taps and dies are generally over looked as tools until you find you've screwed up threads, but the longer you play in the hobby the more you tend to clean out threads with a tap or die before assembling components thru past experience, that experience showing you it tends to prevent problems

your local pro-tool supply stores will generally have a wide selection but don,t be surprised at the prices for the better sets, and be aware the cheaper sets are just that..cheaper, and usually not in a good sense!

you generally get what you pay for and taps and dies run from pure crap imported from over seas (INDIA/CHINA)that tend to cost well under $100 for a 40 piece set, too high quality American or German made sets easily costing $300 plus, yes the more expensive sets ARE WELL WORTH IT if you are doing an almost constant repair and assembly, the cheap crap tends to break and cause almost as much grief as its supposed to cure!

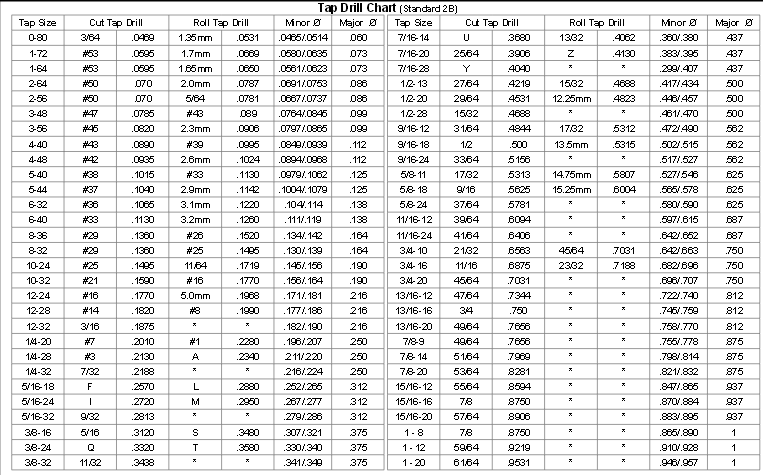

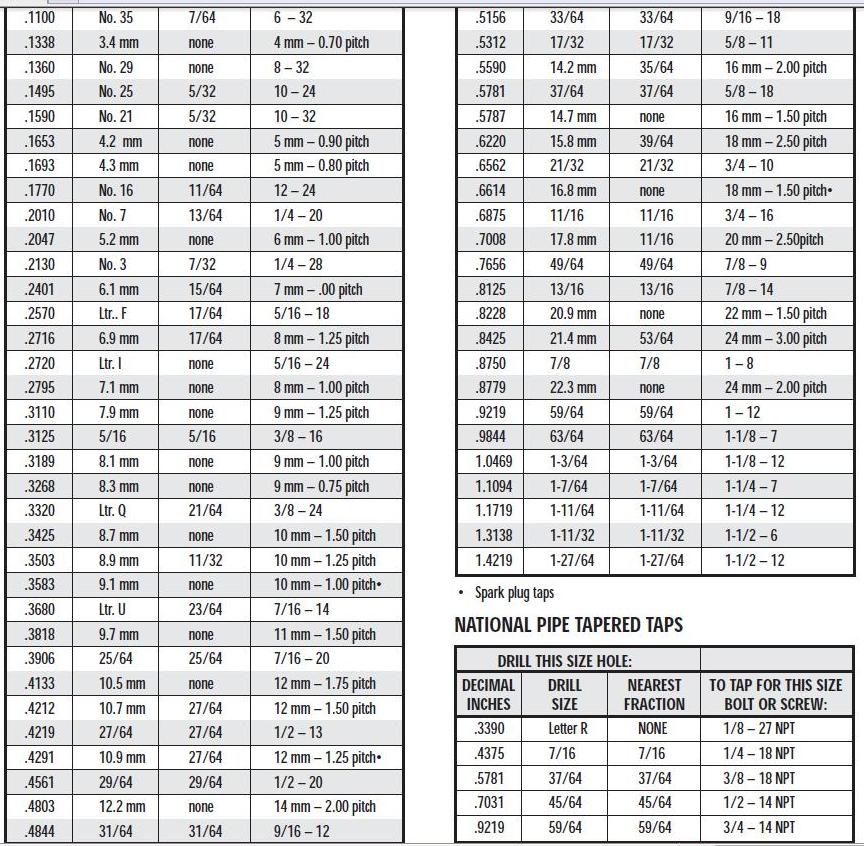

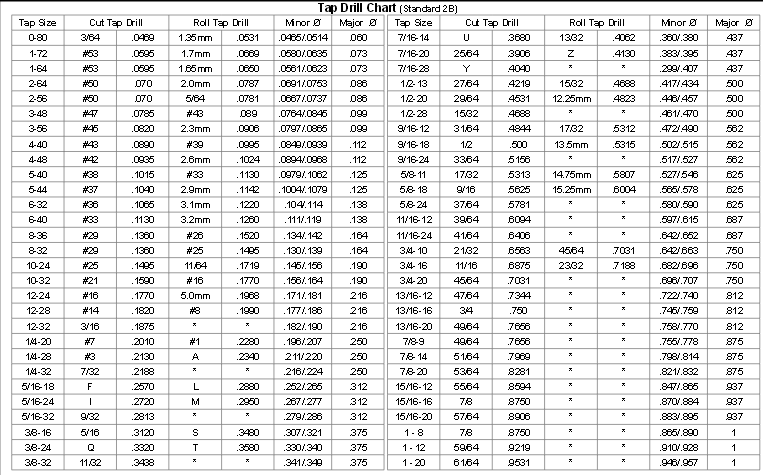

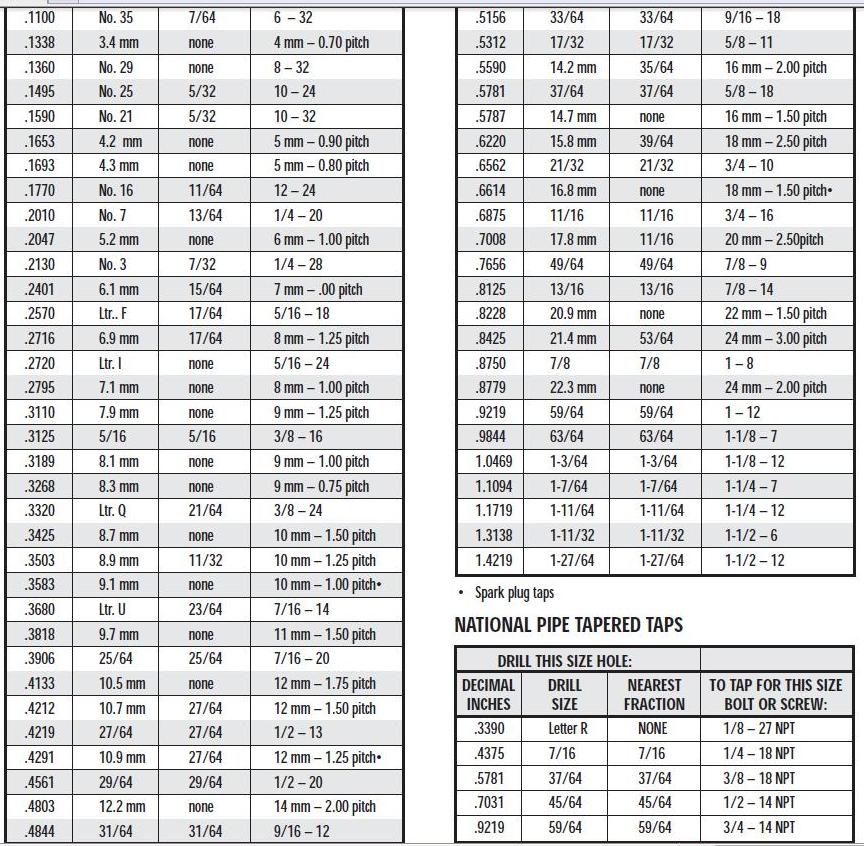

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

http://www.shender4.com/thread_chart.htm

viewtopic.php?f=27&t=1170

http://www.physics.ncsu.edu/pearl/Tap_Drill_Chart.html

http://www.americanfastener.com/technic ... _chart.asp

http://www.kramerusa.com/DrillTapChart.htm

http://www.summitracing.com/parts/EAR-D026ERL/?rtype=10

http://www.harborfreight.com/air-blow-g ... 42939.html

http://www.baystatetoolsupply.com/index ... x&cPath=68

http://www.sears.com/shc/s/ProductDispl ... ogId=12605

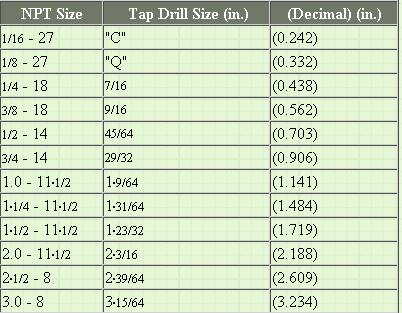

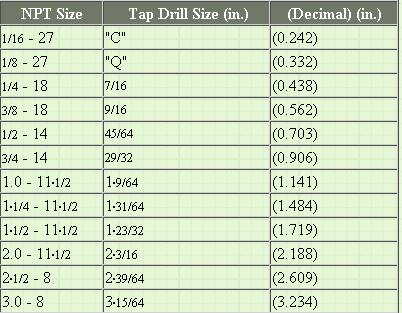

http://www.plumbingsupply.com/pipethreadsizing.html

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

https://mdm6121.800cart.com/?product=R173-ETDS110M

http://www.toolsnow.com/browse.cfm/4,1559.html

http://www.sears.com/shc/s/p_10153_1260 ... 515x00001c

http://www.garrettwade.com/product.asp? ... 1235354814

http://www.wttool.com/category-exec/cat ... p_Die_Sets

WIDGETMASTER POSTED THIS INFO

"Types of Taps

Spiral Point Taps— Also known as gun taps, they have an angular point that shears and shoots chips out ahead of the tap. This keeps chips from clogging the flutes, thus reducing tap breakage. Spiral point taps are generally stronger than hand taps and can be run faster with less power. Use them in through-holes and holes two diameters deeper than the required thread length.

Hand Taps— Have straight flutes for hand and machine threading. Although most are used in machine operations today, the traditional name "hand tap" lives on.

Spiral Flute Taps— Also called helical flute taps, the spiral flute uses a lifting action to remove stringy chips that form when tapping soft materials such as aluminum, brass, copper, and magnesium. Use in deep holes, blind holes, and holes with a keyway or gap.

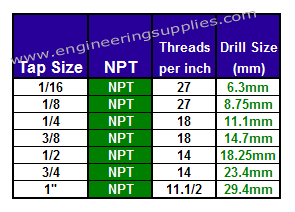

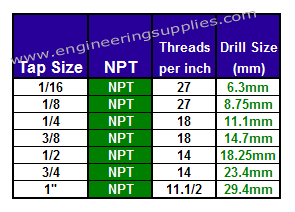

Pipe Taps— Use for internal threading of pipe, pipe fittings, and holes in which you'll be assembling threaded pipe.

Specialty Taps— Include thread forming, extension, nut, ACME tandem, and combined taps and drills.

Materials

Most taps are made of high-speed steel in grades M-1 and M-7, which are for use in a variety of applications on ferrous and nonferrous materials. High performance taps are made of premium high-speed steels and work well on stainless steel, nickel-based alloys, and other exotic metals. Premium steels add abrasion and heat resistance for longer tap life and better tap performance. These taps also have a special cutting design for lower machine power requirements, better chip removal and coolant flow, better thread finishes, and closer tolerance pitch diameter size. Use carbide taps for highly abrasive materials such as cast iron and aluminum. Also excellent for use on cast brass, cobalt chrome alloys, copper and copper alloys, fiberglass, and soft plastics. Carbon steel taps are for jobs that don't require the accuracy of high-speed steel taps and don't need resistance to heat and abrasion (such as in some hand-tapping jobs).

Surface Coatings Coatings improve tap life by as much as 300 to 800 percent over uncoated (bright finish) taps. They also improve the part's surface finish and let you use faster cutting speeds.

TiN (Titanium Nitride)— This gold-colored coating works with a variety of ferrous and nonferrous materials. Not for wrought aluminum and titanium alloys. TiCN (Titanium Carbonitride)— Harder, tougher, and more wear resistant than TiN, TiCN is becoming increasingly popular. Works in a variety of ferrous and nonferrous materials. Color is blue-gray violet.

Surface Treatments

Chrome Plating— Adds hardness to tap threads, improves lubricity, reduces loading, and offers cool cutting. Use on a wide variety of ferrous and nonferrous materials. Silver color.

Oxide— Prevents buildup or welding of workpiece materials on tap surfaces in ferrous materials. Reduces friction between tap and workpiece while providing a porous layer to hold lubricants. Avoid use with nonferrous materials. Blue-black color.

Oxide Over Nitride— Use on ferrous materials, high-temperature alloys, titanium and titanium alloys, free-machining steels, iron, high-tensile steels, and stainless steels. Blue-black color.

Nitride— For use on both ferrous and nonferrous abrasive materials that dull taps. Improves surface toughness of the tap. Use on aluminum, cast iron, brass, bronze, die castings, magnesium, zinc, and copper. Colorless.

Tapping Fluids

The use of tapping fluids is highly recommended for best tapping results. Using tapping fluids increases tap life and production, provides more efficient control of chips, and reduces the frequency of tap resharpening. Fluids are more effective if applied under pressure. Using a top and bottom stream of fluid is desirable when tapping horizontally where the tap is stationary and the part revolves. Do not use a lubricant with hard plastics. Use compressed air to remove chips.

Hope this helps! "

read these threads

viewtopic.php?f=50&t=1222

viewtopic.php?f=44&t=805&p=1171&hilit=sealant+silicone#p1171

http://www.permatex.com/products/Automo ... ealant.htm

viewtopic.php?f=51&t=3774&p=10002&hilit=bottoming+taps#p10002

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51843

http://garage.grumpysperformance.com/index.php?threads/rod-bolt-mics-stretch-gauges.989/#post-51199

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-44530

http://garage.grumpysperformance.co...ing-tools-abrasives-sources.10683/#post-46207

http://garage.grumpysperformance.com/index.php?threads/starter-tool-set.6032/#post-18696

http://garage.grumpysperformance.com/index.php?threads/what-hand-tools-to-buy.4069/#post-10827

http://garage.grumpysperformance.co...te-but-it-will-get-you-started.834/#post-4891

if you use taps youll need several sizes of tap holder t-handles

Lisle 70500 Tap Socket Set (this square drive socket set, socket set allows you to use swivels and ratchets on thread taps)

if youve ever chased threads in a block thats still in a car you have very likely found the typical taps T-handle can have clearance issues

https://www.amazon.com/Lisle-70500-...65953&creativeASIN=B0002SRFOE&m=ATVPDKIKX0DER

https://www.nationaltoolwarehouse.c...SKUs&msclkid=51e6168ce34c1039d01d4b9e7013b0f7

your local pro-tool supply stores will generally have a wide selection but don,t be surprised at the prices for the better sets, and be aware the cheaper sets are just that..cheaper, and usually not in a good sense!

you generally get what you pay for and taps and dies run from pure crap imported from over seas (INDIA/CHINA)that tend to cost well under $100 for a 40 piece set, too high quality American or German made sets easily costing $300 plus, yes the more expensive sets ARE WELL WORTH IT if you are doing an almost constant repair and assembly, the cheap crap tends to break and cause almost as much grief as its supposed to cure!

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

http://www.shender4.com/thread_chart.htm

viewtopic.php?f=27&t=1170

http://www.physics.ncsu.edu/pearl/Tap_Drill_Chart.html

http://www.americanfastener.com/technic ... _chart.asp

http://www.kramerusa.com/DrillTapChart.htm

http://www.summitracing.com/parts/EAR-D026ERL/?rtype=10

http://www.harborfreight.com/air-blow-g ... 42939.html

http://www.baystatetoolsupply.com/index ... x&cPath=68

http://www.sears.com/shc/s/ProductDispl ... ogId=12605

http://www.plumbingsupply.com/pipethreadsizing.html

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

https://mdm6121.800cart.com/?product=R173-ETDS110M

http://www.toolsnow.com/browse.cfm/4,1559.html

http://www.sears.com/shc/s/p_10153_1260 ... 515x00001c

http://www.garrettwade.com/product.asp? ... 1235354814

http://www.wttool.com/category-exec/cat ... p_Die_Sets

WIDGETMASTER POSTED THIS INFO

"Types of Taps

Spiral Point Taps— Also known as gun taps, they have an angular point that shears and shoots chips out ahead of the tap. This keeps chips from clogging the flutes, thus reducing tap breakage. Spiral point taps are generally stronger than hand taps and can be run faster with less power. Use them in through-holes and holes two diameters deeper than the required thread length.

Hand Taps— Have straight flutes for hand and machine threading. Although most are used in machine operations today, the traditional name "hand tap" lives on.

Spiral Flute Taps— Also called helical flute taps, the spiral flute uses a lifting action to remove stringy chips that form when tapping soft materials such as aluminum, brass, copper, and magnesium. Use in deep holes, blind holes, and holes with a keyway or gap.

Pipe Taps— Use for internal threading of pipe, pipe fittings, and holes in which you'll be assembling threaded pipe.

Specialty Taps— Include thread forming, extension, nut, ACME tandem, and combined taps and drills.

Materials

Most taps are made of high-speed steel in grades M-1 and M-7, which are for use in a variety of applications on ferrous and nonferrous materials. High performance taps are made of premium high-speed steels and work well on stainless steel, nickel-based alloys, and other exotic metals. Premium steels add abrasion and heat resistance for longer tap life and better tap performance. These taps also have a special cutting design for lower machine power requirements, better chip removal and coolant flow, better thread finishes, and closer tolerance pitch diameter size. Use carbide taps for highly abrasive materials such as cast iron and aluminum. Also excellent for use on cast brass, cobalt chrome alloys, copper and copper alloys, fiberglass, and soft plastics. Carbon steel taps are for jobs that don't require the accuracy of high-speed steel taps and don't need resistance to heat and abrasion (such as in some hand-tapping jobs).

Surface Coatings Coatings improve tap life by as much as 300 to 800 percent over uncoated (bright finish) taps. They also improve the part's surface finish and let you use faster cutting speeds.

TiN (Titanium Nitride)— This gold-colored coating works with a variety of ferrous and nonferrous materials. Not for wrought aluminum and titanium alloys. TiCN (Titanium Carbonitride)— Harder, tougher, and more wear resistant than TiN, TiCN is becoming increasingly popular. Works in a variety of ferrous and nonferrous materials. Color is blue-gray violet.

Surface Treatments

Chrome Plating— Adds hardness to tap threads, improves lubricity, reduces loading, and offers cool cutting. Use on a wide variety of ferrous and nonferrous materials. Silver color.

Oxide— Prevents buildup or welding of workpiece materials on tap surfaces in ferrous materials. Reduces friction between tap and workpiece while providing a porous layer to hold lubricants. Avoid use with nonferrous materials. Blue-black color.

Oxide Over Nitride— Use on ferrous materials, high-temperature alloys, titanium and titanium alloys, free-machining steels, iron, high-tensile steels, and stainless steels. Blue-black color.

Nitride— For use on both ferrous and nonferrous abrasive materials that dull taps. Improves surface toughness of the tap. Use on aluminum, cast iron, brass, bronze, die castings, magnesium, zinc, and copper. Colorless.

Tapping Fluids

The use of tapping fluids is highly recommended for best tapping results. Using tapping fluids increases tap life and production, provides more efficient control of chips, and reduces the frequency of tap resharpening. Fluids are more effective if applied under pressure. Using a top and bottom stream of fluid is desirable when tapping horizontally where the tap is stationary and the part revolves. Do not use a lubricant with hard plastics. Use compressed air to remove chips.

Hope this helps! "

read these threads

viewtopic.php?f=50&t=1222

viewtopic.php?f=44&t=805&p=1171&hilit=sealant+silicone#p1171

http://www.permatex.com/products/Automo ... ealant.htm

viewtopic.php?f=51&t=3774&p=10002&hilit=bottoming+taps#p10002

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51843

http://garage.grumpysperformance.com/index.php?threads/rod-bolt-mics-stretch-gauges.989/#post-51199

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-44530

http://garage.grumpysperformance.co...ing-tools-abrasives-sources.10683/#post-46207

http://garage.grumpysperformance.com/index.php?threads/starter-tool-set.6032/#post-18696

http://garage.grumpysperformance.com/index.php?threads/what-hand-tools-to-buy.4069/#post-10827

http://garage.grumpysperformance.co...te-but-it-will-get-you-started.834/#post-4891

if you use taps youll need several sizes of tap holder t-handles

Lisle 70500 Tap Socket Set (this square drive socket set, socket set allows you to use swivels and ratchets on thread taps)

if youve ever chased threads in a block thats still in a car you have very likely found the typical taps T-handle can have clearance issues

https://www.amazon.com/Lisle-70500-...65953&creativeASIN=B0002SRFOE&m=ATVPDKIKX0DER

https://www.nationaltoolwarehouse.c...SKUs&msclkid=51e6168ce34c1039d01d4b9e7013b0f7

Last edited by a moderator: