Distributors:

Depending on the year of your TPI engine will depend on the type of distributor that was used. In 1985-86 "F" body (Camaro-Firebird) and 1985-1991 "Y" Body (Corvette), the distributor was the familiar looking large cap HEI distributor. Upon closer examination of the original distributor you will see it's cap is held down by 4 screws. The more common HEI distributors, if you have another 1974-86 small block Chevy to compare, is held with 4 latches. Another difference is the 4 wire EST connector to the wiring harness. While the common HEI has the prongs with two outer slots facing up, the HEI used on the TPI engines, has one of these slots facing to the outside.

You can use the common HEI on your TPI for the years mentioned above, but you will have to swap the connector at the harness or find the connectors at a salvage yard, which can be found on the 1985-86 3.8L V6 found on the FWD vehicles or on the 4.1L V8 Cadillac motors.

Shown above is the large cap HEI distributor, this one is the common variety which the cap is latched instead of being held by four screws. These can have the est connector modified to work on your TPI engine perfectly.

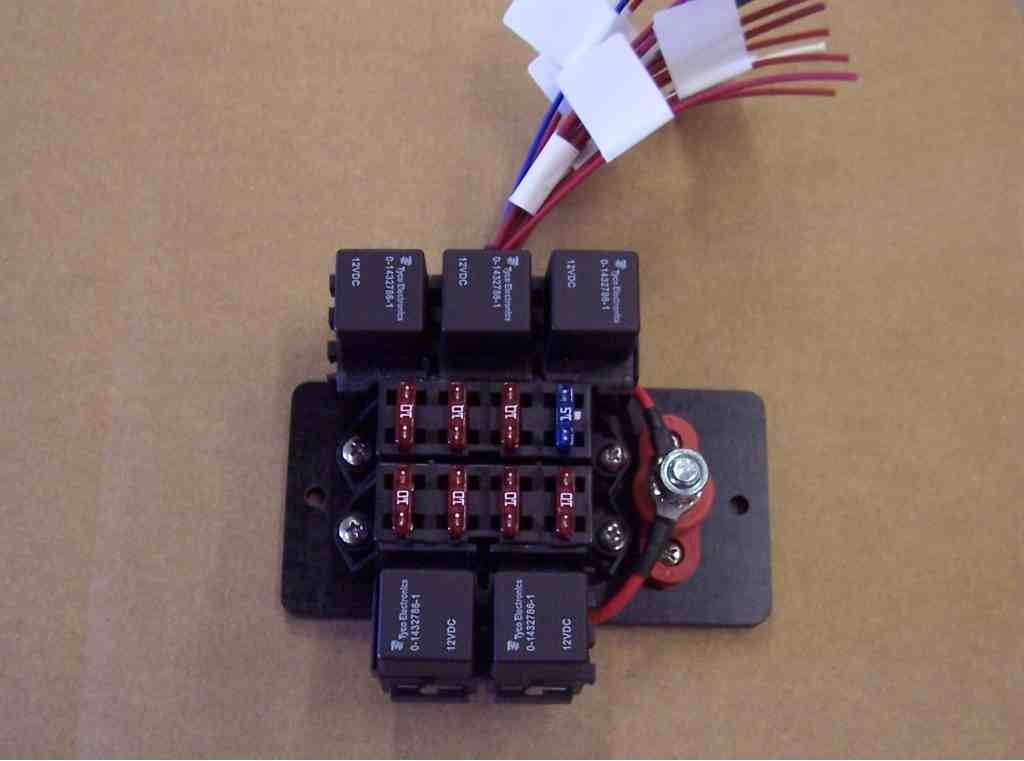

The next distributor was on the 1987 through 1992 Camaro-Firebird TPI engines. This is what I call the "small cap" HEI, which uses a remote mounted coil, typically is bolted to the intake manifold. You will note this is the time period, Chevrolet switched to the roller cam motor, and this distributor was used on these engines.

Shown above is the "small cap" HEI with coil.

The remote coil has two connectors. The gray connector is the 12V coil power supply, the large pink wire goes to ignition "on" power for the distributor, the white wire can be hooked to a tachometer. The black connector has the smaller pink and white wires which goes to the two wire connector on the ignition module on the distributor.

EST connectors that send the ignition signal back to the ecm, The one of the left is for the "small cap" HEI, the center one is for the "common" large cap HEI, note the two outer prongs with slots facing up. The connector on the right is the "TPI" distributor connector (1985-86 only), used with with screw down caps. Note one prong with slot facing up, the prong on the far left has a slot but is facing towards the left.

Be careful in pulling a small cap HEI to use. The distributor to the left is used on the 1987-1992 Camaro/Firebird. Note the smaller base as compared to the distributor on the right, these larger base distributors were used on some 1991-1993 "B" body TBI equipped engines, such as the Chevy Caprice and Buick Roadmaster. They use the TBI throttle bodies which are held down with two studs for the air cleaner, and the manifolds are machined for the large base distributor they

use. They will not interchange.

DISTRIBUTOR GEAR APPLICATIONS

There has been a lot of controversy concerning the interchange of the distributors using a large cap HEI on a 1987 and later block and using a small cap distributor on earlier blocks. It used to be on the safe side, use the large coil in cap HEI on the pre-87 blocks and the smaller remote coil HEI on the 1987 and later engines. Now with the aftermarket coming to the rescue for those who want to use the different distributors due to firewall clearance issues, availability, etc. it is possible to use the distributor of your choice, but you must use the proper distributor gear based on the material the cam distributor gear is made of.

Crane cams makes the proper distributor gears for the roller and non-roller blocks.

General rule is to use a bronze alloy gear for a steel distributor gear on the camshaft (most factory roller cams follow this route). For an cast iron cam use a irondistributor gear (all non roller cams and some later aftermarket roller cams use an iron distributor gear on camshaft.

Crane cams does make a coated steel distributor they say is superior to the bronze alloy gear with a OEM life span. It can be found at this URL through Jeg's performance parts: http://www.jegs.com

Part # 270-11951-1

Coated Steel Distributor Gear

Chevrolet

90° V-6 1978-86, 200 thru 262

V-8 1955-87, 262-thru 400 .491'' Dia. shaft

V-8 1965-90, 396 thru 502

Crane also makes a iron gear that fits the small HEI distributor for use in an earlier non-roller cam application.

Part# 270-11970-1

Iron Distributor Gear

Chevrolet

90° V-6 1985-91, 262 For GM HEI

V-8 1985-99, 305-350 For GM HEI .427'' Dia. shaft

V-8 1991-00, 454-502 For GM HEI

If you want to use the bronze alloy gear it is part # 270-11988-1 for the small HEI (.427" dia. shaft)

For the large HEI it is part # 270-11990-1 (.491" dia. shaft)