.

In 2009 I found a website with some plans for some cantilever shelves. I want shelves that would NOT keep me from

pulling a car into the garage and closing the door, so I needed something that didn't go all the way to the floor. Also

the first shelf was actually going to be a work bench with Butcher Block material.

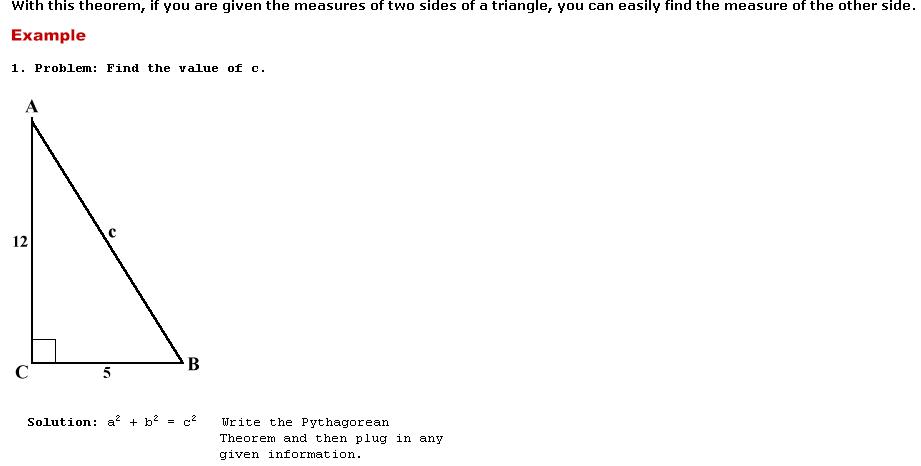

Here are the two links that got me started thinking. You can see how strong this cantilever design is, note this is for

17.5 inch shelves, where mine are 24 inch.

http://woodgears.ca/shelves/index.html

http://woodgears.ca/shelves/garage.html

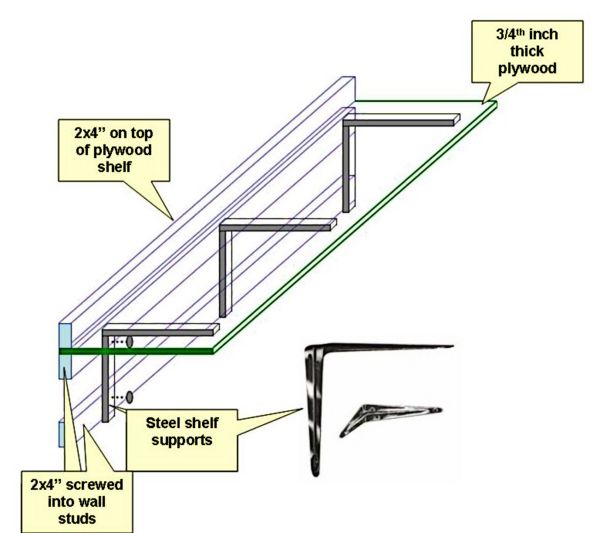

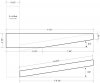

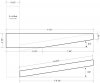

I wanted my shelves to be 24 inches and the braces to be 22 inches, so I modified the plans using Microsoft Visio 2007. Here are the plans:

I made a jig for the screw holes. I wanted long screws, so to keep them from hitting each other, I would flip the jig

over depending on which side it was for.

After cutting out all the pieces, then I started to assemble them with wood glue and deck screws.

Here you can see where I drilled a hole on the bottom of the support. This screws into the vertical 2x4s on the wall.

I needed 3 vertical supports for the shelves. They were spaced at 32" on the wall.

You can see how I flipped the holes from side-to-side to keep the screws from hitting each other. I didn't use wood glue

on these joints so I could adjust them later if needed.

Starting to assemble them on the wall, again vertical supports are on 32" centers.

I've come along ways, but since I'm putting 1 3/4 inch butcher block on the bottom shelf I still have a ways to go yet.

The butcher block was only 5 feet long, so I had the splice it together for an 8 foot bench/shelf.

Finally the FINISHED shelves !!!

Things I would change if I did this again.

I would make the space between the 1st and 2nd shelf larger or maybe the make the 2nd shelf less deep. Say from 24" to

20 inches. When I lean over to work on something up close my head wants to hit the 2nd shelf.

Over time the outside edge of the bench started dropping, it was no longer level. Every time I laid something down, it went

rolling off the bench very quickly. The drop from the wall to the outside edge was about 1.5 inches after a few months. Therefore

I would install the bench top sloping towards the wall initially. If you glue these joints, then maybe it won't be necessary.

I would have made one brace and tested it installed on the wall before making all them to the same dimensions. Since

I have the heavy popcorn texture, my brace would NOT go all the way back against the vertical 2x4s, I had to trim 1/16"

off the back of the shelf brace. See picture below.

.

In 2009 I found a website with some plans for some cantilever shelves. I want shelves that would NOT keep me from

pulling a car into the garage and closing the door, so I needed something that didn't go all the way to the floor. Also

the first shelf was actually going to be a work bench with Butcher Block material.

Here are the two links that got me started thinking. You can see how strong this cantilever design is, note this is for

17.5 inch shelves, where mine are 24 inch.

http://woodgears.ca/shelves/index.html

http://woodgears.ca/shelves/garage.html

I wanted my shelves to be 24 inches and the braces to be 22 inches, so I modified the plans using Microsoft Visio 2007. Here are the plans:

I made a jig for the screw holes. I wanted long screws, so to keep them from hitting each other, I would flip the jig

over depending on which side it was for.

After cutting out all the pieces, then I started to assemble them with wood glue and deck screws.

Here you can see where I drilled a hole on the bottom of the support. This screws into the vertical 2x4s on the wall.

I needed 3 vertical supports for the shelves. They were spaced at 32" on the wall.

You can see how I flipped the holes from side-to-side to keep the screws from hitting each other. I didn't use wood glue

on these joints so I could adjust them later if needed.

Starting to assemble them on the wall, again vertical supports are on 32" centers.

I've come along ways, but since I'm putting 1 3/4 inch butcher block on the bottom shelf I still have a ways to go yet.

The butcher block was only 5 feet long, so I had the splice it together for an 8 foot bench/shelf.

Finally the FINISHED shelves !!!

Things I would change if I did this again.

I would make the space between the 1st and 2nd shelf larger or maybe the make the 2nd shelf less deep. Say from 24" to

20 inches. When I lean over to work on something up close my head wants to hit the 2nd shelf.

Over time the outside edge of the bench started dropping, it was no longer level. Every time I laid something down, it went

rolling off the bench very quickly. The drop from the wall to the outside edge was about 1.5 inches after a few months. Therefore

I would install the bench top sloping towards the wall initially. If you glue these joints, then maybe it won't be necessary.

I would have made one brace and tested it installed on the wall before making all them to the same dimensions. Since

I have the heavy popcorn texture, my brace would NOT go all the way back against the vertical 2x4s, I had to trim 1/16"

off the back of the shelf brace. See picture below.

.

Attachments

Last edited: