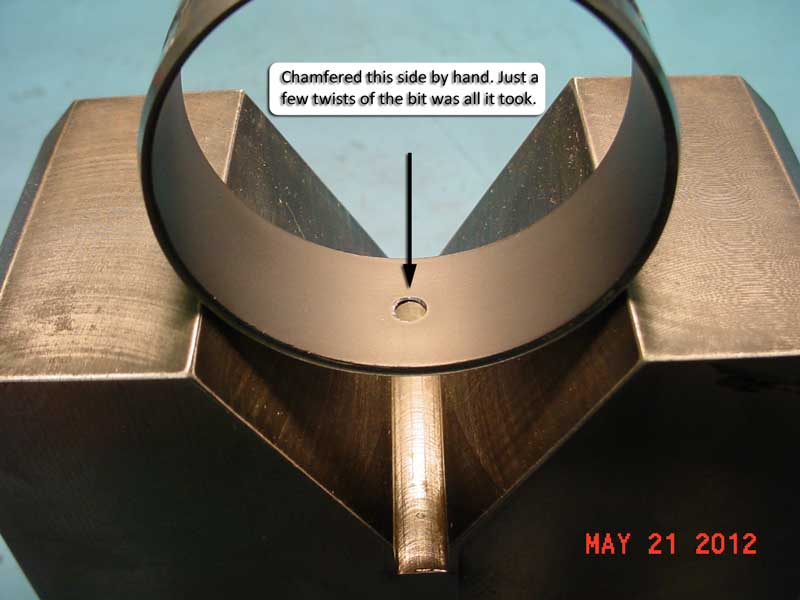

get into the habit of taking notes, examining details and measuring the cam bearings,.. noticing the location of oil feed holes, and taking pictures and notes, on the outer and inner dimensions and that generally one edge is beveled to make installation easier, note that some cam bearings have a reverse side oil feed groove while other brands do not! notice that the oil feed passages and main cap grooves tend to measure differently and not all bearings fit all locations

taking the effort to be observant, measure , and ask questions rather than just jamming parts in anyplace, will save you from making lots of expensive mistakes

http://www.summitracing.com/parts/cca-5605/overview/

http://www.harborfreight.com/6-piece-telescoping-gauge-set-5649.html

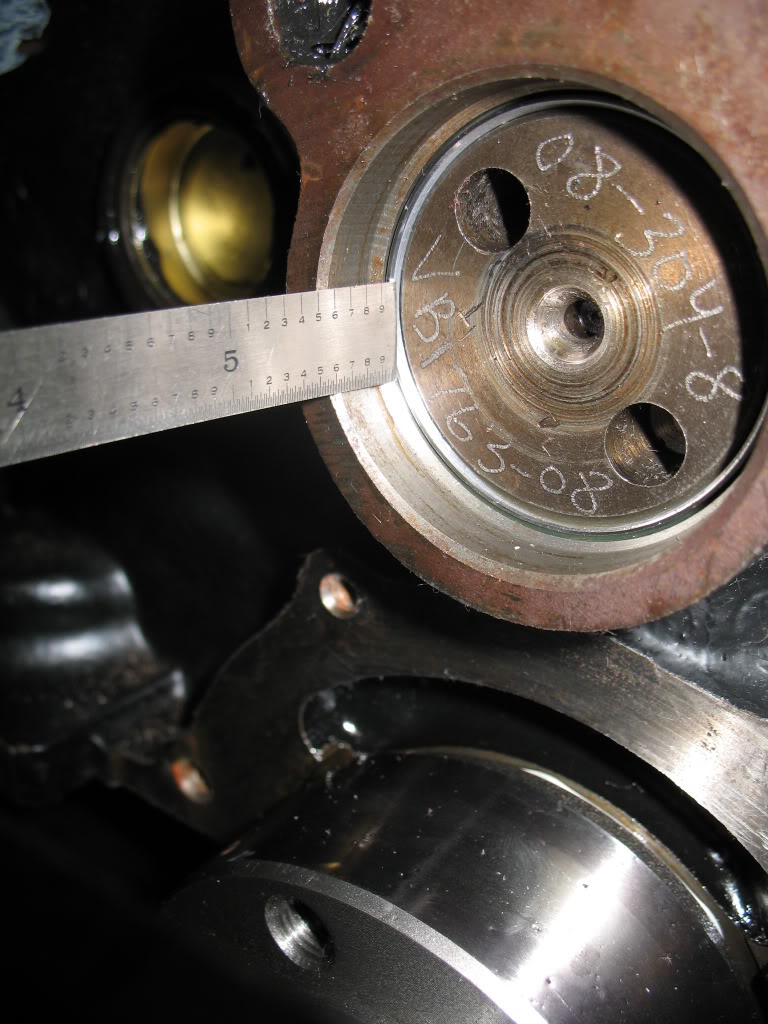

the rear cam tunnel freeze plug?

theres two, sizes

23/32-inch expansion plug or the 47/64ths (cam plug)

or

IF you somehow screw up the install,of the rear cam tunnel freeze plug, by failing to coat the freeze plug with sealant, along its outer edge, before you install it correctly, you can probably knock it out coat it with sealant and re-install it,

but the cost of a new plug is rather minimal and the risk of it failing , if its re-installed, also minimal,but if it was my engine,

yes I'd buy coat and install a new rear cam plug, as having it blow out once the engines installed would be a huge P.I.T.A.

leaving it in place without sealant can be done but you run a slightly higher chance of an oil leak, that would be a P.I.T.A. to fix later on.

this stuff is pretty much interchangeable

the dorman catalog showed both plugs for 62-68 327 & 67 up 350's also.

the small one is dorman # 555-049.

23/32 o.d.,

the large one is 555-080.

47/64 o.d.

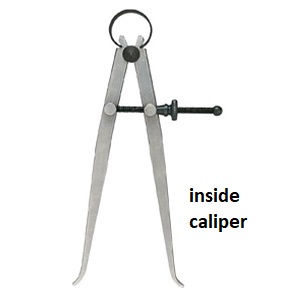

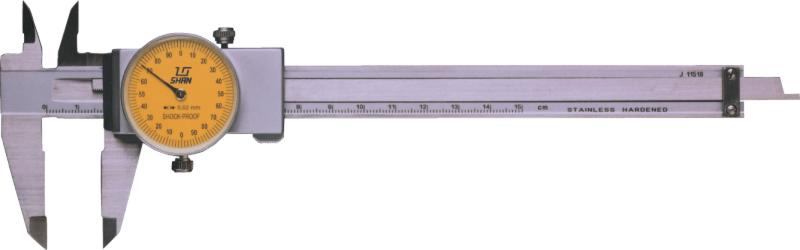

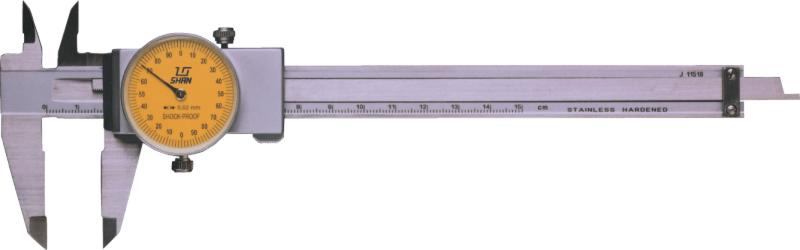

just be sure an measure the one you knock out or the hole it fits and use an accurate caliper

http://www.wizardswarehouse.com/products/tools

This does not just apply to just Chevys,

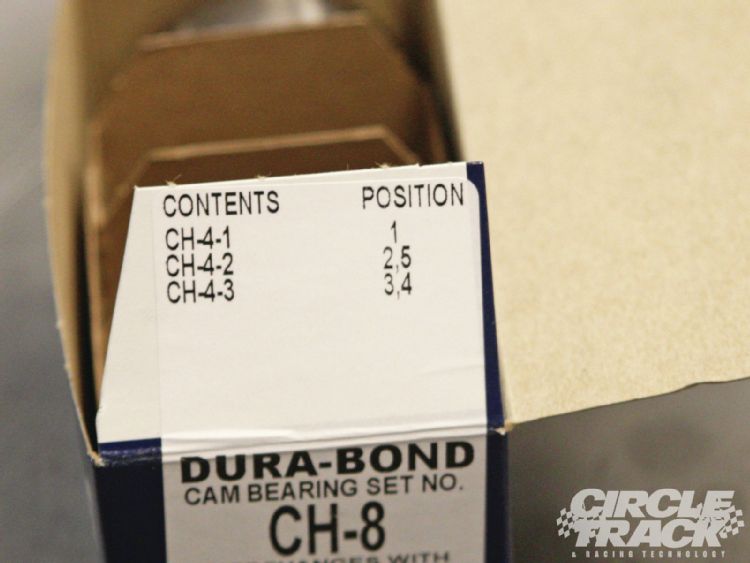

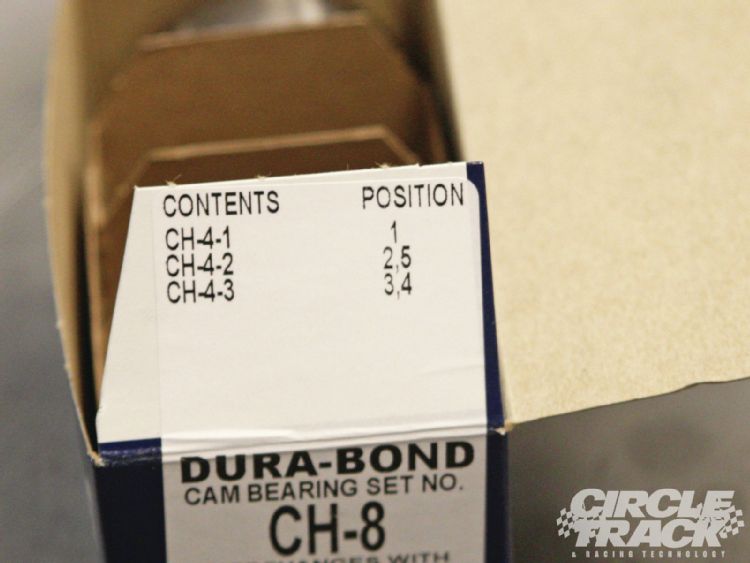

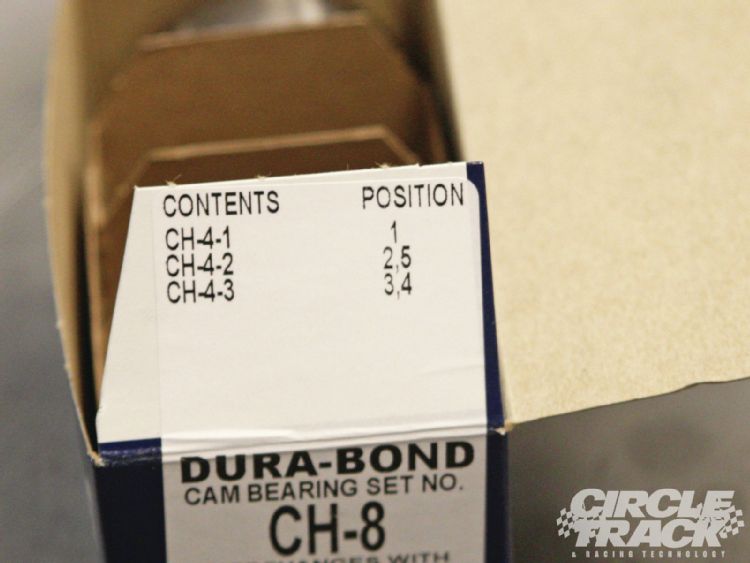

Look closely at the outer side of the back of the cam bearings theres usually a number on the back ,of the bearings, there also usually a small instruction sheet packaged with the bearings listing the outer dia. and the position in the block if the bearings differ in dia., if they do vary in size the rear is normally the smaller bearing

you must align the oil feed holes in the block with the bearing feed holes

on early (1965) bbc engines the rear cam bearing is grooved failure to use a grooved rear cam bearing causes problems on early big blocks

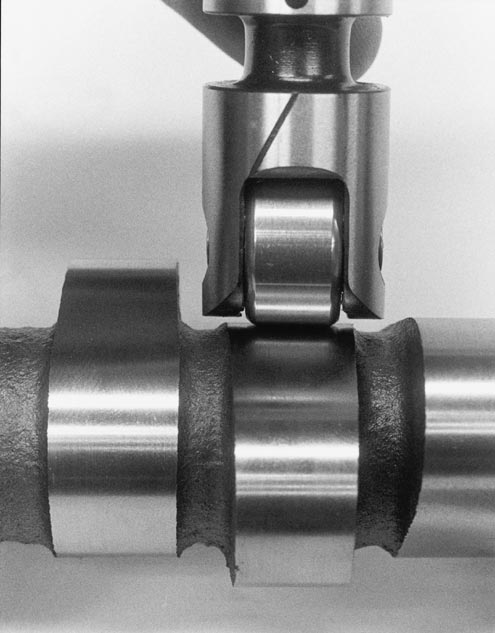

the 1965 and 1966 big block 396 had unique rear cam bearings and required a grooved rear cam journal, most cams you buy currently are not grooved, the groove can be cut on a lathe in the last rear journal on the later cams , centered ,and its about .188 wide and .125 deep, if the cam is cut,for that oil groove the standard cam bearing can be used[/size]

your potential rear cam bearing oil flow issue is found on the 1965- too a few very early 1967 BBC engines ,if you install the older design BBC cam with a grooved rear main in EITHER config with EITHER rear bearing your covered, and since thats just not expensive and any decent machine shop can modify any cam like that cheaply is the smart route to take if your in doubt

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=10360

The correct cam bearings for the engine you have is very impotent some take a grooved rear cam bearing #396 Clevite SH615S 65-66 only!!!

Clevite SH616S 67-93 396-427.

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

SBC CAM BEARING PART NUMBERS [/B]

dura-bond CHP-8

ACL 5C3349C

Clevite SH1349S

FM 2100M

Hi-Tech BC290SP

King CS507HP

TAKE THE EFFORT TO MEASSURE AND VERIFY BEARING LOCATIONS AND CLEARANCES

Taken From AERA Pro-Sis

Cam Bearing Bore diamentions

#1 2.0190-2.0210

#2 and #5 2.0090-2.0110

#3 and #4 1.9990-2.0010

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

BBC CAM BEARING PART NUMBERS

CHP-12

Clevite SH2144S

FM 2101M

Hi-Tech BC616SP

King CS524HP

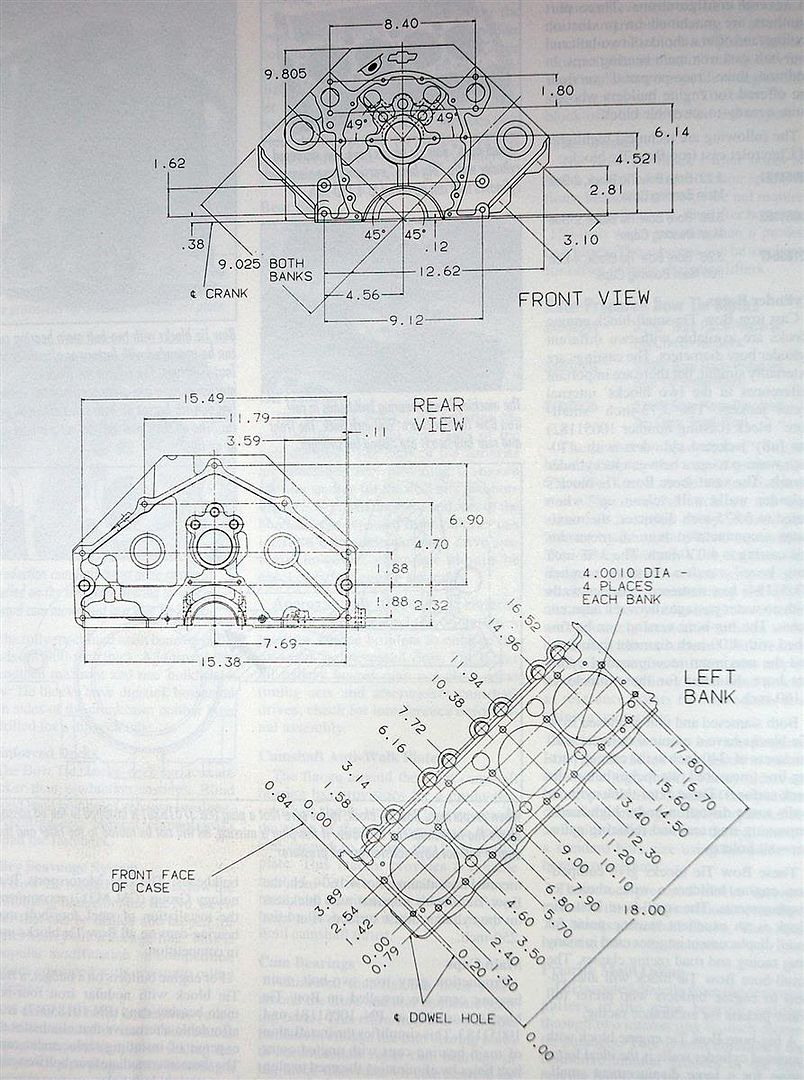

Cam Bore: 2.140 inches (number-1), 2.130 inches (number-2 and number-5), 2.120 inches (number-3 and number-4); cam bearing inside diameter: 1.950 inches

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

PONTIAC CAM BEARING PART NUMBERS

P-4 standard DUR-PP-4T coated, SOME use PB-9 check carefully

ACL 5C292S

Clevite SH292S

Engine Tech CC416

FM 1220M

Hi-Tech BC292S

King CS511BB

SDI MP109

sealed power 1220M

Camshaft Bearing Set

Part Number CS 511BB STD

For 1963-79 Pontiac engines

engines only.

only.

Cross reference- ACL: 5C292 CLE: SH- 292S DUR: P-4 FMO: 1220M

Positions 1 through 5

• cam journal diameter- 1.8992"/ 1.8997"

• cam tunnel bore- 2.0297"/ 2.0317"

• cam bearinglength- 0.6800"

• maximum wall thickness- 0.0644"

You can see from the specs above the cam bearings are basically identical

https://www.summitracing.com/search...-installation-and-removal-tools/universal/yes

shop carefully cam bearing tools sell for $40-$300 plus and almost identical tools car vary in price by over $120, and be awre all cam bearings in a single block may be different sizes based on the location, so pay attention as you remove them as to the oil feed hole location(S), how they are indexed or clocked and the outside diameter and be aware in many cases the bearing is beveled on one side to aid installation

Keep in mind chevy cam bearings are NOT interchangeable to all locations in the block, read the instructions and measure the bearings and the install location

download/file.php?id=2011

http://www.rodandcustommagazine.com/tec ... g_oil.html

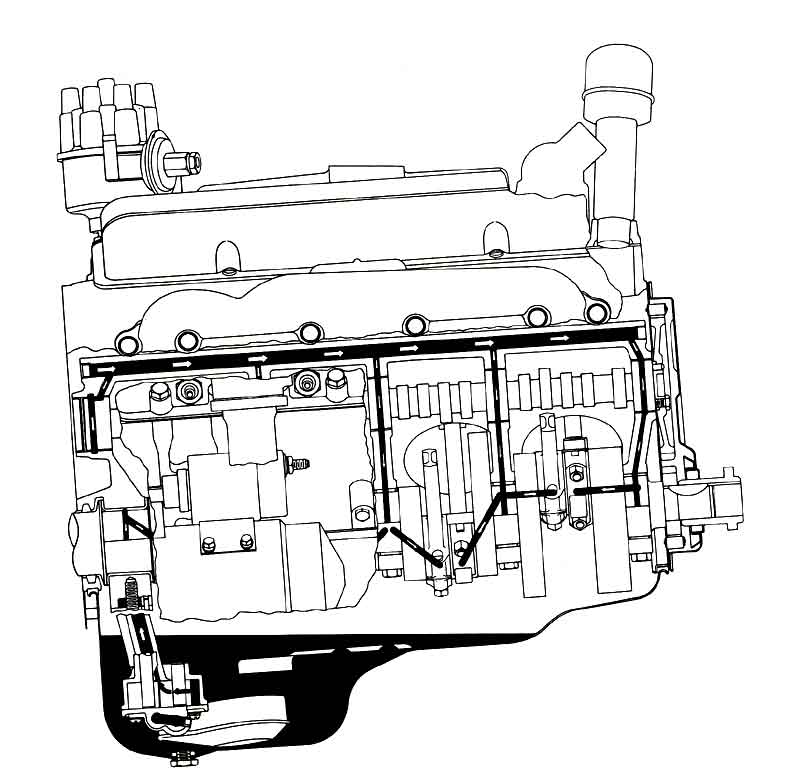

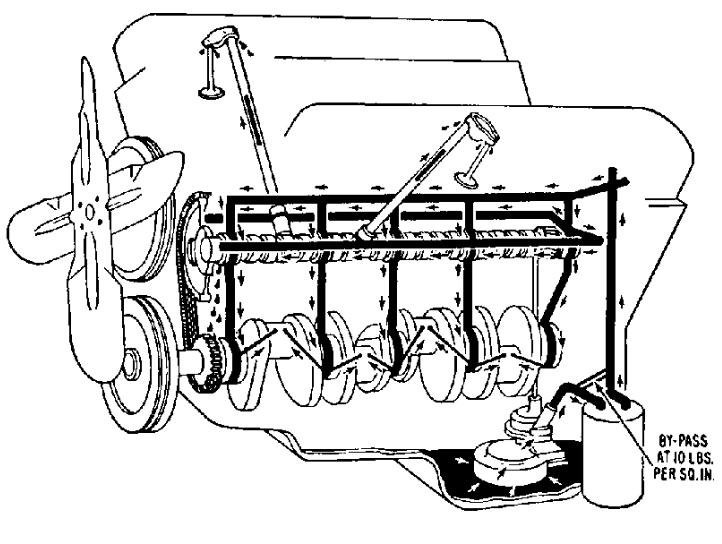

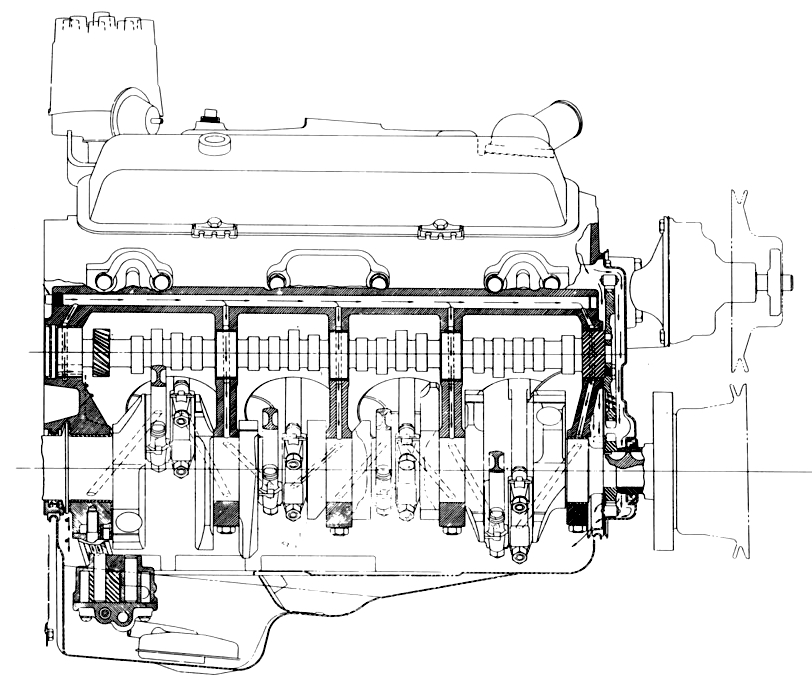

with the block in its normal operational position

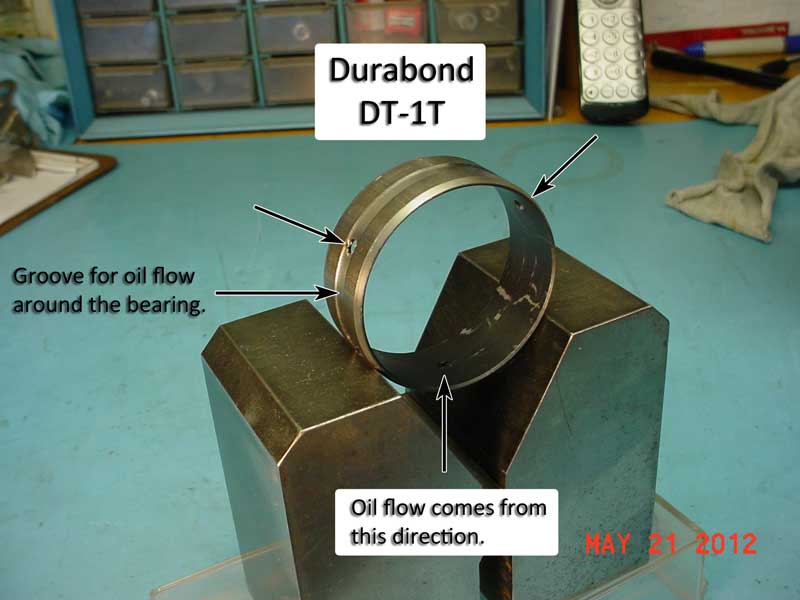

any oil needed will easily travel thru the passages and grooves,on the back side of the cam bearing, obviously if theres no oil groove in the rear of the bearing shell or block you have zero choice but to align the oil feed to the cam bearing oil feed holes. I would keep the bearing feed holes as previously indicated if these a oil feed groove.

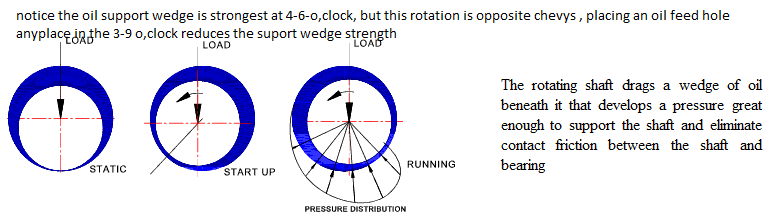

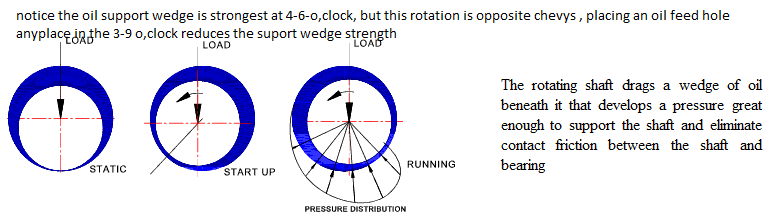

many cam bearings and many blocks are grooved to provide oil flow to the bearing feed holes, direction of the feed flow to the bearing is less important than maintaining the oil wedge under the cam journal at the area of max loads

REMEMBER the pressure in any portion of an hydraulic system is equal throughout that system., your oil pump will maintain pressure and oil flow to the bearings, changing the flow direction of the oil feed passages has little effect

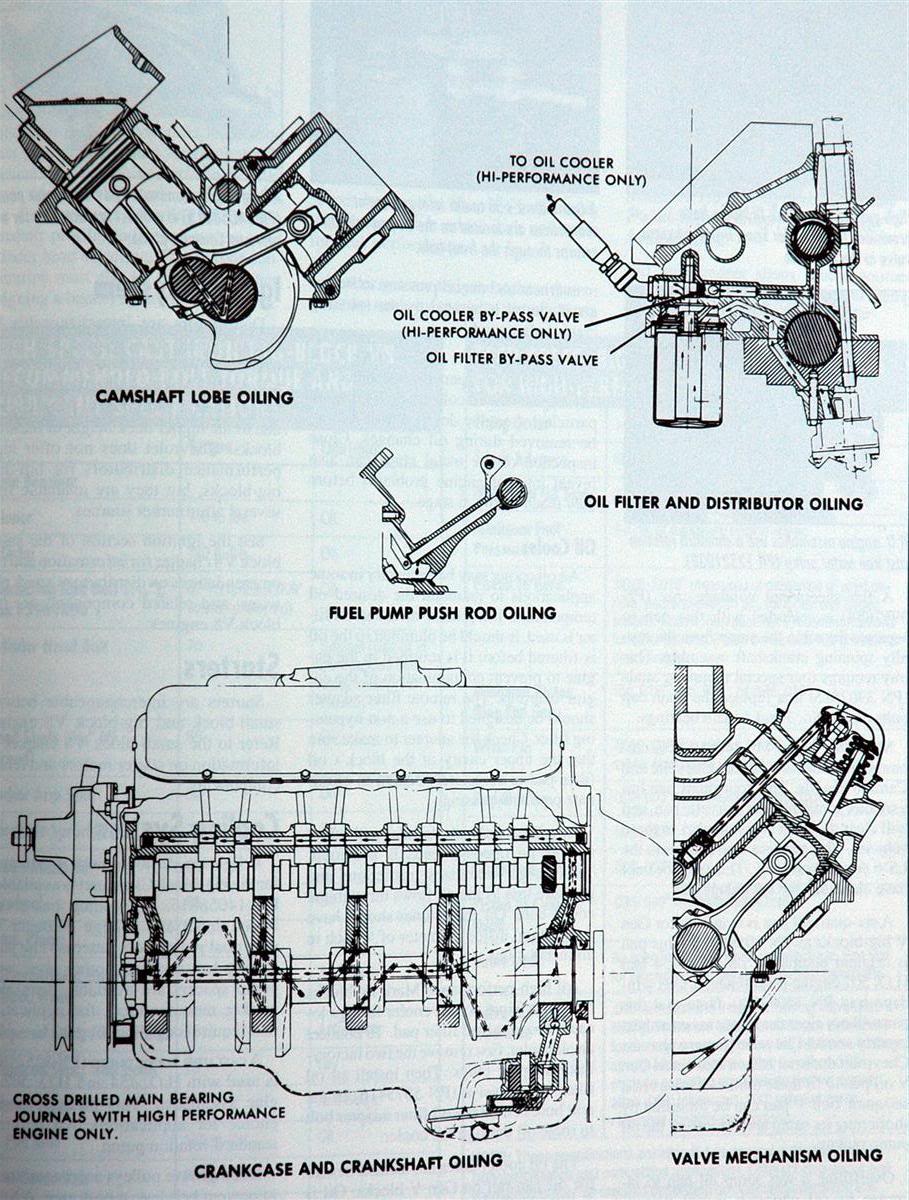

If there's the groove in the block under the cam bearing, it provides the route pressurized oil takes around the bearing that feeds oil to location past that point in the oil distribution,and supplies the feed to the cam bearing, the ideal oil feed is indicated in the upper diagram, if there's no groove in the block under the bearing, your forced to line the holes in the block that feed oil up to the bearing, to the holes in the bearing, or bearing feed hole location.

any and all of the rear 4 bearing oil feed holes will work located in the 12-to-2 0.clock location

looking at the block from the front in its normal operating orientation with the oil pan down, heads on top

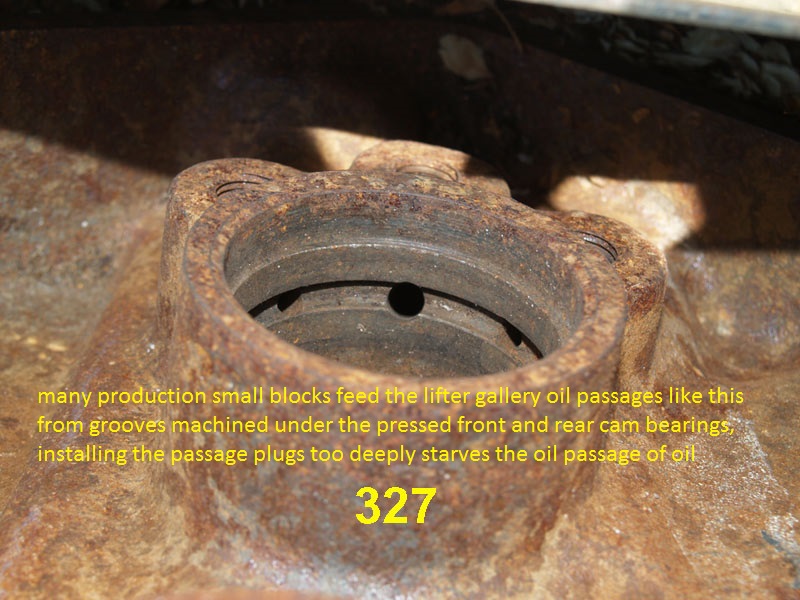

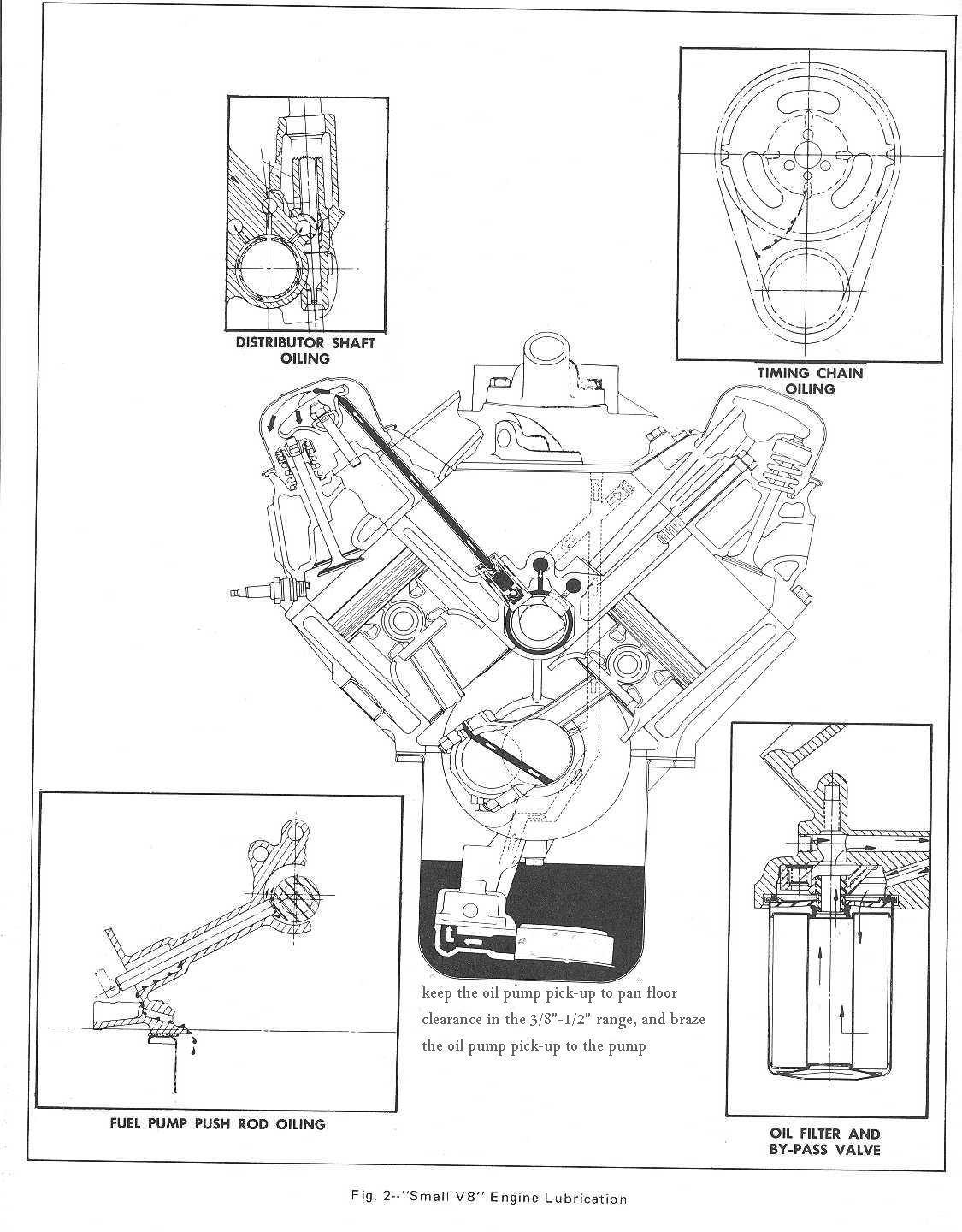

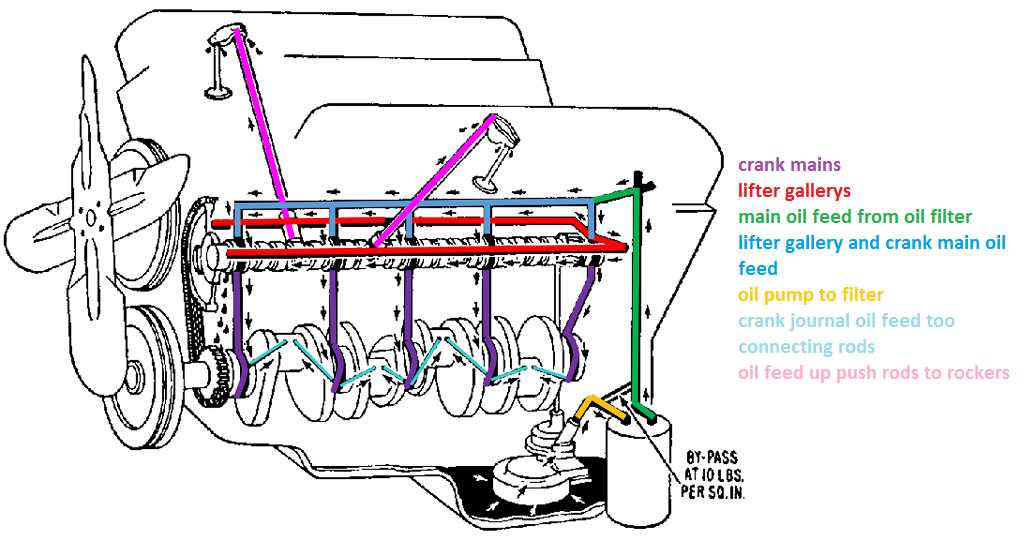

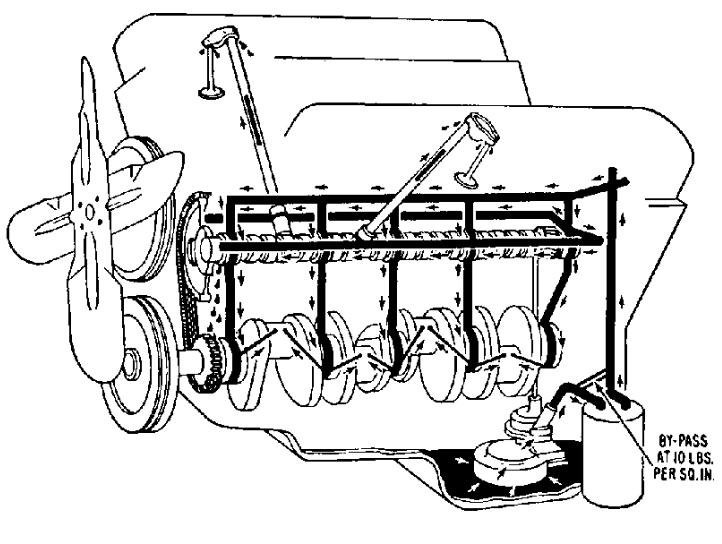

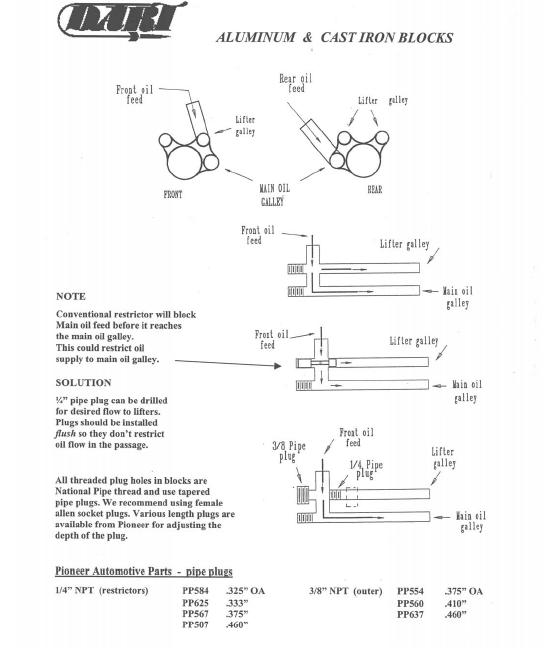

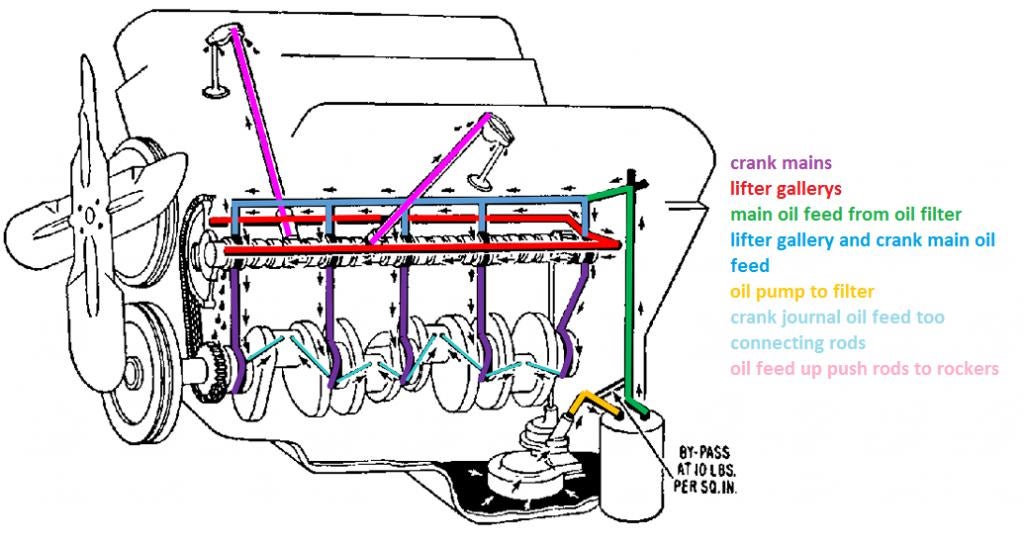

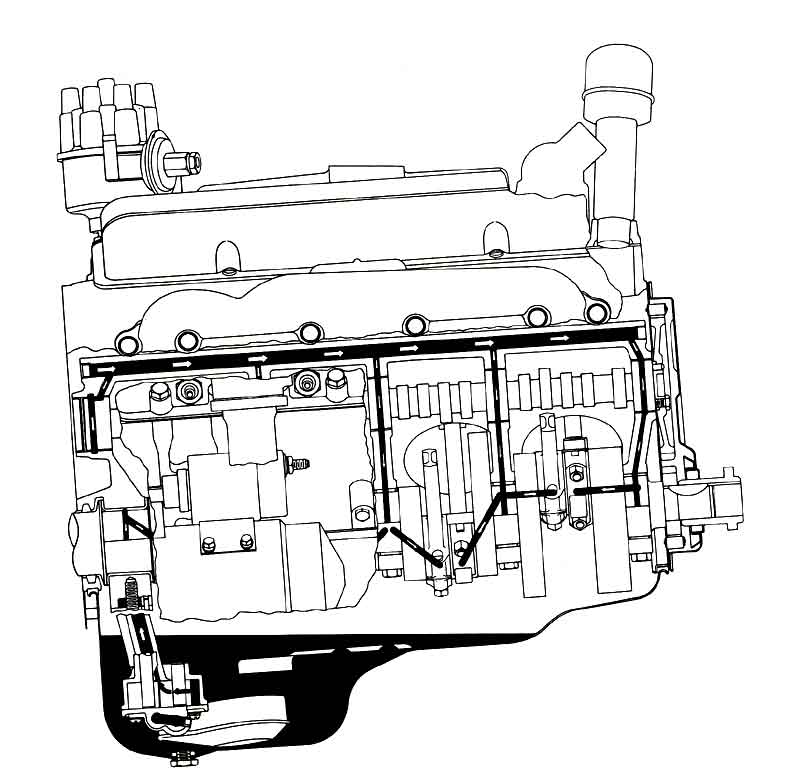

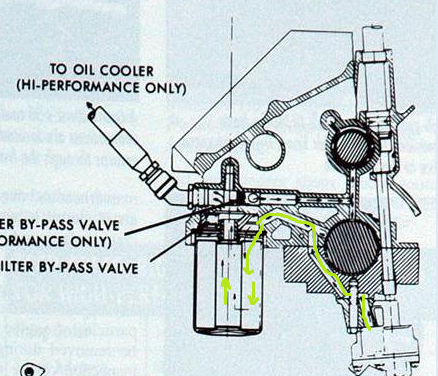

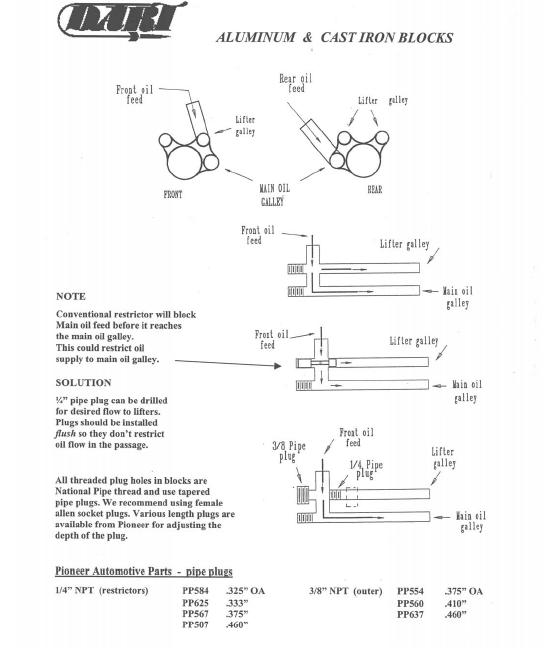

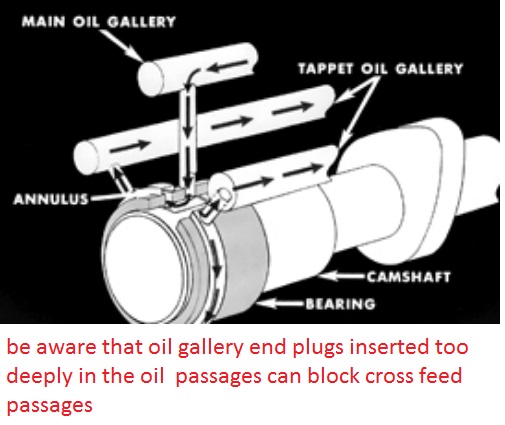

the front bearing , feeds back into the lifters so the diagram below may help clarify this, in fact some guys drill a third hole

and locate the bearing holes with a 10-,12,-2 o.clock hole location, the reason this is done is that if you bust a push-rod and the lifter gets thrown clear of its lifter bore (which while rare does happen) all the lifters farther fore ward in the block on that side ,of the block, drop to a lower oil pressure reading without that reverse oil feed, modification being installed,helping to maintain flow to the lifter feed oil passage,, and while its not going to be perfect it will help during the few seconds it takes you to realize the engine in trouble

[/color]

pontiac

chevy is similar but the cam bearing locations are noty all interchangeable on chevy

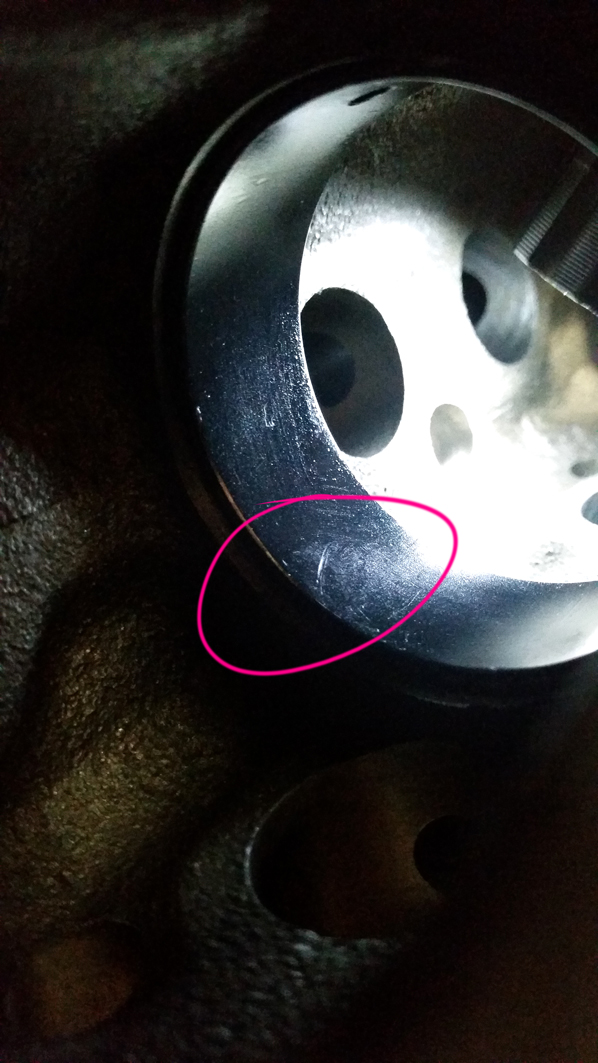

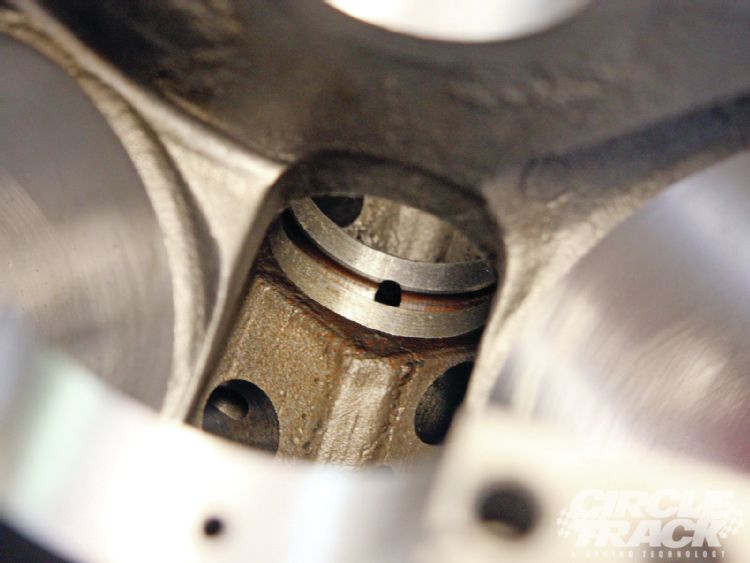

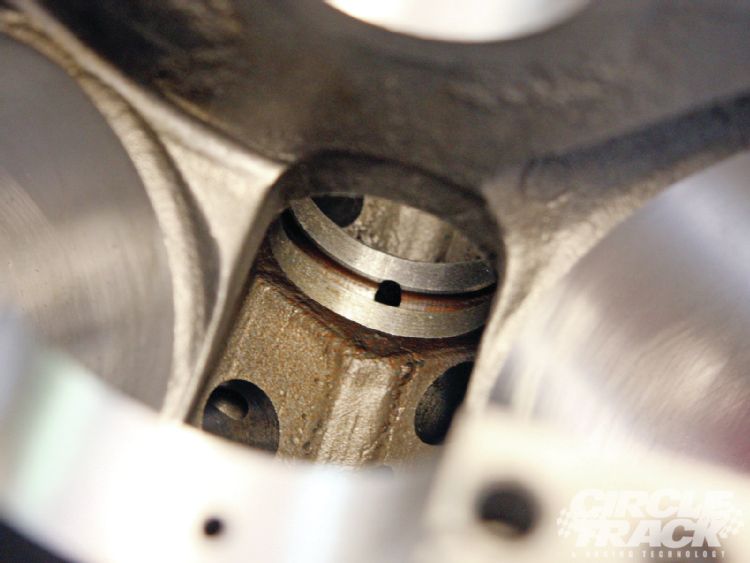

I get asked all the time if you can re-used cam bearings, well its your call but I feel its a dumb move to do so, if you have the engine out and your refurbishing it, the oil passages should be cleaned anyway,any time you have the block stripped its almost a mandatory task to replace cam bearings and clean out oil passages, any time you damage a cam bearing its best to replace it as and surface damage tends to result in lower oil pressure and less bearing support, remember theres easily 1000-2000 ft lbs of valve spring pressure on those cam bearings at all times, so if you can,once you've inspected a damaged cam bearing, Id replace that, damaged cam bearing,(S) you've put too much effort and money into doing things correctly to use a damaged cam bearing, the cost of a full set, even if you damaged new bearings during the engine assembly process ,that youll need too get, is just not that high, neither is it difficult to replace , with the engine out of a car on an engine stand,and yes it will drop your oil pressure a bit if left damaged, I don,t know how much it would reduce the pressure but for something that cheap and easy to replace I would NEVER even consider using it in that condition.

usual cost of about $32

usual cost of about $32

http://www.summitracing.com/parts/AAF-A ... /?rtype=10

http://www.summitracing.com/parts/CLE-S ... refilter=1

READ THRU THIS LINK

http://www.dura-bondbearing.com/Portals ... lletin.pdf

http://www.mellingdurabond.com/Portals/ ... arings.PDF

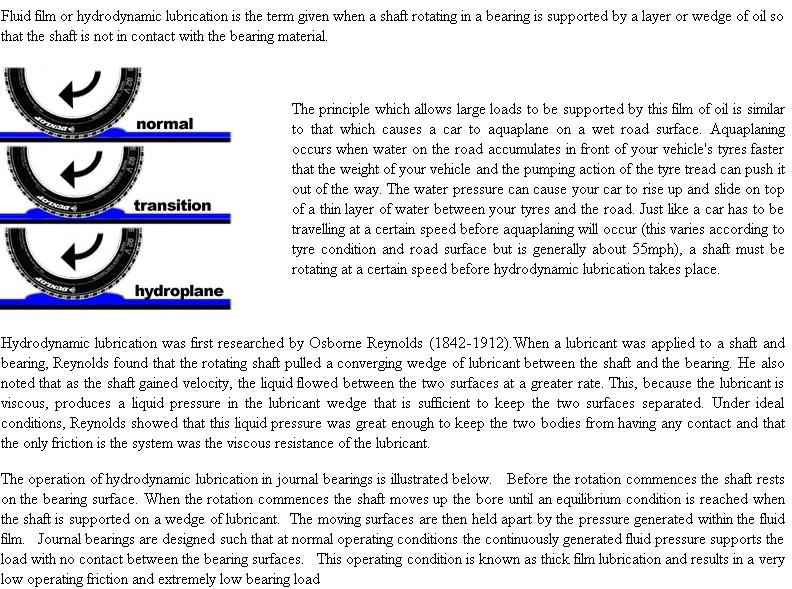

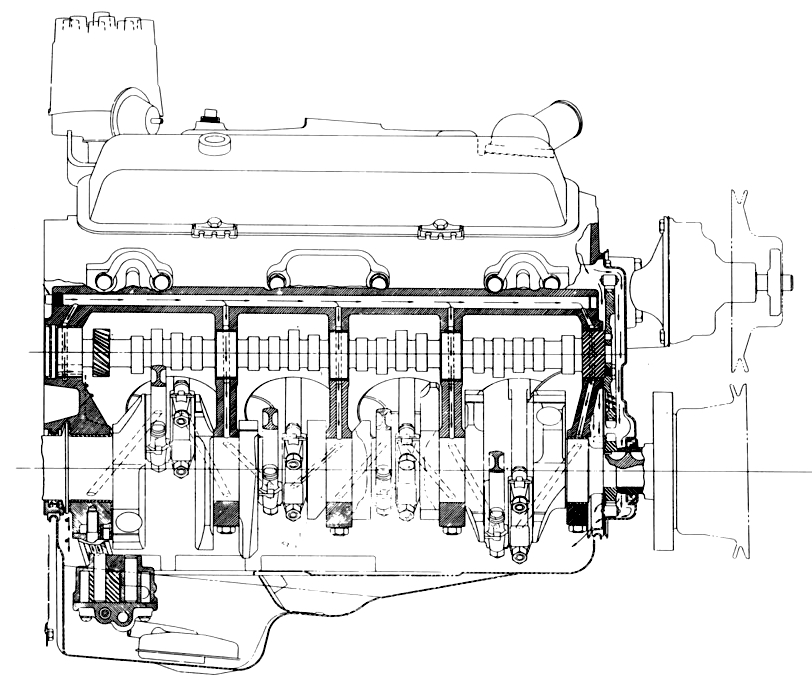

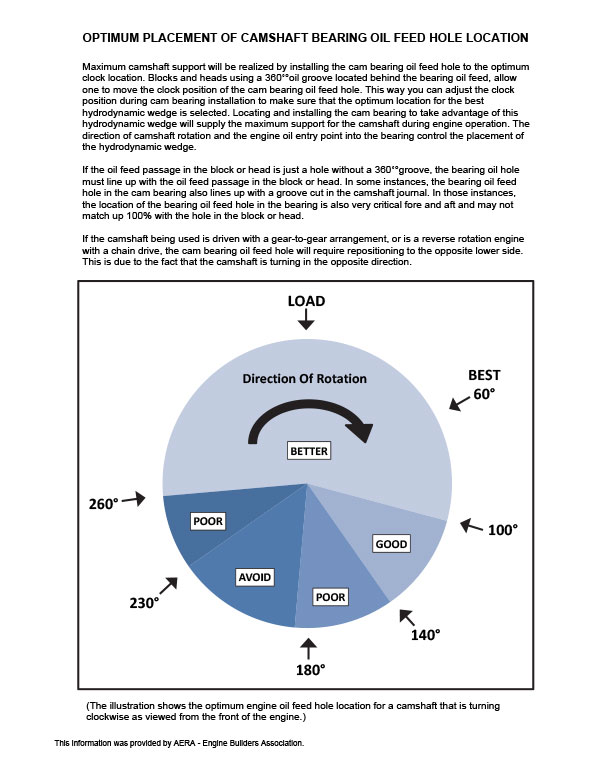

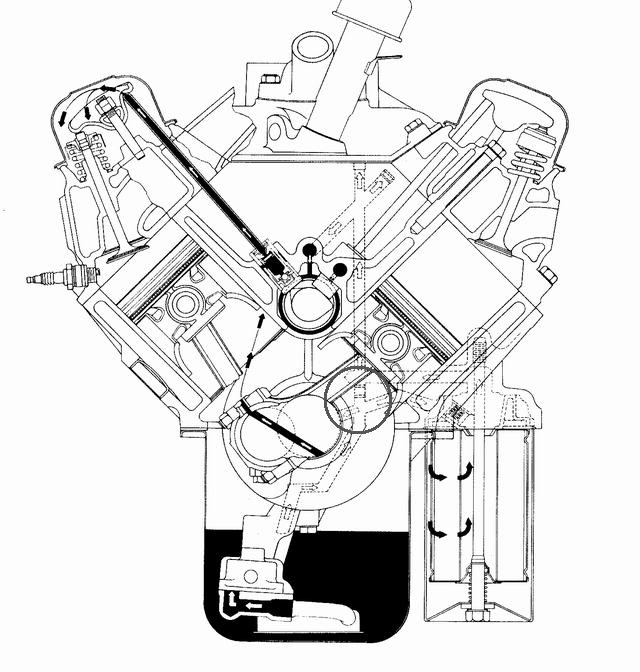

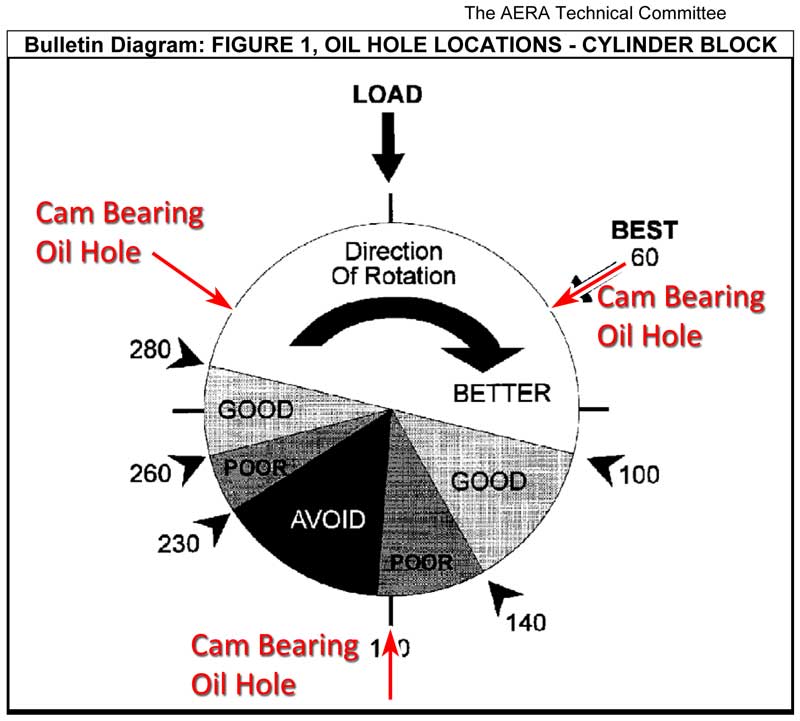

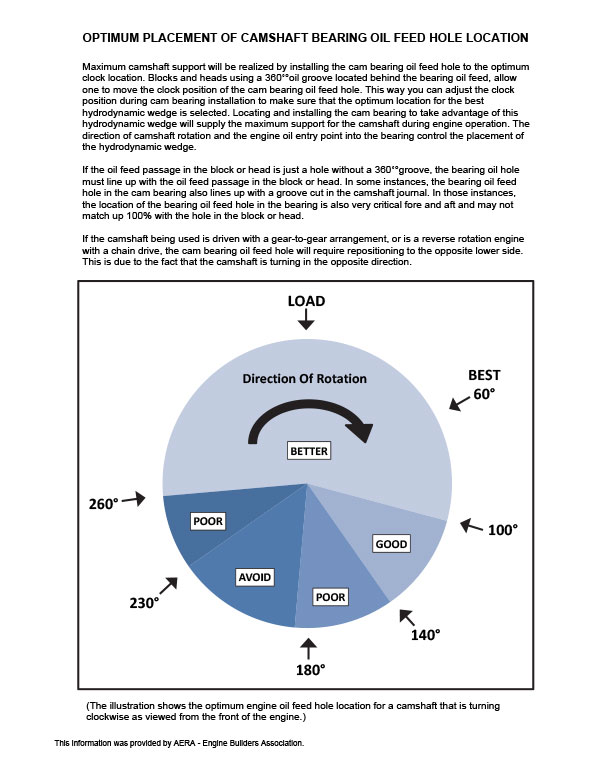

Optimum Placement Of Camshaft Bearing

Oil Feed Hole Location

The AERA Technical Committee offers the following important information on

optimum placement of camshaft bearing oil feed hole location during installation.

This information should be considered any time camshaft bearing replacement is

being done.

Maximum camshaft support will be realized by installing the cam bearing oil feed

hole to the optimum clock location. Blocks and heads using a 360° oil groove

located behind the bearing oil feed, allow one to move the clock position of the cam

bearing oil feed hole. This way you can adjust the clock position during cam

bearing installation to make sure that the optimum location for the best

hydrodynamic wedge is selected. Locating and installing the cam bearing to take

advantage of this hydrodynamic wedge will supply the maximum support for the

camshaft during engine operation. The direction of camshaft rotation and the

engine oil entry point into the bearing control the placement of the hydrodynamic

wedge.

Note: If the oil feed passage in the block or head is just a hole without a 360°

groove, the bearing oil hole must line up with the oil feed passage in the block or

head. In some instances, the bearing oil feed hole in the cam bearing also lines up

with a groove cut in the camshaft journal. In those instances, the location of the

bearing oil feed hole in the bearing is also very critical fore and aft and may not

match up 100% with the hole in the block or head.

The illustration in Figure 1 below shows the optimum engine oil feed hole location

with the block in its normal operational position

(oil pan at the 6 0,clock location)

place the cam bearings in the blocks cam bore exactly like the picture shows

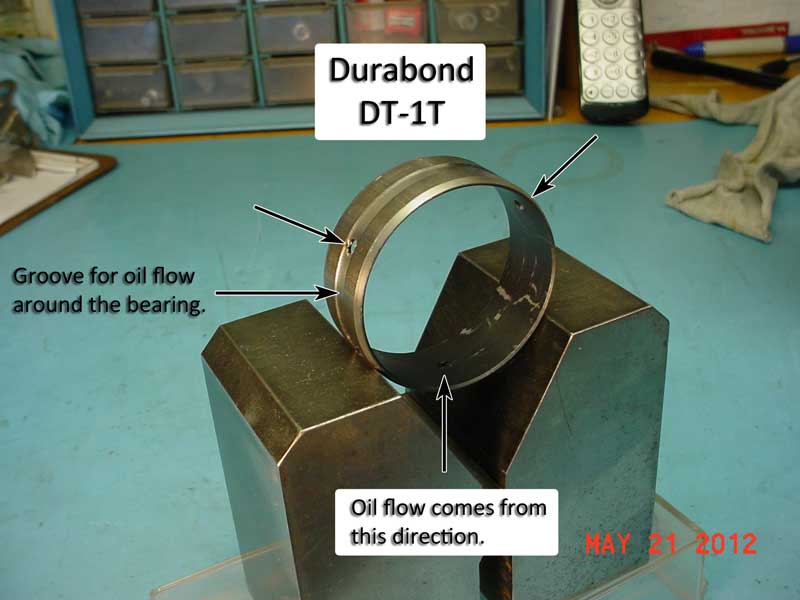

the groove on the back helps to eliminate the total loss of oil reaching the cam journals if it is indexed into the block incorrectly, but having the oil flow enter at the top 1/3rd of the rotation provides the best possible hydraulic oil film. load support

Its generally a very poor idea to locate the oil feed hole at the bottom or 6 ),CLOCK as thats where the oil wedge needs to be the strongest and where the oil feed will be most restricted due to thousands of pounds of valve spring loads on the cam core, trying to seal off the oil feed hole, placing the bearing oil feed hole at between 12 o,clock and 2 o,clock provides the largest possible clearance and oil flow rate plus allows the full 180 degrees of the bearings lower surface to support the cam journal

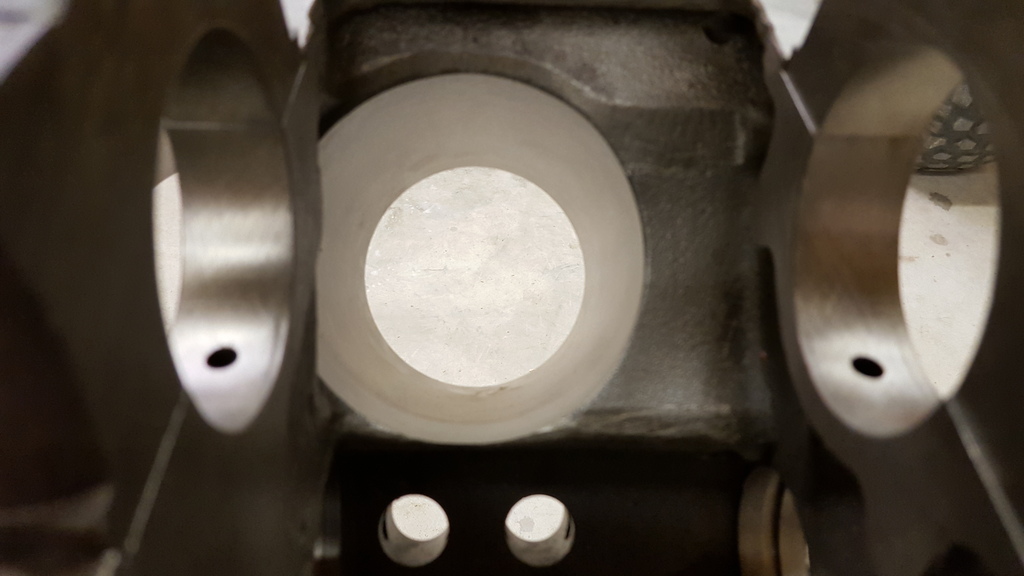

in a properly set up block a pressurized oil film supports the cam and main bearings

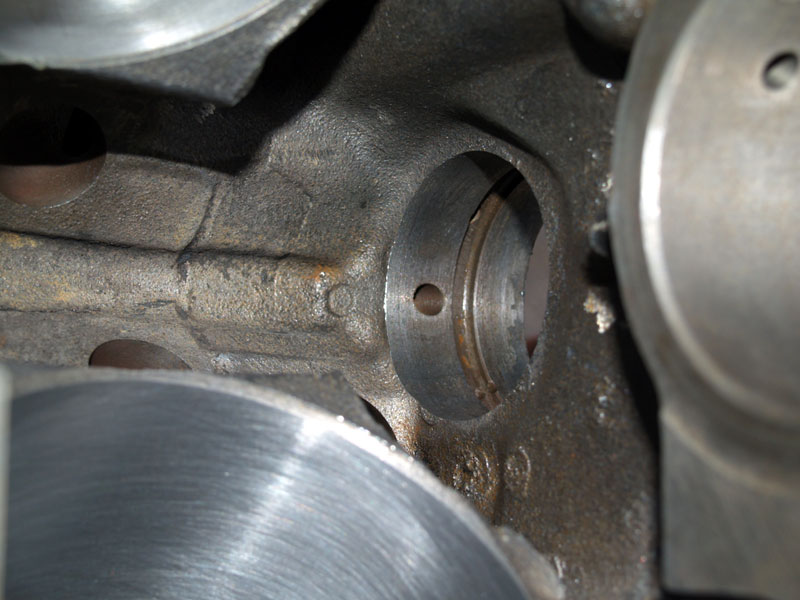

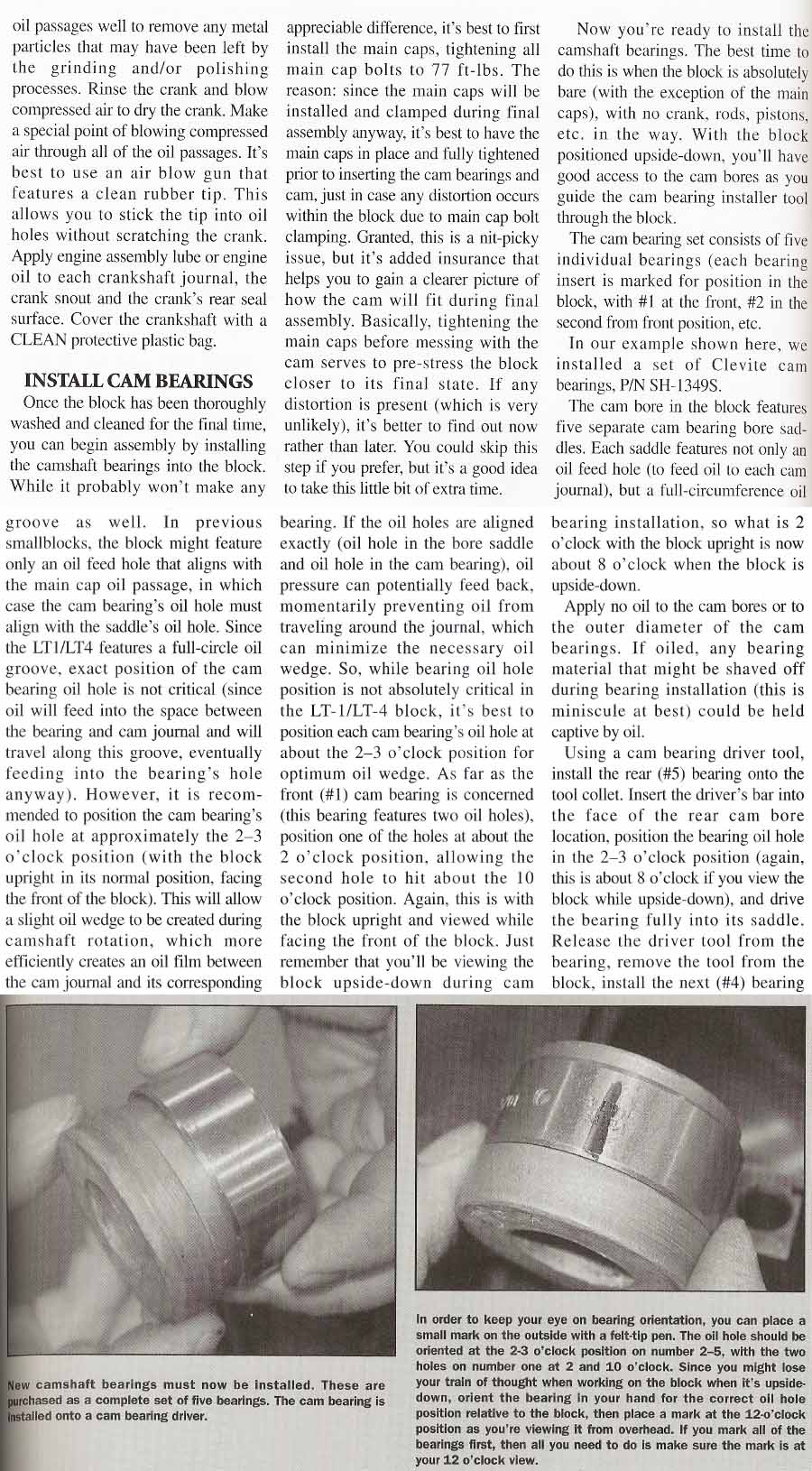

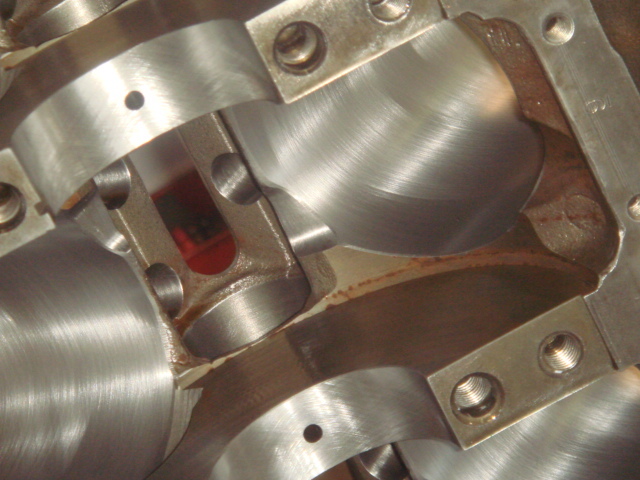

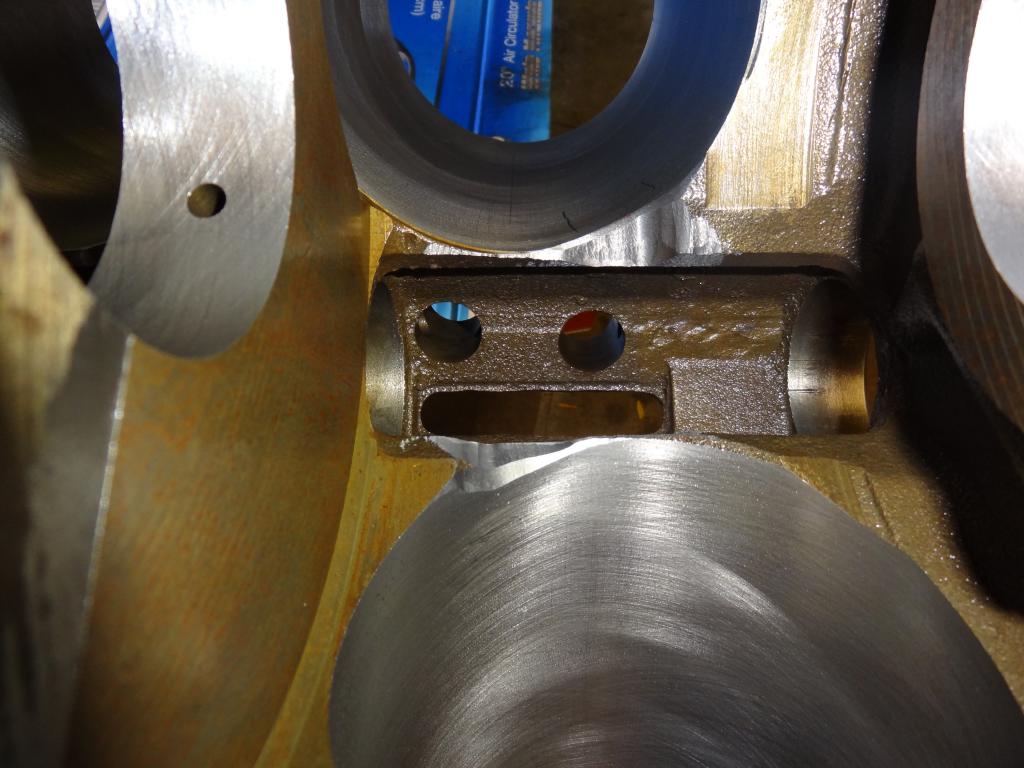

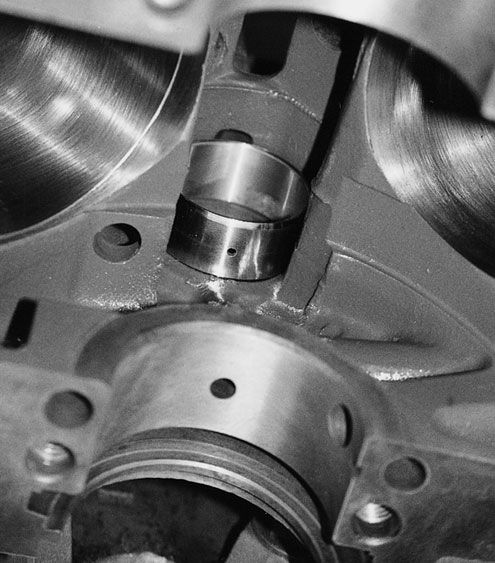

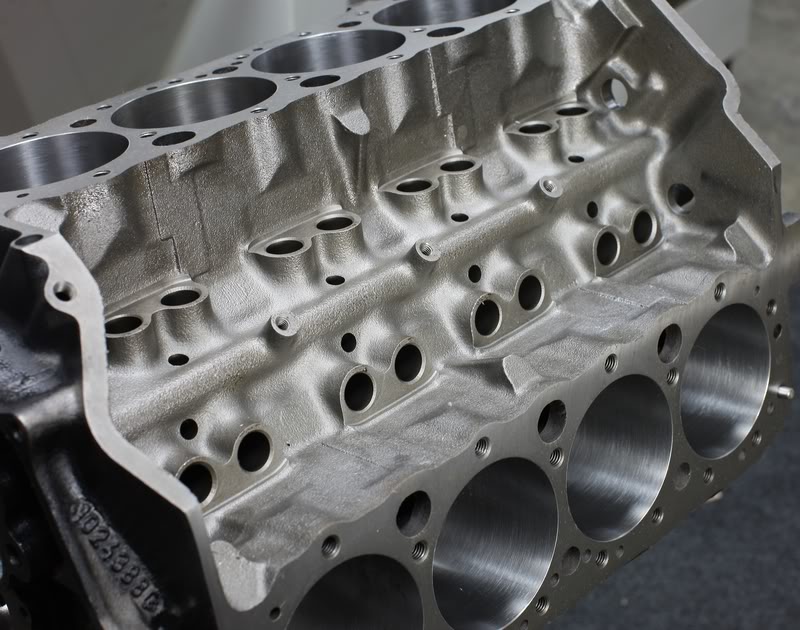

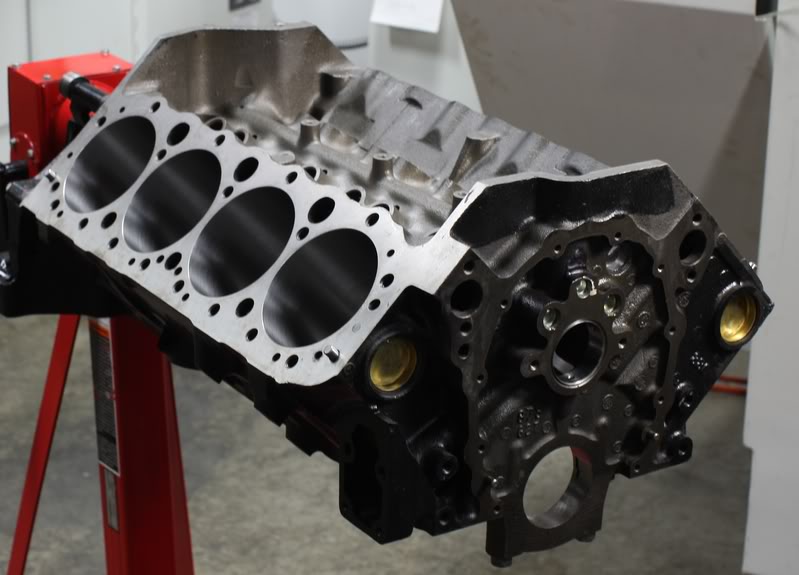

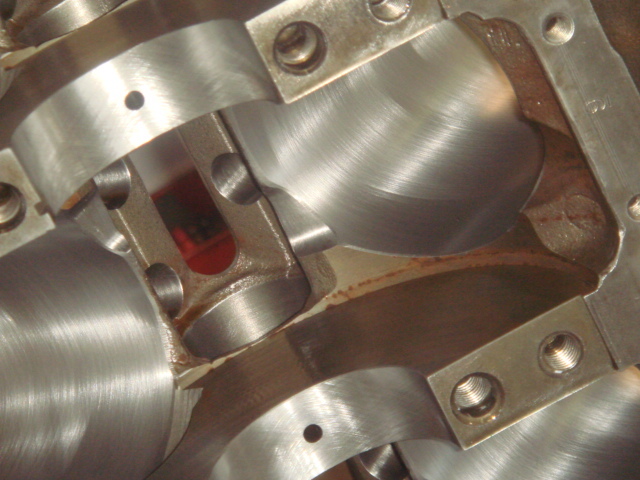

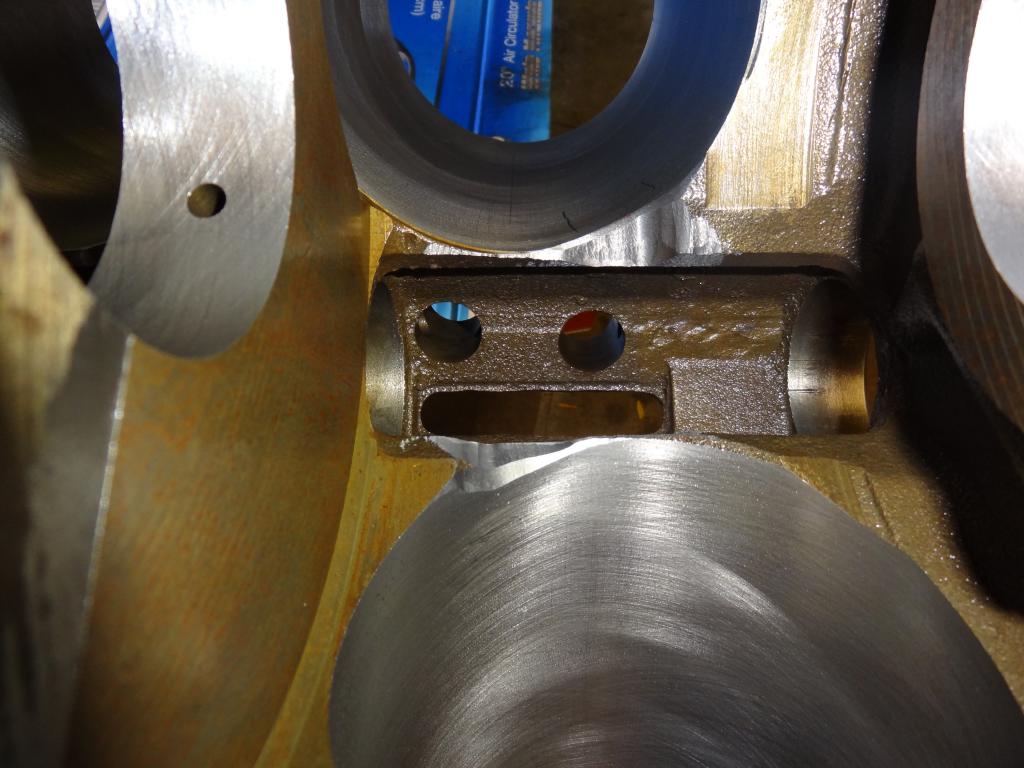

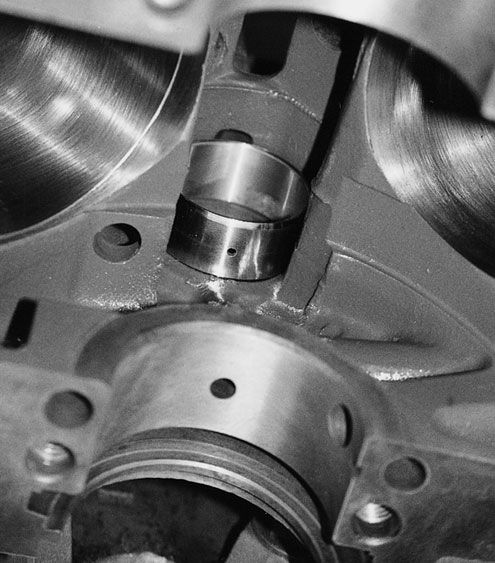

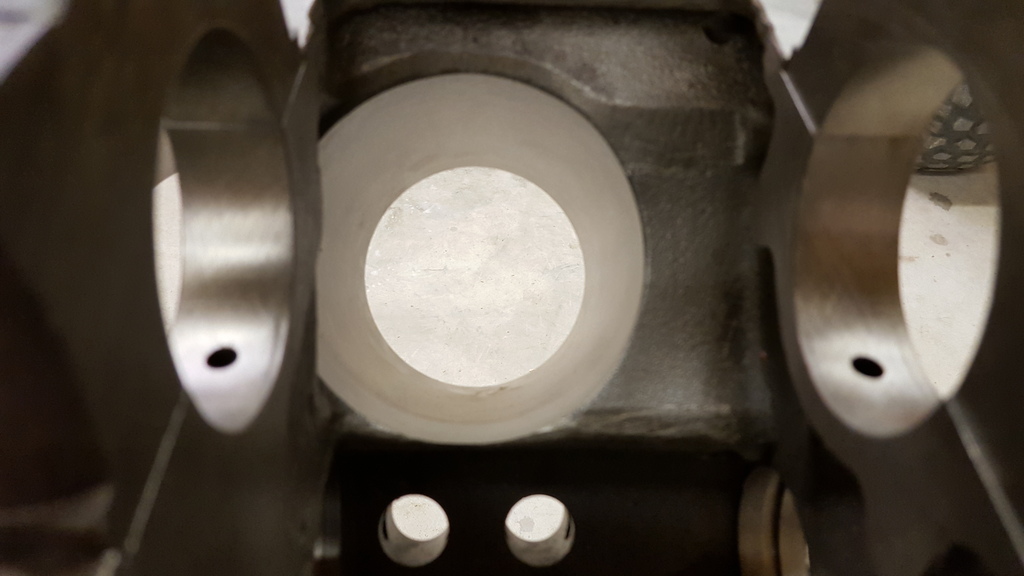

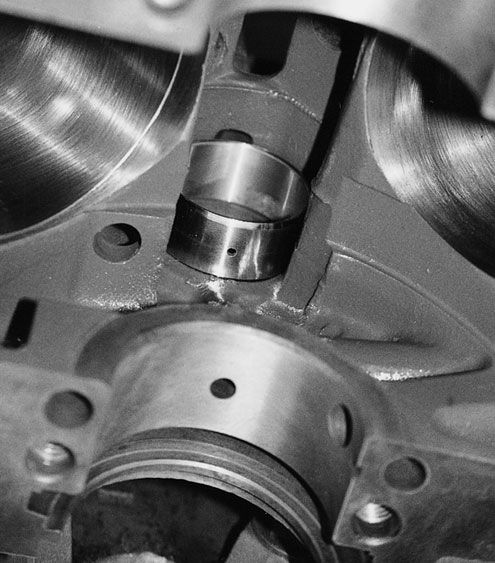

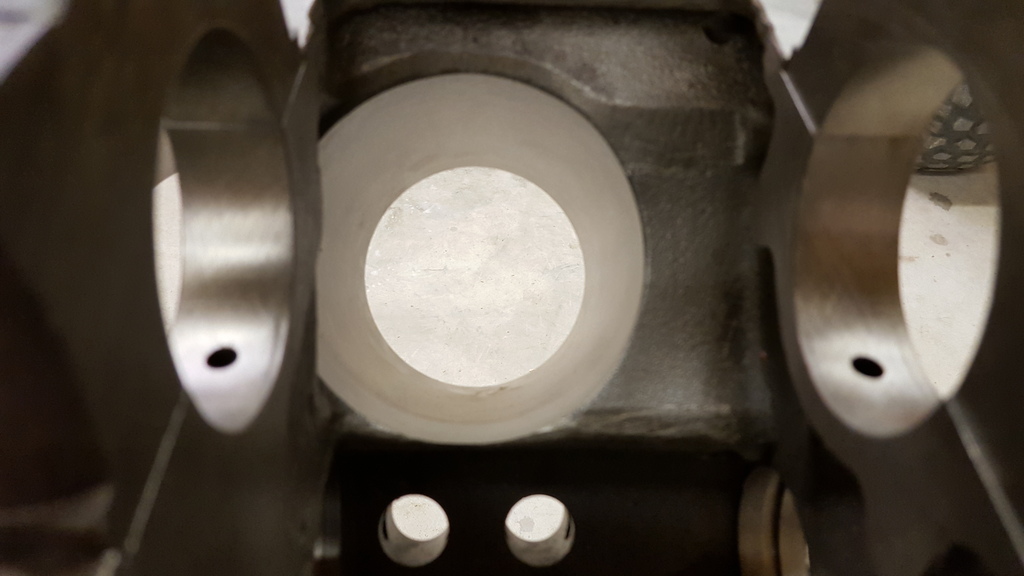

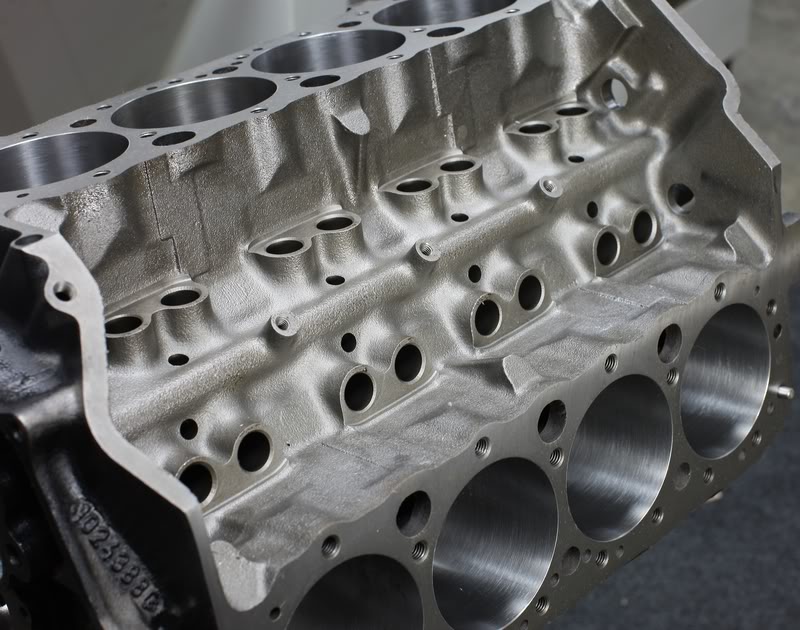

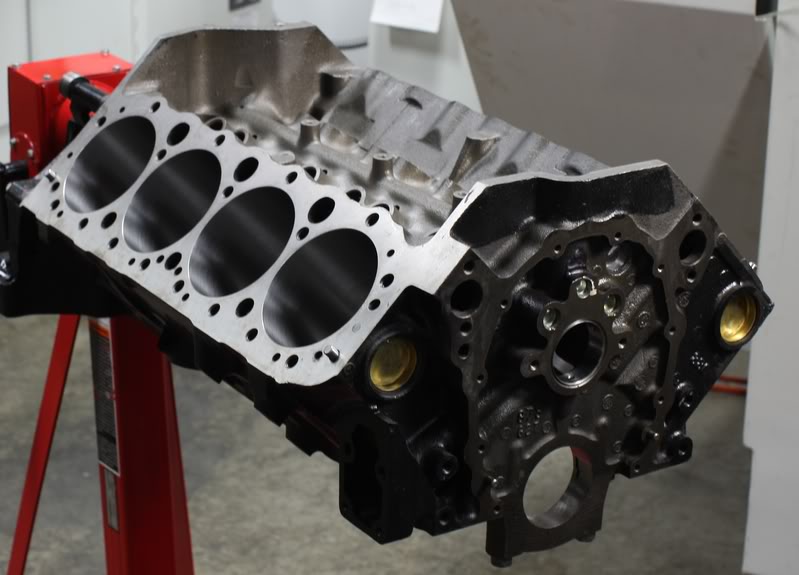

heres the block with the oil pan mounting surface at 12 o,clock or upside down, look at the correctly located oil feed holes in the cam bearings, notice they match the diagram, and two red arrows that show where the dual oil feed holes should be, on bearings with only one feed hole the 12 o,clock to 2 o,clock oil feed hole index is correct, the load is mostly on the cam bearings lower 180 degrees so you sure don,t want oil film strength lowered in that area, by having a oil feed hole that can act like an oil pressure release point in some conditions, you want a maximum thickness oil wedge formed under and supporting the cam journal

be aware both the sbc and bbc engines may not have the block machined for an oil feed groove under the cam bearings in some locations

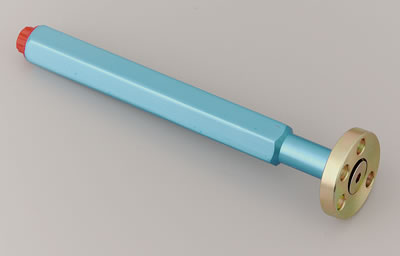

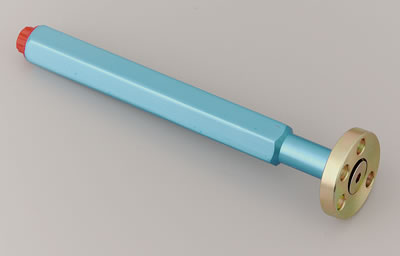

use of a camshaft install handle generally reduces the chances of damaged cam bearings

VERIFY,SOME DART AFTERMARKET BLOCKS DON.T USE OEM CAM BEARINGS

http://www.speedwaymotors.com/Dart-DT-1T-Cam-Bearings-for-Little-M-Chevy-Block-Set-5,24164.html

http://www.lislecorp.com/uploads/instru ... 726DB5.pdf

http://www.kmjent.com/cart/product.php?productid=597 (good value)

http://www.dura-bondbearing.com/Portals ... lletin.pdf

http://www.pbw-india.com/theory.htm

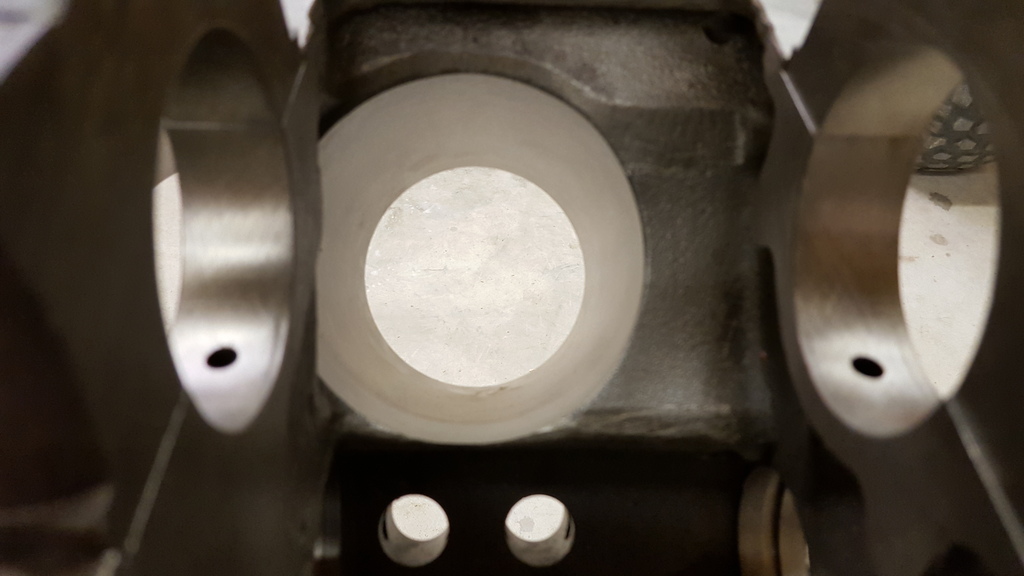

MAIN BEARINGS FEED FROM THE CAM BEARINGS SO LINING UP OIL FEED HOLES IS CRITICAL

most blocks only have the outer or end cam bearing journals grooved under the cam bearings making proper indexing of the oil feed holes on the 3 inner cam bearings critical, some blocks don,t even have those outer block cam bearing locations grooved

any time you go to install new cam bearings in an engine you first take detailed notes and a few pictures of the OLD cam bearing in the block under good lighting to note the location of the oil feed holes and and grooves, then as they are removed you number them each as its removed and measure them as on many engine they are NOT INTERCHANGEABLE between all main cap locations

http://www.amazon.com/Competition-Cams- ... B000A8MQFY

the tool Ive had and used for DECADES, it works reasonably well.

but check around for a used one in good condition, I bought mine at a chevy swap meet for $80

http://www.lislecorp.com/divisions/products/?product=58

http://www.lislecorp.com/uploads/instructions/18000_WebInstr_CC56DD9726DB5.pdf

keep in mind that I was recently quoted these prices for a cam bearing install, at about $110 a set installed it won,t take long to justify buying a decent cam bearing tool

Cam bearings $ 30.00

Cam bearing remove & install $75.00

https://www.summitracing.com/search...toview=SKU&sortby=Default&sortorder=Ascending

http://www.summitracing.com/search/?key ... tool&dds=1

http://www.summitracing.com/search/?key ... ings&dds=1

http://books.google.com/books?id=G2kUib ... q=&f=false

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.jegs.com/i/Proform/778/66794/10002/-1

http://www.rodandcustommagazine.com/tec ... index.html

READ THESE LINKS AND THREADS[/color]

http://www.jegs.com/i/Proform/778/66820/10002/-1

viewtopic.php?f=51&t=125

viewtopic.php?f=54&t=2187&p=5890#p5890

viewtopic.php?f=53&t=2727&p=7078&hilit=magnets+screens#p7078

viewtopic.php?f=51&t=2919&hilit=cleaning+passages+lifters

viewtopic.php?f=53&t=2727&p=7078&hilit=magnets+screens#p7078

http://video.google.com/videosearch?oe= ... Q&start=40

Cam bearing tools

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.aptfast.com/Flyer_HowTo_Dir/ ... arings.htm

http://rodcustom.automotive.com/75500/0 ... index.html

the oil holes should be at the 12 oclock-2 o-clock with the block in the normal position and looking from the front with the block right side up,that allows the oil to form a support wedge under the cam load, on a sbc but carefully verify that the oil passages align with the oil holes in the bearings

bearings are frequently numbered,#1 to #5

*1 is the front one ,The cam bearings are just slightly different in diameter, so you have to make sure you install them in the correct order.the diam. are listed in the link below if you got them mixed up, Make sure the oil holes are lined up when you put them in.12 oclock-3 o-clock with the block in the normal position and looking from the front

read thru this link below carefully

http://static.summitracing.com/global/i ... 900130.pdf

QUOTE

CNC BLOCKS N/E"

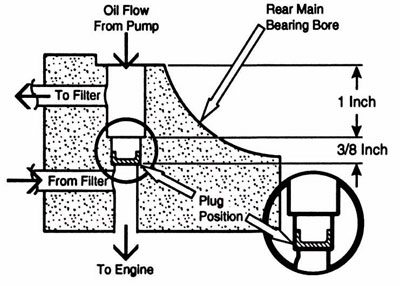

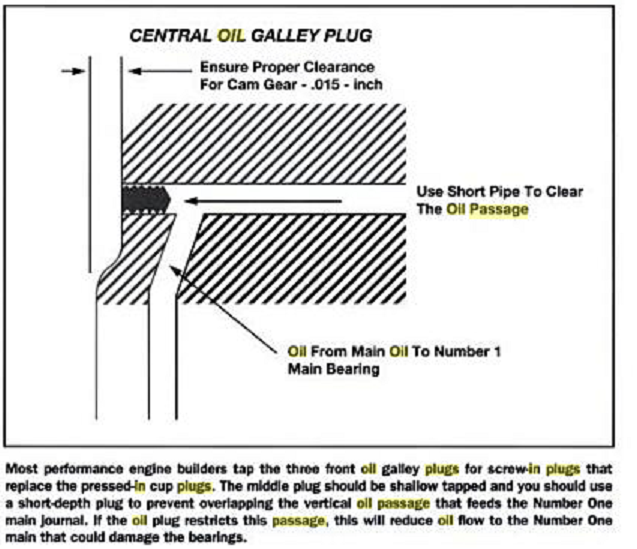

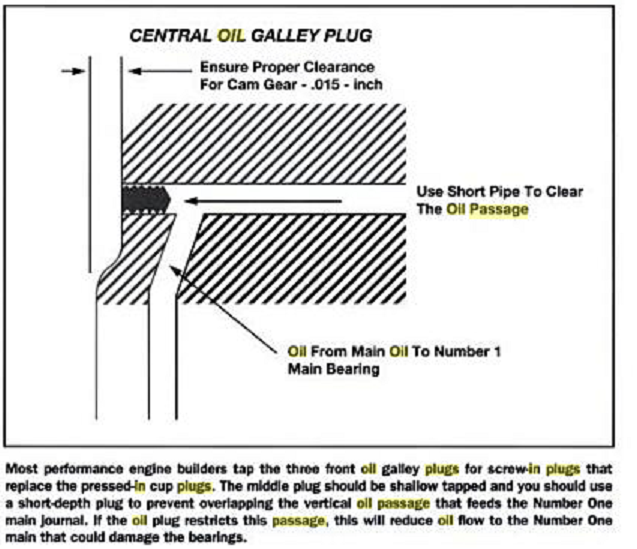

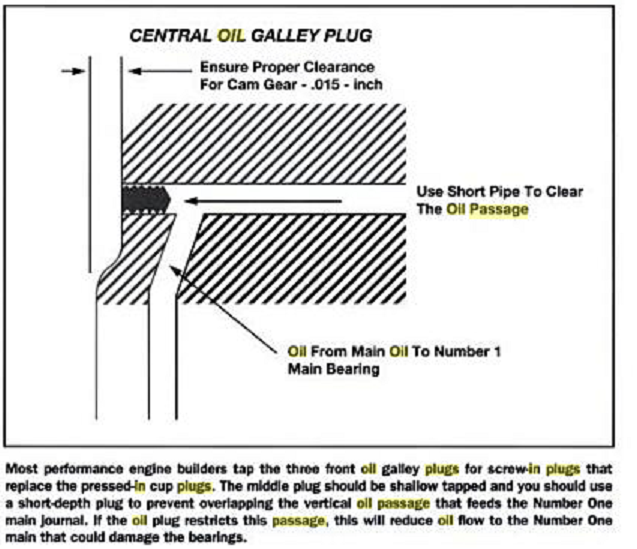

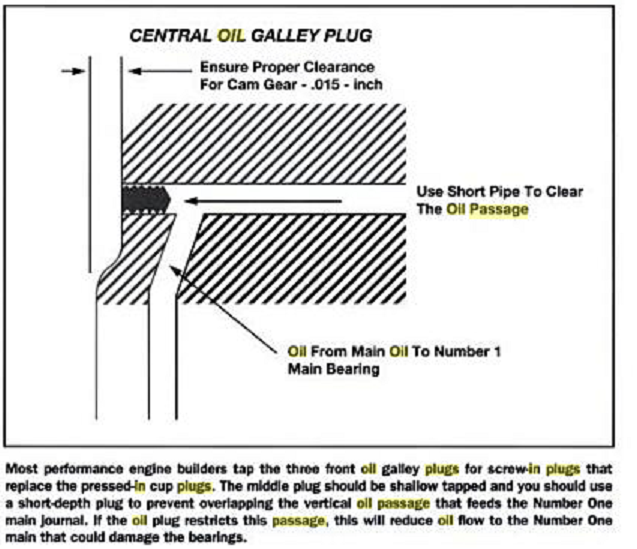

"We put our cam bearings in at 4 O'clock and we tap our front galley plugs 1/4 inch pipe and use red locktite and snug them up.

We use just a 1/4X18 pipe tap which is a standard tap and it really does not cut a deep thread is why we use the lock tite.

Be careful on the middle plug as you can put the pipe plug in to far and shut the oil off to the front main bearing and number 1 rod bearings. As I have seen that done before."

http://www.midwestmotorsportsinc.com/order_part.php?item=CH8&line=DUR

http://store.summitracing.com/partdetail.asp?part=CLE-SH1349S&autoview=sku

http://store.summitracing.com/partdetail.asp?part=DUR-CH-12&autoview=sku

http://store.summitracing.com/partdetail.asp?part=CLE-SH287S&autoview=sku

http://store.summitracing.com/partdetail.asp?part=FEM-1255M&autoview=sku

http://www.aptfast.com/Flyer_HowTo_Dir/ ... arings.htm

http://www.rodandcustommagazine.com/tec ... index.html

http://www.chevyhiperformance.com/tech/ ... to_03.html

http://members.shaw.ca/ritc1/bearingtool.html

cam bearings are easily swapped IF you have the correct tools but its generally cheaper to have the local machine shop replace them than to buy the correct tool unless your doing the job fairly regularly.

different blocks and bearing locations have slightly different configs,

obviously if theres no oil feed groove under the bearing the oil feed holes must align with the oil feed passages,

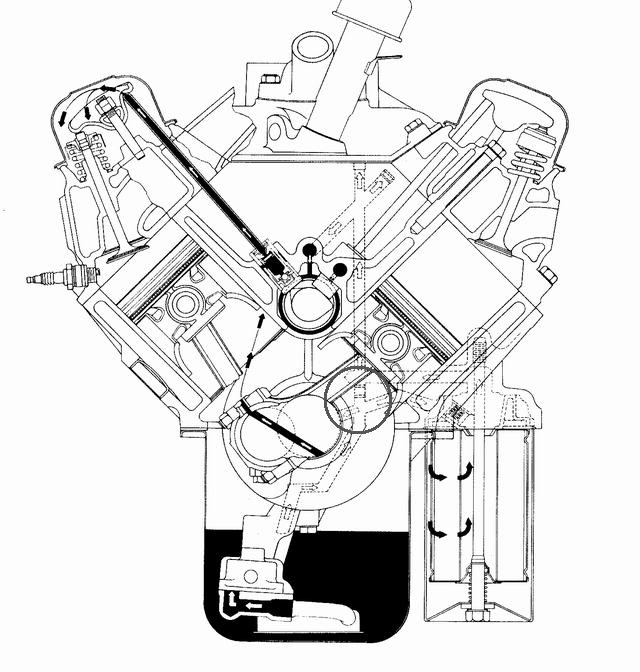

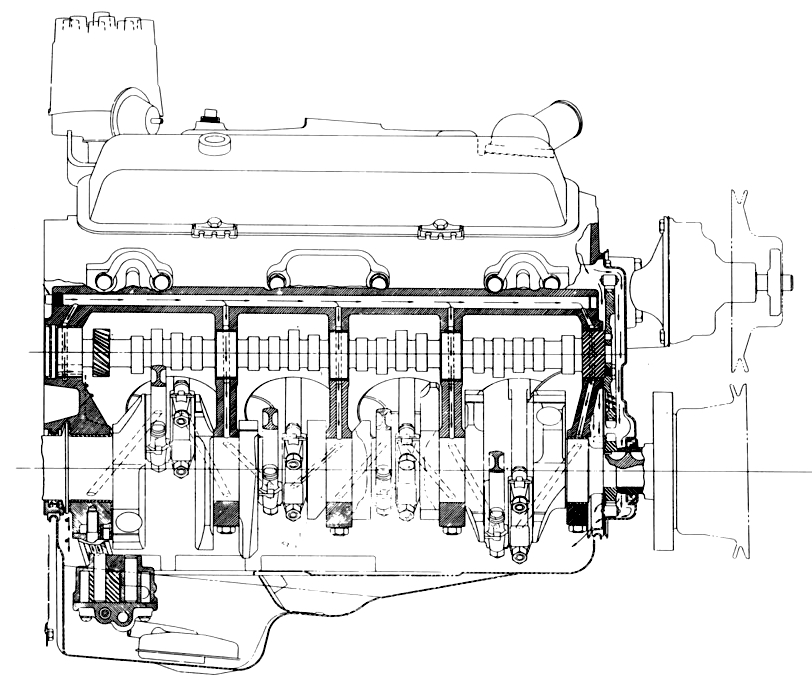

with the block in the upright position the cam bearings are fed,

from the upper central cam, or lifter gallery oil passage, look at the diagrams

most cam bearings come with instructions and diagrams.

and yeah it generally helps to look at the old cam bearings and oil feed hole locations, take notes and in most cases re-install the new bearings in a similar fashion.

chevy V8 cam bearings are NOT universally interchangeable between locations

MAIN BEARINGS FEED FROM THE CAM BEARINGS SO LINING UP OIL FEED HOLES IS CRITICAL

carefully measure the old cam bearings and pay attention to oil feed hole locations

the bearings are not universally interchangeable and yes size varied

http://www.toolsource.com/universal-...l-p-67768.html

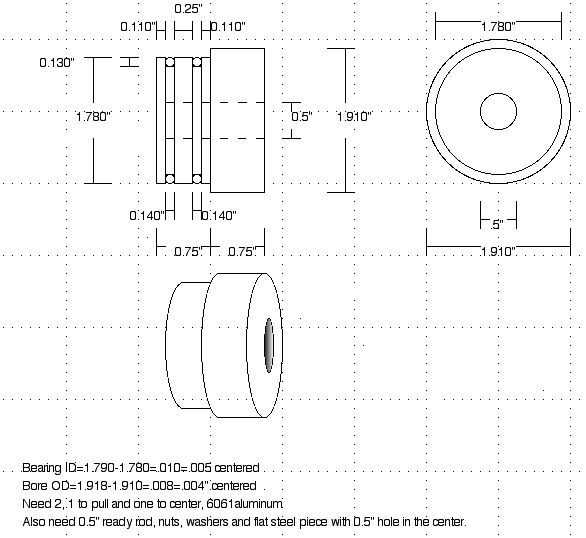

if you have access to a lathe you can fabricate a tool for your application for under $20 in parts a 36" section of 1/2" thread rod a couple washers and nuts and a custom turned bearing holder made on the lathe will do the job

BTW its common for the bearings to be different sizes at different locations,some are numbered, some may require the oil feed hole location to differ, etc, so measure the bearings,take note of the oil hole locations on the old cam bearing before you remove them, don,t just take one, new one randomly out of the package and start beating it into place

Ive even seen parts from these kits

http://www.harborfreight.com/cpi/cta...emnumber=35555

http://www.harborfreight.com/cpi/cta...emnumber=92387

http://www.harborfreight.com/cpi/cta...emnumber=95853

used to install them

read thru this link below carefully

http://static.summitracing.com/global/i ... 900130.pdf

DART BLOCKS HAVE A DIFFERENT OIL ROUTE

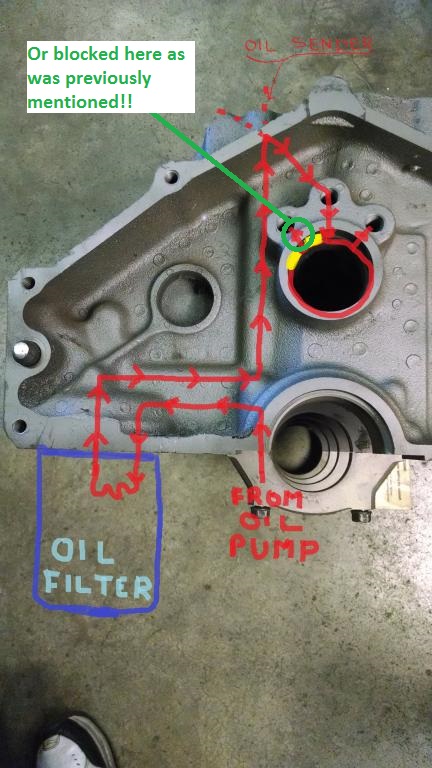

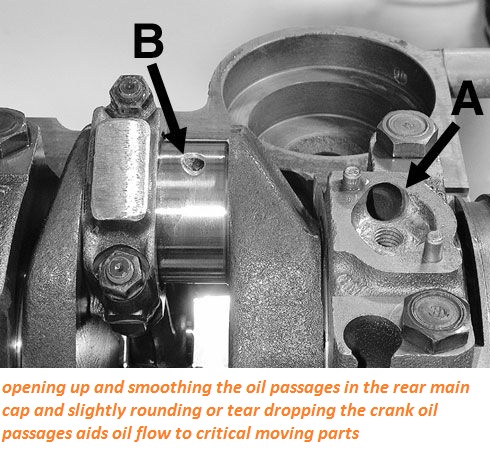

yes its potentially possible that an oil passage is blocked, by an improperly installed oil passage plug,

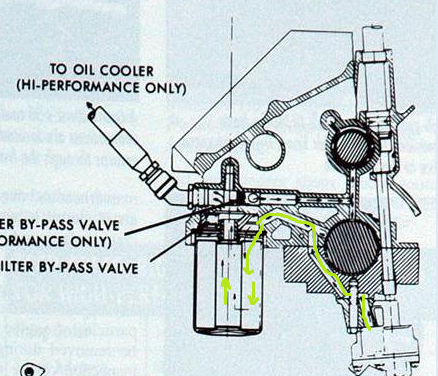

or a cam bearing was improperly installed, or a oil passage plug simply popped out due to oil pressure, you might want to try use of a different brand oil filter,

some are much better quality than others and several people have had similar issues;

that were corrected by simply swapping to a different and better quality oil filter

http://garage.grumpysperformance.co...ilter-you-sellect-does-make-a-differance.117/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

look through the link's and pictures carefully

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.co...g-up-oil-feed-holes-in-bearings-shells.10750/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

the engine needs to come out to replace cam bearings because the rear cam tunnel freeze plug needs to be removed for tool access

in a properly set up block a pressurized oil film supports the cam and main bearings

oil flows around the outer bearing in the groove in the back of the bearing and the matching groove in the cam journal cut in the block

www.jegs.com

www.jegs.com

HERES A GUY THAT FEELS A FAR MORE RIGID STAND IS A BIGGER ADVANTAGE THAN HAVING IT FOLD UP SMALLER FOR EASY STORAGE

http://www.northerntool.com/shop/tools/ ... _200305213

READ THIS LINK AND ITS SUB LINKED INFO

doing it successfully mandates the person involved, in the process, can accurately observe, think, and recognize problems,

and if required, stop and think up solutions.

yes it involves knowing how components are intended to function and accurate precision measurement and access to some specific tools and a skilled well equiped machine shop you can trust, is a mandatory factor and skill set.

so many guys seem to be under the absurd impression that any and all solutions,

to any and all problems,

invariably involve, throwing away some component,

and installing some new out of the box part,

instead of acting logically and actually measuring,

thinking and potentially custom clearancing or at least reading the instructions,

and as most experienced engine builders will tell you ,

almost nothing you can buy fits and functions correctly in out-of-the-box, condition

,too near its true potential.after its ,

carefully, inspected, and correctly clearanced, and fitted.

Camshaft Bearing Installation - Step by Step

In this video we’ll be taking an in depth look at the process of installing camshaft bearing in a Small Block Chevy. Previous video showing engine disassembl...

get into the habit of taking notes, examining details and measuring the cam bearings,.. noticing the location of oil feed holes, and taking pictures and notes, on the outer and inner dimensions and that generally one edge is beveled to make installation easier, note that some cam bearings have a reverse side oil feed groove while other brands do not! notice that the oil feed passages and main cap grooves tend to measure differently and not all bearings fit all locations

taking the effort to be observant, measure , and ask questions rather than just jamming parts in anyplace, will save you from making lots of expensive mistakes

http://www.summitracing.com/parts/cca-5605/overview/

http://www.harborfreight.com/6-piece-telescoping-gauge-set-5649.html

the rear cam tunnel freeze plug?

theres two, sizes

23/32-inch expansion plug or the 47/64ths (cam plug)

or

IF you somehow screw up the install,of the rear cam tunnel freeze plug, by failing to coat the freeze plug with sealant, along its outer edge, before you install it correctly, you can probably knock it out coat it with sealant and re-install it,

but the cost of a new plug is rather minimal and the risk of it failing , if its re-installed, also minimal,but if it was my engine,

yes I'd buy coat and install a new rear cam plug, as having it blow out once the engines installed would be a huge P.I.T.A.

leaving it in place without sealant can be done but you run a slightly higher chance of an oil leak, that would be a P.I.T.A. to fix later on.

this stuff is pretty much interchangeable

the dorman catalog showed both plugs for 62-68 327 & 67 up 350's also.

the small one is dorman # 555-049.

23/32 o.d.,

the large one is 555-080.

47/64 o.d.

just be sure an measure the one you knock out or the hole it fits and use an accurate caliper

http://www.wizardswarehouse.com/products/tools

This does not just apply to just Chevys,

Look closely at the outer side of the back of the cam bearings theres usually a number on the back ,of the bearings, there also usually a small instruction sheet packaged with the bearings listing the outer dia. and the position in the block if the bearings differ in dia., if they do vary in size the rear is normally the smaller bearing

you must align the oil feed holes in the block with the bearing feed holes

on early (1965) bbc engines the rear cam bearing is grooved failure to use a grooved rear cam bearing causes problems on early big blocks

the 1965 and 1966 big block 396 had unique rear cam bearings and required a grooved rear cam journal, most cams you buy currently are not grooved, the groove can be cut on a lathe in the last rear journal on the later cams , centered ,and its about .188 wide and .125 deep, if the cam is cut,for that oil groove the standard cam bearing can be used[/size]

your potential rear cam bearing oil flow issue is found on the 1965- too a few very early 1967 BBC engines ,if you install the older design BBC cam with a grooved rear main in EITHER config with EITHER rear bearing your covered, and since thats just not expensive and any decent machine shop can modify any cam like that cheaply is the smart route to take if your in doubt

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=10360

The correct cam bearings for the engine you have is very impotent some take a grooved rear cam bearing #396 Clevite SH615S 65-66 only!!!

Clevite SH616S 67-93 396-427.

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

SBC CAM BEARING PART NUMBERS [/B]

dura-bond CHP-8

ACL 5C3349C

Clevite SH1349S

FM 2100M

Hi-Tech BC290SP

King CS507HP

TAKE THE EFFORT TO MEASSURE AND VERIFY BEARING LOCATIONS AND CLEARANCES

Taken From AERA Pro-Sis

Cam Bearing Bore diamentions

#1 2.0190-2.0210

#2 and #5 2.0090-2.0110

#3 and #4 1.9990-2.0010

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

BBC CAM BEARING PART NUMBERS

CHP-12

Clevite SH2144S

FM 2101M

Hi-Tech BC616SP

King CS524HP

Cam Bore: 2.140 inches (number-1), 2.130 inches (number-2 and number-5), 2.120 inches (number-3 and number-4); cam bearing inside diameter: 1.950 inches

(VERIFY CAREFULLY WITH YOUR APPLICATIONS NEEDS WITH YOUR SUPPLIER)

PONTIAC CAM BEARING PART NUMBERS

P-4 standard DUR-PP-4T coated, SOME use PB-9 check carefully

ACL 5C292S

Clevite SH292S

Engine Tech CC416

FM 1220M

Hi-Tech BC292S

King CS511BB

SDI MP109

sealed power 1220M

Camshaft Bearing Set

Part Number CS 511BB STD

For 1963-79 Pontiac

Cross reference- ACL: 5C292 CLE: SH- 292S DUR: P-4 FMO: 1220M

Positions 1 through 5

• cam journal diameter- 1.8992"/ 1.8997"

• cam tunnel bore- 2.0297"/ 2.0317"

• cam bearinglength- 0.6800"

• maximum wall thickness- 0.0644"

You can see from the specs above the cam bearings are basically identical

https://www.summitracing.com/search...-installation-and-removal-tools/universal/yes

shop carefully cam bearing tools sell for $40-$300 plus and almost identical tools car vary in price by over $120, and be awre all cam bearings in a single block may be different sizes based on the location, so pay attention as you remove them as to the oil feed hole location(S), how they are indexed or clocked and the outside diameter and be aware in many cases the bearing is beveled on one side to aid installation

Keep in mind chevy cam bearings are NOT interchangeable to all locations in the block, read the instructions and measure the bearings and the install location

download/file.php?id=2011

http://www.rodandcustommagazine.com/tec ... g_oil.html

<break /><break /><break /><break /><break /><break /><break /><break /><break /> Rod & Custom said:By placing the bearing's oil hole at roughly the 2:00 position (anywhere between 2:00 and 3:00 is fine), oil is fed into the clearance between the cam journal and cam bearing as the cam rotates clockwise, creating an oil wedge that travels down and supports the cam much better during cam rotation. This forces a superior oil wedge under the cam, to provide oil support at the bottom (6:00) position.

with the block in its normal operational position

any oil needed will easily travel thru the passages and grooves,on the back side of the cam bearing, obviously if theres no oil groove in the rear of the bearing shell or block you have zero choice but to align the oil feed to the cam bearing oil feed holes. I would keep the bearing feed holes as previously indicated if these a oil feed groove.

many cam bearings and many blocks are grooved to provide oil flow to the bearing feed holes, direction of the feed flow to the bearing is less important than maintaining the oil wedge under the cam journal at the area of max loads

REMEMBER the pressure in any portion of an hydraulic system is equal throughout that system., your oil pump will maintain pressure and oil flow to the bearings, changing the flow direction of the oil feed passages has little effect

If there's the groove in the block under the cam bearing, it provides the route pressurized oil takes around the bearing that feeds oil to location past that point in the oil distribution,and supplies the feed to the cam bearing, the ideal oil feed is indicated in the upper diagram, if there's no groove in the block under the bearing, your forced to line the holes in the block that feed oil up to the bearing, to the holes in the bearing, or bearing feed hole location.

any and all of the rear 4 bearing oil feed holes will work located in the 12-to-2 0.clock location

looking at the block from the front in its normal operating orientation with the oil pan down, heads on top

the front bearing , feeds back into the lifters so the diagram below may help clarify this, in fact some guys drill a third hole

and locate the bearing holes with a 10-,12,-2 o.clock hole location, the reason this is done is that if you bust a push-rod and the lifter gets thrown clear of its lifter bore (which while rare does happen) all the lifters farther fore ward in the block on that side ,of the block, drop to a lower oil pressure reading without that reverse oil feed, modification being installed,helping to maintain flow to the lifter feed oil passage,, and while its not going to be perfect it will help during the few seconds it takes you to realize the engine in trouble

[/color]

pontiac

I get asked all the time if you can re-used cam bearings, well its your call but I feel its a dumb move to do so, if you have the engine out and your refurbishing it, the oil passages should be cleaned anyway,any time you have the block stripped its almost a mandatory task to replace cam bearings and clean out oil passages, any time you damage a cam bearing its best to replace it as and surface damage tends to result in lower oil pressure and less bearing support, remember theres easily 1000-2000 ft lbs of valve spring pressure on those cam bearings at all times, so if you can,once you've inspected a damaged cam bearing, Id replace that, damaged cam bearing,(S) you've put too much effort and money into doing things correctly to use a damaged cam bearing, the cost of a full set, even if you damaged new bearings during the engine assembly process ,that youll need too get, is just not that high, neither is it difficult to replace , with the engine out of a car on an engine stand,and yes it will drop your oil pressure a bit if left damaged, I don,t know how much it would reduce the pressure but for something that cheap and easy to replace I would NEVER even consider using it in that condition.

http://www.summitracing.com/parts/AAF-A ... /?rtype=10

http://www.summitracing.com/parts/CLE-S ... refilter=1

READ THRU THIS LINK

http://www.dura-bondbearing.com/Portals ... lletin.pdf

http://www.mellingdurabond.com/Portals/ ... arings.PDF

Optimum Placement Of Camshaft Bearing

Oil Feed Hole Location

The AERA Technical Committee offers the following important information on

optimum placement of camshaft bearing oil feed hole location during installation.

This information should be considered any time camshaft bearing replacement is

being done.

Maximum camshaft support will be realized by installing the cam bearing oil feed

hole to the optimum clock location. Blocks and heads using a 360° oil groove

located behind the bearing oil feed, allow one to move the clock position of the cam

bearing oil feed hole. This way you can adjust the clock position during cam

bearing installation to make sure that the optimum location for the best

hydrodynamic wedge is selected. Locating and installing the cam bearing to take

advantage of this hydrodynamic wedge will supply the maximum support for the

camshaft during engine operation. The direction of camshaft rotation and the

engine oil entry point into the bearing control the placement of the hydrodynamic

wedge.

Note: If the oil feed passage in the block or head is just a hole without a 360°

groove, the bearing oil hole must line up with the oil feed passage in the block or

head. In some instances, the bearing oil feed hole in the cam bearing also lines up

with a groove cut in the camshaft journal. In those instances, the location of the

bearing oil feed hole in the bearing is also very critical fore and aft and may not

match up 100% with the hole in the block or head.

The illustration in Figure 1 below shows the optimum engine oil feed hole location

with the block in its normal operational position

(oil pan at the 6 0,clock location)

place the cam bearings in the blocks cam bore exactly like the picture shows

the groove on the back helps to eliminate the total loss of oil reaching the cam journals if it is indexed into the block incorrectly, but having the oil flow enter at the top 1/3rd of the rotation provides the best possible hydraulic oil film. load support

Its generally a very poor idea to locate the oil feed hole at the bottom or 6 ),CLOCK as thats where the oil wedge needs to be the strongest and where the oil feed will be most restricted due to thousands of pounds of valve spring loads on the cam core, trying to seal off the oil feed hole, placing the bearing oil feed hole at between 12 o,clock and 2 o,clock provides the largest possible clearance and oil flow rate plus allows the full 180 degrees of the bearings lower surface to support the cam journal

in a properly set up block a pressurized oil film supports the cam and main bearings

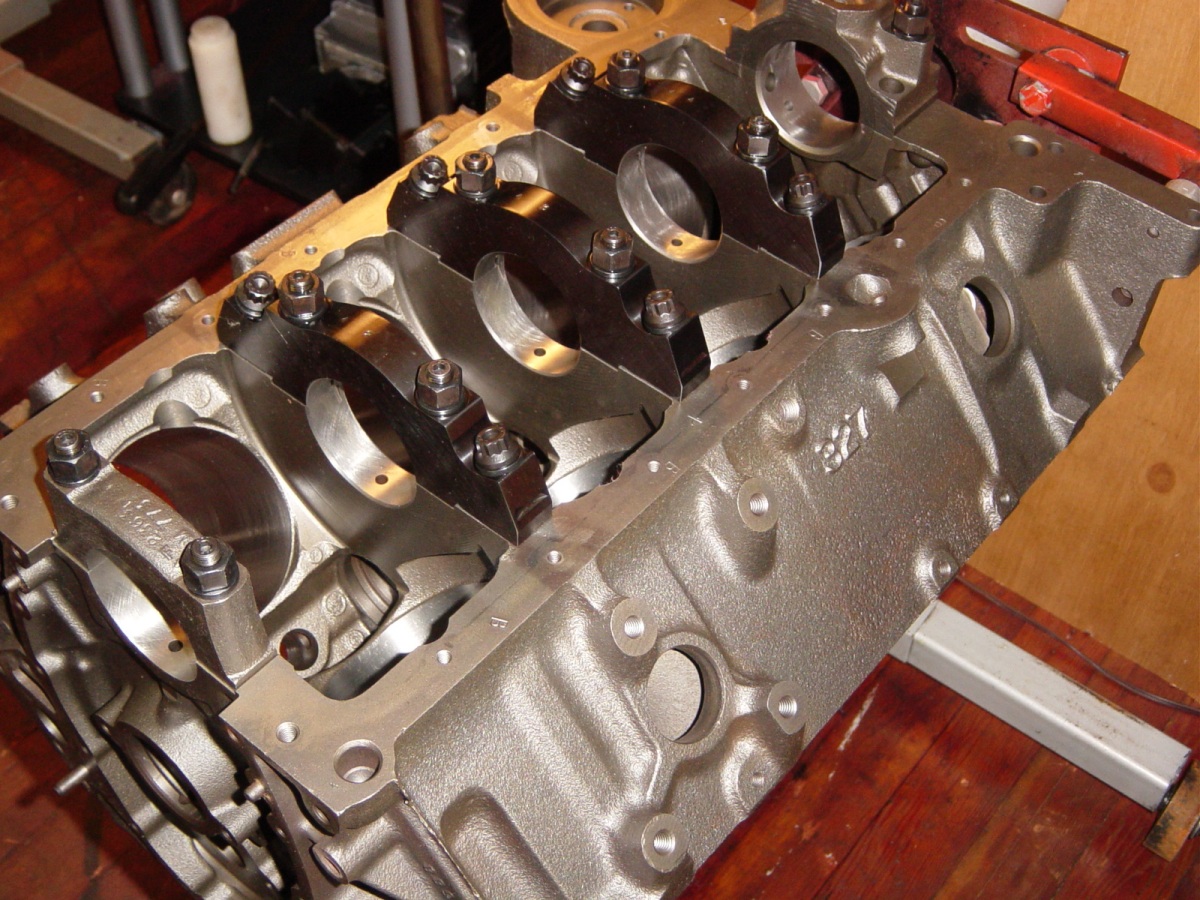

heres the block with the oil pan mounting surface at 12 o,clock or upside down, look at the correctly located oil feed holes in the cam bearings, notice they match the diagram, and two red arrows that show where the dual oil feed holes should be, on bearings with only one feed hole the 12 o,clock to 2 o,clock oil feed hole index is correct, the load is mostly on the cam bearings lower 180 degrees so you sure don,t want oil film strength lowered in that area, by having a oil feed hole that can act like an oil pressure release point in some conditions, you want a maximum thickness oil wedge formed under and supporting the cam journal

be aware both the sbc and bbc engines may not have the block machined for an oil feed groove under the cam bearings in some locations

use of a camshaft install handle generally reduces the chances of damaged cam bearings

VERIFY,SOME DART AFTERMARKET BLOCKS DON.T USE OEM CAM BEARINGS

http://www.speedwaymotors.com/Dart-DT-1T-Cam-Bearings-for-Little-M-Chevy-Block-Set-5,24164.html

http://www.lislecorp.com/uploads/instru ... 726DB5.pdf

http://www.kmjent.com/cart/product.php?productid=597 (good value)

http://www.dura-bondbearing.com/Portals ... lletin.pdf

http://www.pbw-india.com/theory.htm

MAIN BEARINGS FEED FROM THE CAM BEARINGS SO LINING UP OIL FEED HOLES IS CRITICAL

most blocks only have the outer or end cam bearing journals grooved under the cam bearings making proper indexing of the oil feed holes on the 3 inner cam bearings critical, some blocks don,t even have those outer block cam bearing locations grooved

any time you go to install new cam bearings in an engine you first take detailed notes and a few pictures of the OLD cam bearing in the block under good lighting to note the location of the oil feed holes and and grooves, then as they are removed you number them each as its removed and measure them as on many engine they are NOT INTERCHANGEABLE between all main cap locations

http://www.amazon.com/Competition-Cams- ... B000A8MQFY

the tool Ive had and used for DECADES, it works reasonably well.

but check around for a used one in good condition, I bought mine at a chevy swap meet for $80

http://www.lislecorp.com/divisions/products/?product=58

http://www.lislecorp.com/uploads/instructions/18000_WebInstr_CC56DD9726DB5.pdf

keep in mind that I was recently quoted these prices for a cam bearing install, at about $110 a set installed it won,t take long to justify buying a decent cam bearing tool

Cam bearings $ 30.00

Cam bearing remove & install $75.00

https://www.summitracing.com/search...toview=SKU&sortby=Default&sortorder=Ascending

http://www.summitracing.com/search/?key ... tool&dds=1

http://www.summitracing.com/search/?key ... ings&dds=1

http://books.google.com/books?id=G2kUib ... q=&f=false

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.jegs.com/i/Proform/778/66794/10002/-1

http://www.rodandcustommagazine.com/tec ... index.html

READ THESE LINKS AND THREADS[/color]

http://www.jegs.com/i/Proform/778/66820/10002/-1

viewtopic.php?f=51&t=125

viewtopic.php?f=54&t=2187&p=5890#p5890

viewtopic.php?f=53&t=2727&p=7078&hilit=magnets+screens#p7078

viewtopic.php?f=51&t=2919&hilit=cleaning+passages+lifters

viewtopic.php?f=53&t=2727&p=7078&hilit=magnets+screens#p7078

http://video.google.com/videosearch?oe= ... Q&start=40

Cam bearing tools

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://store.summitracing.com/partdetai ... toview=sku

http://www.aptfast.com/Flyer_HowTo_Dir/ ... arings.htm

http://rodcustom.automotive.com/75500/0 ... index.html

the oil holes should be at the 12 oclock-2 o-clock with the block in the normal position and looking from the front with the block right side up,that allows the oil to form a support wedge under the cam load, on a sbc but carefully verify that the oil passages align with the oil holes in the bearings

bearings are frequently numbered,#1 to #5

*1 is the front one ,The cam bearings are just slightly different in diameter, so you have to make sure you install them in the correct order.the diam. are listed in the link below if you got them mixed up, Make sure the oil holes are lined up when you put them in.12 oclock-3 o-clock with the block in the normal position and looking from the front

read thru this link below carefully

http://static.summitracing.com/global/i ... 900130.pdf

QUOTE

CNC BLOCKS N/E"

"We put our cam bearings in at 4 O'clock and we tap our front galley plugs 1/4 inch pipe and use red locktite and snug them up.

We use just a 1/4X18 pipe tap which is a standard tap and it really does not cut a deep thread is why we use the lock tite.

Be careful on the middle plug as you can put the pipe plug in to far and shut the oil off to the front main bearing and number 1 rod bearings. As I have seen that done before."

http://www.midwestmotorsportsinc.com/order_part.php?item=CH8&line=DUR

http://store.summitracing.com/partdetail.asp?part=CLE-SH1349S&autoview=sku

http://store.summitracing.com/partdetail.asp?part=DUR-CH-12&autoview=sku

http://store.summitracing.com/partdetail.asp?part=CLE-SH287S&autoview=sku

http://store.summitracing.com/partdetail.asp?part=FEM-1255M&autoview=sku

http://www.aptfast.com/Flyer_HowTo_Dir/ ... arings.htm

http://www.rodandcustommagazine.com/tec ... index.html

http://www.chevyhiperformance.com/tech/ ... to_03.html

http://members.shaw.ca/ritc1/bearingtool.html

cam bearings are easily swapped IF you have the correct tools but its generally cheaper to have the local machine shop replace them than to buy the correct tool unless your doing the job fairly regularly.

different blocks and bearing locations have slightly different configs,

obviously if theres no oil feed groove under the bearing the oil feed holes must align with the oil feed passages,

with the block in the upright position the cam bearings are fed,

from the upper central cam, or lifter gallery oil passage, look at the diagrams

most cam bearings come with instructions and diagrams.

and yeah it generally helps to look at the old cam bearings and oil feed hole locations, take notes and in most cases re-install the new bearings in a similar fashion.

chevy V8 cam bearings are NOT universally interchangeable between locations

MAIN BEARINGS FEED FROM THE CAM BEARINGS SO LINING UP OIL FEED HOLES IS CRITICAL

carefully measure the old cam bearings and pay attention to oil feed hole locations

the bearings are not universally interchangeable and yes size varied

http://www.toolsource.com/universal-...l-p-67768.html

if you have access to a lathe you can fabricate a tool for your application for under $20 in parts a 36" section of 1/2" thread rod a couple washers and nuts and a custom turned bearing holder made on the lathe will do the job

BTW its common for the bearings to be different sizes at different locations,some are numbered, some may require the oil feed hole location to differ, etc, so measure the bearings,take note of the oil hole locations on the old cam bearing before you remove them, don,t just take one, new one randomly out of the package and start beating it into place

Ive even seen parts from these kits

http://www.harborfreight.com/cpi/cta...emnumber=35555

http://www.harborfreight.com/cpi/cta...emnumber=92387

http://www.harborfreight.com/cpi/cta...emnumber=95853

used to install them

read thru this link below carefully

http://static.summitracing.com/global/i ... 900130.pdf

DART BLOCKS HAVE A DIFFERENT OIL ROUTE

yes its potentially possible that an oil passage is blocked, by an improperly installed oil passage plug,

or a cam bearing was improperly installed, or a oil passage plug simply popped out due to oil pressure, you might want to try use of a different brand oil filter,

some are much better quality than others and several people have had similar issues;

that were corrected by simply swapping to a different and better quality oil filter

http://garage.grumpysperformance.co...ilter-you-sellect-does-make-a-differance.117/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

look through the link's and pictures carefully

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/

http://garage.grumpysperformance.co...g-up-oil-feed-holes-in-bearings-shells.10750/

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

the engine needs to come out to replace cam bearings because the rear cam tunnel freeze plug needs to be removed for tool access

in a properly set up block a pressurized oil film supports the cam and main bearings

oil flows around the outer bearing in the groove in the back of the bearing and the matching groove in the cam journal cut in the block

JEGS 80597: Cam Bearing Tool Set for Installation & Removal of Camshaft Bearings - JEGS

Order a cam bearing tool set online. The cam bearing install tool set has everything you could need for camshaft bearing maintenance. Our camshaft bearing tool kit comes with expanding driver, a drive bar, and more. Buy your cam bearing tool set from JEGS High Performance today!

HERES A GUY THAT FEELS A FAR MORE RIGID STAND IS A BIGGER ADVANTAGE THAN HAVING IT FOLD UP SMALLER FOR EASY STORAGE

http://www.northerntool.com/shop/tools/ ... _200305213

READ THIS LINK AND ITS SUB LINKED INFO

IT durability thats KEY in building a good engine

when ever I get into a discussion with many of the guys I build engines for, the younger guys especially seem to be captivated or primarily focused on the concept of having " a RADICAL CAM, that rumbles at idle, or the new brand X heads that some magazine is pushing in the latest engine build...

garage.grumpysperformance.com

Last edited by a moderator: