You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

darn impressive and logical custom welding project

- Thread starter grumpyvette

- Start date

87vette81big might know where to get parts , he said he occasionally deals in similar projects

8

87vette81big

Guest

I thought you made the custom one off Heavy Duty engine stand Grumpy.

You do need to make a few similar.

Be decent project to complete in a few days & earn extra $$ on the sale.

Bad economy here too.

Know they will sell.

The splined shaft is the "S" CAM from a large air brake diesel truck with Drum brakes.

Front drum steer axle or Rear Daul tire axle.

Kenworth. Peterbuilt. Volvo. Mack trucks. ect.

Any diesel shop has a scrap iron pile.

Find used worn out S cams there.

Worth maybe .50 cent scrap iron price.

The slack adjuster has to match S cam aplication.

Some Slack adjusters are self adjusting. Others not.

Have to investigate more myself.

My boss Jack is the large diesel air brake expert.

So many variations used from 1960-present.

I see & work on them all.

In farmer land.

Ethanol plants all around.

Full sized Kenworth or Peterbuilt with a Caterpiller engine the favorite road machine to haul their corn & make moonshine.

I fix pickups & Cars in same shop. Big shop.

You do need to make a few similar.

Be decent project to complete in a few days & earn extra $$ on the sale.

Bad economy here too.

Know they will sell.

The splined shaft is the "S" CAM from a large air brake diesel truck with Drum brakes.

Front drum steer axle or Rear Daul tire axle.

Kenworth. Peterbuilt. Volvo. Mack trucks. ect.

Any diesel shop has a scrap iron pile.

Find used worn out S cams there.

Worth maybe .50 cent scrap iron price.

The slack adjuster has to match S cam aplication.

Some Slack adjusters are self adjusting. Others not.

Have to investigate more myself.

My boss Jack is the large diesel air brake expert.

So many variations used from 1960-present.

I see & work on them all.

In farmer land.

Ethanol plants all around.

Full sized Kenworth or Peterbuilt with a Caterpiller engine the favorite road machine to haul their corn & make moonshine.

I fix pickups & Cars in same shop. Big shop.

8

87vette81big

Guest

S cams can be found on all 52 foot semi trailers too.

All have drum brakes air powered brake chambers..

Slack Adjusters.

My new 4 Leg wide base engine stand is a POS compared to the home built geared slack. adjuster engine stand.

Just ingenous.

Profesional geared stands cost $800- 4500 bucks.

All have drum brakes air powered brake chambers..

Slack Adjusters.

My new 4 Leg wide base engine stand is a POS compared to the home built geared slack. adjuster engine stand.

Just ingenous.

Profesional geared stands cost $800- 4500 bucks.

Id bet almost anyone with minimum welding and fabrication skills and a few tools like a decent welder could build a better engine stand , or modify an existing stand to be far more user friendly with just a few hours work and some proper planing.

EXAMPLE

about 8 years ago, I added 4 decent quality caster wheels to each of my engine stands in the shop, effectively doubling the cost of the stands but making them far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

these are very similar to what I used (6) of on the engine crane, having 6 large diam. CASTERS rather than 4 small casters and two wheels that don,t change direction is a HUGE IMPROVEMENT in how easily the engine crane moves once an engines suspended from it

I use this style mostly for storage, once you add the larger casters its a decent functional engine stand

www.harborfreight.com

www.harborfreight.com

I have one of these stands, I modified with the larger casters and additional diagonal braces, that I use for most engine builds because its very stable, and a decent bargain for a cheap stand but I would add the engine turning mod in a heart beat if I had the parts required

http://www.northerntool.com/shop/tools/ ... _200305217

EXAMPLE

about 8 years ago, I added 4 decent quality caster wheels to each of my engine stands in the shop, effectively doubling the cost of the stands but making them far FAR more user friendly, because they roll far easier, and you can lock the wheels when working on the engine making torquing the bolts far safer and easier

http://www.harborfreight.com/8-inch-cus ... 46819.html

these are very similar to what I used (6) of on the engine crane, having 6 large diam. CASTERS rather than 4 small casters and two wheels that don,t change direction is a HUGE IMPROVEMENT in how easily the engine crane moves once an engines suspended from it

Harbor Freight Tools – Quality Tools at Discount Prices Since 1977

Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you!

I have one of these stands, I modified with the larger casters and additional diagonal braces, that I use for most engine builds because its very stable, and a decent bargain for a cheap stand but I would add the engine turning mod in a heart beat if I had the parts required

http://www.northerntool.com/shop/tools/ ... _200305217

Last edited by a moderator:

8

87vette81big

Guest

Yes. I am going to add heavy duty ball bearing Rubber tire caster wheels to my new 1250# engine stand.

Love the Truck drum brake slack adjuster idea.

Radius ring machined & welded to pivot neck tube.

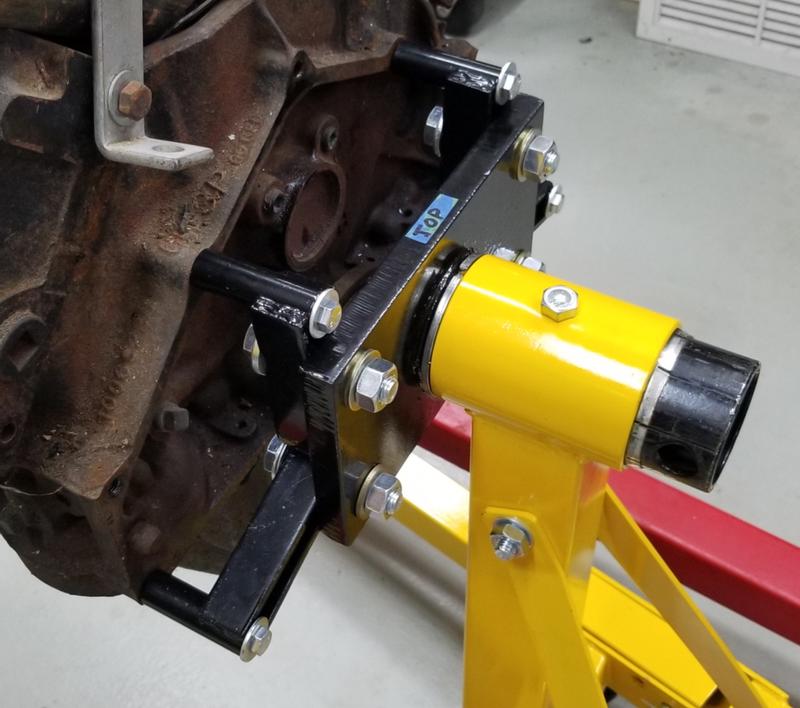

Mine will be different to use with engines & my vintage Kent Moore RWD Turbo 400- 700R4 Trans support & Kent Moore Corvette Dana 44&36 diff holder & another Kent Moore Vintage 1957-64 I-Pontiac 9.300" 3Rd member center section holder. Ebay finds ..

Love the Truck drum brake slack adjuster idea.

Radius ring machined & welded to pivot neck tube.

Mine will be different to use with engines & my vintage Kent Moore RWD Turbo 400- 700R4 Trans support & Kent Moore Corvette Dana 44&36 diff holder & another Kent Moore Vintage 1957-64 I-Pontiac 9.300" 3Rd member center section holder. Ebay finds ..

now that Im forced to buy/build a new engine stand this info will be helpful

www.harborfreight.com

www.harborfreight.com

www.harborfreight.com

www.harborfreight.com

one more in a nearly endless list of reasons every serious engine builder needs a decent welder

8 in. Cushioned Rubber Swivel Caster with Brake

Amazing deals on this 8In Rubber Hd Tire Swivel Caster W/Brake at Harbor Freight. Quality tools & low prices.

1 Ton Capacity Hand Winch

Amazing deals on this 1Ton Hand Winch at Harbor Freight. Quality tools & low prices.

one more in a nearly endless list of reasons every serious engine builder needs a decent welder

Last edited:

does anyone know where you can purchase just the engine stand, mounting, and rotational head assembly for an engine stand at a reasonably low price, as Id love to custom fabricate my own engine stand device,

with a manual engine rotation adapter, and several other upgrades. modifying an existing stand is obviously an option, but Id be wasting a good deal of cash and paying for parts Id throw away, that would be seriously upgraded

like a roller bearing rotational head, larger casters with brakes, and a gear drive rotation on the engine, maybe even an angle adjustment on the block if weights making it droop a bit

, a larger more stable base helps

a quick detach mount head for use on transmissions would not hurt either

www.jegs.com

www.jegs.com

www.jegs.com

www.jegs.com

www.jegs.com

www.jegs.com

this guy in the video above has got some reasonably good ideas and several really bad ones

www.summitracing.com

www.summitracing.com

with a manual engine rotation adapter, and several other upgrades. modifying an existing stand is obviously an option, but Id be wasting a good deal of cash and paying for parts Id throw away, that would be seriously upgraded

like a roller bearing rotational head, larger casters with brakes, and a gear drive rotation on the engine, maybe even an angle adjustment on the block if weights making it droop a bit

, a larger more stable base helps

a quick detach mount head for use on transmissions would not hurt either

JEGS 80059-2: Replacement Chrome Arms for Rotating Engine Stand 555-80059 - JEGS

Get the Best Performance with JEGS Replacement Chrome Arms for Rotating Engine Stand 555-80059 80059-2 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

JEGS 80042-5: Replacement Engine Stand Turning Plate/Head - JEGS

Replacement Turning Plate for 555-80042

ICT Billet 551897: Engine Safe Stand Adapter for Chevy Small Block, Big Block, & GM LS Engines - JEGS

Get the Best Performance with ICT Billet Engine Safe Stand Adapter for Chevy Small Block, Big Block, & GM LS Engines 551897 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

this guy in the video above has got some reasonably good ideas and several really bad ones

Speedmaster PCE407.1006 Procomp Electronics Rotatable Head Engine Stands | Summit Racing

Free Shipping - Procomp Electronics Rotatable Head Engine Stands with qualifying orders of $109. Shop Engine Stands at Summit Racing.

Last edited:

what Im looking for, to purchase (reluctantly) is, the upper engine holding parts painted black on this picture

I know I can easily design a better engine mount plate and rotational head assembly

1 Ton Capacity Hand Winch

Amazing deals on this 1Ton Hand Winch at Harbor Freight. Quality tools & low prices.

Last edited:

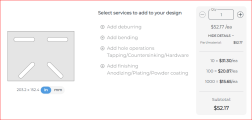

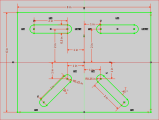

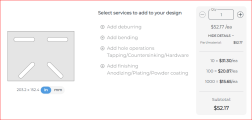

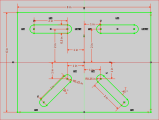

The main plate could be made by sending a dxf file to "Send-Cut-Send" and made from 3/8" mild steel for $52 for a single unit or $42 per unit for two. I used FreeCad to make the drawing. I think shipping is free.

sendcutsend.com

sendcutsend.com

Dimensions For Quote Above Would BE .......

Need to make changes ?????

.

Online Laser Cutting and Waterjet Cutting Service

SendCutSend is an online CNC and laser cutting service, specializing in aluminum, steel, brass, plastics, titanium, and more. Fast turnaround and free shipping!

sendcutsend.com

sendcutsend.com

Dimensions For Quote Above Would BE .......

Need to make changes ?????

.

Last edited:

JEGS 80059-2: Replacement Chrome Arms for Rotating Engine Stand 555-80059 - JEGS High Performance

Buy JEGS 80059-2 at JEGS: JEGS Replacement Chrome Arms for Rotating Engine Stand 555-80059. Guaranteed lowest price!www.jegs.com

JEGS 80042-5: Replacement Engine Stand Turning Plate/Head - JEGS High Performance

Replacement Turning Plate for 555-80042www.jegs.com

I think this stand is a decent deal, considering the features & price

adding 4 decent casters would help

8 in. Cushioned Rubber Swivel Caster with Brake

Amazing deals on this 8In Rubber Hd Tire Swivel Caster W/Brake at Harbor Freight. Quality tools & low prices.

Last edited:

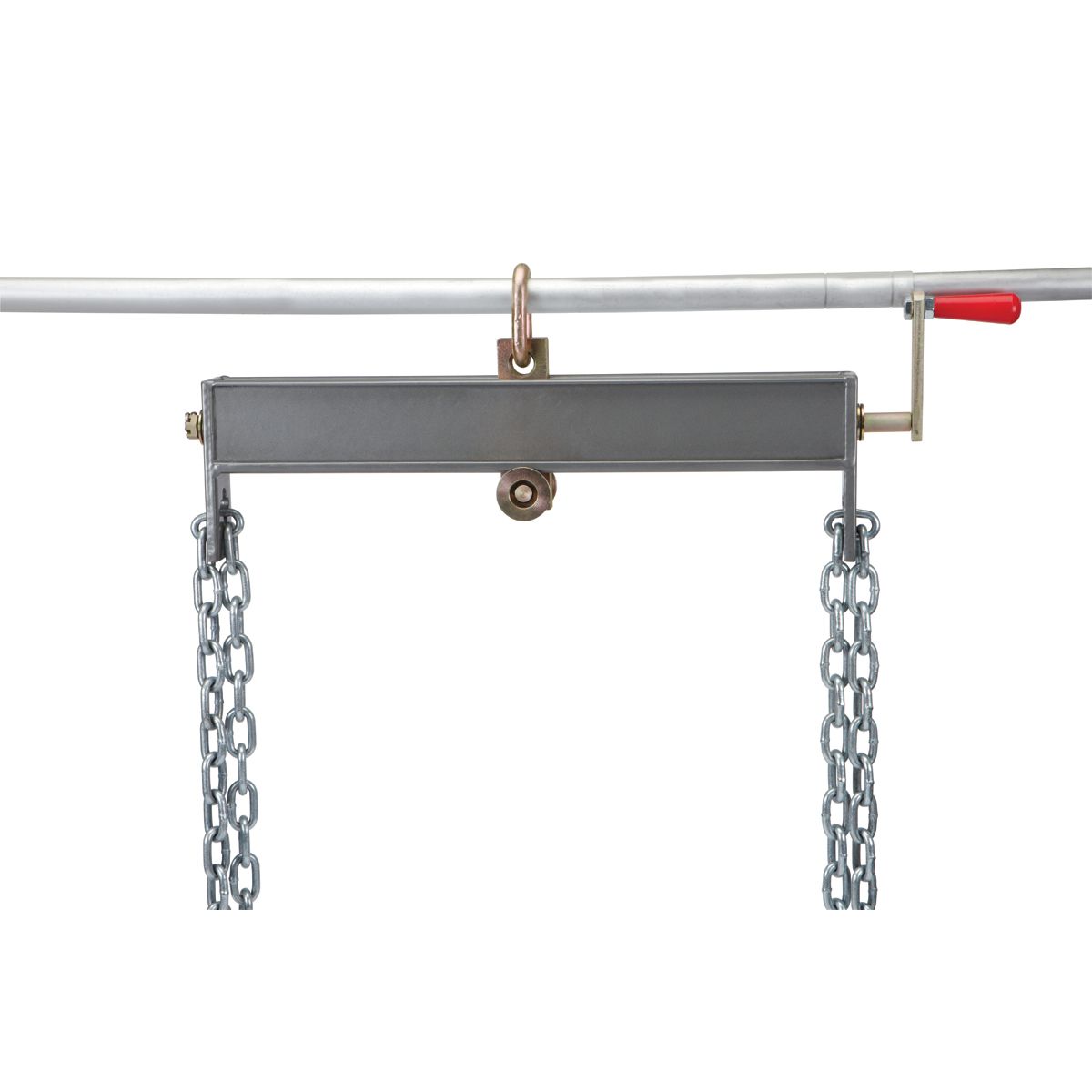

2 Ton Capacity Load Leveler

Amazing deals on this 2T Load Leveler at Harbor Freight. Quality tools & low prices.

Heavy Duty 4000lbs Engine Load Leveler Engine Hoist/Shop Crane/Cherry Picker | eBay

Looking for a smart tool to install and remove engines or transmissions?. Look no further! We have found the perfect product for you. Get one now! From engines to differentials to transmissions and other heavy loads, this hoist gets the job done.

www.ebay.com

Last edited: