I get lots of requests that basically ask, how do I port or improve the heads, that I have so they flow better, because I just don,t have the extra money to dump into better heads,

When it comes to amateur porting, Smokey Yunick put it best in one of his books. Addressing amateur backyard mechanics/stock car racers, Smokey said, “If you are compelled to port your own heads, first go buy a pair of the best, and most expensive available – then TRY and copy them.”

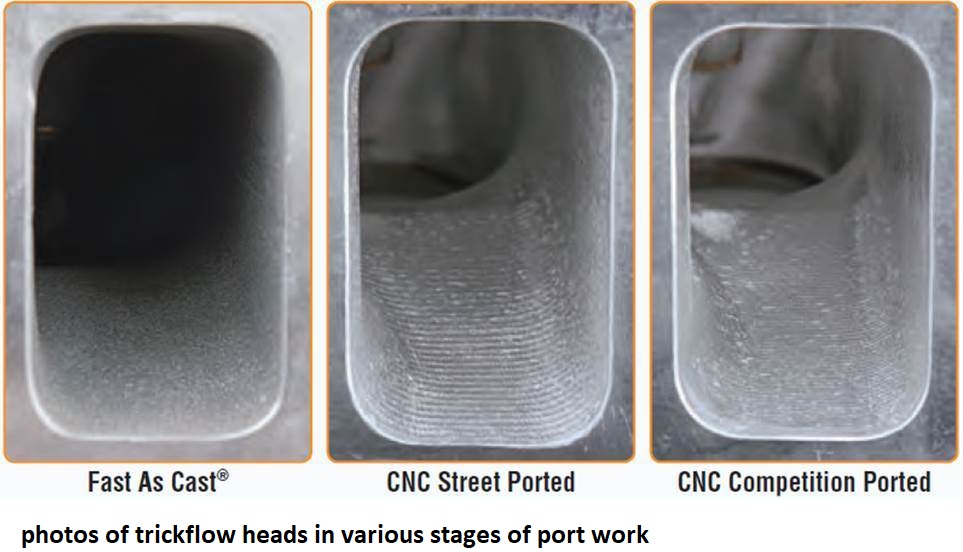

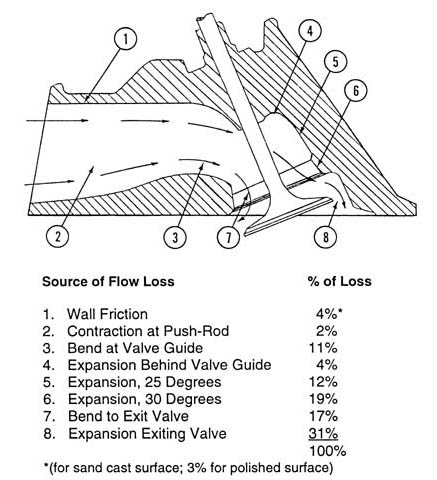

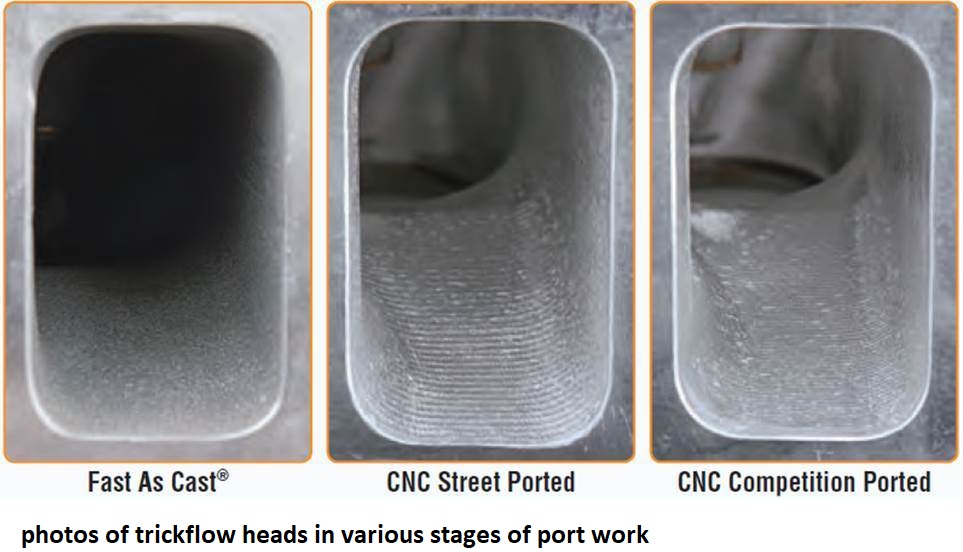

what hes trying to point out is that just removing metal and hogging out the ports almost a sure way to ruin a cylinder head, youll need to fully understand what your trying to accomplish, and its not random metal removal, or increased port volume, its increased flow

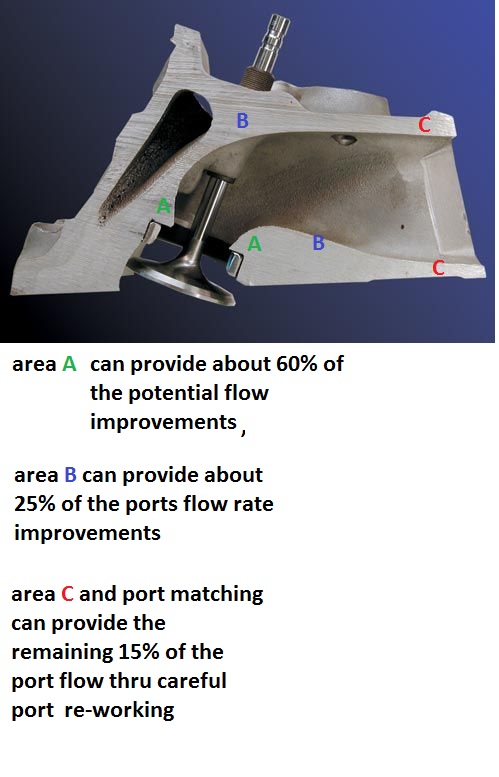

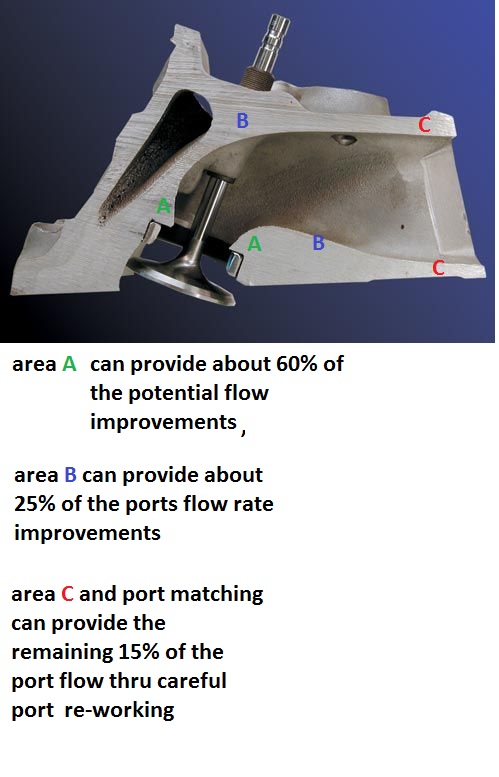

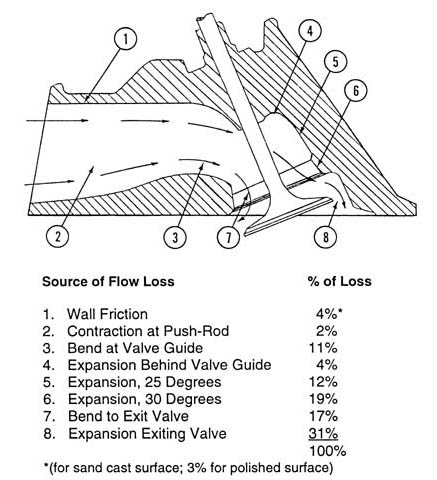

well theres no doubt that most heads can have the flow improved with a port and bowl clean-up and contouring the short side radias and smoothing the bowl area,

but theres a cost to benefit ratio, its fairly easy to increase stock head flow rates in the 5%-10% range but if your looking at spending several hundred dollars in port work and if your looking for major improvements your generally better off selecting aftermarket heads with larger and far better designed ports than sinking a ton of time and money in stock heads, that in many cases your eventually replace.

think it through carefully, its almost always a waste of time and money to sink cash into small port OEM cylinder heads if your goal is to make a great deal more HP, than the original engine made, and by that I generally mean any increase in power goals that exceed about 10%-20% more power than the original engine made, when your looking to boost power to that level your almost always going to need better flowing heads than some re-contouring of the stock head can provide

port throats generally run 80%-85% of total valve diameter because you need to maintain sufficient valve seat contact area to allow sealing and cooling and some wear during operation.

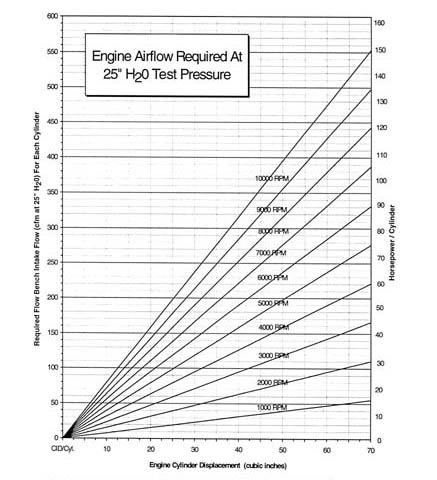

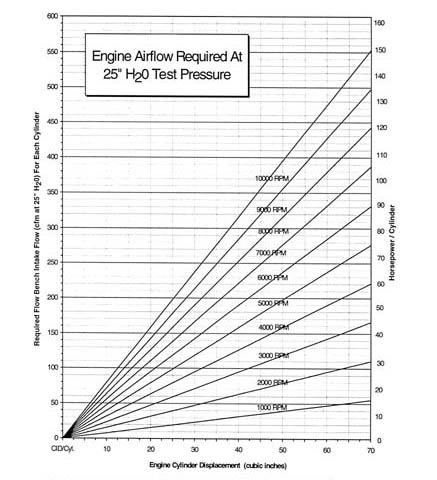

before you reach for your wallet, do some basic math and read a few dozen related links

http://www.wallaceracing.com/calcafhp.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://garage.grumpysperformance.com/index.php?threads/epoxy.14058/

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://www.gmhpclub.com/performancecalculators.htm

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/#post-37705

http://garage.grumpysperformance.co...octane-for-compression-ratio.2718/#post-68131

http://garage.grumpysperformance.com/index.php?threads/cnc-port-work-related.15313/

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

THERES ABOUT 90% of the INFO YOULL NEED IS IN THE SUB LINKS ..READ THOSE ALSO

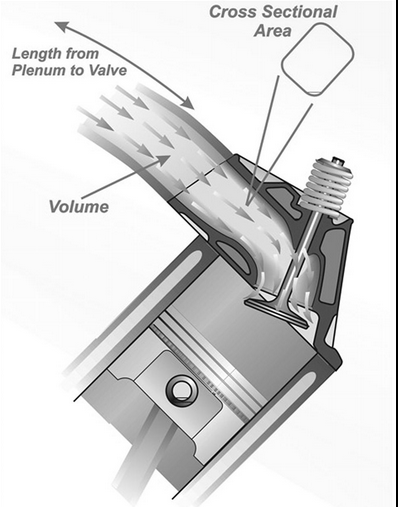

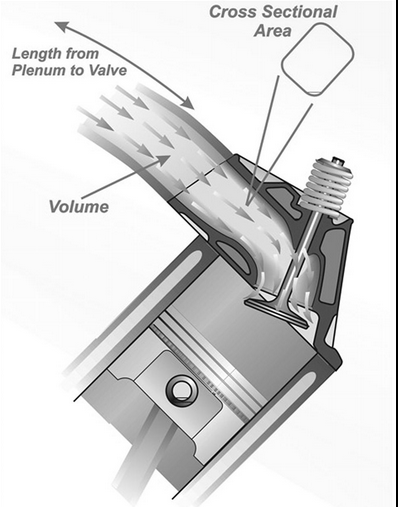

theres also lots of guys who find that the intake manifolds available for the application they have, are rather restrictive, especially for some of the less popular engines like Cadillac, or Pontiac engines Ive worked with in the past, or if the intake designs available are mostly for non-racing applications. runners can be too small in cross sectional area, and aftermarket parts can be non-existent and theres not always enough material in all intake runner designs to allow porting them to a significantly larger port size without having made the gasket sealing area to thin to seal properly.

this does not necessarily mean you have zero options, in many cases a quality machine shop can tig weld extra aluminum on the intake in critical areas to allow you to port the runners larger and then they can reface the gasket sealing area thus allowing you to significantly increase the intake runners cross sectional area.

READ THIS

http://www.maliburacing.com/patrick_budd_article.htm

http://amsoilracing.com/events/amsoil-engine-masters-challenge/

https://www.youtube.com/watch?v=0oXkjfWHT6U

yes its worth the time required to read thru the sub linked info

viewtopic.php?f=27&t=1831&p=4763#p4763

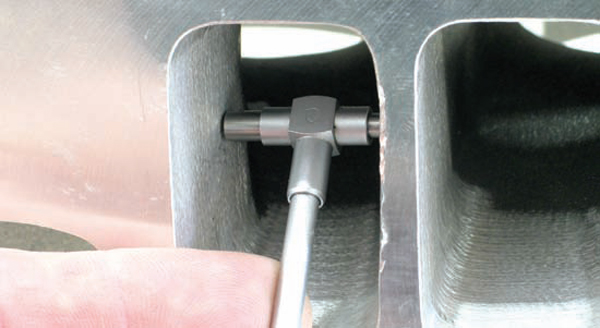

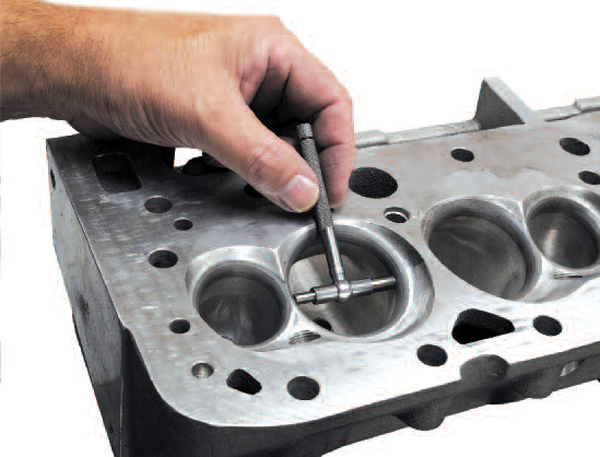

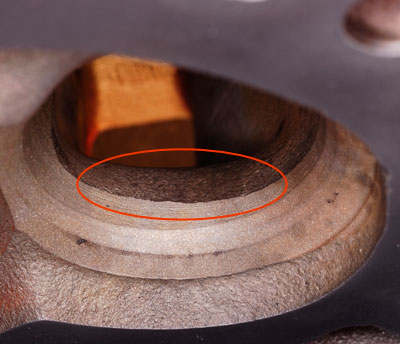

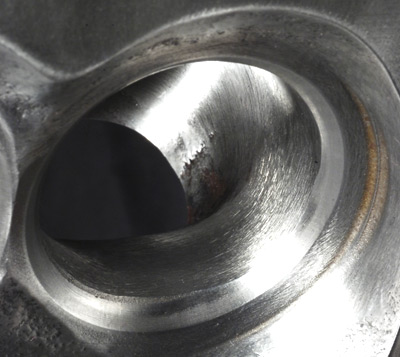

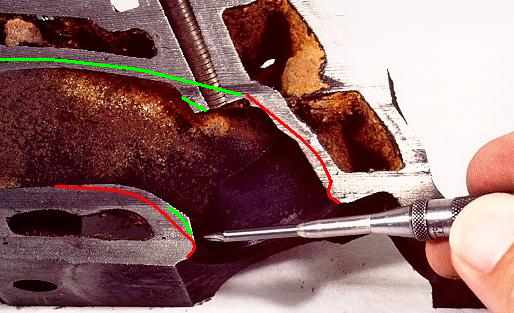

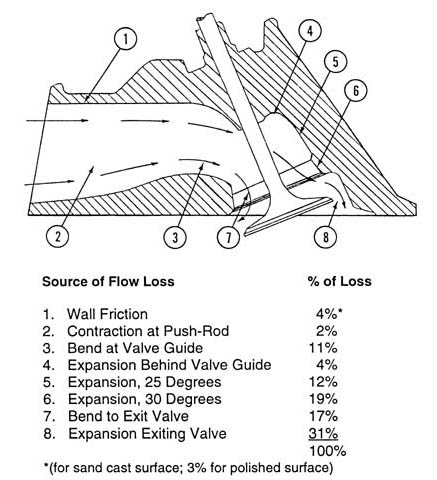

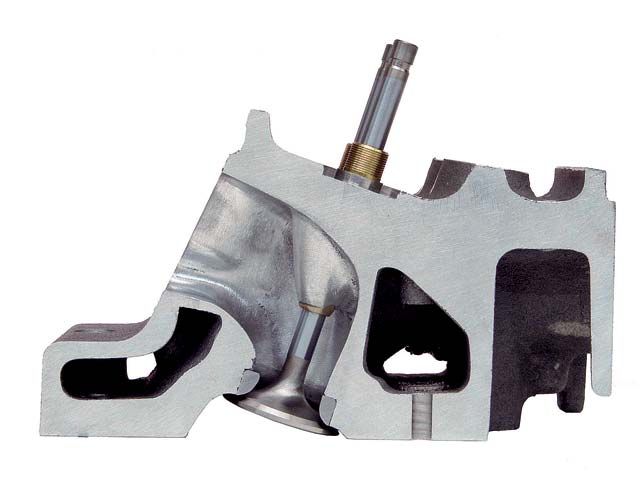

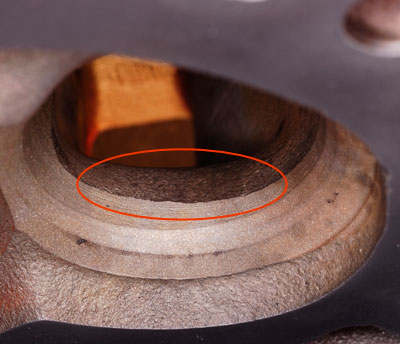

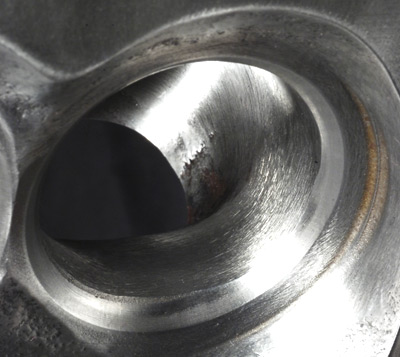

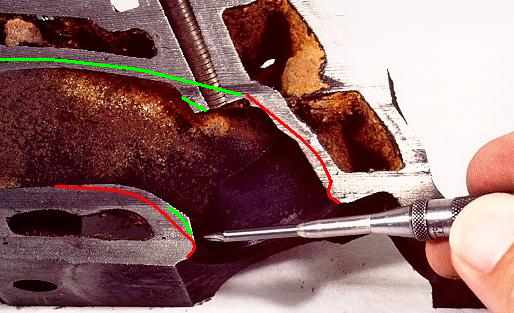

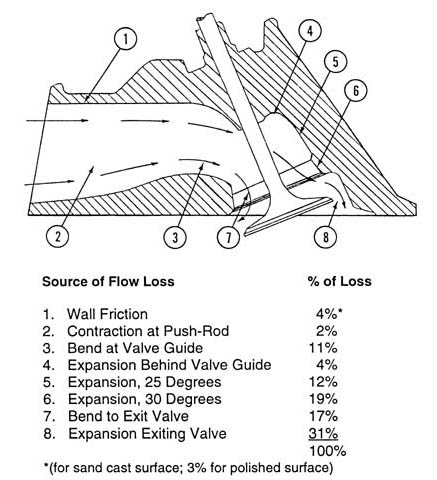

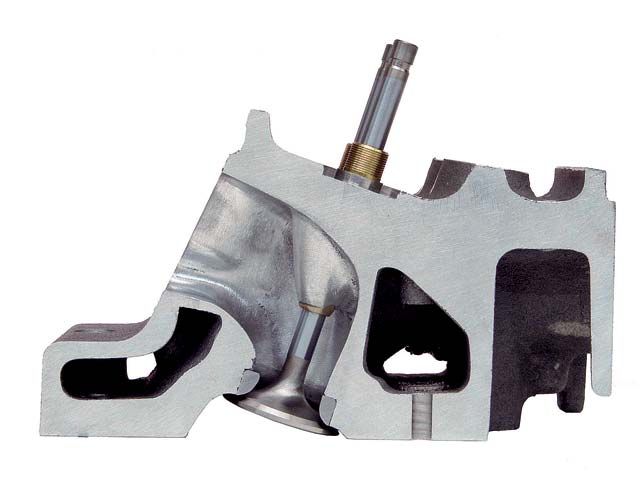

notice how the valve seat supporting casting in the cylinder head, throat extends out into the port and restricts the valve flow, a critical area that port and bowl clean -up can usually gain significant flow improvements

http://www.mondellotwister.com/ArtPtngAtHme.htm

http://www.powerblocktv.com/episodes/HP ... wer-how-to

http://victorylibrary.com/mopar/alternate-c.htm

viewtopic.php?f=52&t=3293&p=8709#p8709 (got twisted wedge heads? read this)

http://www.carbideselect.com/burshpescuts.php

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

http://www.edelbrock.com/automotive/mc/cylinder-heads/chevy/e-series-sb.shtml

viewtopic.php?f=55&t=5378&p=20984&hilit=port+matching#p20984

http://www.circletrack.com/techarticles ... ewall.html

http://www.popularhotrodding.com/engine ... ewall.html

viewtopic.php?f=52&t=10145

http://www.hotrod.com/techarticles/engi ... z28MLMTEYU

http://www.camarohomepage.com/project/part2.htm

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.mondellotwister.com/ArtHeadPort.htm

http://www.ronsportingservice.com/#edelbrock15

http://www.j-performance.com/forum/phpB ... um.php?f=5

http://theamcpages.com/documents/engine ... -ports.doc

viewtopic.php?f=55&t=2773&p=7200#p7200

http://www.j-performance.com/index.php? ... view&id=28

http://www.carcraft.com/techarticles/cc ... index.html

viewtopic.php?f=50&t=3422&p=9066#p9066

http://www.ehow.com/how_4928270_port-po ... heads.html

http://portingtools.com/

READ THRU THIS LINK

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.maximumraceengines.com/intak ... rting.html

http://www.allpar.com/fix/holler/porting.html

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.hotrod.com/howto/3398_alumin ... ld_repair/

http://www.j-performance.com/index.php? ... view&id=27

http://www.allpar.com/fix/holler/porting.html

http://racingsecrets.com/speedtalk_head_porting.shtml

viewtopic.php?f=55&t=4362&p=11826&hilit=porting+plenums#p11826

below are a few ideas

as a guide

read the links carefully

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radius

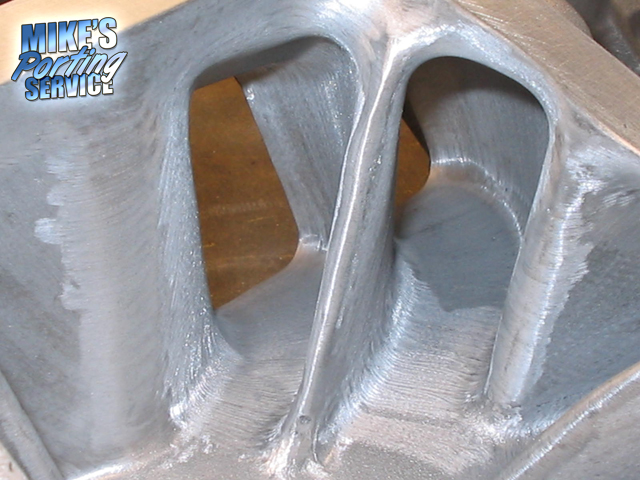

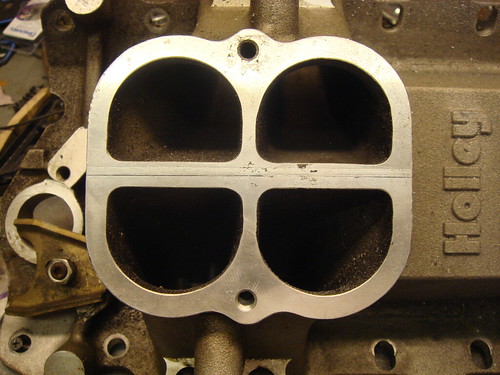

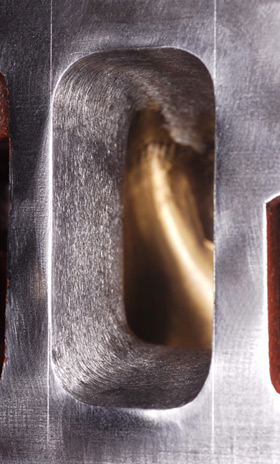

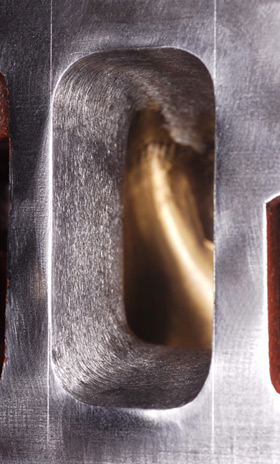

before as cast

after port clean up intake

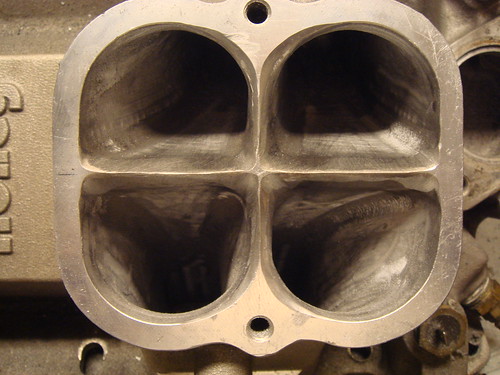

before as cast

after port clean up exhaust

http://www.mondellotwister.com/school.html

http://www.ws6transam.org/ported.html

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://www.eecis.udel.edu/~davis/z28/buildup/plenum/

http://www.babcox.com/editorial/us/us110128.htm

http://www.hotrod.com/howto/51058_cylin ... index.html

http://www.chevyhiperformance.com/techa ... index.html

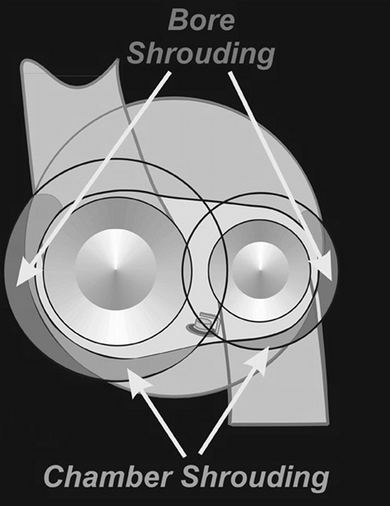

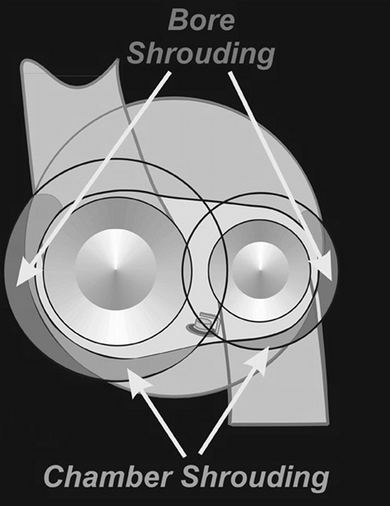

http://www.diyporting.com/Shrouding.html

http://www.gmtips.com/3rd-degree/dox/ti ... t/port.htm

http://www.babcox.com/editorial/ar/eb120121.htm

http://www.babcox.com/editorial/us/us110128.htm

http://www.hotrod.com/techarticles/engine/hrdp_0802_chevy_intake_manifold_porting/index.html

http://www.sa-motorsports.com/diyport.aspx

http://www.circletrack.com/techarticles/general/139_0305_port_matching_engine_porting/index.html

http://speedtalk.com/shows/027_jim_mcfarland.html

http://www.chevyhiperformance.com/techarticles/95518_small_block_cylinder_head_porting/index.html

http://www.gmtips.com/3rd-degree/dox/tips/plen-port/port.htm

http://www.bfranker.badz28.com/96ss/58porting.htm

http://www.eecis.udel.edu/~davis/z28/buildup/plenum/

http://www.diyporting.com/molds.html

http://www.fordmuscle.com/archives/2006/12/MakingMolds/index.php

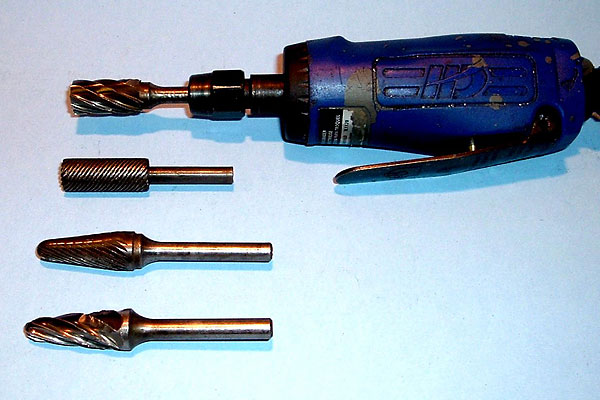

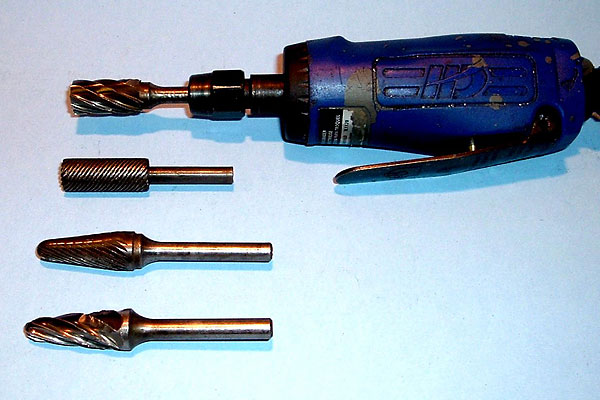

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges

http://www.harborfreight.com/air-die-gr ... 99698.html

I usually buy these three at a time, they last a long time but think of them as disposable like the BURRS because they do wear out and at roughly $20 each are a bargain even if you need to occasionally pitch one in the dumpster

you can order this set of these long carbide burrs for about $36-$40

http://www.abs-products.com/specialty-tools/hogs-carbide-burrs.shtml

http://www.mcsdepot.com/browseproducts/ ... REACH.HTML

http://www.browntool.com/Default.aspx?t ... ductNumber

http://www.grainger.com/category/carbid ... alog/N-9o0

http://www.eastwood.com/8pc-dual-cut-ca ... shank.html

http://www.victornet.com/subdepartments ... /2150.html

http://www.carbideprocessors.com/sgs/long-shank/

http://www.pferdusa.com/products/202a/index.html

http://dewitt-tool.com/b_dc_oval.aspx

http://boroburrs.com/14-shank-burs/

http://www.falcontool.com/Falcon_Carbide_burs.pdf

most of the time you'll find a few seconds time to put on safety equipment and the minimal cost spent is far FAR less than it costs in time and money to deal with the medical cost resulting from rushing into a job without their use!Ive generally used and strongly suggest you consider using, one or both of these when using angle grinders or while porting heads due to learning from past experiences

http://www.homedepot.com/p/DEWALT-Safet ... 220499-_-N

http://www.harborfreight.com/adjustable ... 46526.html

When it comes to amateur porting, Smokey Yunick put it best in one of his books. Addressing amateur backyard mechanics/stock car racers, Smokey said, “If you are compelled to port your own heads, first go buy a pair of the best, and most expensive available – then TRY and copy them.”

what hes trying to point out is that just removing metal and hogging out the ports almost a sure way to ruin a cylinder head, youll need to fully understand what your trying to accomplish, and its not random metal removal, or increased port volume, its increased flow

well theres no doubt that most heads can have the flow improved with a port and bowl clean-up and contouring the short side radias and smoothing the bowl area,

but theres a cost to benefit ratio, its fairly easy to increase stock head flow rates in the 5%-10% range but if your looking at spending several hundred dollars in port work and if your looking for major improvements your generally better off selecting aftermarket heads with larger and far better designed ports than sinking a ton of time and money in stock heads, that in many cases your eventually replace.

think it through carefully, its almost always a waste of time and money to sink cash into small port OEM cylinder heads if your goal is to make a great deal more HP, than the original engine made, and by that I generally mean any increase in power goals that exceed about 10%-20% more power than the original engine made, when your looking to boost power to that level your almost always going to need better flowing heads than some re-contouring of the stock head can provide

port throats generally run 80%-85% of total valve diameter because you need to maintain sufficient valve seat contact area to allow sealing and cooling and some wear during operation.

before you reach for your wallet, do some basic math and read a few dozen related links

http://www.wallaceracing.com/calcafhp.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://garage.grumpysperformance.com/index.php?threads/epoxy.14058/

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://www.gmhpclub.com/performancecalculators.htm

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/#post-37705

http://garage.grumpysperformance.co...octane-for-compression-ratio.2718/#post-68131

http://garage.grumpysperformance.com/index.php?threads/cnc-port-work-related.15313/

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

THERES ABOUT 90% of the INFO YOULL NEED IS IN THE SUB LINKS ..READ THOSE ALSO

theres also lots of guys who find that the intake manifolds available for the application they have, are rather restrictive, especially for some of the less popular engines like Cadillac, or Pontiac engines Ive worked with in the past, or if the intake designs available are mostly for non-racing applications. runners can be too small in cross sectional area, and aftermarket parts can be non-existent and theres not always enough material in all intake runner designs to allow porting them to a significantly larger port size without having made the gasket sealing area to thin to seal properly.

this does not necessarily mean you have zero options, in many cases a quality machine shop can tig weld extra aluminum on the intake in critical areas to allow you to port the runners larger and then they can reface the gasket sealing area thus allowing you to significantly increase the intake runners cross sectional area.

READ THIS

http://www.maliburacing.com/patrick_budd_article.htm

http://amsoilracing.com/events/amsoil-engine-masters-challenge/

https://www.youtube.com/watch?v=0oXkjfWHT6U

yes its worth the time required to read thru the sub linked info

viewtopic.php?f=27&t=1831&p=4763#p4763

notice how the valve seat supporting casting in the cylinder head, throat extends out into the port and restricts the valve flow, a critical area that port and bowl clean -up can usually gain significant flow improvements

http://www.mondellotwister.com/ArtPtngAtHme.htm

http://www.powerblocktv.com/episodes/HP ... wer-how-to

http://victorylibrary.com/mopar/alternate-c.htm

viewtopic.php?f=52&t=3293&p=8709#p8709 (got twisted wedge heads? read this)

http://www.carbideselect.com/burshpescuts.php

http://www.superchevy.com/how-to/engines-drivetrain/sucp-0209-chevy-gm-cylinder-heads/

http://www.edelbrock.com/automotive/mc/cylinder-heads/chevy/e-series-sb.shtml

viewtopic.php?f=55&t=5378&p=20984&hilit=port+matching#p20984

http://www.circletrack.com/techarticles ... ewall.html

http://www.popularhotrodding.com/engine ... ewall.html

viewtopic.php?f=52&t=10145

http://www.hotrod.com/techarticles/engi ... z28MLMTEYU

http://www.camarohomepage.com/project/part2.htm

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.mondellotwister.com/ArtHeadPort.htm

http://www.ronsportingservice.com/#edelbrock15

http://www.j-performance.com/forum/phpB ... um.php?f=5

http://theamcpages.com/documents/engine ... -ports.doc

viewtopic.php?f=55&t=2773&p=7200#p7200

http://www.j-performance.com/index.php? ... view&id=28

http://www.carcraft.com/techarticles/cc ... index.html

viewtopic.php?f=50&t=3422&p=9066#p9066

http://www.ehow.com/how_4928270_port-po ... heads.html

http://portingtools.com/

READ THRU THIS LINK

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.maximumraceengines.com/intak ... rting.html

http://www.allpar.com/fix/holler/porting.html

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.project33.com/Categoryarticl ... ory=Engine

http://www.hotrod.com/howto/3398_alumin ... ld_repair/

http://www.j-performance.com/index.php? ... view&id=27

http://www.allpar.com/fix/holler/porting.html

http://racingsecrets.com/speedtalk_head_porting.shtml

viewtopic.php?f=55&t=4362&p=11826&hilit=porting+plenums#p11826

below are a few ideas

as a guide

read the links carefully

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radius

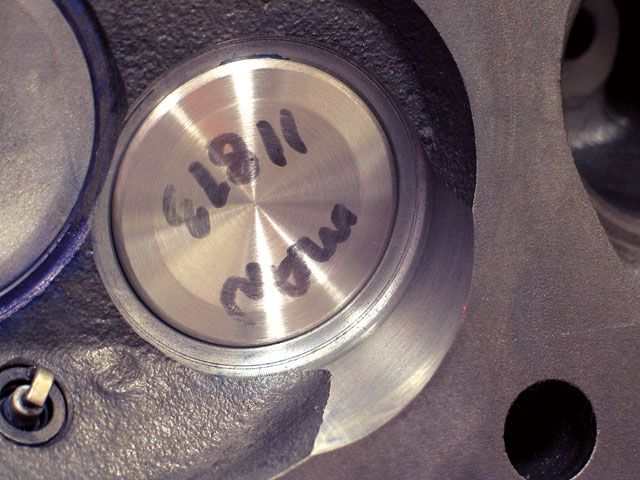

before as cast

after port clean up intake

before as cast

after port clean up exhaust

http://www.mondellotwister.com/school.html

http://www.ws6transam.org/ported.html

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://victorylibrary.com/mopar/chamber-tech-c.htm

http://www.eecis.udel.edu/~davis/z28/buildup/plenum/

http://www.babcox.com/editorial/us/us110128.htm

http://www.hotrod.com/howto/51058_cylin ... index.html

http://www.chevyhiperformance.com/techa ... index.html

http://www.diyporting.com/Shrouding.html

http://www.gmtips.com/3rd-degree/dox/ti ... t/port.htm

http://www.babcox.com/editorial/ar/eb120121.htm

http://www.babcox.com/editorial/us/us110128.htm

http://www.hotrod.com/techarticles/engine/hrdp_0802_chevy_intake_manifold_porting/index.html

http://www.sa-motorsports.com/diyport.aspx

http://www.circletrack.com/techarticles/general/139_0305_port_matching_engine_porting/index.html

http://speedtalk.com/shows/027_jim_mcfarland.html

http://www.chevyhiperformance.com/techarticles/95518_small_block_cylinder_head_porting/index.html

http://www.gmtips.com/3rd-degree/dox/tips/plen-port/port.htm

http://www.bfranker.badz28.com/96ss/58porting.htm

http://www.eecis.udel.edu/~davis/z28/buildup/plenum/

http://www.diyporting.com/molds.html

http://www.fordmuscle.com/archives/2006/12/MakingMolds/index.php

btw it helps a great deal to dip the burr in a shot glass of WD.40 about every 20-30 seconds as it helps keep it from picking up crud sticking to the burrs cutting edges

http://www.harborfreight.com/air-die-gr ... 99698.html

I usually buy these three at a time, they last a long time but think of them as disposable like the BURRS because they do wear out and at roughly $20 each are a bargain even if you need to occasionally pitch one in the dumpster

you can order this set of these long carbide burrs for about $36-$40

http://www.abs-products.com/specialty-tools/hogs-carbide-burrs.shtml

http://www.mcsdepot.com/browseproducts/ ... REACH.HTML

http://www.browntool.com/Default.aspx?t ... ductNumber

http://www.grainger.com/category/carbid ... alog/N-9o0

http://www.eastwood.com/8pc-dual-cut-ca ... shank.html

http://www.victornet.com/subdepartments ... /2150.html

http://www.carbideprocessors.com/sgs/long-shank/

http://www.pferdusa.com/products/202a/index.html

http://dewitt-tool.com/b_dc_oval.aspx

http://boroburrs.com/14-shank-burs/

http://www.falcontool.com/Falcon_Carbide_burs.pdf

most of the time you'll find a few seconds time to put on safety equipment and the minimal cost spent is far FAR less than it costs in time and money to deal with the medical cost resulting from rushing into a job without their use!Ive generally used and strongly suggest you consider using, one or both of these when using angle grinders or while porting heads due to learning from past experiences

http://www.homedepot.com/p/DEWALT-Safet ... 220499-_-N

http://www.harborfreight.com/adjustable ... 46526.html

Last edited by a moderator: