as many of you know I recently moved from Florida to Texas, 99% of my tools are still locked in (4) 16" ft long PACKRAT storage containers

IM, waiting for my new home and shop to be completed, they charge me roughly $300 a month for each pod, or roughly $1200 a month to hold these pods in storage and as I have zero place to put my parts and tools etc. at my sons home or my new home site while its being built,

I decided to have a temporary storage shed built and placed at my sons home in the back yard.

I can't watch it at my new home location, while I live at my sons home.

I'm assured this whole project can be completed in under 60 days by the local shed contractor,

and having talked to several local people who had similar work done in under 2 months time I feel sure that's a reasonable estimate!

keep in mind this is simply a place to store tools and a car and tractor, I don't currently expect to wire it with fans, lights etc.

this expense is on going and to me annoying in that I have zero access to my automotive and engine diagnostic and engine building tools reloading equipment etc.

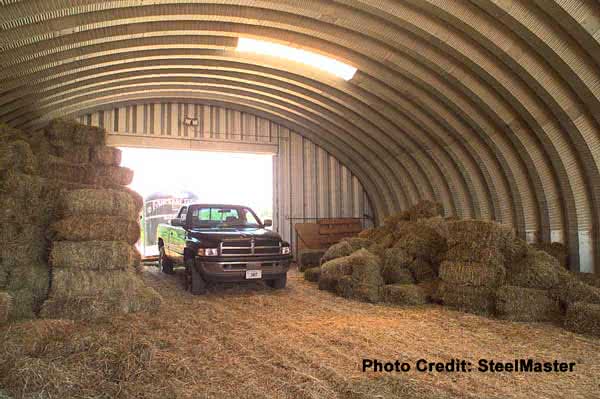

a temp metal 30 x 50 shed on a concrete pad , only roughly rather similar to this. pictured below, built on my sons property while not dirt cheap, at about $45K will allow me access to those tools and also leave my son with a place to park his car tractor etc, once I leave and go to my own property

while I can then unload the packrat pods and get access to my tools etc,

thats frustrating because it seems every week theres some minor project I know I could do if I had access to my TOOLS!!

Id like to assemble a reloading bench, now I figure Id build a bench along one end of the shed wall, a sheet of 3/4" plywood being 48"x 96" I can either have 3 8ft long 15.75" wide or two 23.9" wide bench shelves,

as you might know these really should be double thick if mounting a reload press as stress,

on the bench/desk/shelf top from the press function requires a solid stiff solidly supported surface.

I figure Ill use 4 ft tall front 4x4 posts vertically in the front every 6 feet and 8 ft tall 4x4 support posts in the rear spaced every 6 ft, as the taller rear supports allow over head shelves and overlap on the bench plywood or the ends of the horizontal plywood at about a 2 foot section where the 6 ft or 8 foot long sections of plywood are used to make the bench, screwed together while alternating seams in the plywood and using 2x4 boards under the plywood bolted and screwed to the 4x4 upright supports, if carefully done and with a L section extending out 8 feet at each end of the roughly 29 ft length this should be more than adequate to allow function of the reloading equipment and a shelf under the bench to allow lots of storage of various items and the rest of the temp garage will allow me to store my 1996 corvette, tractor and several thousand dollars in tools automotive parts etc I shipped while I wait on my main construction progress that appears currently may take well over a year more to complete.

IM, waiting for my new home and shop to be completed, they charge me roughly $300 a month for each pod, or roughly $1200 a month to hold these pods in storage and as I have zero place to put my parts and tools etc. at my sons home or my new home site while its being built,

I decided to have a temporary storage shed built and placed at my sons home in the back yard.

I can't watch it at my new home location, while I live at my sons home.

I'm assured this whole project can be completed in under 60 days by the local shed contractor,

and having talked to several local people who had similar work done in under 2 months time I feel sure that's a reasonable estimate!

keep in mind this is simply a place to store tools and a car and tractor, I don't currently expect to wire it with fans, lights etc.

this expense is on going and to me annoying in that I have zero access to my automotive and engine diagnostic and engine building tools reloading equipment etc.

a temp metal 30 x 50 shed on a concrete pad , only roughly rather similar to this. pictured below, built on my sons property while not dirt cheap, at about $45K will allow me access to those tools and also leave my son with a place to park his car tractor etc, once I leave and go to my own property

while I can then unload the packrat pods and get access to my tools etc,

thats frustrating because it seems every week theres some minor project I know I could do if I had access to my TOOLS!!

Id like to assemble a reloading bench, now I figure Id build a bench along one end of the shed wall, a sheet of 3/4" plywood being 48"x 96" I can either have 3 8ft long 15.75" wide or two 23.9" wide bench shelves,

as you might know these really should be double thick if mounting a reload press as stress,

on the bench/desk/shelf top from the press function requires a solid stiff solidly supported surface.

I figure Ill use 4 ft tall front 4x4 posts vertically in the front every 6 feet and 8 ft tall 4x4 support posts in the rear spaced every 6 ft, as the taller rear supports allow over head shelves and overlap on the bench plywood or the ends of the horizontal plywood at about a 2 foot section where the 6 ft or 8 foot long sections of plywood are used to make the bench, screwed together while alternating seams in the plywood and using 2x4 boards under the plywood bolted and screwed to the 4x4 upright supports, if carefully done and with a L section extending out 8 feet at each end of the roughly 29 ft length this should be more than adequate to allow function of the reloading equipment and a shelf under the bench to allow lots of storage of various items and the rest of the temp garage will allow me to store my 1996 corvette, tractor and several thousand dollars in tools automotive parts etc I shipped while I wait on my main construction progress that appears currently may take well over a year more to complete.

Last edited:

I'm building on my sons property, while I plan and build a much better shop on my property, obviously hes not too upset as he gets a free garage shop in the process

I'm building on my sons property, while I plan and build a much better shop on my property, obviously hes not too upset as he gets a free garage shop in the process