YES YOU NEED TO READ THRU THE LINKS THAT'S WHAT THEY ARE THERE FOR...AND THERE'S A GREAT DEAL OF USEFUL INFO IN THOSE LINKS,

don,t get over whelmed, make a list and test adjust correct or replace each problem,

and check it off the list then move to the next issue,

its a finite list and theres not a damn thing on it you can,t accomplish,

with a bit of research, a few questions and this web-sites help

(a few tools the right attitude and a thick stack of cash would also be useful of course)

think carefully about both the initial cost and the structural strength of the engine block you select, the OEM blocks used in production car engines will RARELY accept a .030 plus over bore with out having one or more cylinders having marginally thin bore walls, this results in inadequate bore to ring sealing if its in the wrong area and promotes stress cracks. A .060 over bore in a SBC is rather commonly pushing that bore wall thickness up to or over a reasonable limit so you need to sonic and magnetically check the block for cracks and wall thickness.

you could easily dump $500-$1500 into machine work on a block that won,t last more than a few months under high stress if its not carefully checked PRIOR to the machine work being done.

THIS BEAM STYLE TORQUE WRENCH IS THE TYPE TORQUE WRENCH YOU WANT TO CHECK ROTATIONAL RESISTANCE

yes it always helps too double check bearing clearances and take the time too verify oil passages are clean,

and bearing oil feed holes properly line up with the oil feed passages and verify,

those clearances, and not just simply assume, they are correct

, and assemble and re-verify those clearances.

Theory into Practice

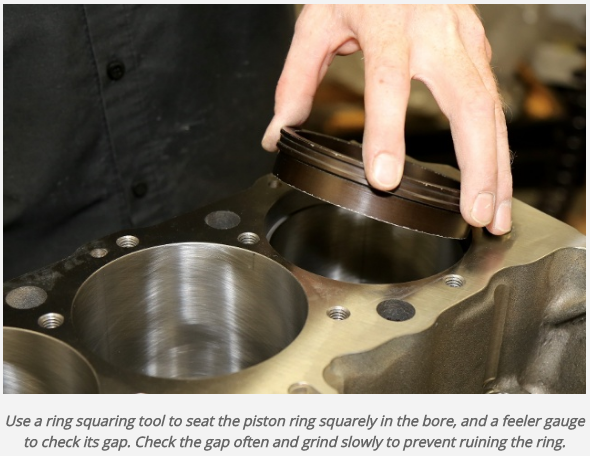

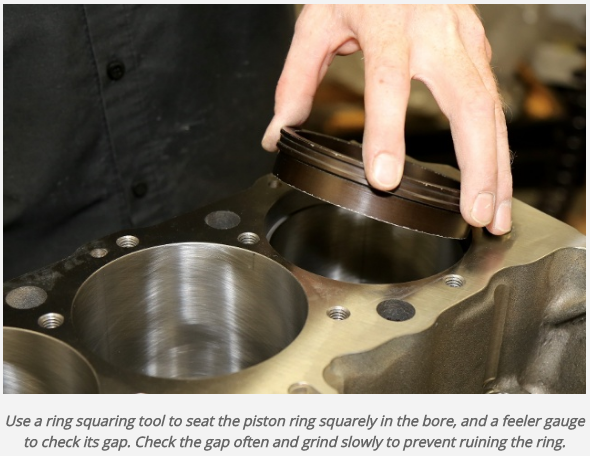

Now that we’ve covered the “why” of piston ring gapping, it’s time to put that knowledge to work. We asked DiBlasi for the main issues people run into, and he gave us some very practical advice, saying, “There are several mistakes people make when setting ring end gaps. I myself have done it in the past, so it happens to everyone. I will also address ring install problems in general…”

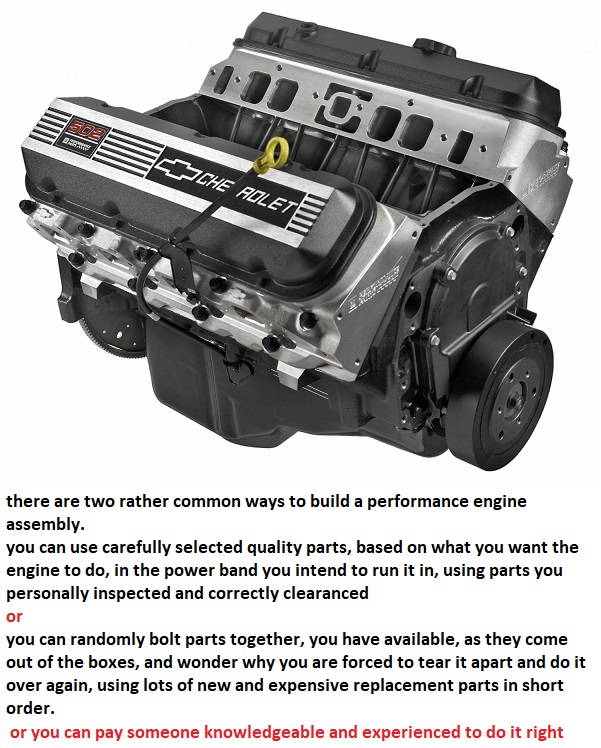

every part you choose is a compromise , and may require changes,

that cost you in time, money or performance to some degree,

and almost every part will require a bit of fitting or clearance work,

or adjustment to fit and function to get the best results

if it drops out of the package and bolts together as it drops out of the package,

its almost certain its not functional to nearly its full potential

your job is to think things through carefully and make sure parts fit and function to their full potential,

little things like checking piston ring end gap, verifying bearing clearances, and ccing the heads and checking piston to valve clearance, degreeing in the cam and verifying the valve train geometry, polishing combustion chambers, getting a decent 3 angle valve job,verifying the piston to bore clearance, MATTER's

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

http://blog.wiseco.com/everything-you-need-to-know-about-ring-gap

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68205

http://blog.wiseco.com/engine-building-practices-you-need-to-know

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-64733

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/

http://blog.wiseco.com/how-to-file-fit-and-install-piston-rings

https://www.carshopinc.com/product_info.php/products_id/49347/SPG1-12

read the links don,t skip them, youll likely save a great deal of cash and time knowing whats involved

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-383-vs-a-350.715/

http://garage.grumpysperformance.com/index.php?threads/blocks-from-summitt-or-comp-products.10174/

http://garage.grumpysperformance.co...s-why-doesn-t-anyone-ever-ask-or-check.11532/

viewtopic.php?f=53&t=247

viewtopic.php?f=51&t=588&hilit=honing%E2%80%A6

http://www.bhjproducts.com/bhj_content/ ... pplist.php

viewtopic.php?f=53&t=1797

http://www.hastingsmfg.com/ServiceTips/ ... ishing.htm

http://www.enginebuildermag.com/Item/38 ... rings.aspx

viewtopic.php?f=69&t=3814&start=240

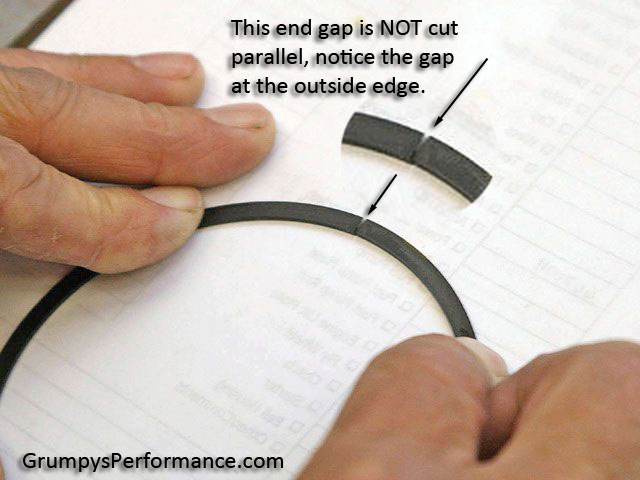

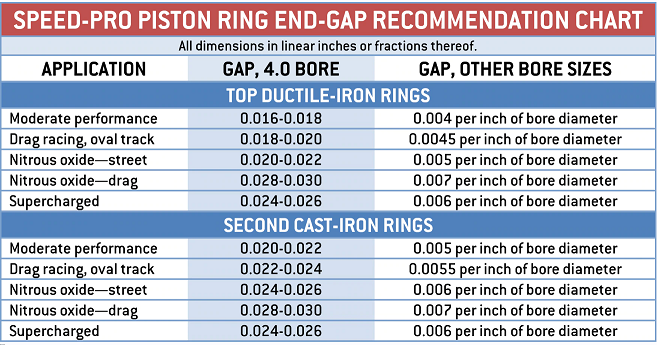

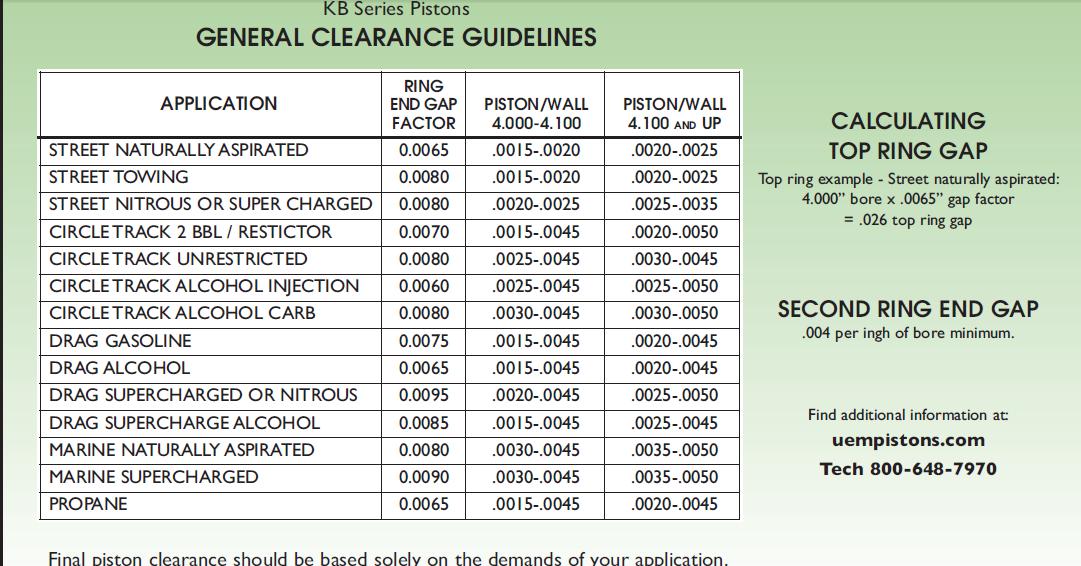

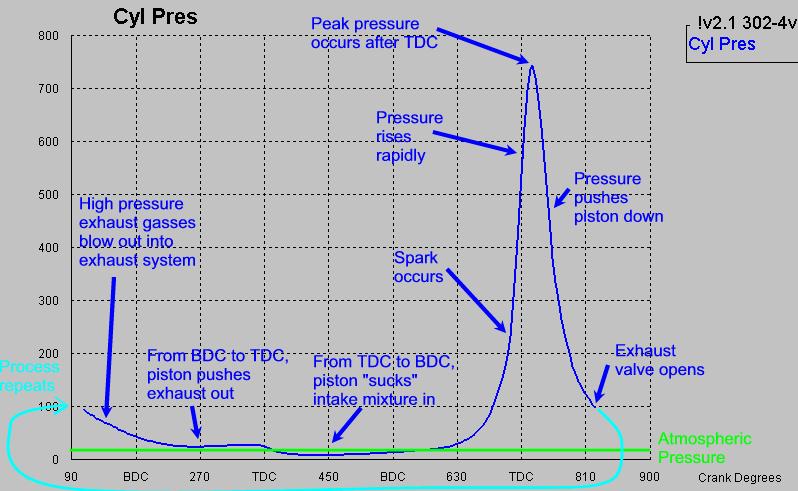

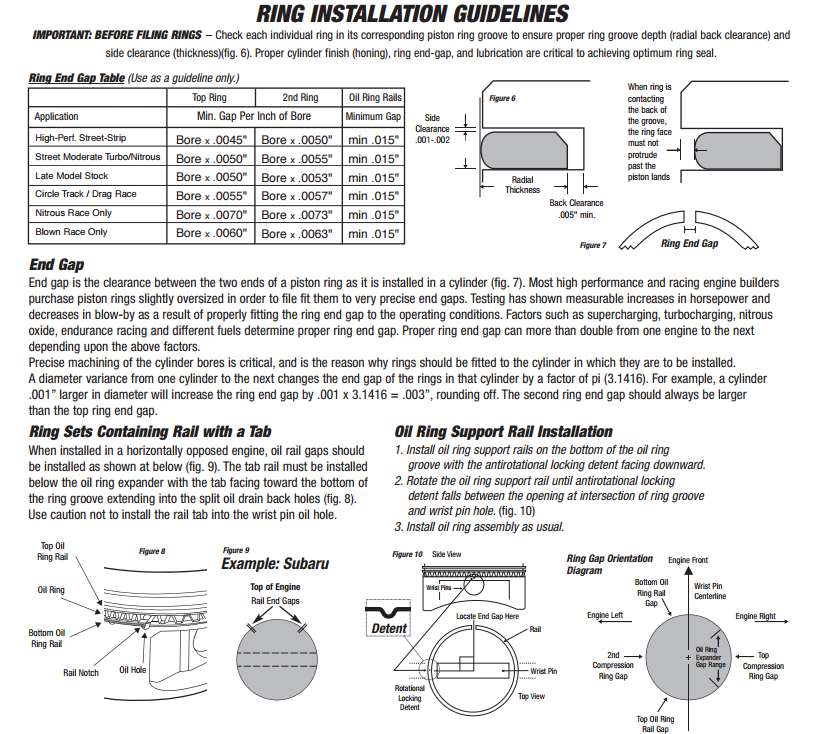

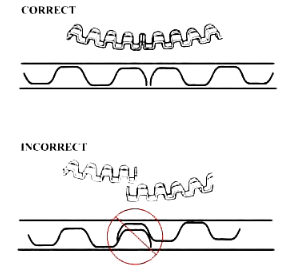

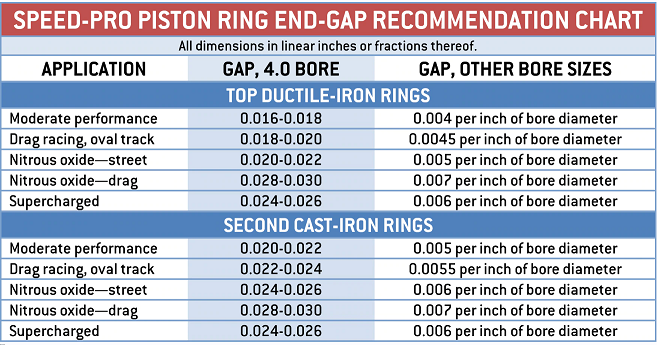

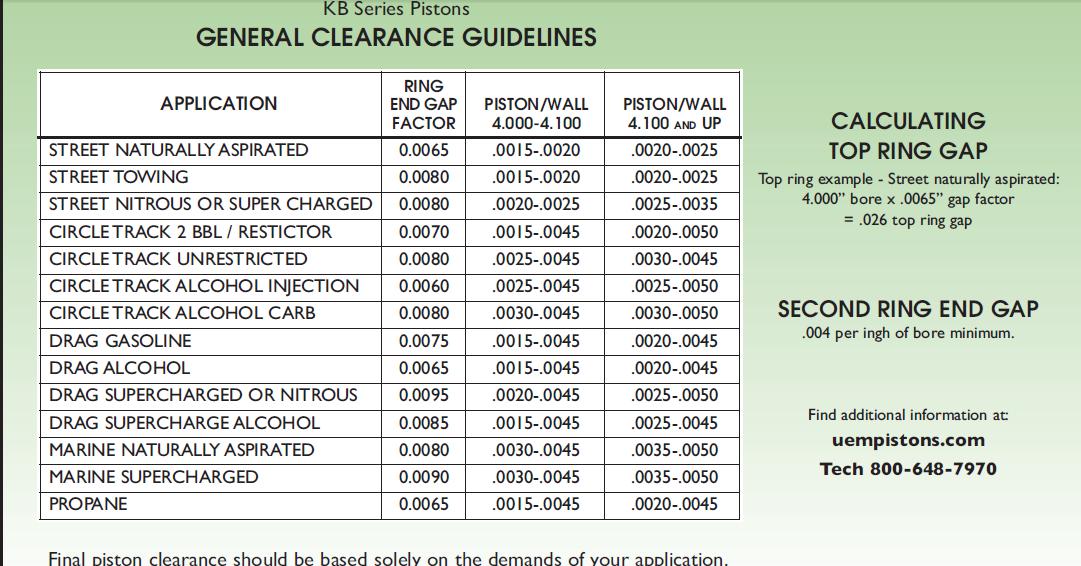

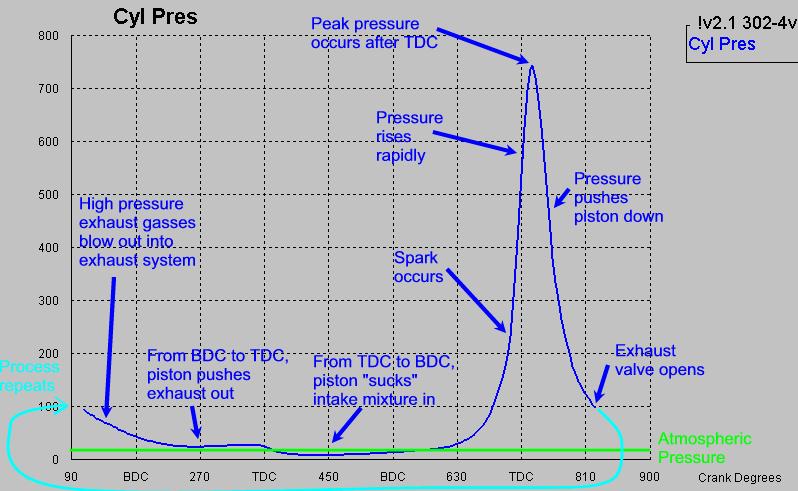

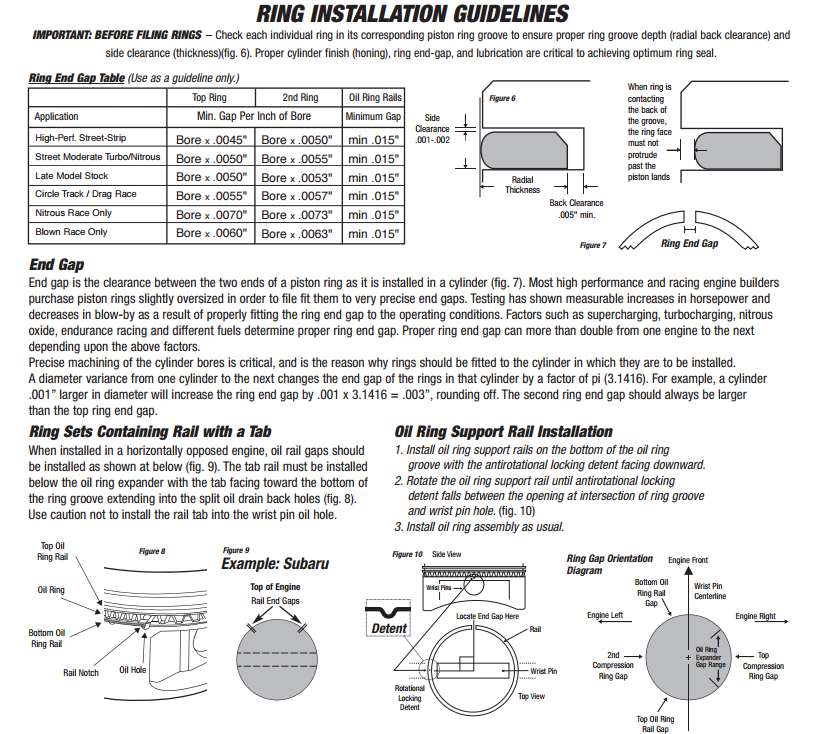

GET THE RING END GAP TOO TIGHT ,OR PISTON SIDE CLEARANCE TOO TIGHT,OR NOT PAY ATTENTION TO THE LUBE SYSTEM DETAILS,AND WHEN THE RINGS EXPAND WITH ENGINE HEAT THE ENDS TOUCH THE RINGS LOCK IN THE BORE AND THE PISTON LANDS SHEAR OFF, it RESULTS IN EXPENSIVE FAILURES GET THE GAP A BIT TOO LARGE AND YOU MIGHT BURN A BIT MORE OIL OR LOOSE SOME COMPRESSION, YOU'LL SEE A CHART LATER IN THE THREAD, BUT GENERALLY YOU'LL WANT .0045-.0065 PER INCH OF BORE DIAM. FOR A RING END GAP

The truth here is that if the ring end gap is anywhere in the .016-.030 the rings will work out fine,

the piston ring manufacturer's know from testing that compression and oil control,

emissions and all other test results tend to show ring gaps under about .040,

have nearly zero effect on how the engine runs, how much oil it uses or its ability to pass emissions,

that .016 is the IDEAL end gap on a daily driver engine , remember as the pistons heat up the rings expand,

and the end gap narrows significantly. a .016 end gap should result in having the ring ends almost,

but not touch under normal operating conditions, almost all ring manufactures strongly suggest a bit larger end gap,

if you use any power booster , as that tends to noticeably increase operational heat and result in tighter end gaps. the piston alloy the fuel you use your fuel/air ratio and ignition advance curve all effect the engines operational temps, and as a result the true operational piston ring end gap.

keep in mind a piston even at only about 800 rpm,has a compression stroke 13 -14 times a SECOND, now get out your feeler gauge and look how thin a .030 feeler gauge is and remember the piston to bore wall clearance at operational temps is under .001, thus the potential end gap can,t potentially allow much flow through what is in effect a fast moving oil filled pin hole thats being slamed from bdc to tdc 13 times to 60 times per second depending on engine rpms

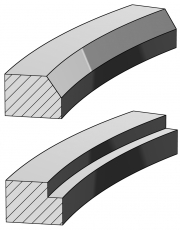

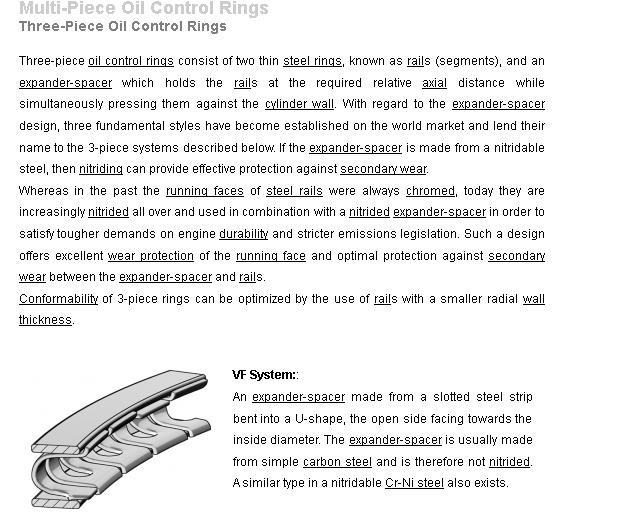

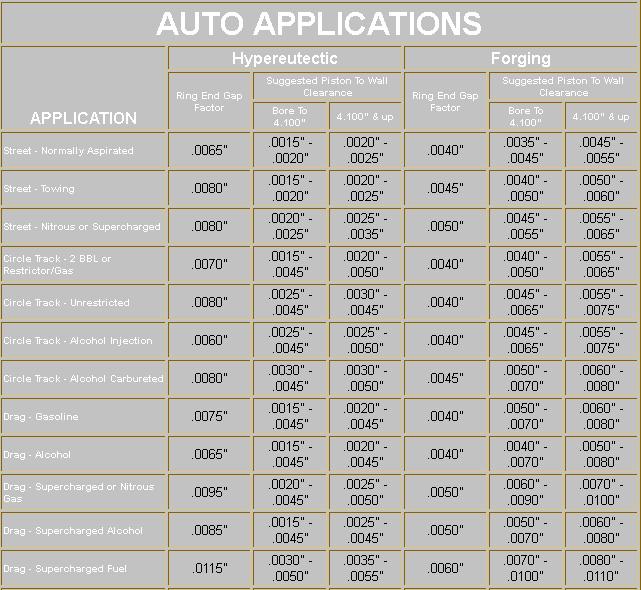

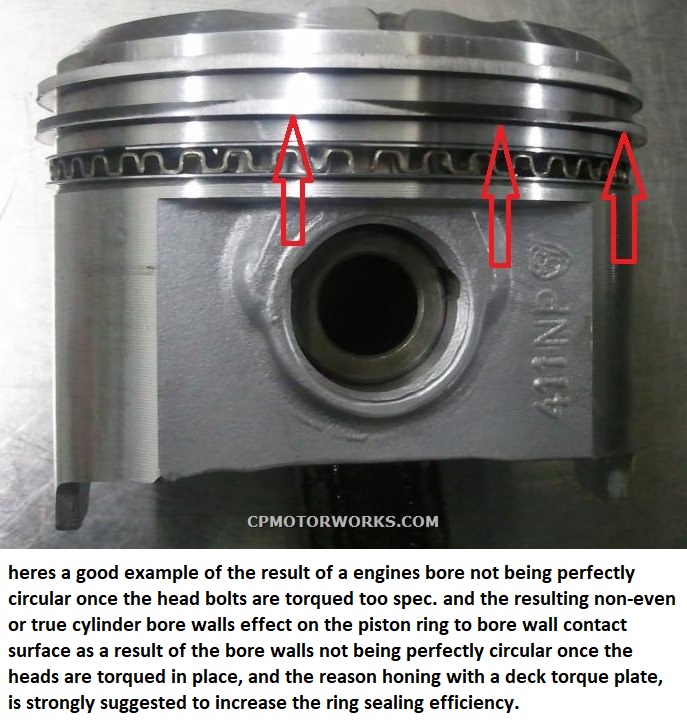

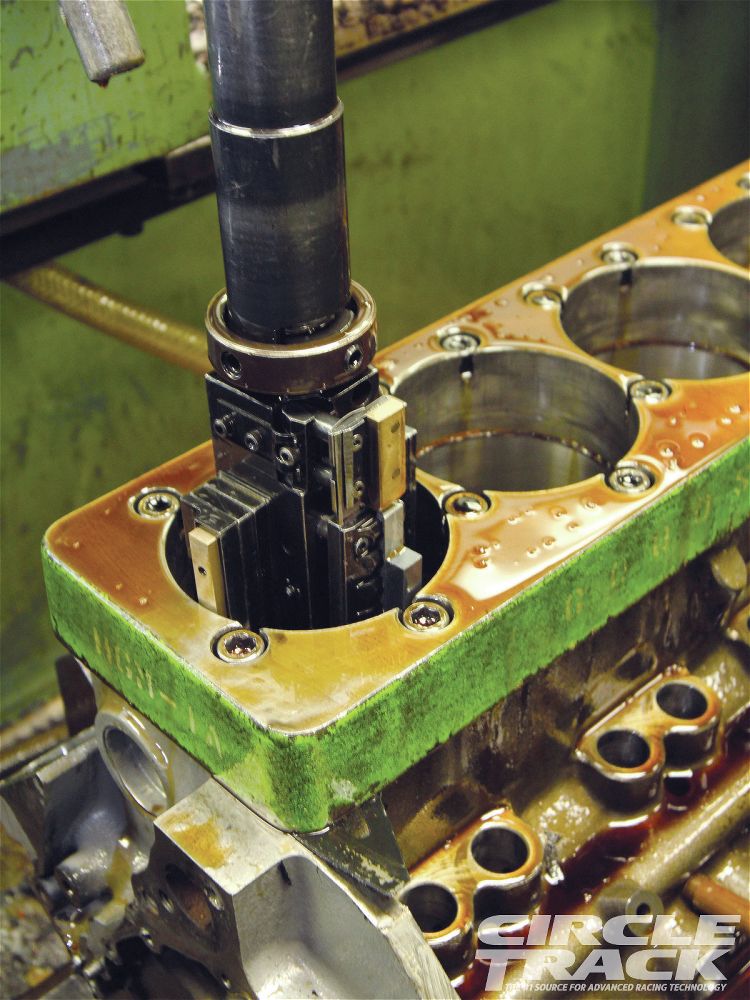

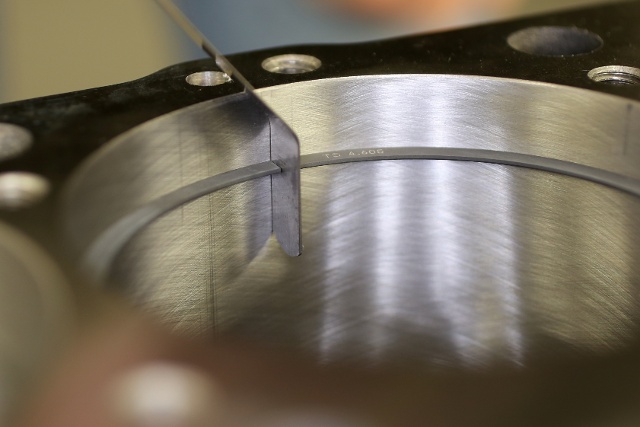

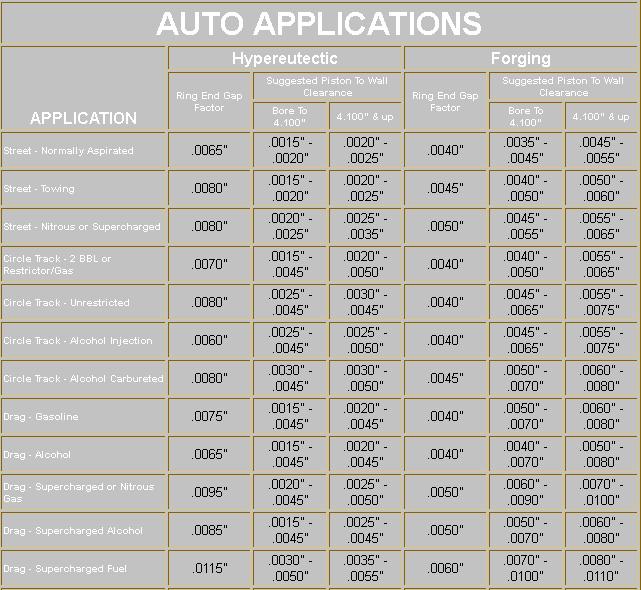

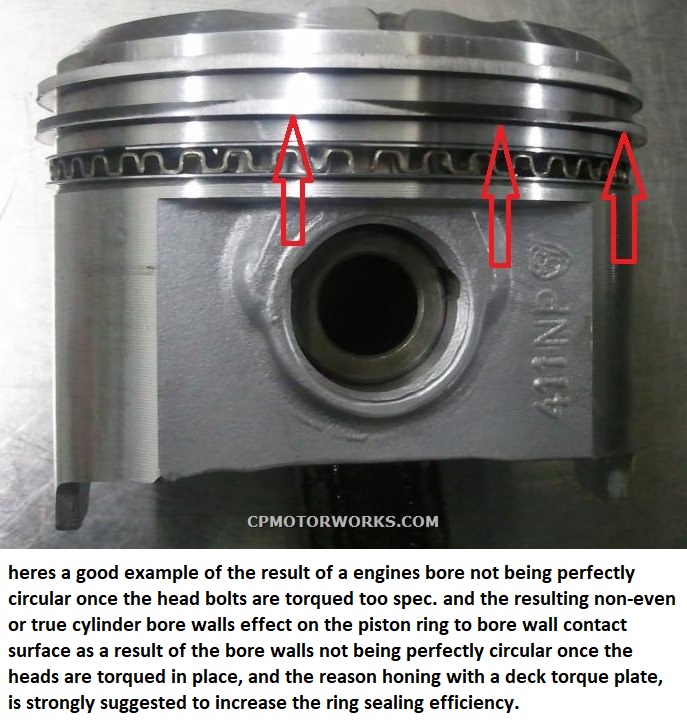

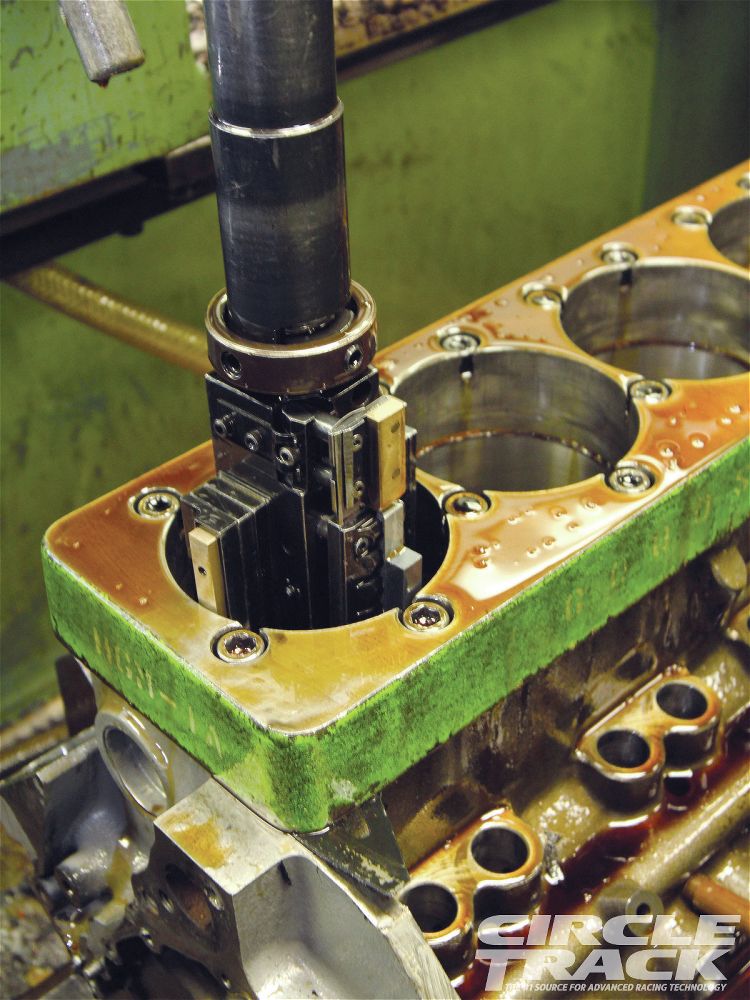

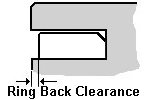

HONE WITH HONE PLATES to duplicate the stress the head bolts place on the cylinder walls to get a true round bore wall surface

use of a deck plate allows the head bolts to be torqued ,this duplicates the stress the heads when installed exert on the block and allows a much better ring seal

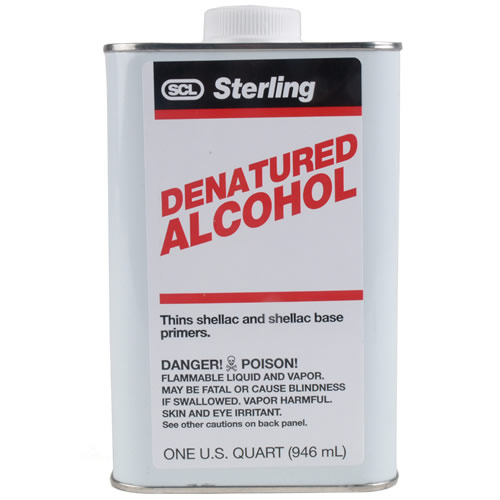

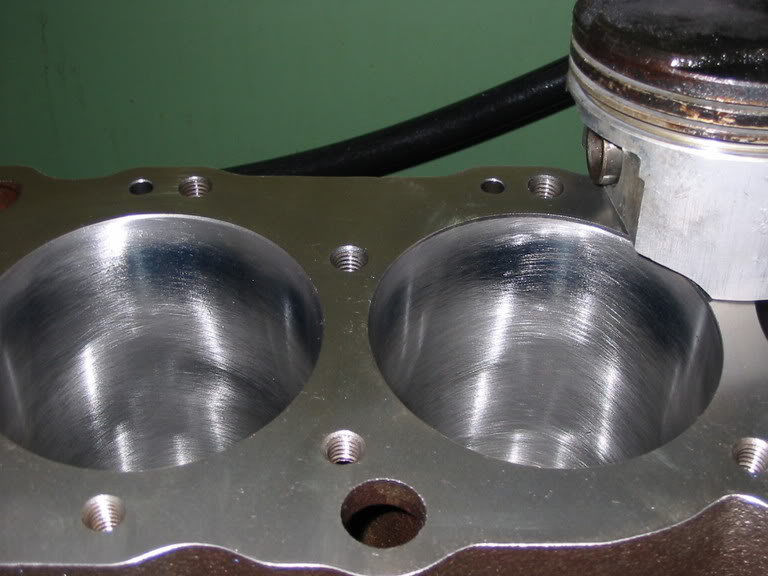

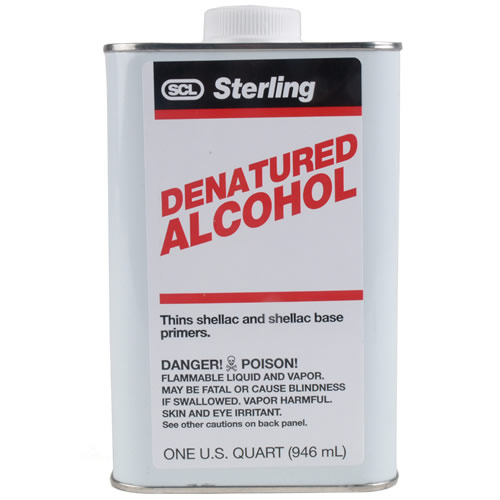

BORING and HONING a blocks bore are best done at a local machine shop where clearances and surface finish are more accurately controlled, BUT, IF your going to be honing the bores for MOLY rings I,d suggest a 240-280 grit hone a 45 degree cross hatch angle and a constant flow of flushing liquid washing over the stones and bore surface to keep the stones from clogging with micro grit trash, that gets removed from the high points in the bore surface.

Ive used both a flush of 90% diesel fuel mixed with 10% marvel mystery oil, as a flush and Ive used hot water with a couple teaspoons of dawn dish washing soap, both work, but I think the hot water and dawn solution produced the most uniform result, on the bore surface but that requires a good deal of cleaning and washing the block just like the diesel fuel mix as you darn sure want to remove all traces of grit and prevent rust forming from moisture so after hone work I power wash the block with a pressure washer,, flush the surface with alcohol paint thinner as it tends to get under and lift out micro crud and speed surface dry time ,then I spray it over with WD40 and heat it with a heat gun to remove moisture traces then re-spray it with WD, 40 [/b]

washing the blocks surface with alcohol, and drying with high pressure air helps dry a lock after a pressure washing

http://www.harborfreight.com/1600-watt- ... 69342.html

http://www.circletrack.com/enginetech/c ... for_speed/

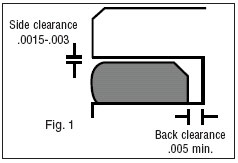

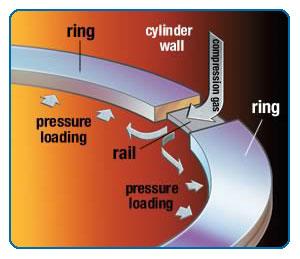

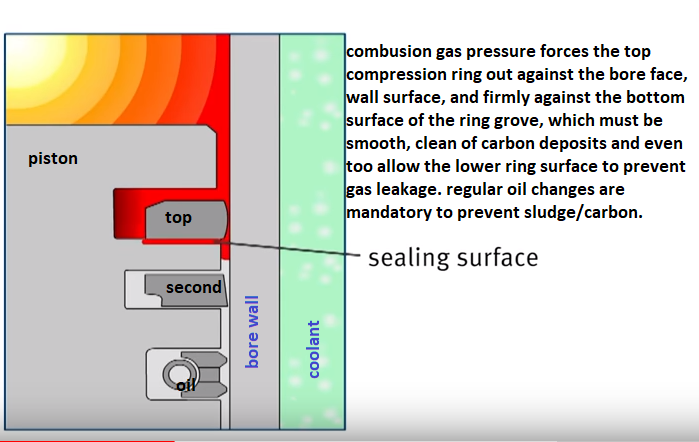

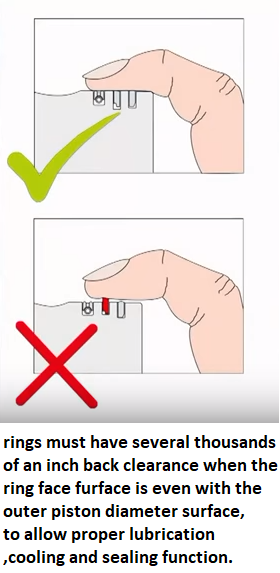

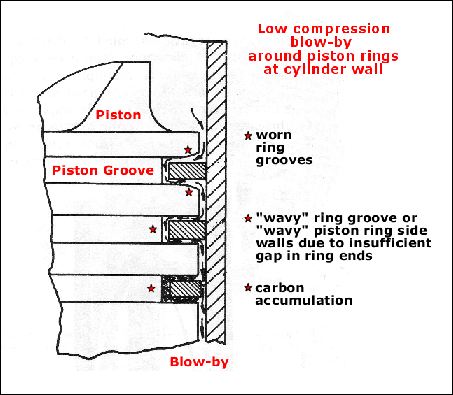

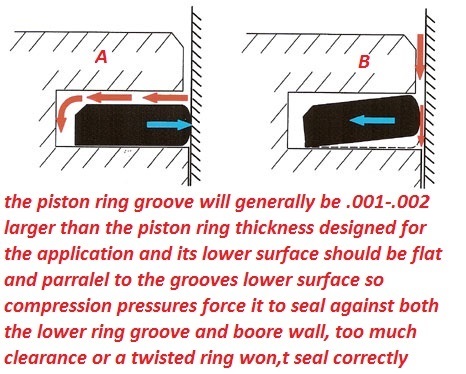

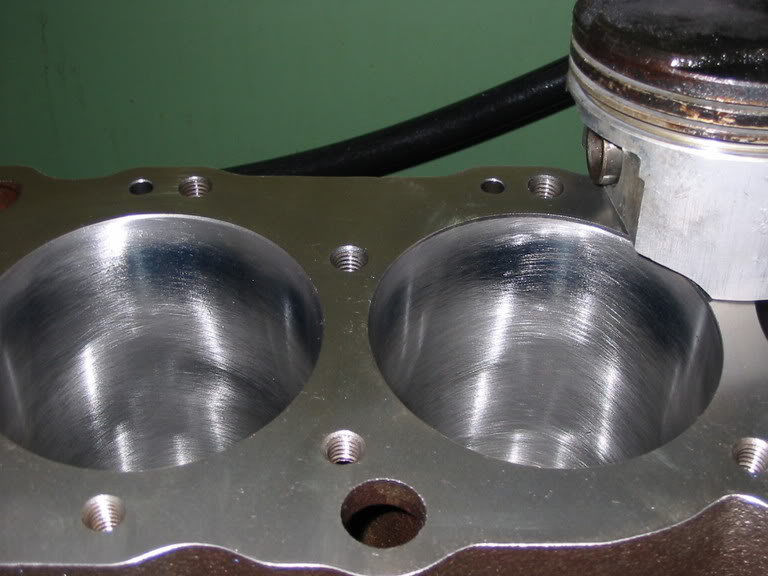

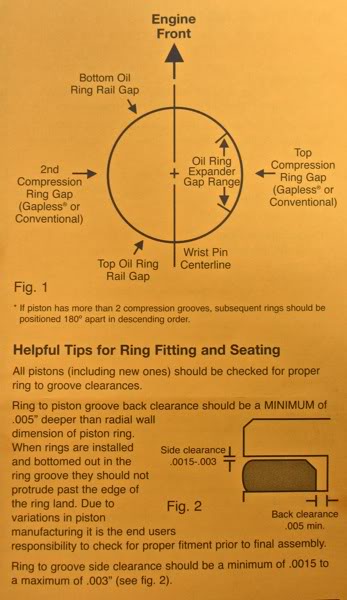

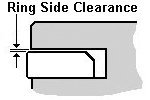

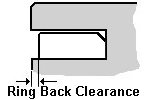

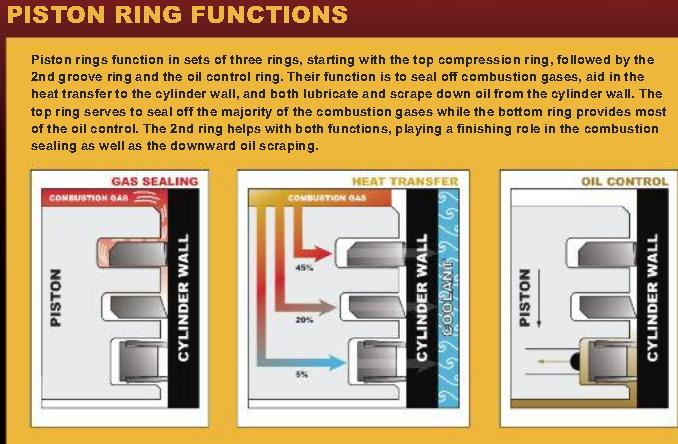

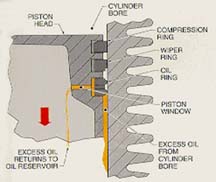

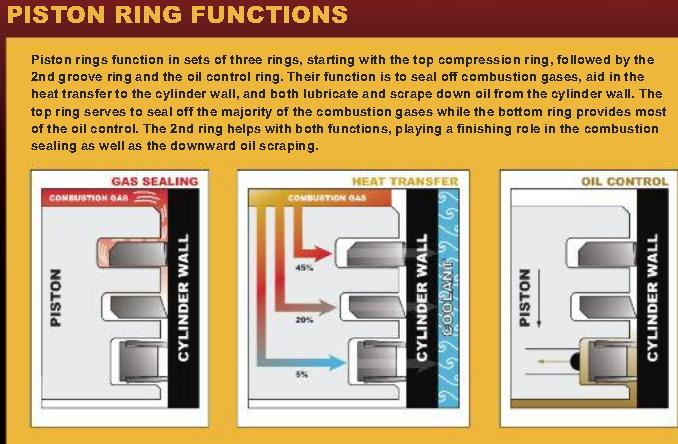

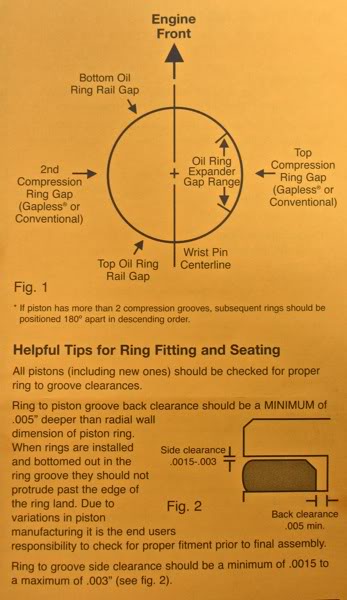

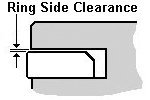

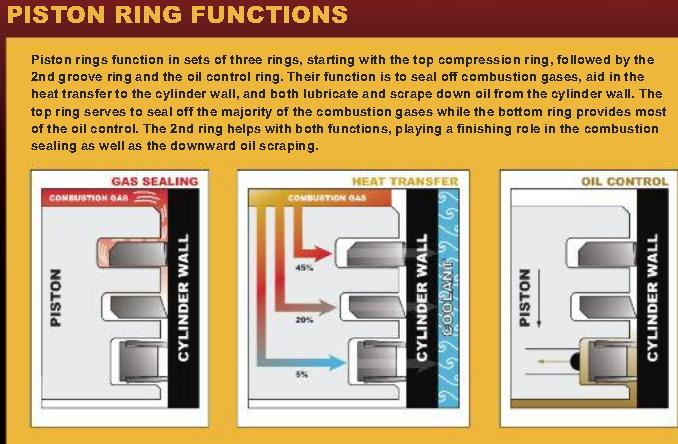

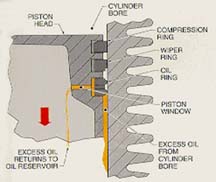

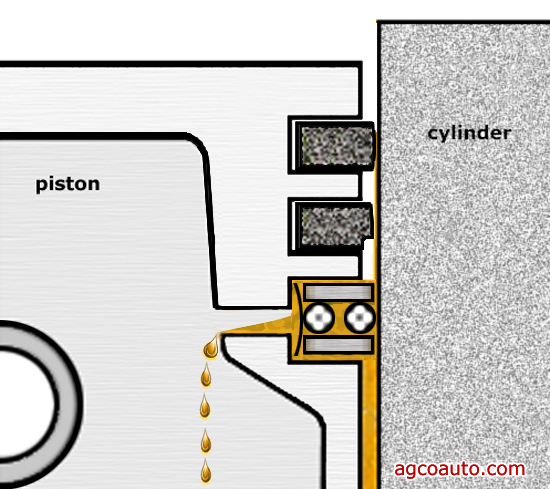

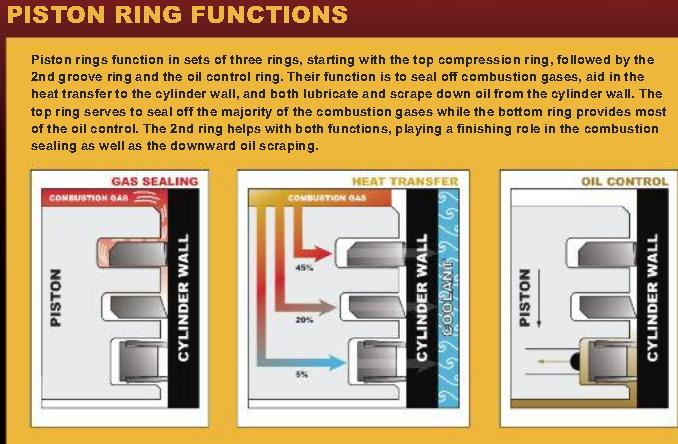

one factor I find amazing is how few guys realize that the rings MUST have space both above the ring and behind the ring in the piston grooves simply because its the hundreds of PSI of cylinder pressure that first forces the ring into the bottom of its groove then the pressure gets behind the ring and tends to expand it and hold it into the bore that is a huge factor in how effective the ring seals combustion pressure in the combustion chamber, if the clearances are filled with carbon build up the rings loose a great deal of there ability to seal.

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably;y more than the ring tension alone can do.

http://www.sjdiscounttools.com/lis24000.html

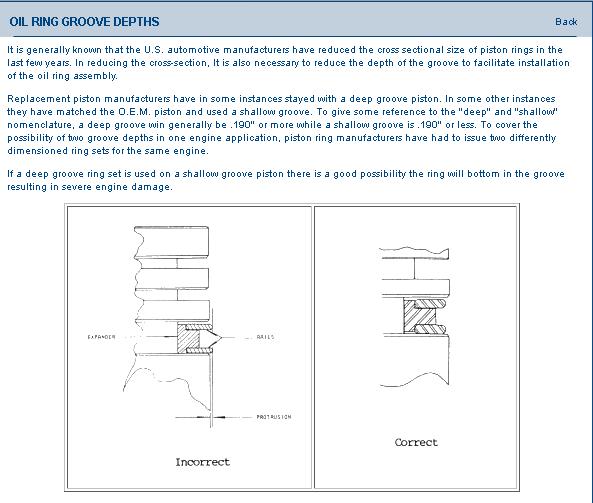

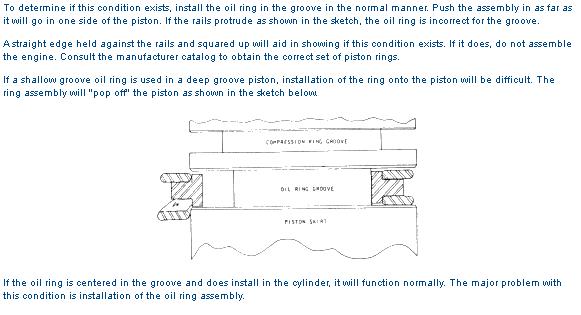

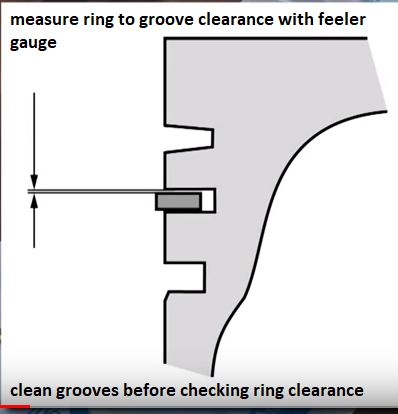

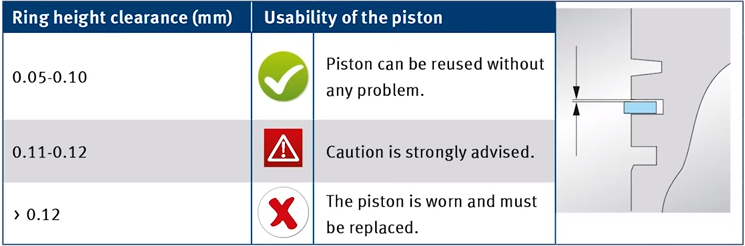

measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

viewtopic.php?f=53&t=1797&p=4586#p4586

viewtopic.php?f=53&t=3897&p=26602&hilit=tool+groove+piston#p26602

viewtopic.php?f=53&t=509&p=632&hilit=tool+groove+piston#p632

viewtopic.php?f=53&t=9490&p=34908&hilit=ring+compressor#p34908

viewtopic.php?f=53&t=5454&p=16301&hilit=ring+back+space#p16301

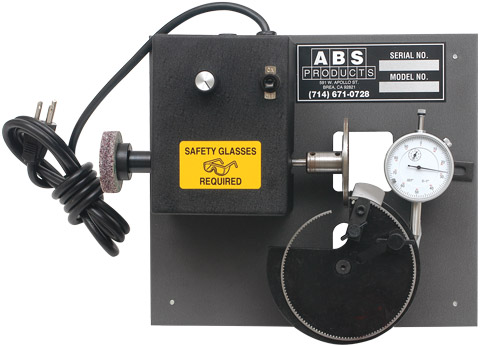

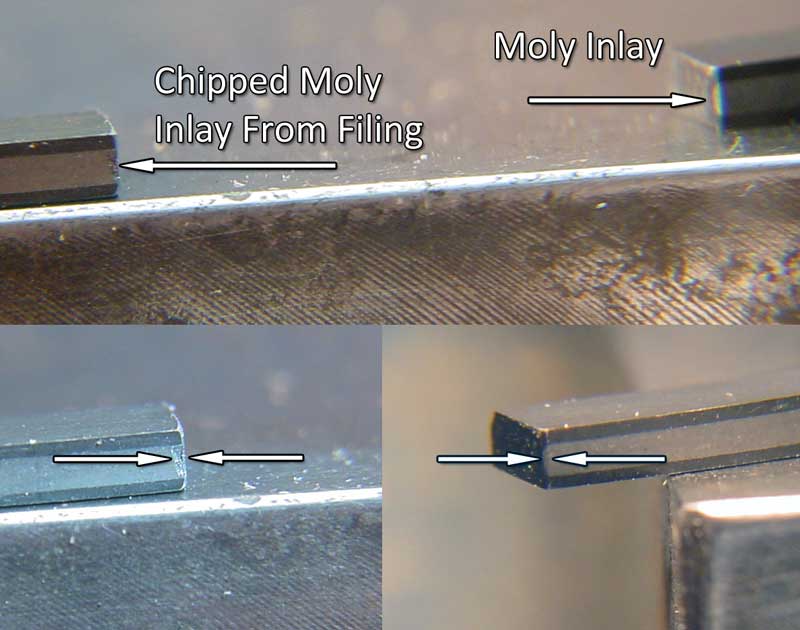

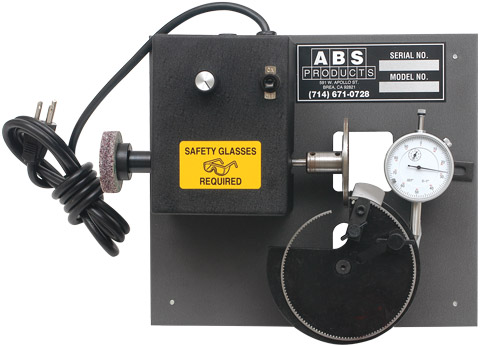

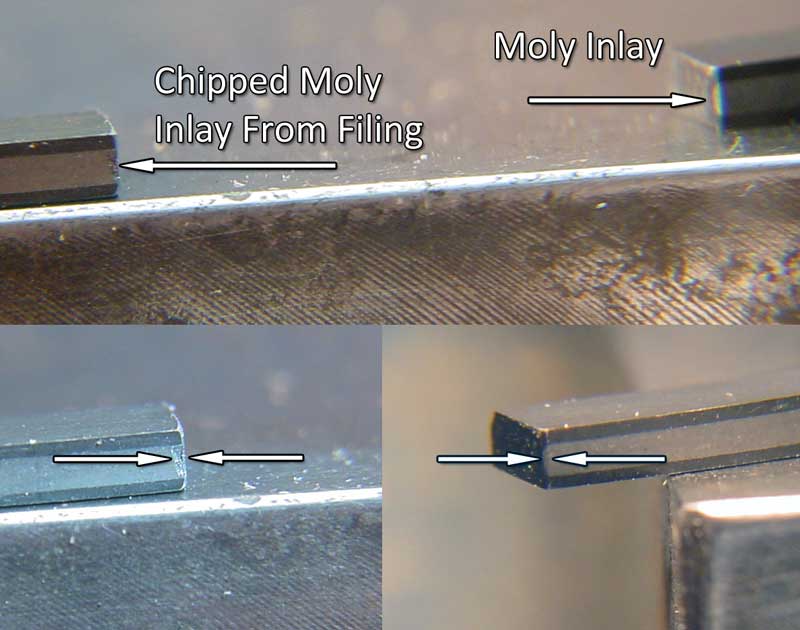

yes thats a VERY commonly over looked factor, the chipping seeming to be sensitive to how aggressive I pushed the ring into the grinding wheel, and how agreasive the grit used is, the slightly higher cost diamond grit wheel IS worth the cost difference and how fast its spinning all effect results, even the direction the grinding disc spins effects the cut, it generally works best is the wheel , on the ring filer disc is rather smooth and the rings barely moved into the cutting disk with minimal resistance

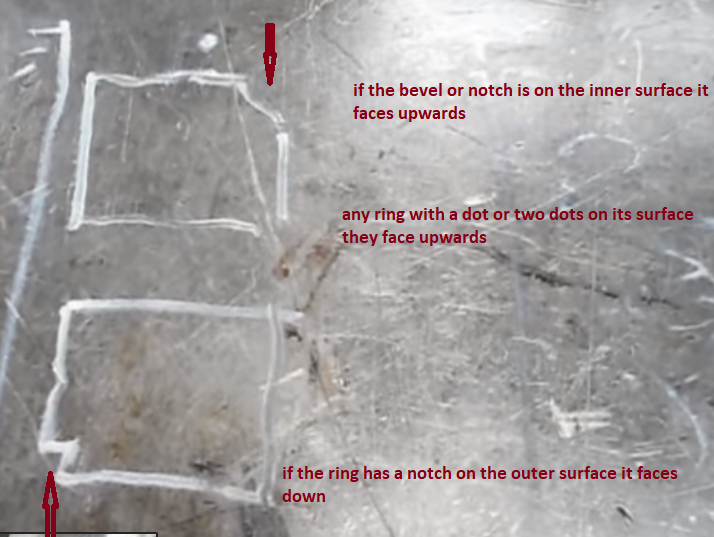

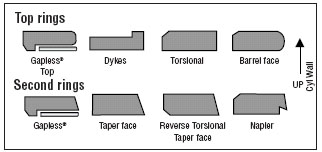

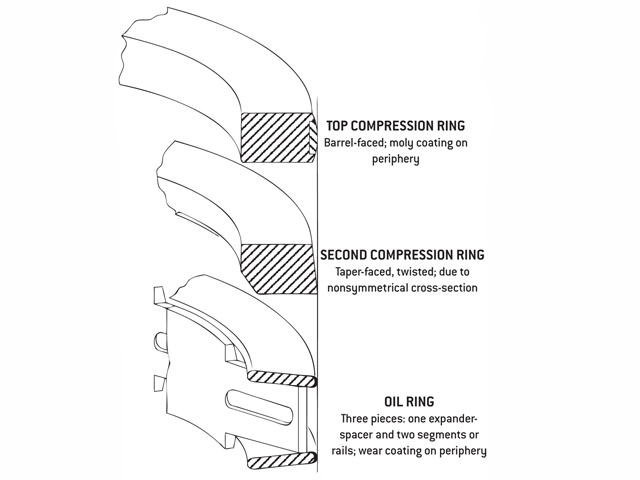

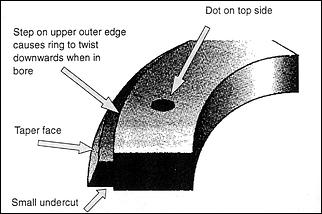

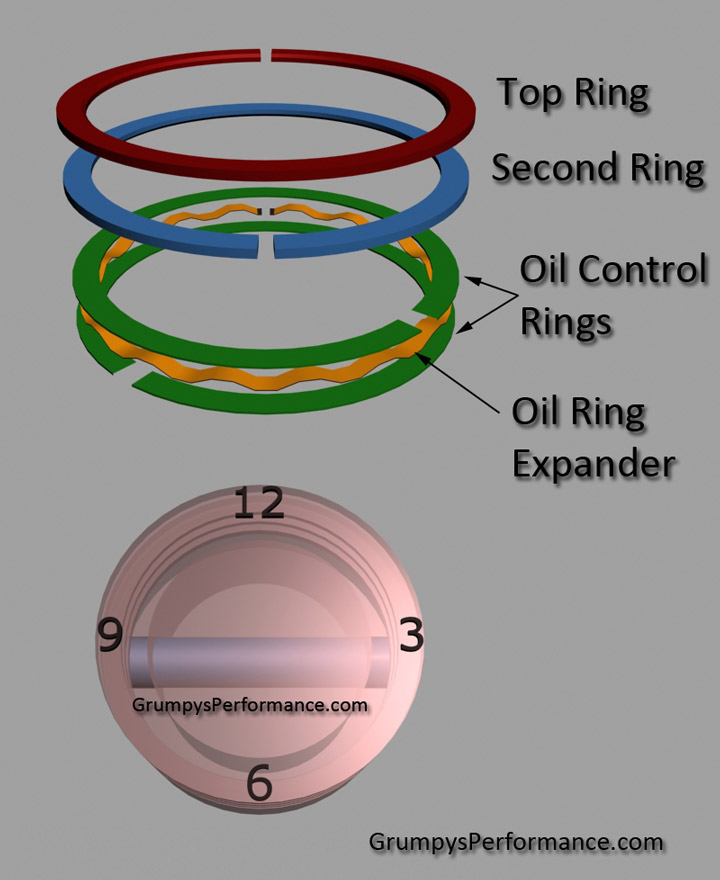

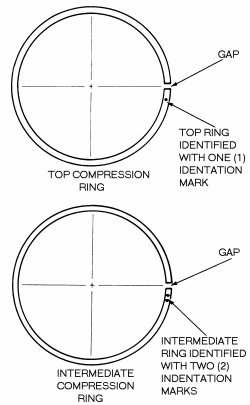

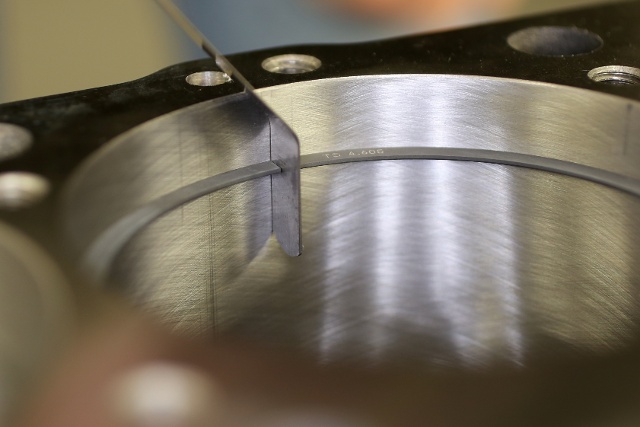

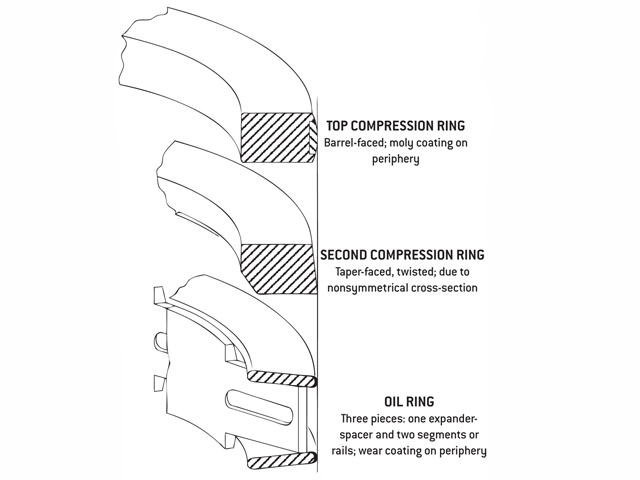

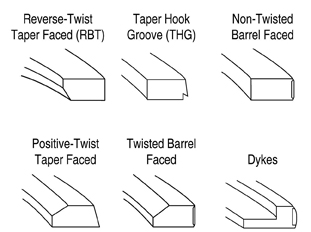

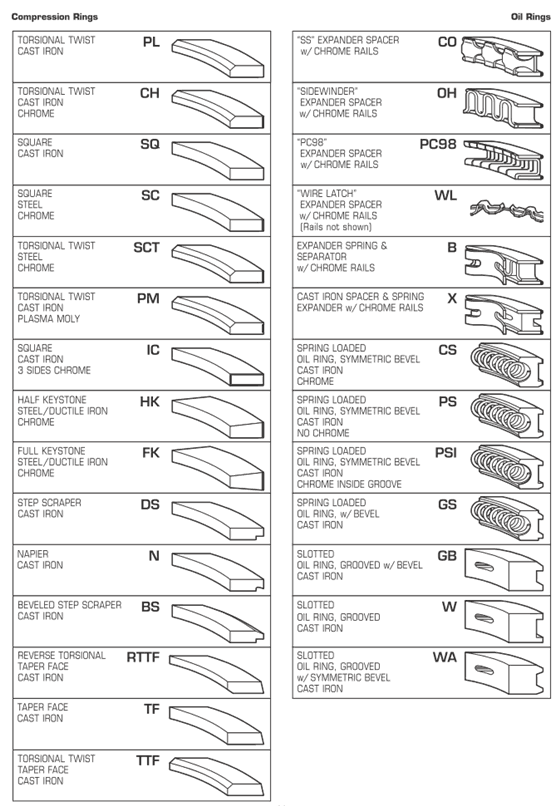

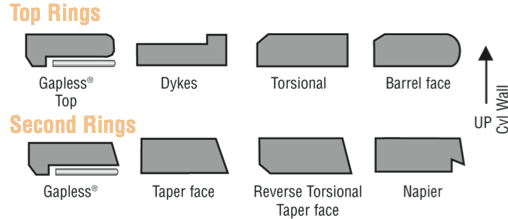

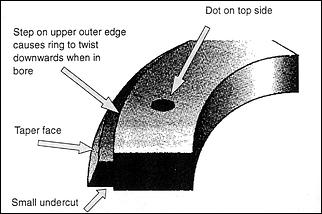

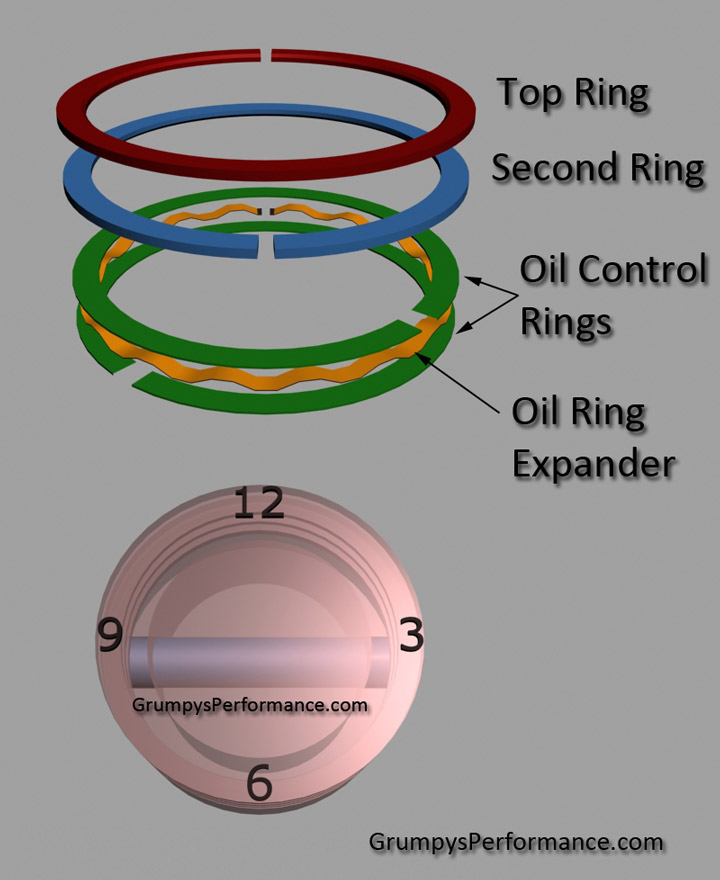

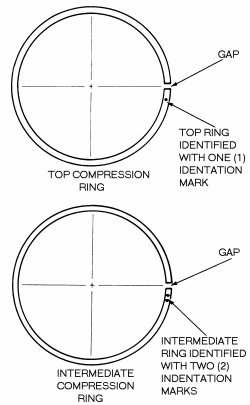

BTW, most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

http://www.tooltopia.com/fowler-72-646-300.aspx

https://www.youtube.com/watch?v=gjN0fGfUzl0&t=71s

https://www.youtube.com/watch?v=LcOHsZxuqAM&t=23s

yes as always theres cheap,functional, and theres expensive precision ring filers

http://www.abs-products.com/specialty-t ... nder.shtml

Indycars posted these GREAT PICTURES OF HIS RINGS UNDER MAGNIFICATION SHOWING THE MICRO CHIPS IN THE MOLY RING FACING

http://www.speedwaymotors.com/Precision ... ,2915.html

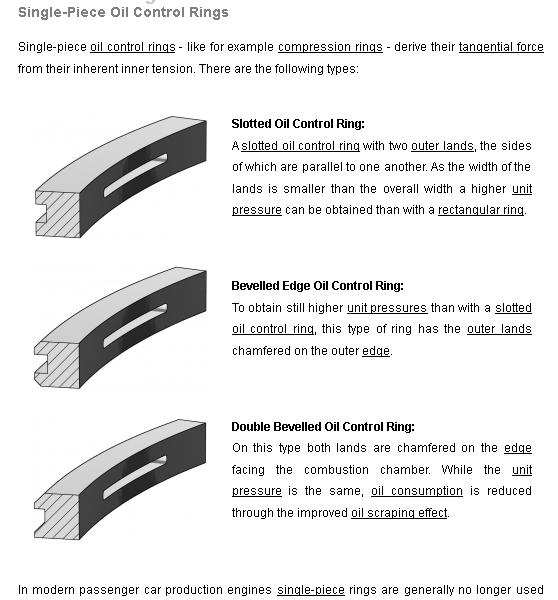

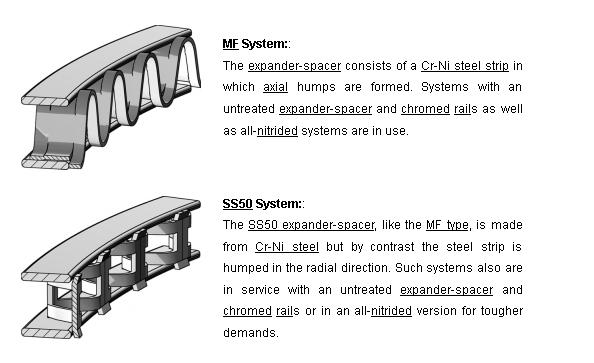

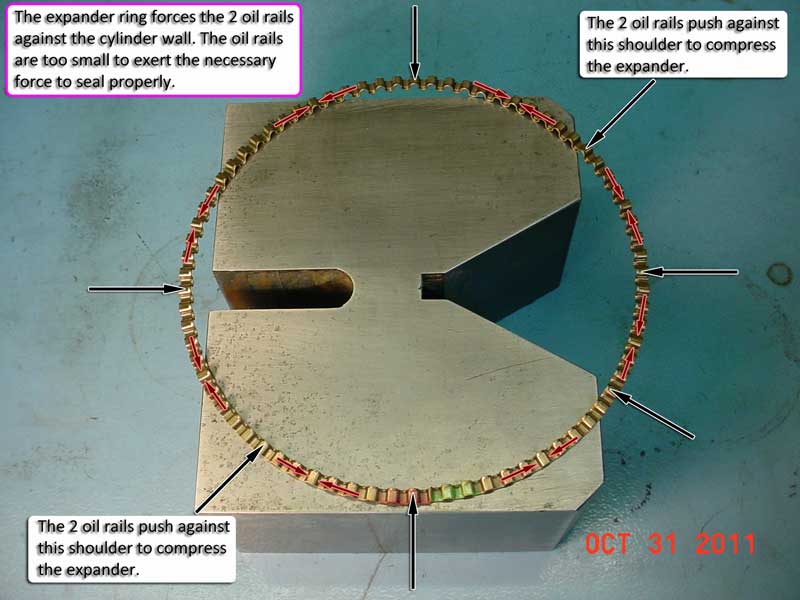

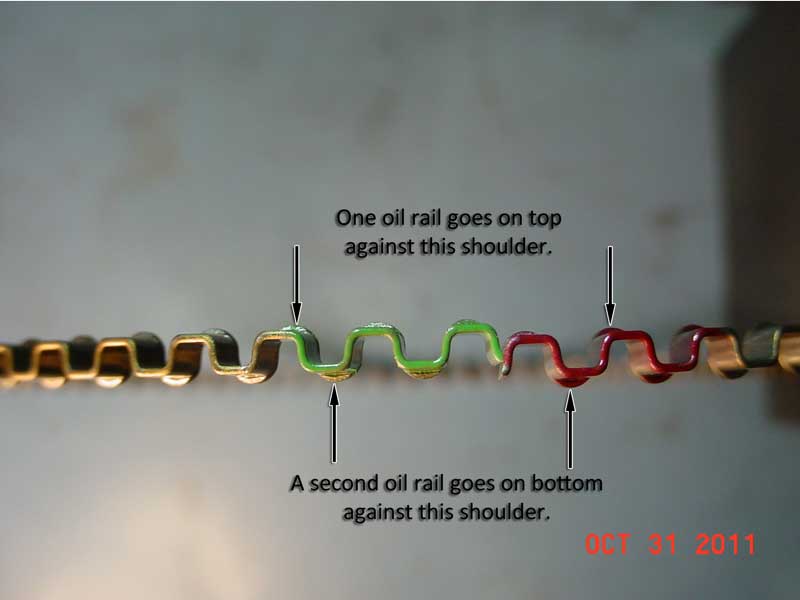

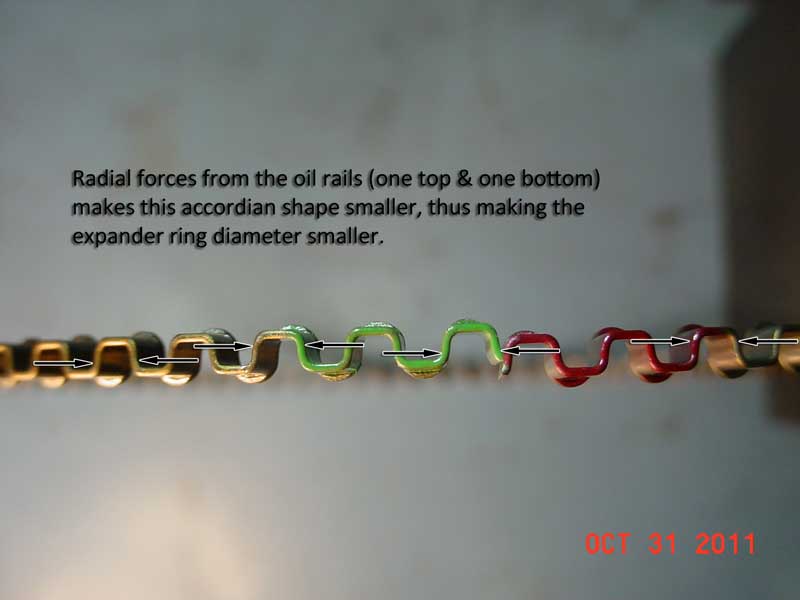

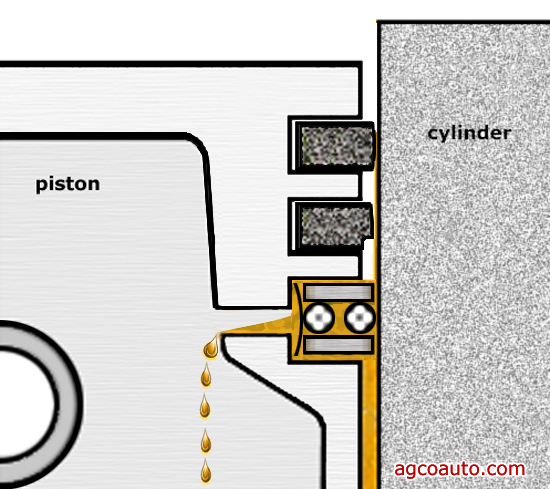

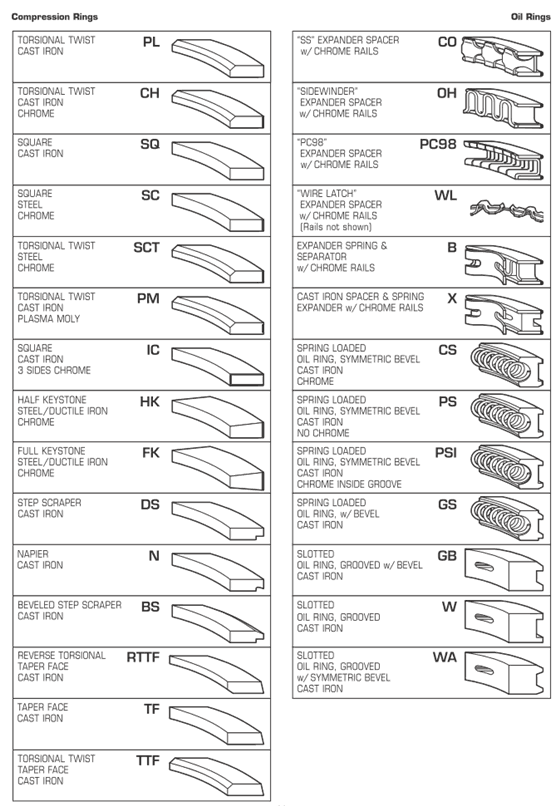

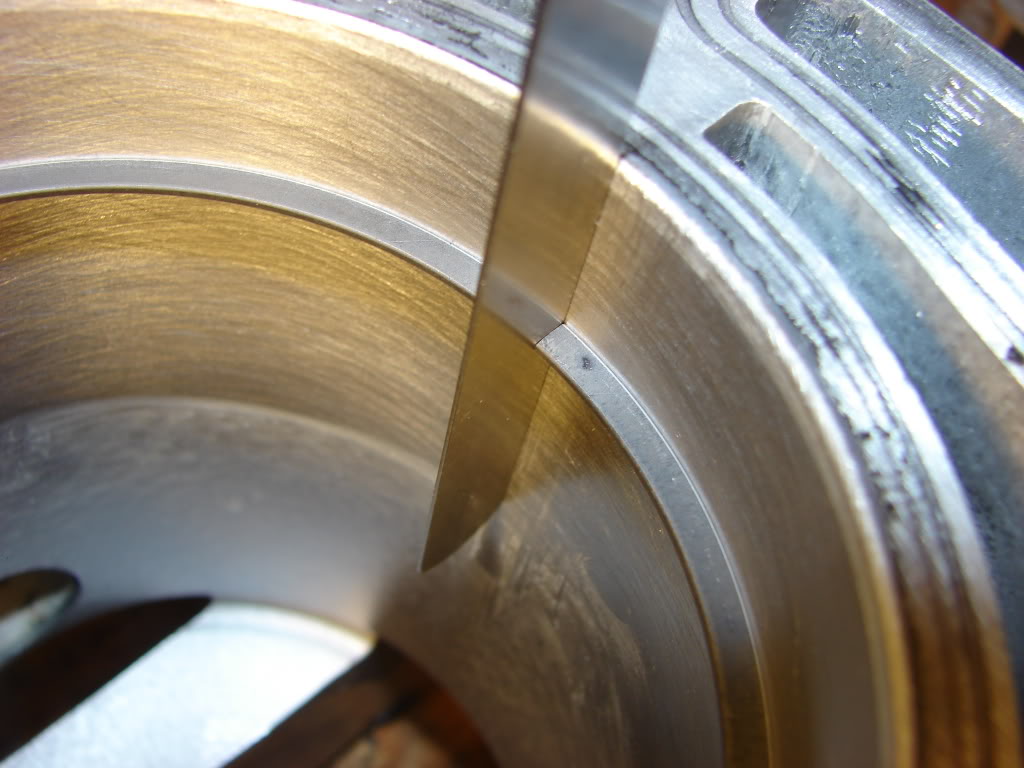

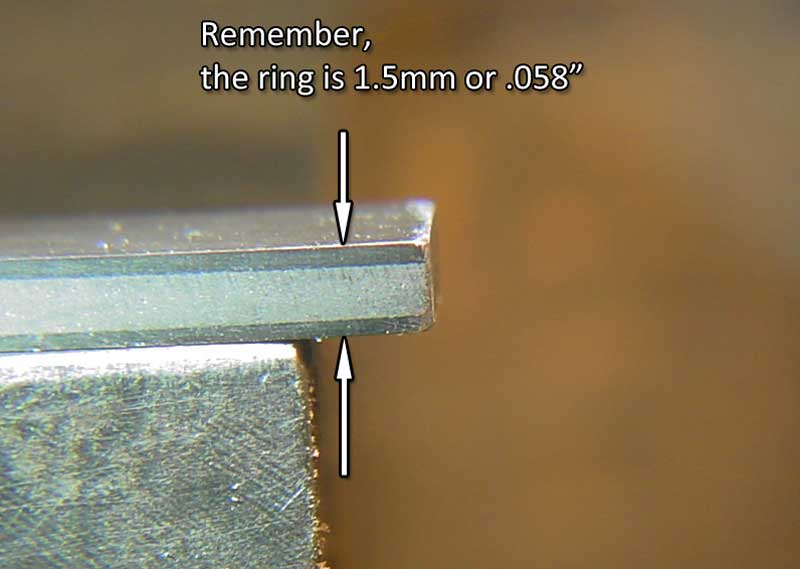

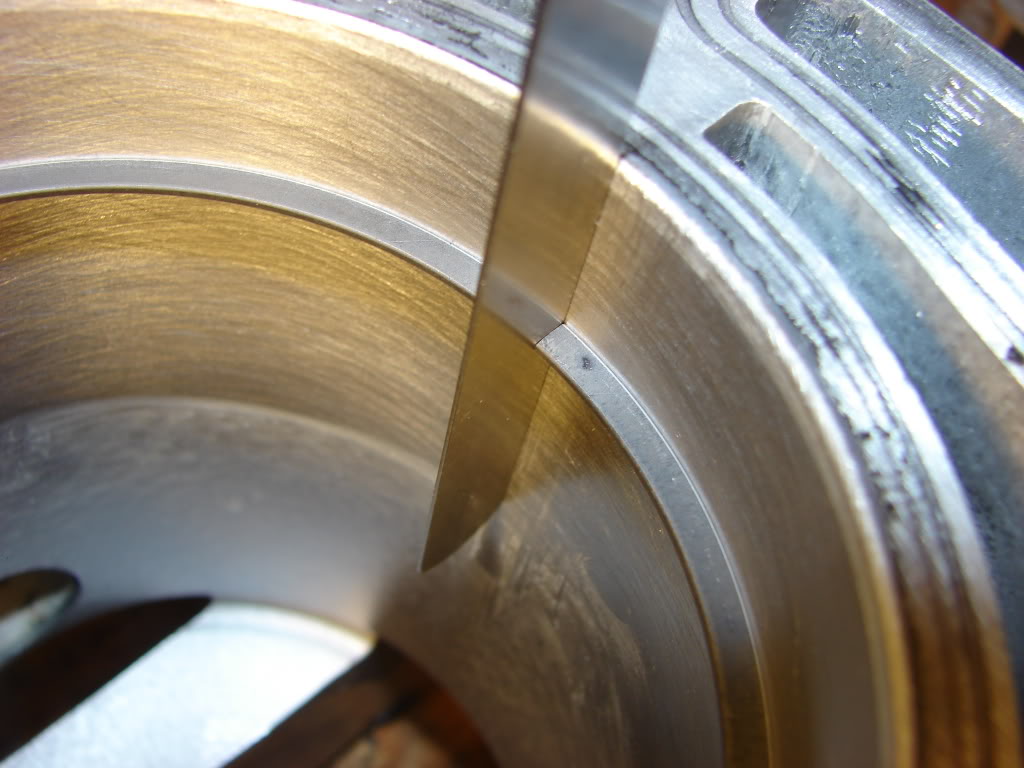

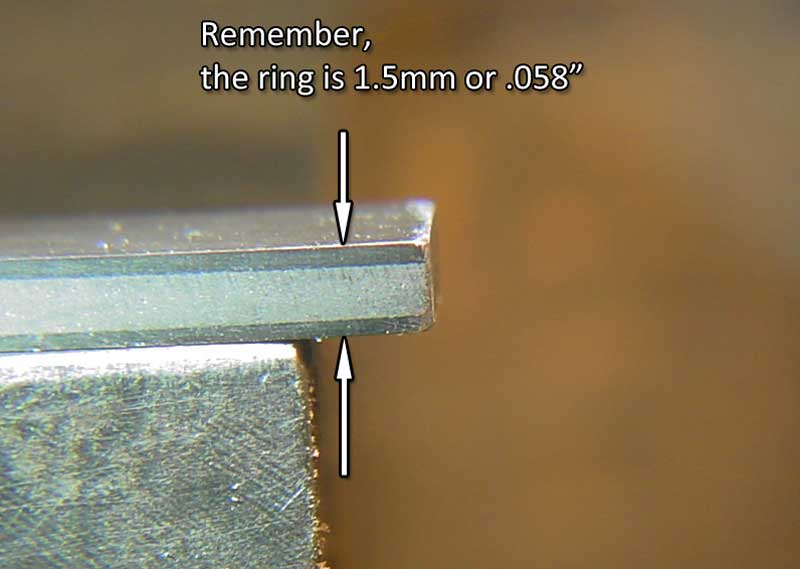

NOTICE the two totally different OIL ring scraper ring widths in this picture above,OIL RINGS come in dozens of designs so, you can not use all oil rings on all pistons and you can,t swap expanders and wipe rings thru different designs, and you must verify piston groove measurements , measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

http://www.summitracing.com/parts/SUM-906795/

http://www.muller.net/sonny/crx/rings/index.html

http://www.teglerizer.com/triumphstuff/75w_newrings.htm

http://www.summitracing.com/parts/PRO-66785/

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

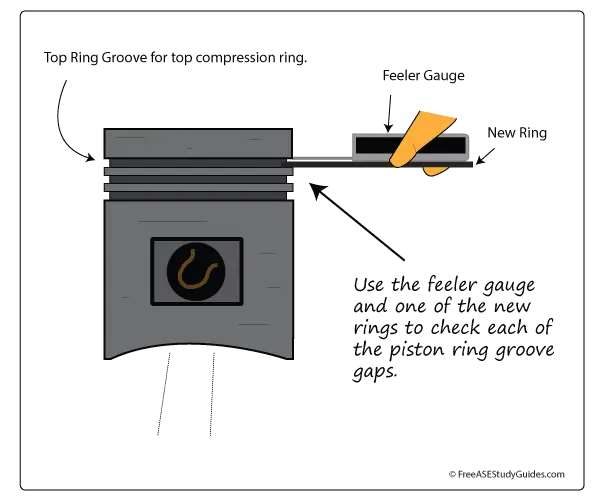

your going to need decent feeler gauges

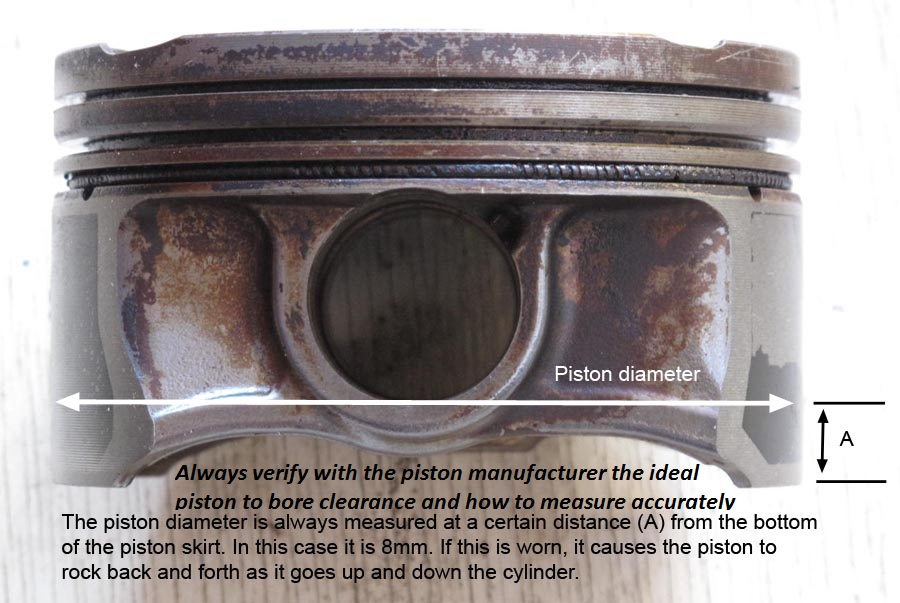

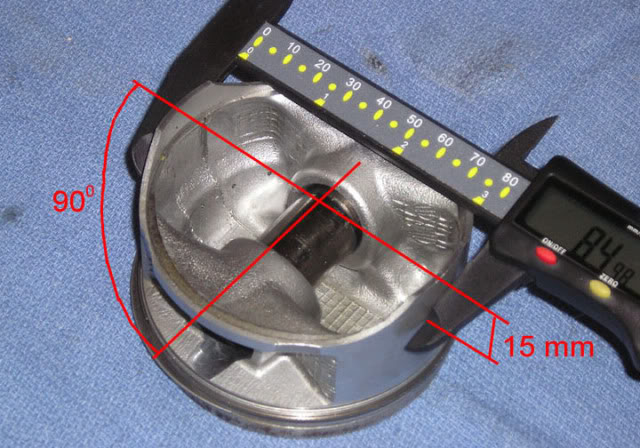

if the ring gaps, or piston to bore clearances are not carefully checked, or not correct your engine could easily get screwed up

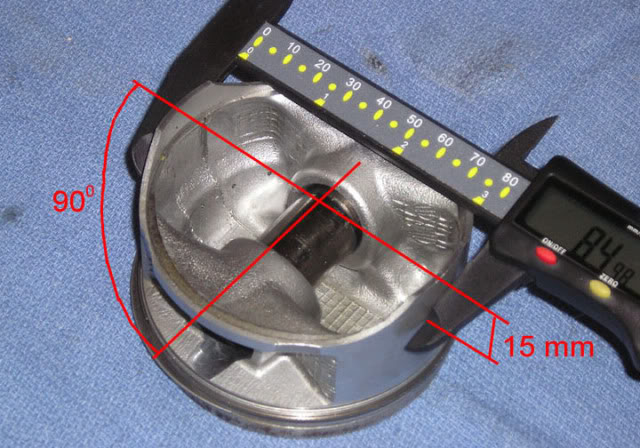

Due to machining tolerances on both pistons and bore sizes theres always some minor differences between components,

when your assembling any engine, youll file fit the ring gaps to individual cylinders,and youll,

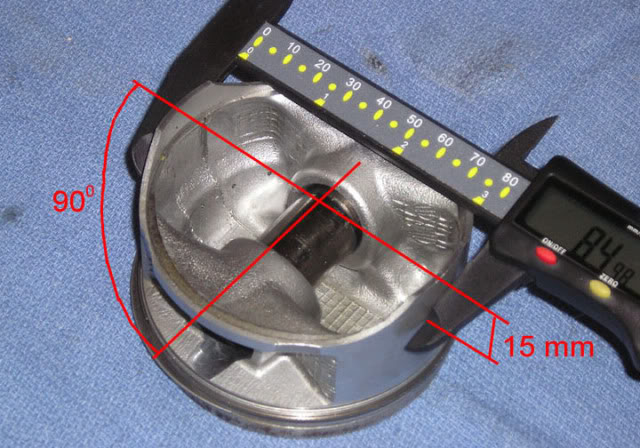

generally you'll want to carefully measure each individual piston diameter and each individual bore diameter very carefully,

and match the larger pistons to the larger bore sizes to keep the average side clearance as consistent as possible

most applications would have a ring gap of about .004-.005 per inch of bore diam.

but tests have shown even a .050 end gap has only a marginal effect on engine power or blow by, simply because at even 1000rpm theres slightly more than 8 power strokes per second, and the pressure is near max mostly in the 10 degrees before and 30 degrees after TDC, theres very little time to force much thru a .005 or less piston to bore clearance and two .050 end gaps even if that was the case

here is where you, or your machine shop can screw things up on ring to bore seal,Don’t get crazy trying to get the minimum end gap.

if you have a minimum possible end gap for the piston rings, they will not provide a significantly better seal than the correct or slightly larger end gap, do not push it to minimum spec. the saying goes like this: if the gap is too big nobody will know, but if it is too small everybody will know, be cause if the end gaps too small the ring ends touch, lock the piston in the bore, shear off the ring lands and destroy the engine, a but to large results in not much but a tiny bit more oil being used

Often filing rings is required, so be sure to clean the filed area with sandpaper to smooth the burr then wash with soap and water. Little horsepower is lost through the increased gap and what good is horsepower if your rings come together and break a piston or two

when you hone the bores,get and use block deck hone plates, during the hone process , keep in kind you want to use the same (STUDS OR BOLTS) the machine shop used and the same torque settings they used when the cylinders were honed with deck plates or the distortion of the bore and ring seal won,t be identical (exactly round)or ideal , ring tension helps seal the bore on the intake stroke but on the power stroke cylinder pressure forces the rings hard against the lower ring land surface, the space above and behind the ring is nearly instantly filled with hundreds of psi of cylinder pressure forcing the ring out against the bore wall.

think about this a second,before spending your cash on gap less rings.that can cost 3 times what standard gap piston rings do,

With the engine temps up to operational levels the ring end gap is generally in the .007-.005 range and actual piston to bore side clearance is in the .001-.002 range, that's not counting a film of oil covering and filling much of that remaining clearance,and piston temps that can easily exceed 400f , now consider that at even just 3000rpm, theres 25 compression strokes per second, which are taking up 1/4 of that rotational time frame, so in effect, to get gas leakage past the rings you have to forced the compressed gases past two piston ring end gaps (FIRST AND SECOND COMPRESSION RINGS) located in a randomly staggered location, thru a pair of ring end gaps that are about .002 x.006, in less than 4% of a seconds time.

when they do those impressive leak down tests the piston and rings are stationary, not reciprocating at and changing between high cylinder pressure and several dozen inches of exhaust scavenging vacuum,25-60 times PER SECOND, like rings in a running engine, nor is the engine operating at anything close to operational temps and pressures

while theres zero doubt that the gap less rings in theory will seal a bit better,if properly installed, the real world advantages, are minimal during true operational conditions, because you can,t force much compressed gas forcing its way past the piston ,down thru a hole on a set of staggered ring gaps, over that very brief time frame, thru what is effectively the size of a hole in a needles eye.

watch this and read thru the linked info, posted below, there's only a few ways to screw up an engine rebuild faster than NOT having the rings installed correctly or gaped to match the application, and heat range.

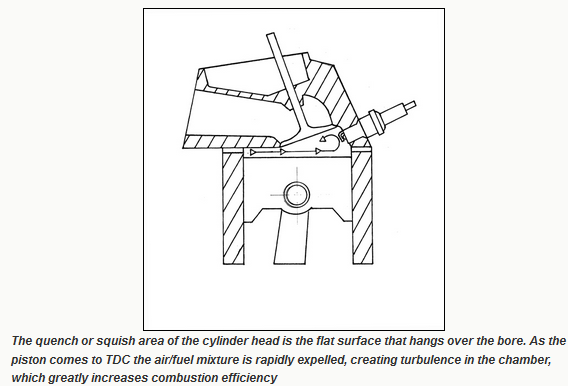

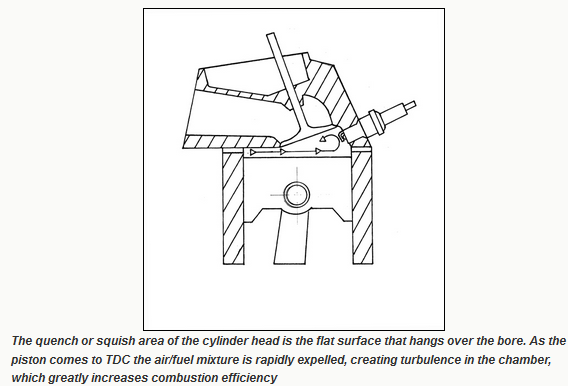

run the ring gap too tight, and the ring ends touch and the ring can lock against the bore, frequently busting ring lands or pulling the top of the piston ring land clear off, resulting in,having chunks of busted piston ring land compressed into the quench area, or results in bent connecting rods and cracked cylinder heads, bent valves etc.

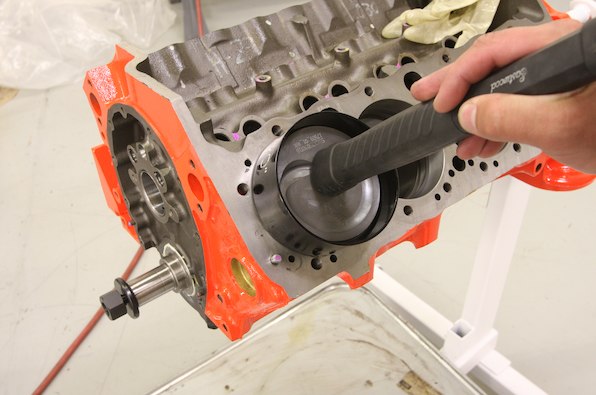

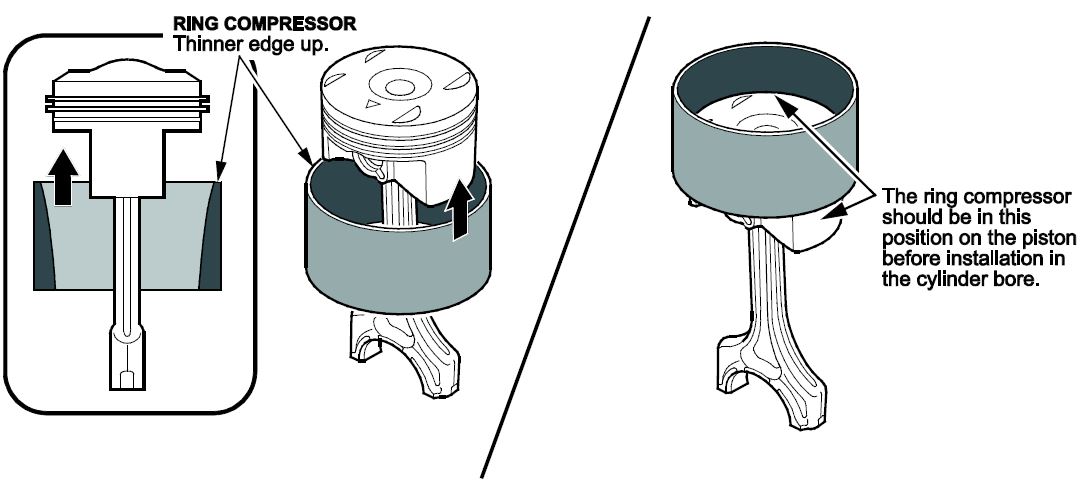

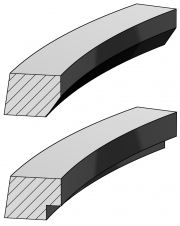

BTW when you go to buy a ring compressor....this type(ABOVE & BELOW) works far better than the others, but its specific to a very limited range in bore size applications

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

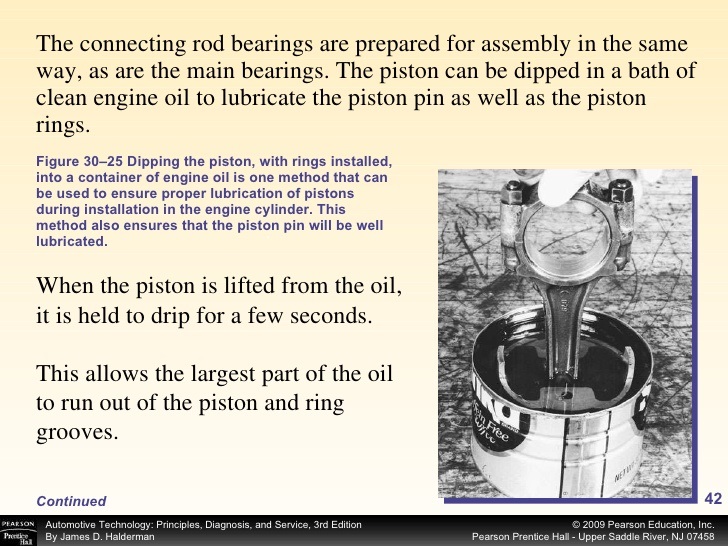

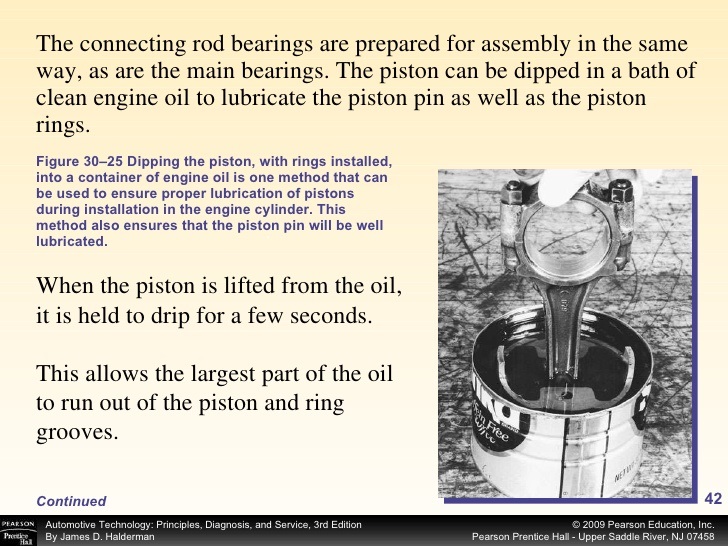

remember to dip the piston and rings in high quality oil just prior too or before assembly I,ve used MARVEL MYSTERY OIL FOR DECADES

https://www.summitracing.com/parts/sme-90a4000

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

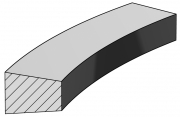

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

this style ring compressor below has a nasty habit of not keeping the rings evenly compressed and not seating evenly on the block , Ive used them but the type above is much easier to use

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66785&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SME-906000W&N=700+115&autoview=sku

http://www.sswesco.com/ss/sssugges.htm

viewtopic.php?f=53&t=5454

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

http://www.babcox.com/editorial/us/us20114.htm

https://www.engineprofessional.com/EPQ2-2020/mobile/index.html#p=17

http://www.circletrack.com/enginetech/c ... index.html

http://www.kb-silvolite.com/article.php ... ad&A_id=56

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

http://www.stockcarracing.com/techartic ... index.html

http://www.riken.co.jp/e/piston/b/b_1.html

http://www.carcraft.com/techarticles/pi ... index.html

http://www.aa1car.com/library/ar293.htm

http://www.gmhightechperformance.com/te ... ation.html

http://www.aa1car.com/library/2005/eb010550.htm

http://www.jepistons.com/dept/tech/dl/p ... rc4032.pdf

http://www.aa1car.com/library/ring_end_gap.htm

http://www.aa1car.com/library/ring_end_gap.htm

http://www.circletrack.com/howto/1818/index.html

http://www.chevyhiperformance.com/howto/0706ch_file_fitting_pistons/index.html

http://www.popularhotrodding.com/en...em_building_the_short_block/piston_rings.html

http://kb-silvolite.com/article.php?action=read&A_id=56

http://www.sswesco.com/ss/sspow.htm

http://www.racetep.com/totalsealframe.html

http://www.cdxetextbook.com/engines/com ... rings.html

http://www.dragracingaction.com/index.p ... press=3504

http://www.federalmogul.com/korihandboo ... ion_18.htm

http://kb-silvolite.com/article.php?action=read&A_id=32

http://moodle.student.cnwl.ac.uk/moodle ... rings.html

you have the option of ordering slightly over sized rings and carefully file fitting the end gaps,

no mater what size rings or end gap , you use the rings will normally take 5-20 minutes or so to lap into and perfectly seat and fit the bore walls

obviously the closer they match the application on start-up the more rapidly you could expect that to happen.

remember a properly honed bore using deck plated helps the process a great deal.

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-81042

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.co...on-ring-info-youll-need.509/page-2#post-71538

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-12416

http://garage.grumpysperformance.co...plate-honing-makes-a-differance.588/#post-869

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-10316

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

http://www.amazon.com/KD-Tools-850-Diam ... 0002STSMG/

this type (ABOVE) handles many applications but the cheap versions are a P.I.T.A. to work with

BTW when you go to buy a ring compressor....this type(ABOVE & BELOW) which is an adjustable diameter and tapered design, works far better than the others,

but its specific to a very limited range in bore size applications

so youll need to buy the correct matching size

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

you'll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor.

IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections.

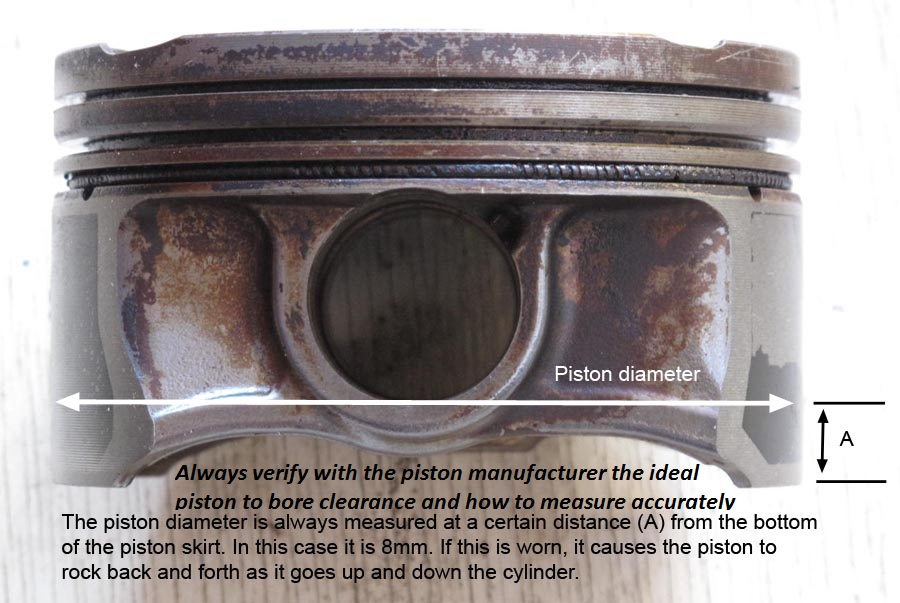

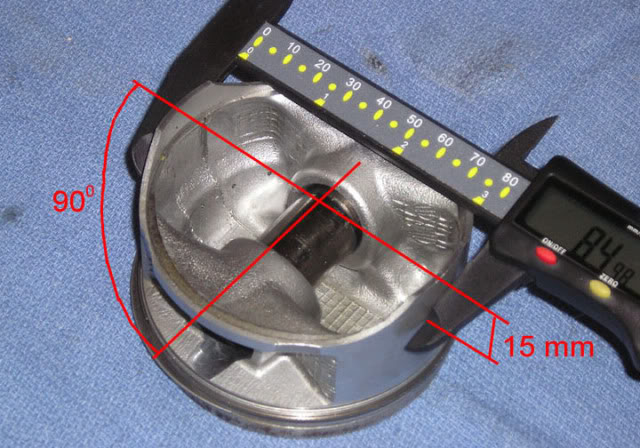

be sure you, measure EACH bore and EACH piston,

(CORRECTLY with the proper tools in the way the tool and piston manufacturers suggested)

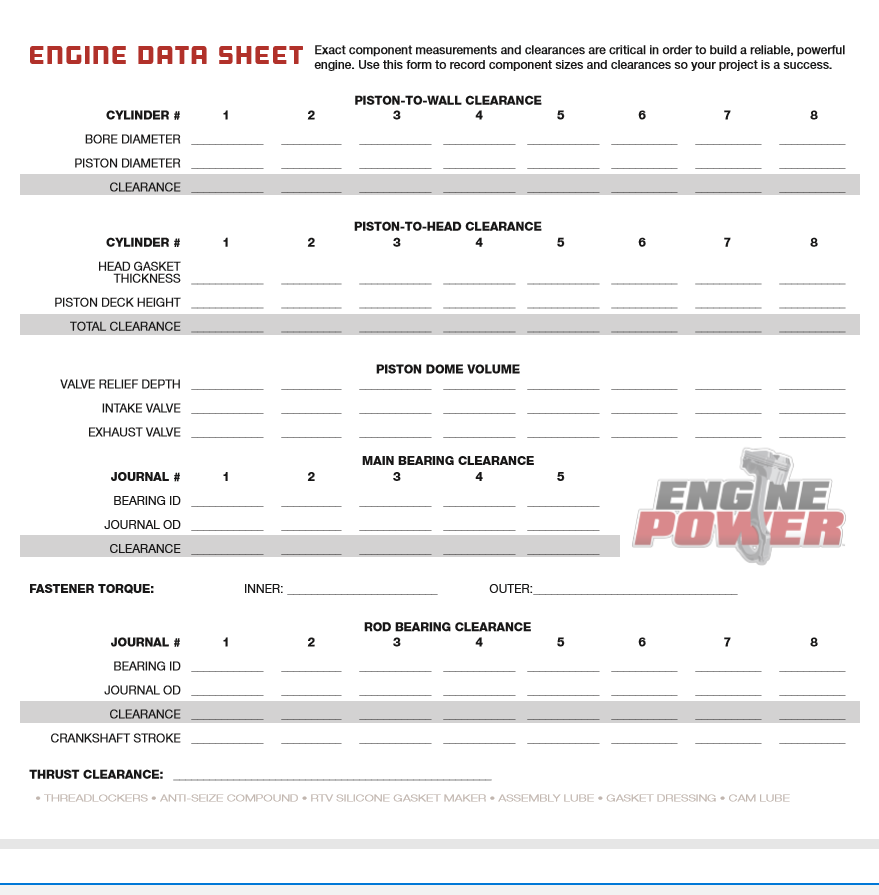

and number them on an engine build sheet indicating the bore and piston diam.

from large to smallest on each and install them on each cylinder to get the most consistent piston to bore clearance's

yes the difference may only be a few ten thousands if the bores are machined correctly, but you'll get the best results , most consistent lubrication, best durability and less heat build up that might result in detonation issues that way. its the little things that add up to making a good durable engine assembly,

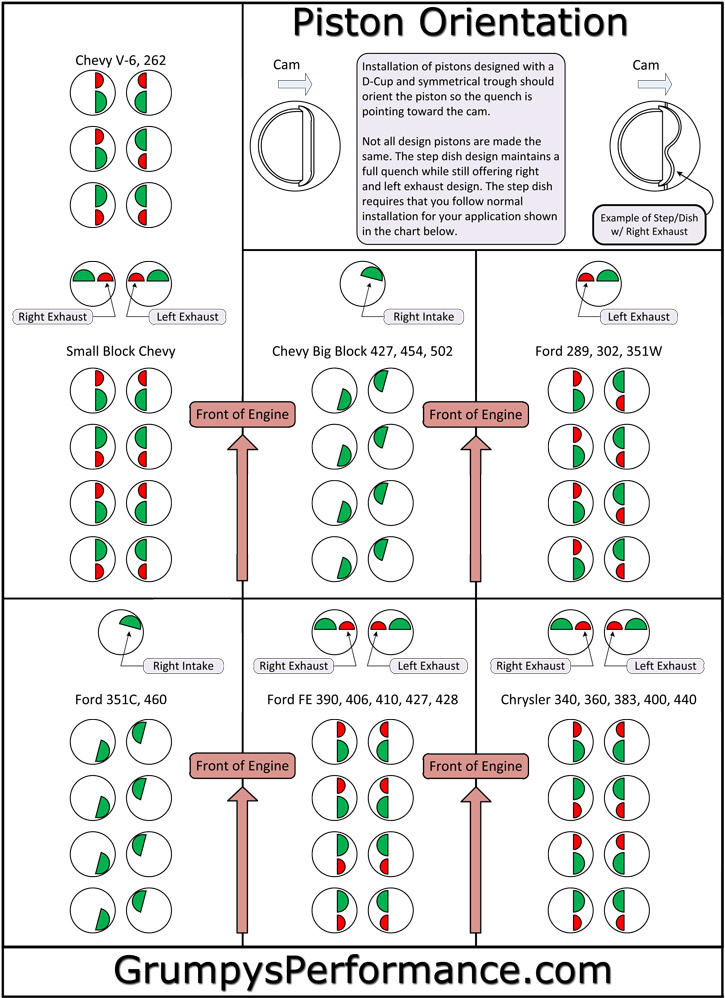

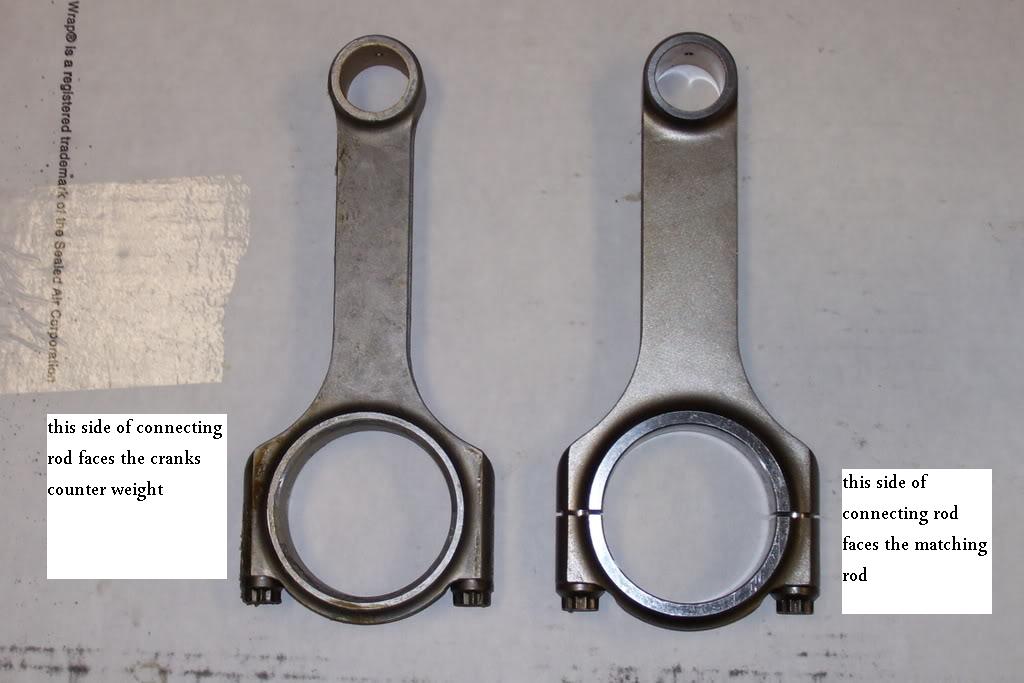

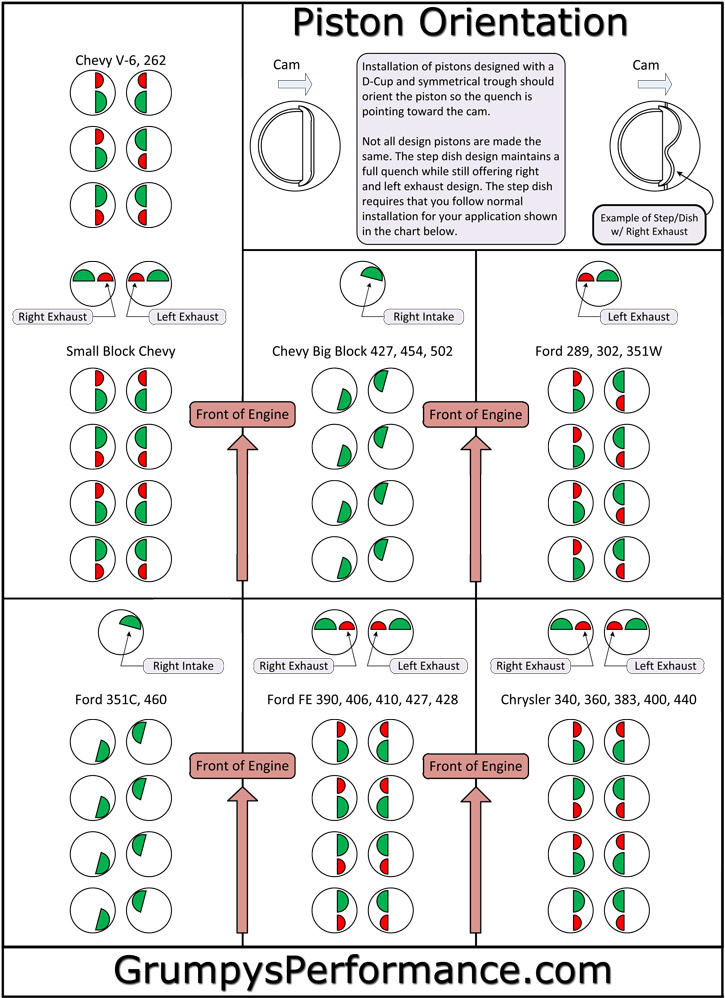

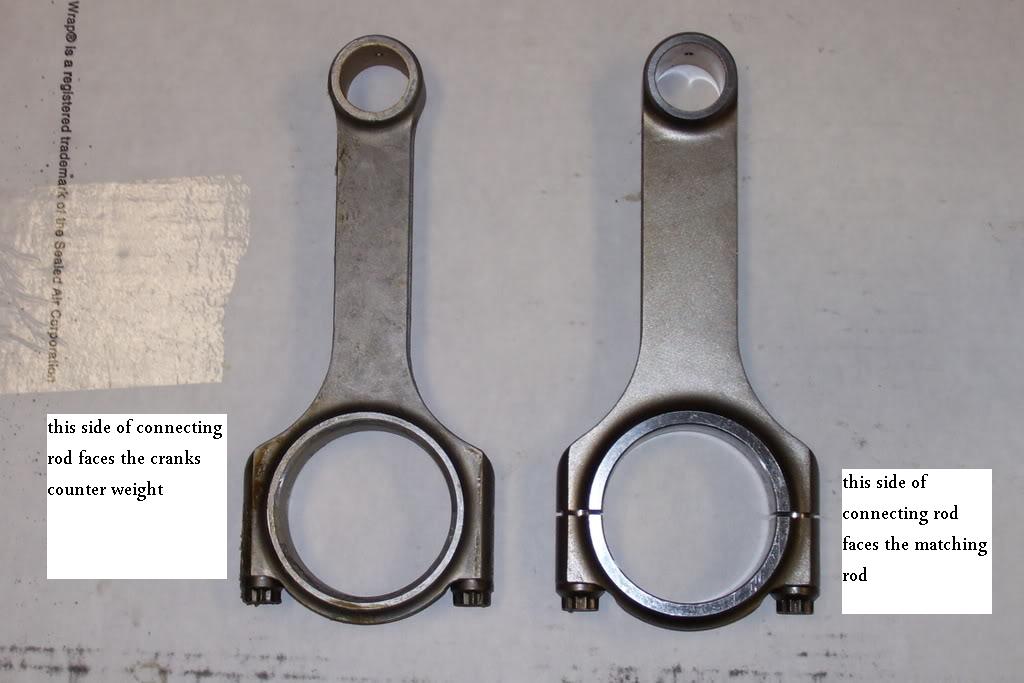

BTW check rod orientation, so the beveled sides don't fact the adjacent rods, and check the bearing clearances with plasti guage

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

garage.grumpysperformance.com

KEEP IN MIND

any ring compressor design you use regardless ,of the design MUST have its lower surface kept firmly in contact with the block surface and parallel to the bore to allow the rings to smoothly transition from the inner surface of the compressor to the blocks bore, and IDEALLY the compressor internal diameter will be marginally smaller in internal diameter that the cylinder bore the pistons sliding into from it!

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor, btw IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections

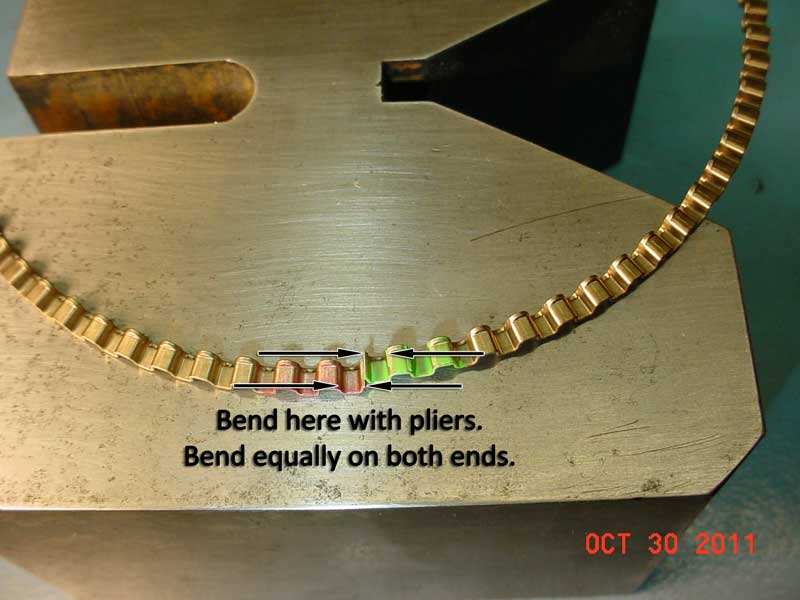

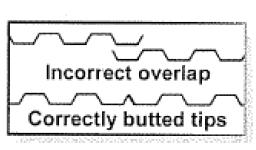

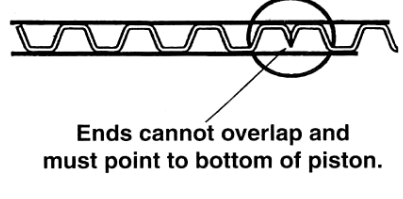

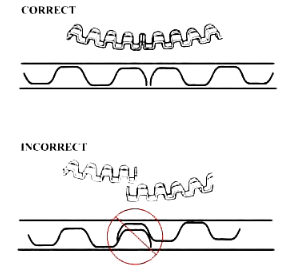

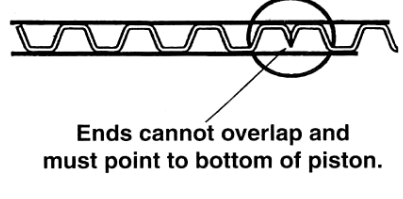

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

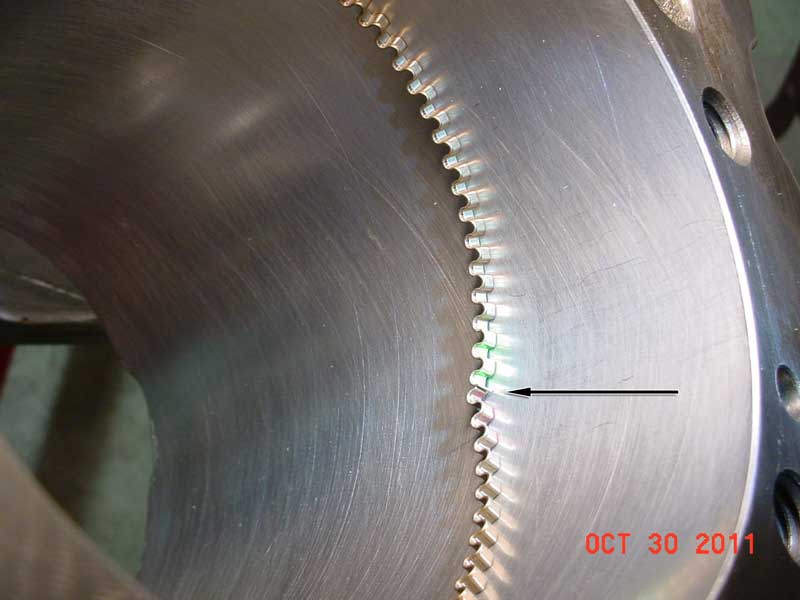

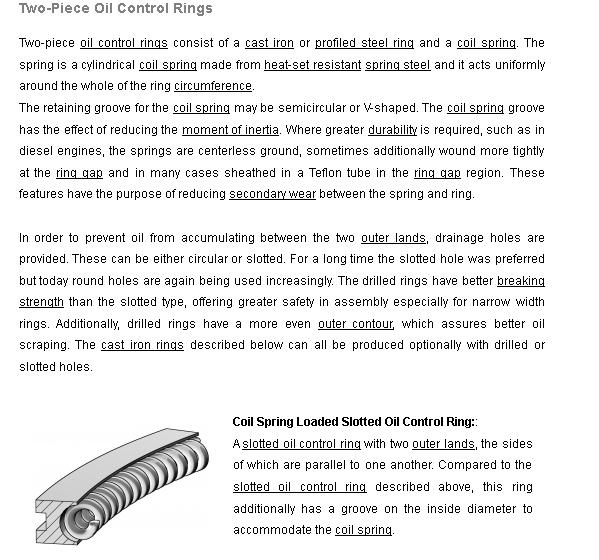

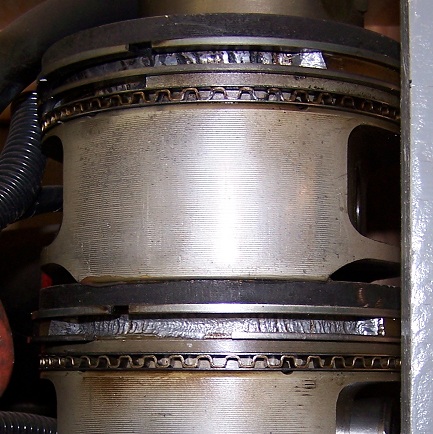

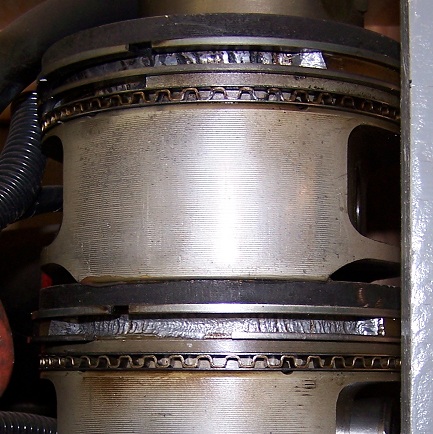

btw heres typical detonation damage, and in this case, resulting from a bit of nitrous, that boosted the pressure, but the results would be similar on a high compression engine subjected to crappy fuel and high loads at high rpms without nitrous, notice the sugary/frosted appearance and rounded edges of the melted areas

damage to the ring lands can be caused by detonation or just the ring gaps set too tightly, if the piston shows no frosted appearance its usually the ring gaps too small, or excessive heat, to lean a mix, to much ignition advance,etc.

most applications would have a ring gap of about .004-.005 per inch of bore diam.

but tests have shown even a .050 end gap has only a marginal effect on engine power or blow by, simply because at even 1000rpm theres slightly more than 8 power strokes per second, and the pressure is near max mostly in the 10 degrees before and 30 degrees after TDC, theres very little time to force much thru a .005 or less piston to bore clearance and two .050 end gaps even if that was the case

damage like this is rather frequently the result of the piston rings gap being too tight, the rings ends touch as they expand,

due to excessive heat and with no clearance the rings temporarily lock against the bore wall, the result is a broken ring, and fractured piston ring groove

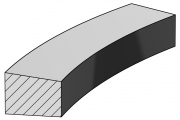

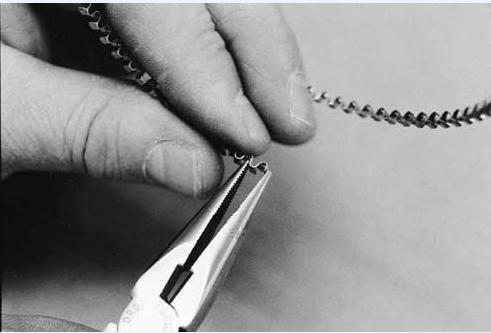

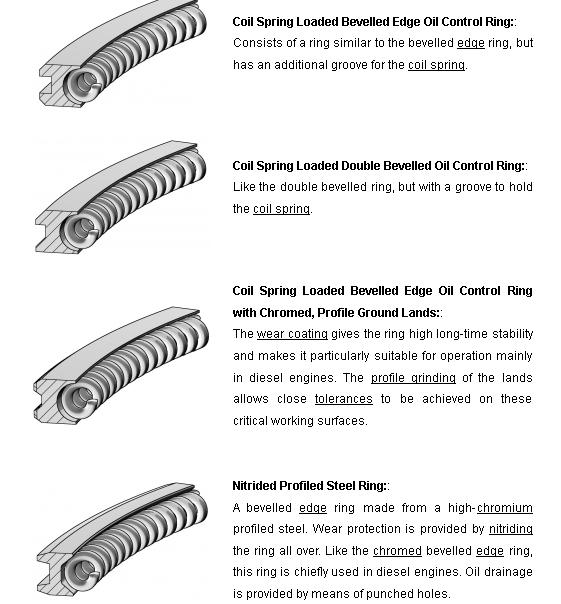

obviously if you've been around engine rebuilds, long enough, your aware that you'll eventually see guys installing rings in piston grooves by spiral twisting them into place, like the picture below depicts

the 80MM-120MM tool fits almost all chevy V8 engines

the problem, with that method is that its not at all difficult to leave the piston ring twisted permanently,

or warping it to the point it either breaks ,

or its bent ,degrading its ability to seal against the bore wall.

yeah! I know all your buddies do it that way! its still a potential problem and has and will continue to cause problems

so its a good idea to carefully use a expander tool, but only expand the ring enough to install it.

http://www.summitracing.com/parts/shc-94662

don,t get over whelmed, make a list and test adjust correct or replace each problem,

and check it off the list then move to the next issue,

its a finite list and theres not a damn thing on it you can,t accomplish,

with a bit of research, a few questions and this web-sites help

(a few tools the right attitude and a thick stack of cash would also be useful of course)

think carefully about both the initial cost and the structural strength of the engine block you select, the OEM blocks used in production car engines will RARELY accept a .030 plus over bore with out having one or more cylinders having marginally thin bore walls, this results in inadequate bore to ring sealing if its in the wrong area and promotes stress cracks. A .060 over bore in a SBC is rather commonly pushing that bore wall thickness up to or over a reasonable limit so you need to sonic and magnetically check the block for cracks and wall thickness.

you could easily dump $500-$1500 into machine work on a block that won,t last more than a few months under high stress if its not carefully checked PRIOR to the machine work being done.

diagnosing a busted 632 BBC

there's a whole lot of info on the 632 CID BBC they go over, if you don't watch and listen carefully you'll miss important details the engine, disassembly can tell you a great deal, and look carefully at the components, listen carefully, and they point out a great many parts, strong points and...

garage.grumpysperformance.com

yes it always helps too double check bearing clearances and take the time too verify oil passages are clean,

and bearing oil feed holes properly line up with the oil feed passages and verify,

those clearances, and not just simply assume, they are correct

, and assemble and re-verify those clearances.

resistance to rotation, of crank durring short blk assembly

Ok youve just installed your crankshaft in the engine block, with new main bearings and everything's well coated with assembly lube,and oil, and youve torqued down the main caps to spec. in at least three stages, and then gone back and rechecked the studs or bolts per the manufacturers...

garage.grumpysperformance.com

Theory into Practice

Now that we’ve covered the “why” of piston ring gapping, it’s time to put that knowledge to work. We asked DiBlasi for the main issues people run into, and he gave us some very practical advice, saying, “There are several mistakes people make when setting ring end gaps. I myself have done it in the past, so it happens to everyone. I will also address ring install problems in general…”

- Mistake #1 - Not setting ring gaps at all.“Some people think that the rings are pre-gapped and ready to drop in. Ring manufacturers have a pretty larger tolerance when it comes to the gaps right out of the box. Always place each ring in the cylinder you are going to set it for and measure. Keep that ring designated for the cylinder the entire time. Sometimes your cylinders are a few .0001in’s different from each other, so you will want to be consistent. I personally get zip lock bags and number each bag with a cylinder number. Those ring stay in those bags with the correct cylinder they belong in until I am ready to gap them, then go back into the bag until I am ready to install them one by one.”

- Mistake #2 - Not reading the suggested ring end gaps provided by the piston manufacturer.“Many ring suppliers only provide data on OEM ring gaps. Follow the ring gap instructions for the pistons you are using. Never use OEM ring end gap specs, as the material and applications are wildly different. We often get calls about people setting ring gaps to OEM specs which can be as little as 1/3 the amount of ring gap that’s actually required.”

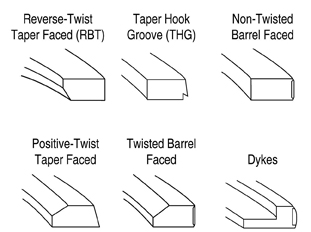

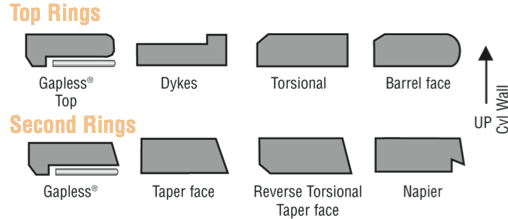

- Mistake #3 - Putting rings in upside down or in the wrong location.“99% of every top and second ring set has a specific orientation. There are bevels, twist, coatings, and various other things that make rings directional. There is typically writing or a dot on all first and second rings that indicate which side is up. In terms of location, some pistons have the same thickness top and second rings. Pay attention to the shape and what each ring does so you know where it goes.”

- Mistake #4 - Gapping gaffes.DiBlasi breaks this down even farther, saying, “This is going to be a boring process with a lot of filing, counting, placing in the bore, measuring, and repeating.” It’s easy to get lazy or careless, but working cautiously and paying attention during this process is critical.

- Filing rings before initially measuring end gaps.“Some people assume the rings are already too small and start filing away without a baseline measurement. Always measure first.”

- Count your turns if using a manual ring filer.“This will help you understand how much material removed each turn on the filer equates to.”

- Not being aware of the material of the ring you are filing.“A steel ring is going to need significantly more turns on a ring filer to remove material than a cast ring. A steel ring might require 30 turns on the filer to yield .005in of gap increase, where a cast ring requires 10 turns. I made this mistake 10 years ago and filed an extra .020 from a cast ring and had to buy another ring…”

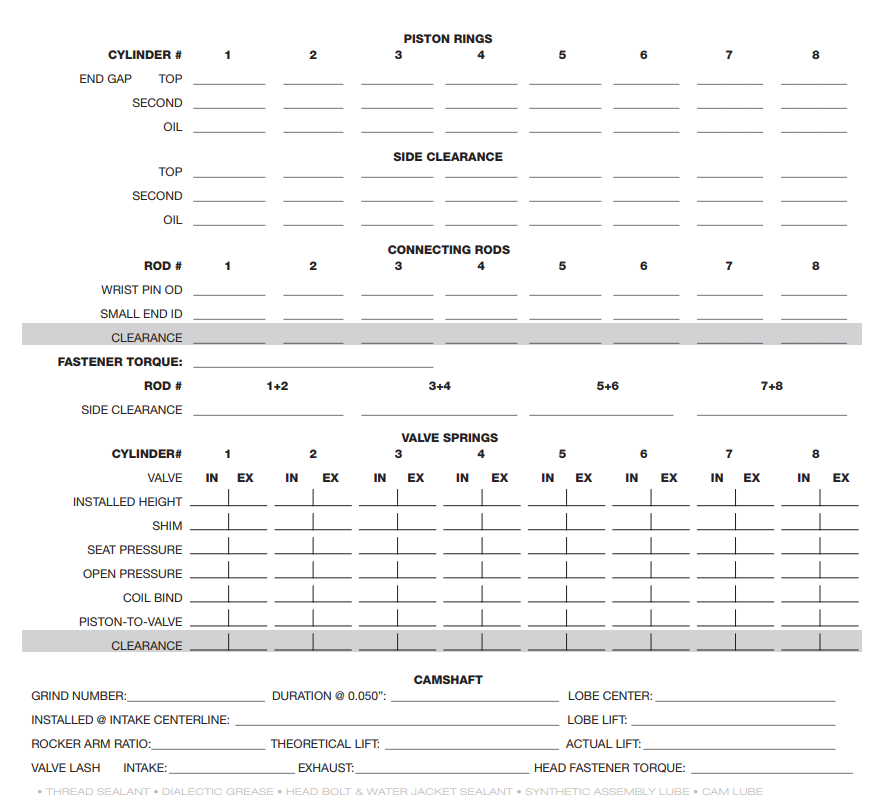

- Not squaring your end gaps off.“Make sure your ring end gaps are square and perpendicular to the cylinder wall surface. You do not want a taper, as the measurement of the end gap will not be correct.”

- Not taking your time.“This process is boring and requires back and forth measuring so you can be precise. Take your time and start filing little at a time. Once you are a few cylinders in, you will have an idea of how much each ring requires as far as turns.”

every part you choose is a compromise , and may require changes,

that cost you in time, money or performance to some degree,

and almost every part will require a bit of fitting or clearance work,

or adjustment to fit and function to get the best results

if it drops out of the package and bolts together as it drops out of the package,

its almost certain its not functional to nearly its full potential

your job is to think things through carefully and make sure parts fit and function to their full potential,

little things like checking piston ring end gap, verifying bearing clearances, and ccing the heads and checking piston to valve clearance, degreeing in the cam and verifying the valve train geometry, polishing combustion chambers, getting a decent 3 angle valve job,verifying the piston to bore clearance, MATTER's

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256

http://blog.wiseco.com/everything-you-need-to-know-about-ring-gap

http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68205

http://blog.wiseco.com/engine-building-practices-you-need-to-know

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-64733

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/

http://blog.wiseco.com/how-to-file-fit-and-install-piston-rings

https://www.carshopinc.com/product_info.php/products_id/49347/SPG1-12

read the links don,t skip them, youll likely save a great deal of cash and time knowing whats involved

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.com/index.php?threads/engine-block-cylinder-wall-thickness.976/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-383-vs-a-350.715/

http://garage.grumpysperformance.com/index.php?threads/blocks-from-summitt-or-comp-products.10174/

http://garage.grumpysperformance.co...s-why-doesn-t-anyone-ever-ask-or-check.11532/

viewtopic.php?f=53&t=247

viewtopic.php?f=51&t=588&hilit=honing%E2%80%A6

http://www.bhjproducts.com/bhj_content/ ... pplist.php

viewtopic.php?f=53&t=1797

http://www.hastingsmfg.com/ServiceTips/ ... ishing.htm

http://www.enginebuildermag.com/Item/38 ... rings.aspx

viewtopic.php?f=69&t=3814&start=240

GET THE RING END GAP TOO TIGHT ,OR PISTON SIDE CLEARANCE TOO TIGHT,OR NOT PAY ATTENTION TO THE LUBE SYSTEM DETAILS,AND WHEN THE RINGS EXPAND WITH ENGINE HEAT THE ENDS TOUCH THE RINGS LOCK IN THE BORE AND THE PISTON LANDS SHEAR OFF, it RESULTS IN EXPENSIVE FAILURES GET THE GAP A BIT TOO LARGE AND YOU MIGHT BURN A BIT MORE OIL OR LOOSE SOME COMPRESSION, YOU'LL SEE A CHART LATER IN THE THREAD, BUT GENERALLY YOU'LL WANT .0045-.0065 PER INCH OF BORE DIAM. FOR A RING END GAP

The truth here is that if the ring end gap is anywhere in the .016-.030 the rings will work out fine,

the piston ring manufacturer's know from testing that compression and oil control,

emissions and all other test results tend to show ring gaps under about .040,

have nearly zero effect on how the engine runs, how much oil it uses or its ability to pass emissions,

that .016 is the IDEAL end gap on a daily driver engine , remember as the pistons heat up the rings expand,

and the end gap narrows significantly. a .016 end gap should result in having the ring ends almost,

but not touch under normal operating conditions, almost all ring manufactures strongly suggest a bit larger end gap,

if you use any power booster , as that tends to noticeably increase operational heat and result in tighter end gaps. the piston alloy the fuel you use your fuel/air ratio and ignition advance curve all effect the engines operational temps, and as a result the true operational piston ring end gap.

keep in mind a piston even at only about 800 rpm,has a compression stroke 13 -14 times a SECOND, now get out your feeler gauge and look how thin a .030 feeler gauge is and remember the piston to bore wall clearance at operational temps is under .001, thus the potential end gap can,t potentially allow much flow through what is in effect a fast moving oil filled pin hole thats being slamed from bdc to tdc 13 times to 60 times per second depending on engine rpms

HONE WITH HONE PLATES to duplicate the stress the head bolts place on the cylinder walls to get a true round bore wall surface

use of a deck plate allows the head bolts to be torqued ,this duplicates the stress the heads when installed exert on the block and allows a much better ring seal

BORING and HONING a blocks bore are best done at a local machine shop where clearances and surface finish are more accurately controlled, BUT, IF your going to be honing the bores for MOLY rings I,d suggest a 240-280 grit hone a 45 degree cross hatch angle and a constant flow of flushing liquid washing over the stones and bore surface to keep the stones from clogging with micro grit trash, that gets removed from the high points in the bore surface.

Ive used both a flush of 90% diesel fuel mixed with 10% marvel mystery oil, as a flush and Ive used hot water with a couple teaspoons of dawn dish washing soap, both work, but I think the hot water and dawn solution produced the most uniform result, on the bore surface but that requires a good deal of cleaning and washing the block just like the diesel fuel mix as you darn sure want to remove all traces of grit and prevent rust forming from moisture so after hone work I power wash the block with a pressure washer,, flush the surface with alcohol paint thinner as it tends to get under and lift out micro crud and speed surface dry time ,then I spray it over with WD40 and heat it with a heat gun to remove moisture traces then re-spray it with WD, 40 [/b]

washing the blocks surface with alcohol, and drying with high pressure air helps dry a lock after a pressure washing

http://www.harborfreight.com/1600-watt- ... 69342.html

http://www.circletrack.com/enginetech/c ... for_speed/

one factor I find amazing is how few guys realize that the rings MUST have space both above the ring and behind the ring in the piston grooves simply because its the hundreds of PSI of cylinder pressure that first forces the ring into the bottom of its groove then the pressure gets behind the ring and tends to expand it and hold it into the bore that is a huge factor in how effective the ring seals combustion pressure in the combustion chamber, if the clearances are filled with carbon build up the rings loose a great deal of there ability to seal.

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably;y more than the ring tension alone can do.

http://www.sjdiscounttools.com/lis24000.html

measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

viewtopic.php?f=53&t=1797&p=4586#p4586

viewtopic.php?f=53&t=3897&p=26602&hilit=tool+groove+piston#p26602

viewtopic.php?f=53&t=509&p=632&hilit=tool+groove+piston#p632

viewtopic.php?f=53&t=9490&p=34908&hilit=ring+compressor#p34908

viewtopic.php?f=53&t=5454&p=16301&hilit=ring+back+space#p16301

yes thats a VERY commonly over looked factor, the chipping seeming to be sensitive to how aggressive I pushed the ring into the grinding wheel, and how agreasive the grit used is, the slightly higher cost diamond grit wheel IS worth the cost difference and how fast its spinning all effect results, even the direction the grinding disc spins effects the cut, it generally works best is the wheel , on the ring filer disc is rather smooth and the rings barely moved into the cutting disk with minimal resistance

BTW, most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

http://www.tooltopia.com/fowler-72-646-300.aspx

https://www.youtube.com/watch?v=LcOHsZxuqAM&t=23s

yes as always theres cheap,functional, and theres expensive precision ring filers

http://www.abs-products.com/specialty-t ... nder.shtml

Indycars posted these GREAT PICTURES OF HIS RINGS UNDER MAGNIFICATION SHOWING THE MICRO CHIPS IN THE MOLY RING FACING

http://www.speedwaymotors.com/Precision ... ,2915.html

NOTICE the two totally different OIL ring scraper ring widths in this picture above,OIL RINGS come in dozens of designs so, you can not use all oil rings on all pistons and you can,t swap expanders and wipe rings thru different designs, and you must verify piston groove measurements , measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

http://www.summitracing.com/parts/SUM-906795/

http://www.muller.net/sonny/crx/rings/index.html

http://www.teglerizer.com/triumphstuff/75w_newrings.htm

http://www.summitracing.com/parts/PRO-66785/

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

your going to need decent feeler gauges

if the ring gaps, or piston to bore clearances are not carefully checked, or not correct your engine could easily get screwed up

Due to machining tolerances on both pistons and bore sizes theres always some minor differences between components,

when your assembling any engine, youll file fit the ring gaps to individual cylinders,and youll,

generally you'll want to carefully measure each individual piston diameter and each individual bore diameter very carefully,

and match the larger pistons to the larger bore sizes to keep the average side clearance as consistent as possible

most applications would have a ring gap of about .004-.005 per inch of bore diam.

but tests have shown even a .050 end gap has only a marginal effect on engine power or blow by, simply because at even 1000rpm theres slightly more than 8 power strokes per second, and the pressure is near max mostly in the 10 degrees before and 30 degrees after TDC, theres very little time to force much thru a .005 or less piston to bore clearance and two .050 end gaps even if that was the case

here is where you, or your machine shop can screw things up on ring to bore seal,Don’t get crazy trying to get the minimum end gap.

if you have a minimum possible end gap for the piston rings, they will not provide a significantly better seal than the correct or slightly larger end gap, do not push it to minimum spec. the saying goes like this: if the gap is too big nobody will know, but if it is too small everybody will know, be cause if the end gaps too small the ring ends touch, lock the piston in the bore, shear off the ring lands and destroy the engine, a but to large results in not much but a tiny bit more oil being used

Often filing rings is required, so be sure to clean the filed area with sandpaper to smooth the burr then wash with soap and water. Little horsepower is lost through the increased gap and what good is horsepower if your rings come together and break a piston or two

when you hone the bores,get and use block deck hone plates, during the hone process , keep in kind you want to use the same (STUDS OR BOLTS) the machine shop used and the same torque settings they used when the cylinders were honed with deck plates or the distortion of the bore and ring seal won,t be identical (exactly round)or ideal , ring tension helps seal the bore on the intake stroke but on the power stroke cylinder pressure forces the rings hard against the lower ring land surface, the space above and behind the ring is nearly instantly filled with hundreds of psi of cylinder pressure forcing the ring out against the bore wall.

think about this a second,before spending your cash on gap less rings.that can cost 3 times what standard gap piston rings do,

With the engine temps up to operational levels the ring end gap is generally in the .007-.005 range and actual piston to bore side clearance is in the .001-.002 range, that's not counting a film of oil covering and filling much of that remaining clearance,and piston temps that can easily exceed 400f , now consider that at even just 3000rpm, theres 25 compression strokes per second, which are taking up 1/4 of that rotational time frame, so in effect, to get gas leakage past the rings you have to forced the compressed gases past two piston ring end gaps (FIRST AND SECOND COMPRESSION RINGS) located in a randomly staggered location, thru a pair of ring end gaps that are about .002 x.006, in less than 4% of a seconds time.

when they do those impressive leak down tests the piston and rings are stationary, not reciprocating at and changing between high cylinder pressure and several dozen inches of exhaust scavenging vacuum,25-60 times PER SECOND, like rings in a running engine, nor is the engine operating at anything close to operational temps and pressures

while theres zero doubt that the gap less rings in theory will seal a bit better,if properly installed, the real world advantages, are minimal during true operational conditions, because you can,t force much compressed gas forcing its way past the piston ,down thru a hole on a set of staggered ring gaps, over that very brief time frame, thru what is effectively the size of a hole in a needles eye.

watch this and read thru the linked info, posted below, there's only a few ways to screw up an engine rebuild faster than NOT having the rings installed correctly or gaped to match the application, and heat range.

run the ring gap too tight, and the ring ends touch and the ring can lock against the bore, frequently busting ring lands or pulling the top of the piston ring land clear off, resulting in,having chunks of busted piston ring land compressed into the quench area, or results in bent connecting rods and cracked cylinder heads, bent valves etc.

BTW when you go to buy a ring compressor....this type(ABOVE & BELOW) works far better than the others, but its specific to a very limited range in bore size applications

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

remember to dip the piston and rings in high quality oil just prior too or before assembly I,ve used MARVEL MYSTERY OIL FOR DECADES

https://www.summitracing.com/parts/sme-90a4000

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

this style ring compressor below has a nasty habit of not keeping the rings evenly compressed and not seating evenly on the block , Ive used them but the type above is much easier to use

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66785&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SME-906000W&N=700+115&autoview=sku

http://www.sswesco.com/ss/sssugges.htm

viewtopic.php?f=53&t=5454

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

http://www.babcox.com/editorial/us/us20114.htm

https://www.engineprofessional.com/EPQ2-2020/mobile/index.html#p=17

http://www.circletrack.com/enginetech/c ... index.html

http://www.kb-silvolite.com/article.php ... ad&A_id=56

http://www.wiseco.com/PDFs/Manuals/RingEndGap.pdf

http://www.stockcarracing.com/techartic ... index.html

http://www.riken.co.jp/e/piston/b/b_1.html

http://www.carcraft.com/techarticles/pi ... index.html

http://www.aa1car.com/library/ar293.htm

http://www.gmhightechperformance.com/te ... ation.html

http://www.aa1car.com/library/2005/eb010550.htm

http://www.jepistons.com/dept/tech/dl/p ... rc4032.pdf

http://www.aa1car.com/library/ring_end_gap.htm

http://www.aa1car.com/library/ring_end_gap.htm

http://www.circletrack.com/howto/1818/index.html

http://www.chevyhiperformance.com/howto/0706ch_file_fitting_pistons/index.html

http://www.popularhotrodding.com/en...em_building_the_short_block/piston_rings.html

http://kb-silvolite.com/article.php?action=read&A_id=56

http://www.sswesco.com/ss/sspow.htm

http://www.racetep.com/totalsealframe.html

http://www.cdxetextbook.com/engines/com ... rings.html

http://www.dragracingaction.com/index.p ... press=3504

http://www.federalmogul.com/korihandboo ... ion_18.htm

http://kb-silvolite.com/article.php?action=read&A_id=32

http://moodle.student.cnwl.ac.uk/moodle ... rings.html

you have the option of ordering slightly over sized rings and carefully file fitting the end gaps,

no mater what size rings or end gap , you use the rings will normally take 5-20 minutes or so to lap into and perfectly seat and fit the bore walls

obviously the closer they match the application on start-up the more rapidly you could expect that to happen.

remember a properly honed bore using deck plated helps the process a great deal.

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-81042

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.co...on-ring-info-youll-need.509/page-2#post-71538

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-12416

http://garage.grumpysperformance.co...plate-honing-makes-a-differance.588/#post-869

http://garage.grumpysperformance.co...ing-piston-to-bore-ring-seal.3897/#post-10316

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

http://www.amazon.com/KD-Tools-850-Diam ... 0002STSMG/

this type (ABOVE) handles many applications but the cheap versions are a P.I.T.A. to work with

BTW when you go to buy a ring compressor....this type(ABOVE & BELOW) which is an adjustable diameter and tapered design, works far better than the others,

but its specific to a very limited range in bore size applications

so youll need to buy the correct matching size

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

you'll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor.

IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections.

be sure you, measure EACH bore and EACH piston,

(CORRECTLY with the proper tools in the way the tool and piston manufacturers suggested)

and number them on an engine build sheet indicating the bore and piston diam.

from large to smallest on each and install them on each cylinder to get the most consistent piston to bore clearance's

yes the difference may only be a few ten thousands if the bores are machined correctly, but you'll get the best results , most consistent lubrication, best durability and less heat build up that might result in detonation issues that way. its the little things that add up to making a good durable engine assembly,

BTW check rod orientation, so the beveled sides don't fact the adjacent rods, and check the bearing clearances with plasti guage

piston to bore clearance

ok first some facts (1)cylinders will not be honed to true round as they will be in use with out the use of a deck plate to simulate and duplicate the bolt clamp stress on the cylinder walls, bores in blocks without a head or deck plate with the bolts or studs torqued to spec are not nearly the...garage.grumpysperformance.com

don,t guess on clearances and journal surface

So I decided to buy a couple of worthless old 283s to learn how to build engines. If I acquire the appropriate skills, I'm going to build a torquey 383 out of the anemic '77 350 in my C30. It tows cars, but it doesn't exactly set the road on fire, if you know what I mean. Anyway, I bought two...garage.grumpysperformance.com

ring gapping and basic piston ring info YOULL NEED

YES YOU NEED TO READ THRU THE LINKS THAT'S WHAT THEY ARE THERE FOR...AND THERE'S A GREAT DEAL OF USEFUL INFO IN THOSE LINKS, don,t get over whelmed, make a list and test adjust correct or replace each problem, and check it off the list then move to the next issue, its a finite list and theres...garage.grumpysperformance.com

assembling and installing connecting rods/pistons

look closely at the connecting rods one edge of the main bearing are is beveled noticeably more than the other that beveled side faces away from the rod its paired with because it matches the slight radiased bevel of the crank journal many builder class pistons are designed to go in, in either...garage.grumpysperformance.com

KEEP IN MIND

any ring compressor design you use regardless ,of the design MUST have its lower surface kept firmly in contact with the block surface and parallel to the bore to allow the rings to smoothly transition from the inner surface of the compressor to the blocks bore, and IDEALLY the compressor internal diameter will be marginally smaller in internal diameter that the cylinder bore the pistons sliding into from it!

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor, btw IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

btw heres typical detonation damage, and in this case, resulting from a bit of nitrous, that boosted the pressure, but the results would be similar on a high compression engine subjected to crappy fuel and high loads at high rpms without nitrous, notice the sugary/frosted appearance and rounded edges of the melted areas

damage to the ring lands can be caused by detonation or just the ring gaps set too tightly, if the piston shows no frosted appearance its usually the ring gaps too small, or excessive heat, to lean a mix, to much ignition advance,etc.

most applications would have a ring gap of about .004-.005 per inch of bore diam.

but tests have shown even a .050 end gap has only a marginal effect on engine power or blow by, simply because at even 1000rpm theres slightly more than 8 power strokes per second, and the pressure is near max mostly in the 10 degrees before and 30 degrees after TDC, theres very little time to force much thru a .005 or less piston to bore clearance and two .050 end gaps even if that was the case

damage like this is rather frequently the result of the piston rings gap being too tight, the rings ends touch as they expand,

due to excessive heat and with no clearance the rings temporarily lock against the bore wall, the result is a broken ring, and fractured piston ring groove

obviously if you've been around engine rebuilds, long enough, your aware that you'll eventually see guys installing rings in piston grooves by spiral twisting them into place, like the picture below depicts

the 80MM-120MM tool fits almost all chevy V8 engines

the problem, with that method is that its not at all difficult to leave the piston ring twisted permanently,

or warping it to the point it either breaks ,

or its bent ,degrading its ability to seal against the bore wall.

yeah! I know all your buddies do it that way! its still a potential problem and has and will continue to cause problems

so its a good idea to carefully use a expander tool, but only expand the ring enough to install it.

http://www.summitracing.com/parts/shc-94662

Last edited by a moderator: