now having a floor jack, REALLY <(PREFERABLY TWO FLOOR JACKS) ,is one of the basic tools every shop needs along with several decent full size jack stands.

floor jacks alone, should NEVER be used to support the car while you work under it, for jobs like clutch changes, but only to lift the car while you use the floor jacks for placement of those jack stands on the cars frame for rock solid support while your under the car.

Id also strongly suggest taking the time and effort to use FOUR 12 ton, jack stands to support the car under the FRAME as this is FAR more secure than just using TWO under the front to support the car while your under it for jobs like transmission or clutch replacement jobs, yes it takes more time and effort but your also far less likely to have the car fall if its securely supported and level, and not having any wheels on the ground that can roll

ramps are frequently used to allow fast access under the car for small jobs like oil changes, but wheel chalks should always be used with ramps to prevent the car rolling off the ramps, and ramps are not nearly as solid as properly placed jack stands because they can move or the cars alignment driving up onto them can vary significantly, and in some cases ramps move during the car placement process, of getting the car up onto them.

keep in mind your required to both safely lift the car with the floor jacks and place it on sturdy jack stands and have a tool that can be depended on to easily slide under the car and lift it high enough to allow easy access and placement of those jack stands under the car

I try to look for and buy American made products any time I can and don,t mind one bit paying an additional 10%-20%-even 30% more because I know from experience that theres frequently a good deal more quality components than in import clone parts, making the parts well worth the cost difference, there not much point in saving 30% on a part or tool that won,t do the job its designed to do, or one that can,t do its job safely!

but in a side by side comparison the import looked to be better made,

So I think your fighting a lost battle here,the last time I researched this, a decent 10-12 ton rated American made jack stand that has a wide base and can get a car frame 20'-24" off the floor safely, is well over 200$ EACH

Ive used 6 12 ton rated jack stands like these for almost 20 years now in my shop they are well made

http://www.homedepot.com/buy/tools-hard ... 70912.html

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=26

http://forum.grumpysperformance.com/viewtopic.php?f=59&t=3178&p=11972#p11972

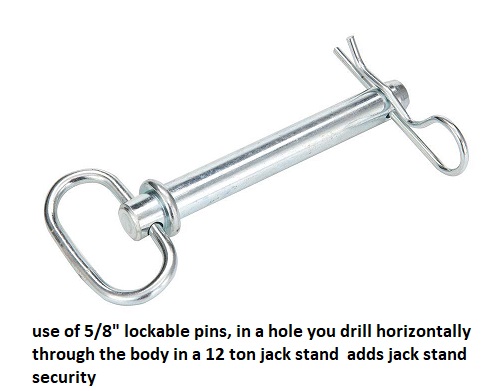

as many of you guys know if you read these threads Ive used (4) 12 ton jack stands and a mechanics creeper for decades, and continue to use them at times even though I own a car lift, but when I suggested to a member that he buy 4 he found the current cost plus shipping exceeded $200 so he asked about cheaper options.

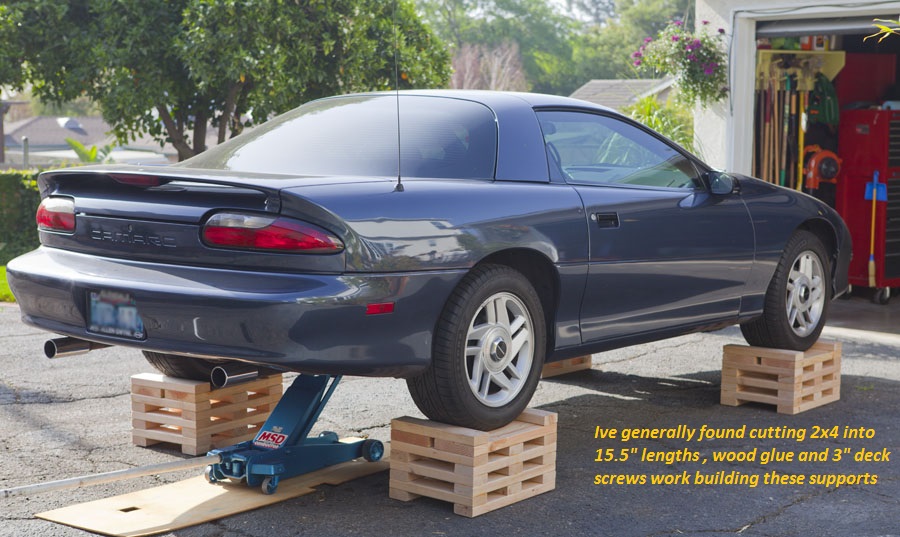

well home depot sells 2x4 boards 8 ft long for about $3 each and will cut them for a nominal charge or at times for free

If you don,t want to spend big bucks on 4 large sturdy jack stands.. like I bought for my shop,you can make supports like in this picture below, just be sure your floor jack can lift the car to the height you build, as I had a friend recently build a set of 4 supports thats about 4" taller than he can lift his truck

http://www.harborfreight.com/12-ton-jack-stands-34924.html

https://www.harborfreight.com/3-ton-professional-steel-floor-jack-super-duty-63183.html

http://garage.grumpysperformance.co...-diy-project-video-well-worth-watching.15647/

buy 8-10 8 foot long 2"x4" boards cut into 15 7/8" lengths and some good wood glue, and 4 16" square pieces of 3/4" plywood that are used to make sure each support stays square, plywood square placed mid stack, with 3 2x4s in each layer of the stack except the top where you use only the outer two, to prevent the tire from rolling off the stack,this will result in a support collum about 14" tall under each tire,

be sure, you use good water proof wood glue, and allow it to set up over nite, before using the support stacks, and painting at a minimum, the bottom surface so it won,t absorb moisture is a good idea and a few dozen 3" wood screws

this will give you 24 sections for each support for less than $40

I generally keep about a dozen 16" square pieces of 3/4" plywood I can use to stack under my jack stands on asphalt drive ways, when I visit a friends house because jack stands don,t play well with asphalt drive ways in florida heat,(you get about 15 out of a sheet of plywood and home depot will frequently cut a sheet into squares cheaply or for free) these can be used to shove under the 2x4 support stands to vary the height on un-even or inclined ground

I have built several sets of those under the tires support stands from 2x4 and pieces of scrap plywood Ive salvaged from construction sites in the past, but generally found I have donated those to someone ,as they only cost me time and a couple bottles of wood glue and a few dozen 3" deck screws as I own 6 of those harbor freight 12 ton jack stands

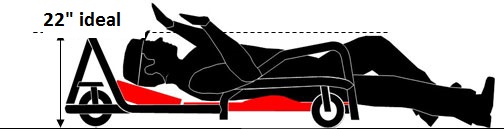

as to swapping a trans and the required clearance under the car.. the clearance will vary with the car, mechanics creeper height, tire diameter and your belt size, this thread might be useful

viewtopic.php?f=59&t=3178&p=33551&hilit=creeper#p33551

http://www.northerntool.com/shop/tools/ ... _200330725

Ive used several brands, and the cheap auto parts store type ,that are generally rated at 2.1/4 ton or less and weight under about 50 lbs, are built for low price not safety or durability, most stores that sell them ,sell for well under $75 are generally trash & dangerous. but then they are usually a small step up from the OEM jacks supplied in most car trunks.

read these threads / links

viewtopic.php?f=27&t=26

viewtopic.php?f=27&t=672

http://www.zr1netregistry.com/jackupzr1.htm

IN MANY CASES USING A SMALL RAMP AIDS CLEARANCE FOR A FLOOR JACK

JACKING UP, ONLY THE FRONT OF THE CAR AND SUPPORTING ONLY THE FRONT< LEAVES THE CAR IN A POTENTIALLY DANGEROUS POSITION WHERE IT MIGHT ROLL,, YES EVEN IF WHEEL CHALKS ARE USED

+++++++++

+++++++++

THE CARS MORE STABLE ON FOUR 12 TON JACK STANDS IF YOU WANT TO USE A MECHANICS CREEPER, EVEN IF THE 12 TON JACK STANDS ARE AT THE LOWEST HEIGHT YOUR FAIRLY SAFE UNDER THE CAR, NOT SO WITH THE SMALLER 3 and 6 TON RATED JACK STANDS

heres an example (OF WHAT YOU CERTAINLY DON,T WANT)

http://advanceauto.shoplocal.com/advanc ... id=2370190

you don,t necessarily need to spend a bundle either, but its a tool that should last for many years so getting a decent floor jacks a good idea.

EXAMPLE

http://www.napaonline.com/MasterPages/N ... Floor+Jack

http://www.napaonline.com/MasterPages/N ... Floor+Jack

heres a few decent compromises, not top quality by any stretch but reasonable values for the cost.

http://www.northerntool.com/webapp/wcs/ ... _200345429

http://www.northerntool.com/webapp/wcs/ ... _200305249

http://www2.northerntool.com/auto-repai ... 144236.htm

http://www.sears.com/shc/s/p_10153_1260 ... 000P?mv=rr

BTW

http://www.harborfreight.com/cpi/ctaf/d ... mber=34924

I bought 4 of these 12 ton jack stands and their one of the few things I got from HF that are worth the money hands down!

if you catch them on sale, and if you get one of those coupons in the flier for 15% off you can get two for UNDER $50 and 4 for UNDER $100, they are MUCH larger and heavier than the typical auto store 3-4 ton jack stands and FAR more difficult to rock or tip over the car with when in use.

they provide a much larger base and on the low setting are the correct height to work under the car for most clutch replacements Etc. IF YOU RAISE THE CAR TO THE SAME HEIGHT ON 3-6 TON RATED JACK STANDS THERE'S NO COMPARING THE STABILITY

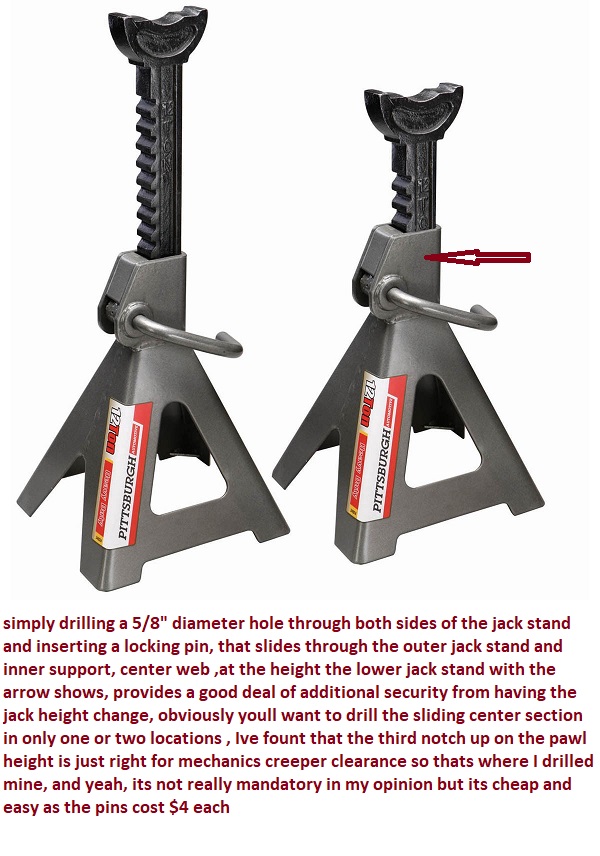

(4 of the 12 ton rated HF jack stands, set at the height of the lower jack stand in the picture below set under a corvettes frame hold a corvette securely at the correct height for using a mechanics creeper )

http://www.harborfreight.com/12-ton-jac ... 34924.html

These super heavy duty jack stands will hold most cars and trucks safely over 2 feet off the ground. Perfect for repair work or storage.

Height: 19-1/2'' to 30-1/8''

Base: 12'' x 12-1/2''

Shipping Weight: 69.50 lbs.

COMPARE THESE WITH THESE(THESE ARE AMAZING , I CAN,T BELIEVE ANYONE TRUSTS THESE THINGS, A SINGLE 1/4" OR 5/16" BOLT SHEARS AND YOUR DEAD OR TRAPPED UNDER THE CAR!

this floor jack has good reviews

http://www.northerntool.com/shop/tools/ ... _200345429

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper

look closely at the FLIMSY JACK STANDS IN THIS PICTURE, Ive seen several of that jack stand design , suddenly fail and collapse

"1: why 12 ton? Ain't 6 ton more than enough?

2: how do you jack up the car? do you enroll your wife?

3: what floor jack do you use? Prices vary quite a bit?"

(1)

the 12 ton are BOTH FAR MORE STABLE from tipping or the car shifting,because of the much larger base AND if the cars supported on the first or second notch they are exactly the correct height to allow comfortably accessing the under side of the car, place the 6 ton next to a 12 ton and raise both to the height of the 12 ton stands on the first notch, theres absolutely no comparison in your safety under the car, THERES ABSOLUTELY NO WAY YOU CAN COMPARE THE DEGREE OF STABILITY THE LARGER BASE AND STRONGER MATERIALS THE 12 TON STANDS PROVIDE, to the smaller stands when your cars lifted high enough to easily work under it on a mechanics creeper

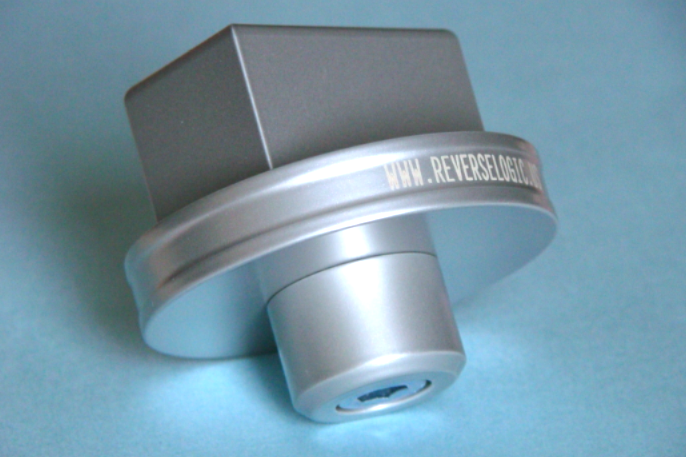

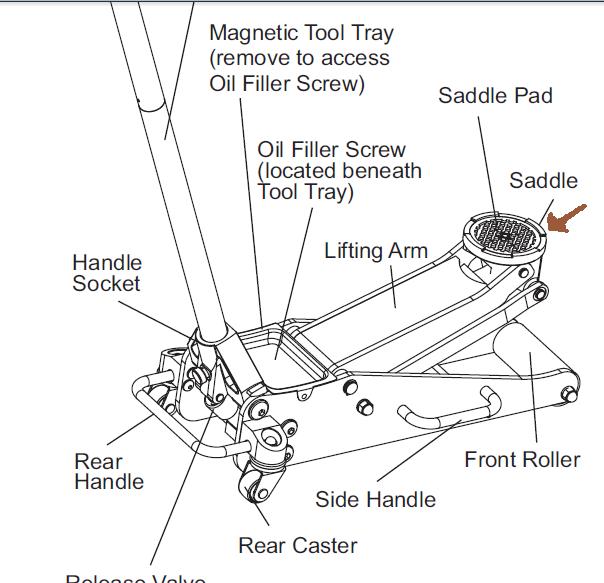

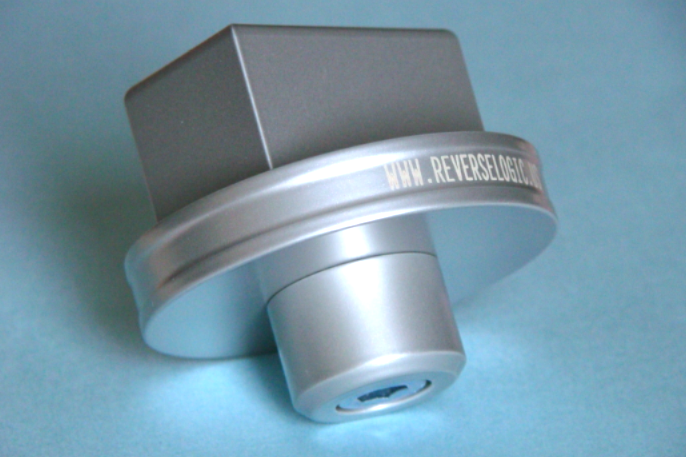

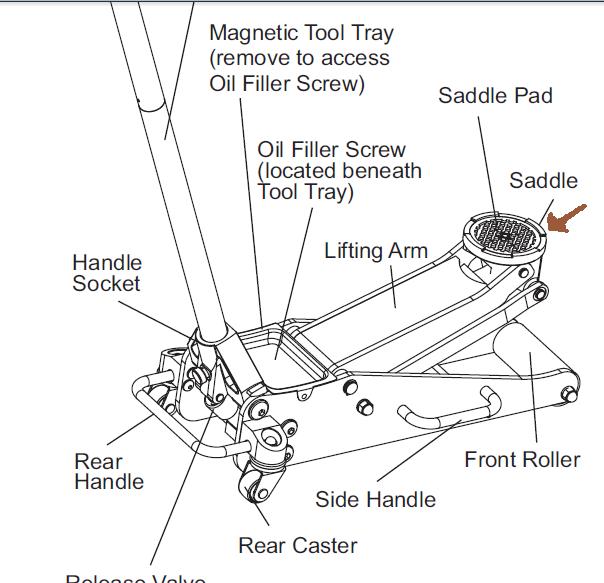

(2) your hardly the first guy to run into this, problem, you may need to fabricate or purchase floor jack spacer pads if your floor jack won,t raise the car high enough, I know I did, it was an easy process and I welded up my own, and both bolted and glued a 6: square section of old tire tread to the pads upper surface to prevent scaring the vettes car frame, so I could use the 12 ton jack stands, because my sears floor jacks could just barely reach the required height I fabricated spacers, with out the spacer pads, getting the 12 ton jack stands in place was more of a hassle,obviously this requires a bit of thinking in the procedure in getting the car up safely,to allow the taller jack height under the car frame,

on most floor jacks the lift pad is easily interchangeable , you can buy a replacement jack saddle

and weld a 2"-3" thick pad to the spares and drill and bolt and glue a section of old tire tread you find on any high way or from an old tire you can cut with a sawsall to make a second custom set of jack spacers if your floor jack won,t allow the car to be lifted high enough

one of my old geezer friends found 4 of these plates for $1 each at a yard sale and used a large center bolt, two washers and his shop welder to make a custom floor jack spacer pad for both his floor jacks, I thought that was rather ingenious s

OK first you DON,T raise a car one corner at a time! you drive it up on the inclined ramps to get clearance for the floor jack then slide the floor jack with the spacer if your floor jack requires one under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle of the frame allows you to either use a second floor jack or move the front floor jack to the rear frame of the car, and lift the whole back or move both floor jacks to the rear frame on opposite sides and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the inclined ramps, that way theres almost less chance the car can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rhino ramps and 4 12 ton jack stand WHEN I was under the corvette I use those 12 ton stand on when I use a mechanics creeper as I don,t want to be doing bench presses with a vette!:

btw keep your eyes out for used floor jacks at yard sales, and if a friends floor jack fails it might only require minimal maintenance to repair,this is were having a bit of curiosity and mechanical skill helps , one of my friends has a sears jack that he used for 20 years, it eventually started having a problem where it would slowly loose height if not regularly pumped up so he donated it to me and bought a new floor jack, it took me about 45 minutes to figure out how to disassemble and clean it , and replace a couple worn o-rings but for 45-60 minutes work and less than 80 cents in o-ring's, and $7 in hydraulic jack oil, I had a spare functional floor jack.

prices are up recently,

http://www.harborfreight.com/12-ton-jac ... 34924.html

http://promocodesforyou.com/index.php?i ... 7AodJGG8BQ

check on sales, look for discount coupons and ask for the manager of the store as he has a great deal of leeway in pricing, when I bought mine the standard price was $60 a pair, but I went during a sale and they were marked 10% off plus I told the store manager I had a desire to buy 2 pairs if he made it worth my while, he dropped the price to $150 for 6 stands and no sales taxes

I would strongly advise pitching them in the dumpster if you own any[/color]

floor jacks alone, should NEVER be used to support the car while you work under it, for jobs like clutch changes, but only to lift the car while you use the floor jacks for placement of those jack stands on the cars frame for rock solid support while your under the car.

Id also strongly suggest taking the time and effort to use FOUR 12 ton, jack stands to support the car under the FRAME as this is FAR more secure than just using TWO under the front to support the car while your under it for jobs like transmission or clutch replacement jobs, yes it takes more time and effort but your also far less likely to have the car fall if its securely supported and level, and not having any wheels on the ground that can roll

ramps are frequently used to allow fast access under the car for small jobs like oil changes, but wheel chalks should always be used with ramps to prevent the car rolling off the ramps, and ramps are not nearly as solid as properly placed jack stands because they can move or the cars alignment driving up onto them can vary significantly, and in some cases ramps move during the car placement process, of getting the car up onto them.

keep in mind your required to both safely lift the car with the floor jacks and place it on sturdy jack stands and have a tool that can be depended on to easily slide under the car and lift it high enough to allow easy access and placement of those jack stands under the car

I try to look for and buy American made products any time I can and don,t mind one bit paying an additional 10%-20%-even 30% more because I know from experience that theres frequently a good deal more quality components than in import clone parts, making the parts well worth the cost difference, there not much point in saving 30% on a part or tool that won,t do the job its designed to do, or one that can,t do its job safely!

but in a side by side comparison the import looked to be better made,

So I think your fighting a lost battle here,the last time I researched this, a decent 10-12 ton rated American made jack stand that has a wide base and can get a car frame 20'-24" off the floor safely, is well over 200$ EACH

Ive used 6 12 ton rated jack stands like these for almost 20 years now in my shop they are well made

http://www.homedepot.com/buy/tools-hard ... 70912.html

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=26

http://forum.grumpysperformance.com/viewtopic.php?f=59&t=3178&p=11972#p11972

as many of you guys know if you read these threads Ive used (4) 12 ton jack stands and a mechanics creeper for decades, and continue to use them at times even though I own a car lift, but when I suggested to a member that he buy 4 he found the current cost plus shipping exceeded $200 so he asked about cheaper options.

well home depot sells 2x4 boards 8 ft long for about $3 each and will cut them for a nominal charge or at times for free

If you don,t want to spend big bucks on 4 large sturdy jack stands.. like I bought for my shop,you can make supports like in this picture below, just be sure your floor jack can lift the car to the height you build, as I had a friend recently build a set of 4 supports thats about 4" taller than he can lift his truck

http://www.harborfreight.com/12-ton-jack-stands-34924.html

https://www.harborfreight.com/3-ton-professional-steel-floor-jack-super-duty-63183.html

http://garage.grumpysperformance.co...-diy-project-video-well-worth-watching.15647/

buy 8-10 8 foot long 2"x4" boards cut into 15 7/8" lengths and some good wood glue, and 4 16" square pieces of 3/4" plywood that are used to make sure each support stays square, plywood square placed mid stack, with 3 2x4s in each layer of the stack except the top where you use only the outer two, to prevent the tire from rolling off the stack,this will result in a support collum about 14" tall under each tire,

be sure, you use good water proof wood glue, and allow it to set up over nite, before using the support stacks, and painting at a minimum, the bottom surface so it won,t absorb moisture is a good idea and a few dozen 3" wood screws

this will give you 24 sections for each support for less than $40

I generally keep about a dozen 16" square pieces of 3/4" plywood I can use to stack under my jack stands on asphalt drive ways, when I visit a friends house because jack stands don,t play well with asphalt drive ways in florida heat,(you get about 15 out of a sheet of plywood and home depot will frequently cut a sheet into squares cheaply or for free) these can be used to shove under the 2x4 support stands to vary the height on un-even or inclined ground

I have built several sets of those under the tires support stands from 2x4 and pieces of scrap plywood Ive salvaged from construction sites in the past, but generally found I have donated those to someone ,as they only cost me time and a couple bottles of wood glue and a few dozen 3" deck screws as I own 6 of those harbor freight 12 ton jack stands

as to swapping a trans and the required clearance under the car.. the clearance will vary with the car, mechanics creeper height, tire diameter and your belt size, this thread might be useful

viewtopic.php?f=59&t=3178&p=33551&hilit=creeper#p33551

http://www.northerntool.com/shop/tools/ ... _200330725

Ive used several brands, and the cheap auto parts store type ,that are generally rated at 2.1/4 ton or less and weight under about 50 lbs, are built for low price not safety or durability, most stores that sell them ,sell for well under $75 are generally trash & dangerous. but then they are usually a small step up from the OEM jacks supplied in most car trunks.

read these threads / links

viewtopic.php?f=27&t=26

viewtopic.php?f=27&t=672

http://www.zr1netregistry.com/jackupzr1.htm

IN MANY CASES USING A SMALL RAMP AIDS CLEARANCE FOR A FLOOR JACK

JACKING UP, ONLY THE FRONT OF THE CAR AND SUPPORTING ONLY THE FRONT< LEAVES THE CAR IN A POTENTIALLY DANGEROUS POSITION WHERE IT MIGHT ROLL,, YES EVEN IF WHEEL CHALKS ARE USED

THE CARS MORE STABLE ON FOUR 12 TON JACK STANDS IF YOU WANT TO USE A MECHANICS CREEPER, EVEN IF THE 12 TON JACK STANDS ARE AT THE LOWEST HEIGHT YOUR FAIRLY SAFE UNDER THE CAR, NOT SO WITH THE SMALLER 3 and 6 TON RATED JACK STANDS

heres an example (OF WHAT YOU CERTAINLY DON,T WANT)

http://advanceauto.shoplocal.com/advanc ... id=2370190

you don,t necessarily need to spend a bundle either, but its a tool that should last for many years so getting a decent floor jacks a good idea.

EXAMPLE

http://www.napaonline.com/MasterPages/N ... Floor+Jack

http://www.napaonline.com/MasterPages/N ... Floor+Jack

heres a few decent compromises, not top quality by any stretch but reasonable values for the cost.

http://www.northerntool.com/webapp/wcs/ ... _200345429

http://www.northerntool.com/webapp/wcs/ ... _200305249

http://www2.northerntool.com/auto-repai ... 144236.htm

http://www.sears.com/shc/s/p_10153_1260 ... 000P?mv=rr

BTW

http://www.harborfreight.com/cpi/ctaf/d ... mber=34924

I bought 4 of these 12 ton jack stands and their one of the few things I got from HF that are worth the money hands down!

if you catch them on sale, and if you get one of those coupons in the flier for 15% off you can get two for UNDER $50 and 4 for UNDER $100, they are MUCH larger and heavier than the typical auto store 3-4 ton jack stands and FAR more difficult to rock or tip over the car with when in use.

they provide a much larger base and on the low setting are the correct height to work under the car for most clutch replacements Etc. IF YOU RAISE THE CAR TO THE SAME HEIGHT ON 3-6 TON RATED JACK STANDS THERE'S NO COMPARING THE STABILITY

(4 of the 12 ton rated HF jack stands, set at the height of the lower jack stand in the picture below set under a corvettes frame hold a corvette securely at the correct height for using a mechanics creeper )

http://www.harborfreight.com/12-ton-jac ... 34924.html

These super heavy duty jack stands will hold most cars and trucks safely over 2 feet off the ground. Perfect for repair work or storage.

Height: 19-1/2'' to 30-1/8''

Base: 12'' x 12-1/2''

Shipping Weight: 69.50 lbs.

COMPARE THESE WITH THESE(THESE ARE AMAZING , I CAN,T BELIEVE ANYONE TRUSTS THESE THINGS, A SINGLE 1/4" OR 5/16" BOLT SHEARS AND YOUR DEAD OR TRAPPED UNDER THE CAR!

this floor jack has good reviews

http://www.northerntool.com/shop/tools/ ... _200345429

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=34924

If your going to work under your car I hope you support the car safely, some of you might think Im old fashion but some repairs (even thou I own a LIFT) are easier to do with (4) 12 ton jack stands and a mechanics creeper

look closely at the FLIMSY JACK STANDS IN THIS PICTURE, Ive seen several of that jack stand design , suddenly fail and collapse

"1: why 12 ton? Ain't 6 ton more than enough?

2: how do you jack up the car? do you enroll your wife?

3: what floor jack do you use? Prices vary quite a bit?"

(1)

the 12 ton are BOTH FAR MORE STABLE from tipping or the car shifting,because of the much larger base AND if the cars supported on the first or second notch they are exactly the correct height to allow comfortably accessing the under side of the car, place the 6 ton next to a 12 ton and raise both to the height of the 12 ton stands on the first notch, theres absolutely no comparison in your safety under the car, THERES ABSOLUTELY NO WAY YOU CAN COMPARE THE DEGREE OF STABILITY THE LARGER BASE AND STRONGER MATERIALS THE 12 TON STANDS PROVIDE, to the smaller stands when your cars lifted high enough to easily work under it on a mechanics creeper

(2) your hardly the first guy to run into this, problem, you may need to fabricate or purchase floor jack spacer pads if your floor jack won,t raise the car high enough, I know I did, it was an easy process and I welded up my own, and both bolted and glued a 6: square section of old tire tread to the pads upper surface to prevent scaring the vettes car frame, so I could use the 12 ton jack stands, because my sears floor jacks could just barely reach the required height I fabricated spacers, with out the spacer pads, getting the 12 ton jack stands in place was more of a hassle,obviously this requires a bit of thinking in the procedure in getting the car up safely,to allow the taller jack height under the car frame,

on most floor jacks the lift pad is easily interchangeable , you can buy a replacement jack saddle

and weld a 2"-3" thick pad to the spares and drill and bolt and glue a section of old tire tread you find on any high way or from an old tire you can cut with a sawsall to make a second custom set of jack spacers if your floor jack won,t allow the car to be lifted high enough

one of my old geezer friends found 4 of these plates for $1 each at a yard sale and used a large center bolt, two washers and his shop welder to make a custom floor jack spacer pad for both his floor jacks, I thought that was rather ingenious s

OK first you DON,T raise a car one corner at a time! you drive it up on the inclined ramps to get clearance for the floor jack then slide the floor jack with the spacer if your floor jack requires one under the center of the front (CROSS MEMBER) and lift the front and place BOTH front 12 ton jack stands, under the frame , wide spaced, then the angle of the frame allows you to either use a second floor jack or move the front floor jack to the rear frame of the car, and lift the whole back or move both floor jacks to the rear frame on opposite sides and place both REAR 12 ton jack stands, on the rear frame. now personally I usually leave the rear jack stands and the jack holding the rear up ,and the 12 ton jack stands on the front with the tires hanging just above the inclined ramps, that way theres almost less chance the car can fall, even if some component were to fail.

Ill ALSO point out I have and have always used two floor jacks, twin rhino ramps and 4 12 ton jack stand WHEN I was under the corvette I use those 12 ton stand on when I use a mechanics creeper as I don,t want to be doing bench presses with a vette!:

btw keep your eyes out for used floor jacks at yard sales, and if a friends floor jack fails it might only require minimal maintenance to repair,this is were having a bit of curiosity and mechanical skill helps , one of my friends has a sears jack that he used for 20 years, it eventually started having a problem where it would slowly loose height if not regularly pumped up so he donated it to me and bought a new floor jack, it took me about 45 minutes to figure out how to disassemble and clean it , and replace a couple worn o-rings but for 45-60 minutes work and less than 80 cents in o-ring's, and $7 in hydraulic jack oil, I had a spare functional floor jack.

prices are up recently,

http://www.harborfreight.com/12-ton-jac ... 34924.html

http://promocodesforyou.com/index.php?i ... 7AodJGG8BQ

check on sales, look for discount coupons and ask for the manager of the store as he has a great deal of leeway in pricing, when I bought mine the standard price was $60 a pair, but I went during a sale and they were marked 10% off plus I told the store manager I had a desire to buy 2 pairs if he made it worth my while, he dropped the price to $150 for 6 stands and no sales taxes

I would strongly advise pitching them in the dumpster if you own any[/color]

Last edited by a moderator: