You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

468 build

- Thread starter muddtruck

- Start date

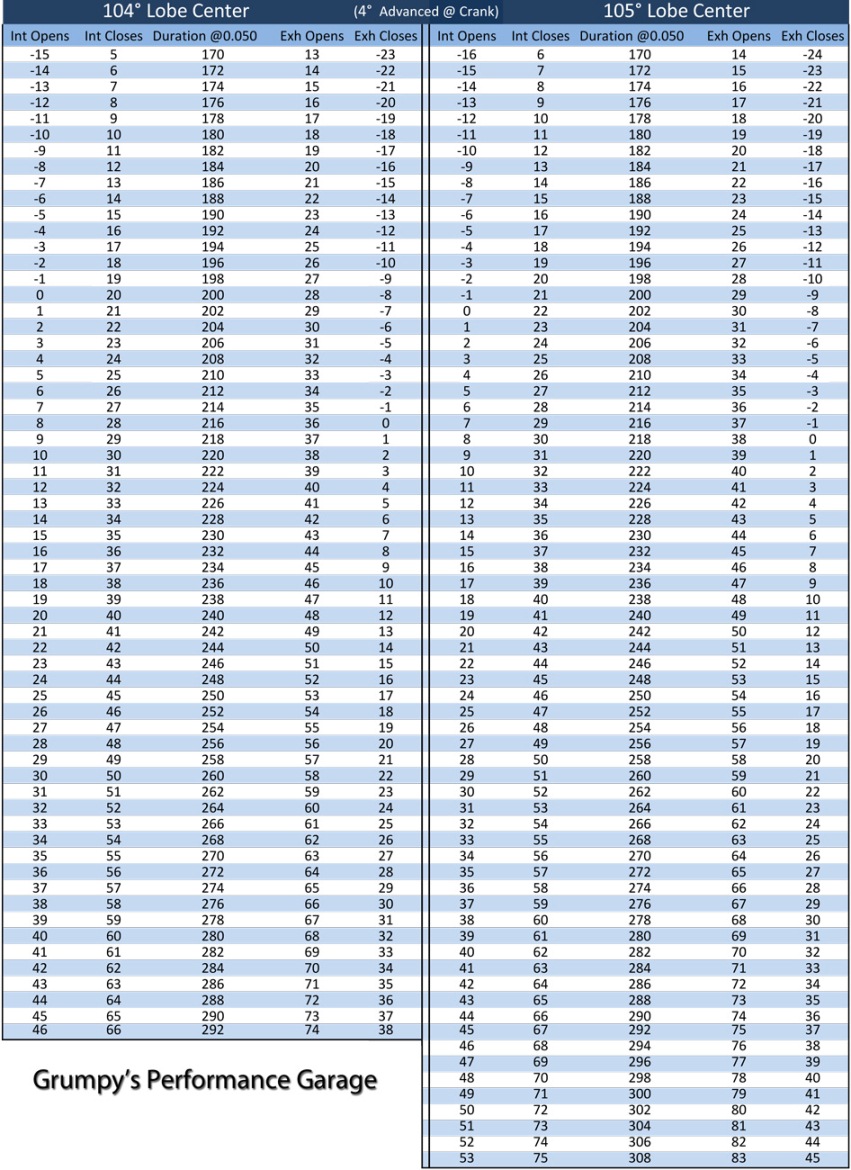

you may find cross checking the figures against the CROWER charts useful

http://garage.grumpysperformance.com/index.php?threads/crowers-valve-timing-charts.4299/

while not exact, simply because lobe acceleration rates differ,between manufacturers and flat tappet vs roller lobe designs, , adding about 17 degrees to each cam lobe ramp to get the seat duration from the .050 lift value will frequently get you close to seat duration

example

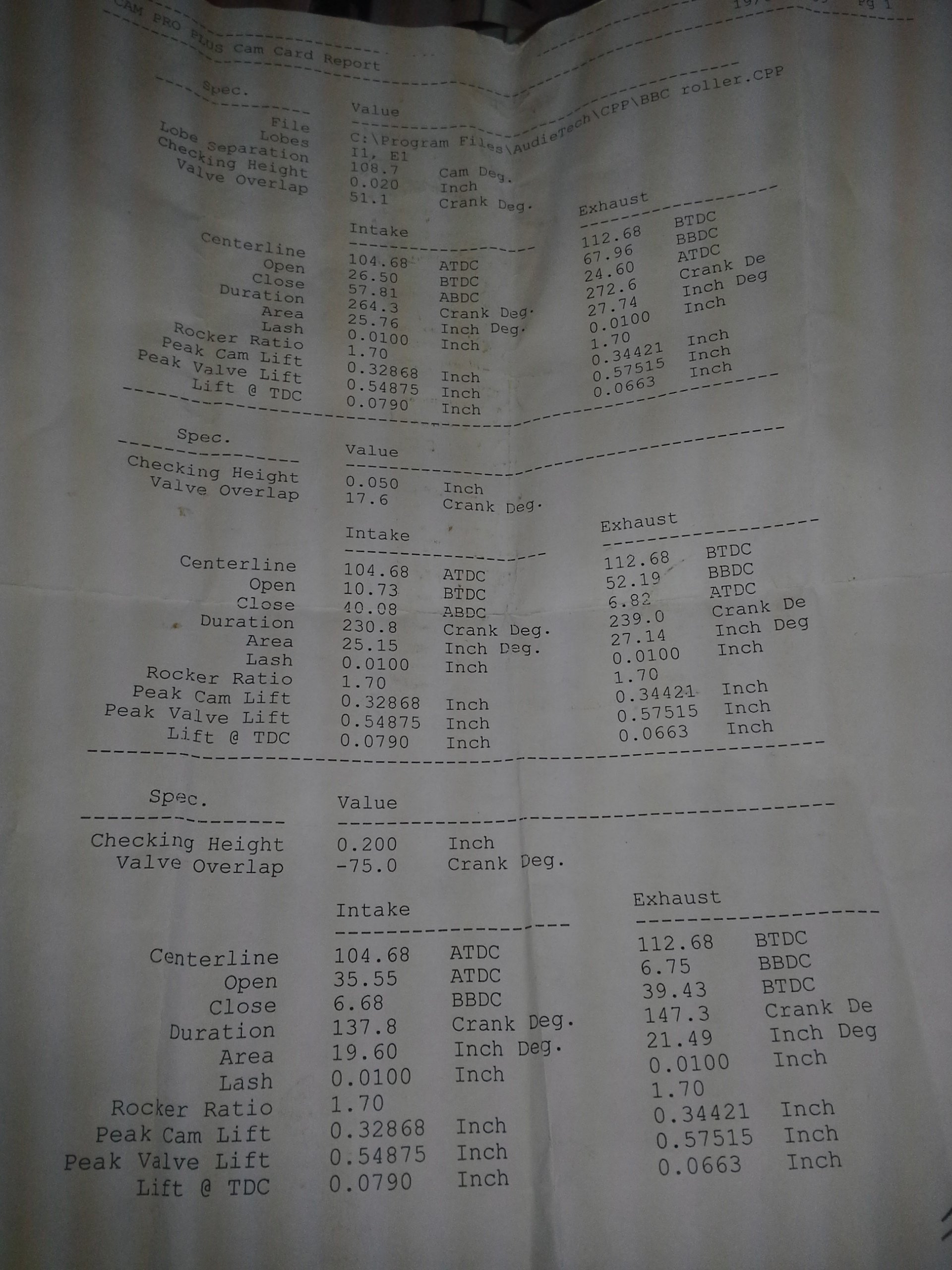

its listed as a 230.8 @ .050 lift and 264 advertised

SO 17+230.8+17=264.8

Last edited:

muddtruck

Active Member

So I got my hands on some 30cc dome pistons. According to my simpleton compression calculator I should be around 10-10.5:1. Still checking out different cams....comp cams recommended this grind: hydraulic flat tappet 248@50, intake 566 exhaust 578, 108 lsa.Comparing bang for buck and power, how does it stack up compared to the roller I mentioned? 234@50, 548 intake 575 exhaust 108 lsa. Pretty close?

http://garage.grumpysperformance.co...-the-extra-cost-vs-a-flat-tappet-design.3802/

ROLLER

less friction

faster valve lift

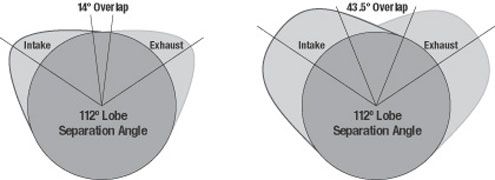

longer effective duration

less chance of lobe failure

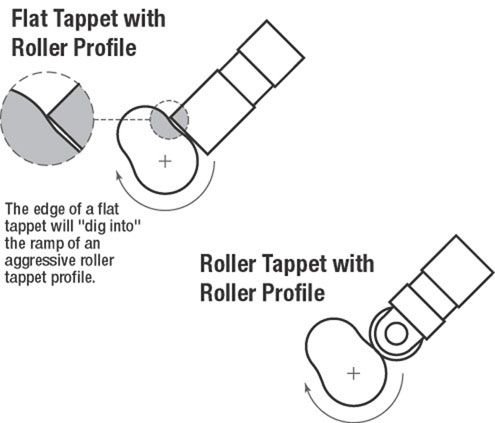

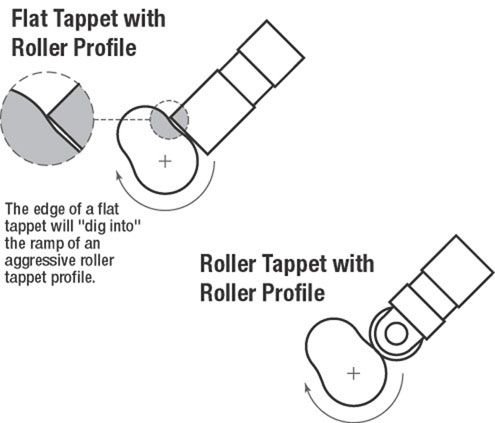

you should also keep in mind that a roller cam valve train with the same lift and duration as a flat tappet cam, can provide a good deal more port flow potential and resulting power, , how much more power is mostly the result of how much more port flow and volumetric efficiency you can get from the engine combo that the flat tappet cam will not be able top access because the valve opens longer per degree of rotation on the roller cam lobe and the lift and duration,the valve sees increases, roller cams have a far lower percentage of lobe wear and less friction, both tend to result in more usable horsepower.

now if your current flat tappet cam is providing most of the engines potential then the roller cam will only provide a mild improvement, but in most cases you can expect a 15hp-40 hp gain, (depending on displacement, port flow,exhaust scavenging etc,)over a similar flat tappet design with similar duration at .050 lift, but in many case the roller cams peak lift will be noticeably more.

within certain limits ,the larger the lifter diameter the faster the cam lobe acceleration ramp can be, chevy has a lifter diam. .842

ford uses a .874 diam, Chrysler .904 diam.

the roller will easily allow you to exceed the 550 hp level, I'd go that route,

yes the flat tappets initially cheaper, but youll very likely regret going that route later if you did go that route

ROLLER

less friction

faster valve lift

longer effective duration

less chance of lobe failure

you should also keep in mind that a roller cam valve train with the same lift and duration as a flat tappet cam, can provide a good deal more port flow potential and resulting power, , how much more power is mostly the result of how much more port flow and volumetric efficiency you can get from the engine combo that the flat tappet cam will not be able top access because the valve opens longer per degree of rotation on the roller cam lobe and the lift and duration,the valve sees increases, roller cams have a far lower percentage of lobe wear and less friction, both tend to result in more usable horsepower.

now if your current flat tappet cam is providing most of the engines potential then the roller cam will only provide a mild improvement, but in most cases you can expect a 15hp-40 hp gain, (depending on displacement, port flow,exhaust scavenging etc,)over a similar flat tappet design with similar duration at .050 lift, but in many case the roller cams peak lift will be noticeably more.

within certain limits ,the larger the lifter diameter the faster the cam lobe acceleration ramp can be, chevy has a lifter diam. .842

ford uses a .874 diam, Chrysler .904 diam.

the roller will easily allow you to exceed the 550 hp level, I'd go that route,

yes the flat tappets initially cheaper, but youll very likely regret going that route later if you did go that route

Last edited:

muddtruck

Active Member

That graph of the area under the curve puts things into perspective. When I showed a friend the roller lift/ duration numbers he said it was a bit small of a cam. Then again I dont have an all out drag racing motor like the ones hes used to. Sounds like its worth the extra coin that a roller costs. Maybe I'll find a deal somewhere. Thanks for the info again Grumpy. Indycars the only card for the roller is the paper I posted. I'll attach the flat tappet card too. Thanks alot for the info

Last edited:

muddtruck

Active Member

This was the cam I wanted compared to the roller, wrote the wrong one down earlier. Sorry too many number floating around in my notepad

http://www.compcams.com/Company/CC/cam-specs/Details.aspx?csid=402&sb=2

http://www.compcams.com/Company/CC/cam-specs/Details.aspx?csid=402&sb=2

Last edited:

muddtruck

Active Member

http://www.angelfire.com/wv/fuzzychevy/gm188.html

Found these numbers

Found these numbers

Ok the head flow numbers for a PN14096188 are:

DynoSim5 calculate the SCR to be 10.79.

.

- PORT SIZE: 317

- CHAMBER: 115cc

- VALVE SIZE: 2.19 / 1.88

- PRICE: N/A

- FLOW@.100: 68 / 45

- FLOW@.200: 129 / 90

- FLOW@.300: 188 / 131

- FLOW@.400: 233 / 170

- FLOW@.500: 259 / 188

- FLOW@.600: 291 / 195

- FLOW@.700: 313 / 200

DynoSim5 calculate the SCR to be 10.79.

.

Rick,

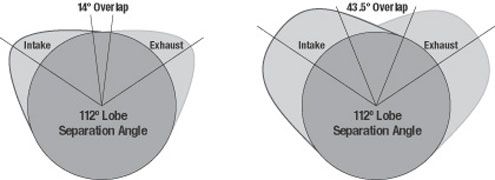

on that dyno sim,

could you,retard the cam center line 6 degrees from where you show it,

and it should be 2 degrees retard from split overlap center line,

and that should produce better mid and upper rpm power.

without a huge drop in lower rpm torque,

I think you'll find a better average power curve.

if possible over lay the two graphs to show what retarding the cam installed location does to the power curve.

on that dyno sim,

could you,retard the cam center line 6 degrees from where you show it,

and it should be 2 degrees retard from split overlap center line,

and that should produce better mid and upper rpm power.

without a huge drop in lower rpm torque,

I think you'll find a better average power curve.

if possible over lay the two graphs to show what retarding the cam installed location does to the power curve.

Not if you are referring to the camshaft info in the photograph.Is there enough info on the roller cam specs to see what your dynosim says with it in comparison to the flat tappet?

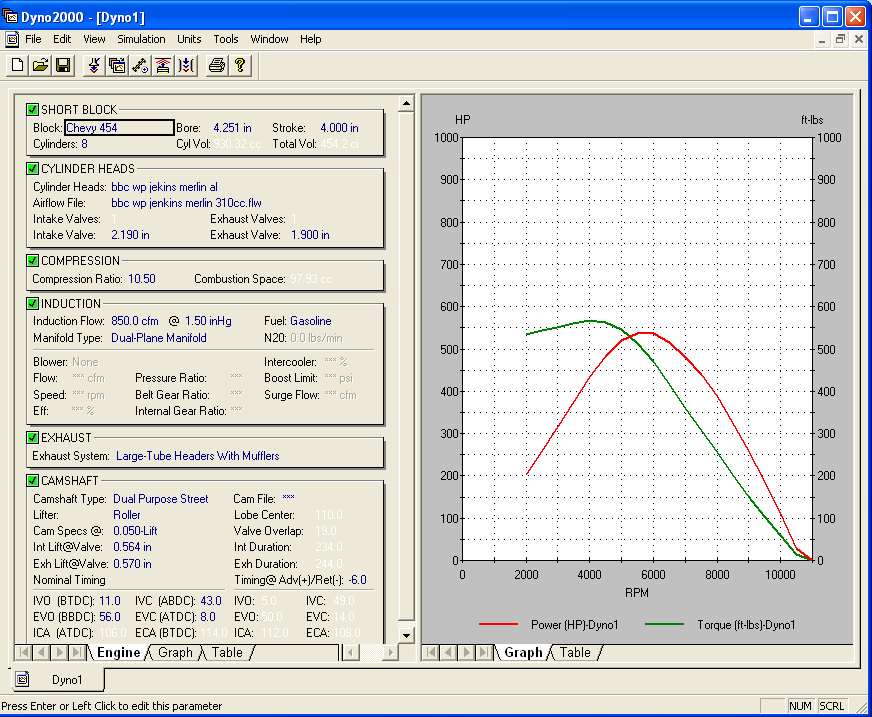

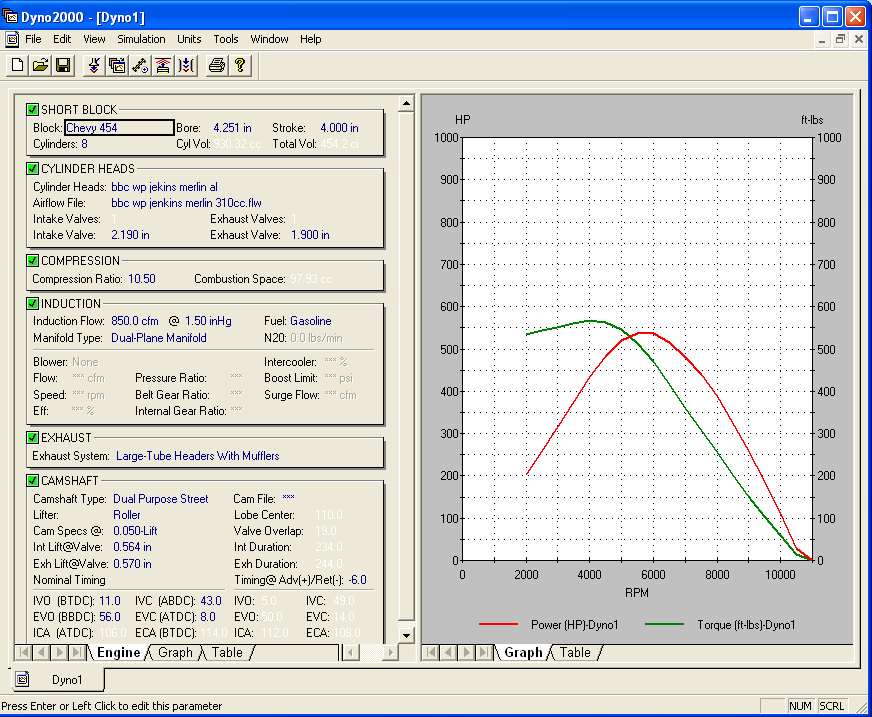

I did a quick software dyno using 10.5 compression, that hydraulic roller cam, headers with mufflers and I used some mild merlin 310cc rectangular port heads,

Valve Lift--.300 --.400 --.500 --.600 --.700 --.800

2.300 ------- 208 -- 267 -- 321 -- 363 -- 383 -- 374

1.880 ------- 151 -- 193 -- 232 -- 259 -- 276 -- 286

while the flow specs are not an exact match they should be close after a mild port & bowl area clean-up, on those chevy rectangular port heads.

and the power and torque seem very reasonable for the combo at about 540hp @ 5700rpm and 560 tq at about 4100 rpm, and power dropping rapidly after 6100 rpm

http://www.dragzine.com/tech-stories/engine/ultimate-guide-to-budget-bbc-cylinder-heads-under-2000/

Valve Lift--.300 --.400 --.500 --.600 --.700 --.800

2.300 ------- 208 -- 267 -- 321 -- 363 -- 383 -- 374

1.880 ------- 151 -- 193 -- 232 -- 259 -- 276 -- 286

while the flow specs are not an exact match they should be close after a mild port & bowl area clean-up, on those chevy rectangular port heads.

and the power and torque seem very reasonable for the combo at about 540hp @ 5700rpm and 560 tq at about 4100 rpm, and power dropping rapidly after 6100 rpm

http://www.dragzine.com/tech-stories/engine/ultimate-guide-to-budget-bbc-cylinder-heads-under-2000/