You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical Wiring for a TBucket

- Thread starter Indycars

- Start date

I think youll be ok once you connect the battery ground to the cars frame, and yes it's starting to look like it might even get driven eventually???

http://www.jegs.com/p/Powermaster/Powermaster-GM-CS144-Style-Alternators/1534945/10002/-1

http://www.jegs.com/p/Powermaster/Powermaster-GM-CS144-Style-Alternators/1534945/10002/-1

Last edited by a moderator:

I'm pretty damn sure you already know that, Smart Asses Are A Dime Dozen"HappyVette said:and yes it's starting to look like it might even get driven eventually???

I love it when you give me a hard time! Cause there is no doubt with my computer and graphic skills you will loose this bout!!!!!! :mrgreen:

Last edited:

Moving the distributor and choke ground wires is a good idea, that will

clean it up a little! I ran those wire several months ago and didn't even

think about it when I started adding the 8 AWG grounding wires.

As far too many ground wires ..... it seems I've read not to depend on

threads to provide a good ground. They have antiseez on those for the

manifold and everywhere else is a gasket. You could be right Mathieu,

but I can't go wrong having too many grounds.

busterrm said:HappyVette, :lol: :lol: :lol: , tell that one to Grumpy's wife!!!! '

I would Bob, but I don't want her to hurt herself, when she falls down LAUGHING !!!

busterrm

solid fixture here in the forum

I think its gonna be driven soon, I want to be his first passenger, unless his wife has dibs on that!grumpyvette said:I think youll be ok once you connect the battery ground to the cars frame, and yes it's starting to look like it might even get driven eventually???

mathd

solid fixture here in the forum

The head have a "head to block" ground.. the dowels pins ;/Indycars said:

Moving the distributor and choke ground wires is a good idea, that will

clean it up a little! I ran those wire several months ago and didn't even

think about it when I started adding the 8 AWG grounding wires.

As far too many ground wires ..... it seems I've read not to depend on

threads to provide a good ground. They have antiseez on those for the

manifold and everywhere else is a gasket. You could be right Mathieu,

but I can't go wrong having too many grounds.

The starter and engine block has good contact and probably no antiseize anyway.(i never heard of a starter to block grounding problem?

The intake.. only electrical thing that ground off of it is the choke and distributor wich your going to move to the heads anyway... dont need a 8 awg for just that.

and the starter to frame.. you have engine to battery(and battery is ground to frame).. your just wasting your money and time man. probably creating ground loop with soo many grounds. or magnetic fields(if you ever worked with vacuum tube electronic.. you know what i mean).

Overkill is good, but not this time i think so.

http://www.epanorama.net/documents/grou ... asics.html

mathd said:The head have a "head to block" ground.. the dowels pins ;/

The starter and engine block has good contact and probably no antiseize anyway.(i never heard of a starter to block grounding problem?

I'm not sure you can count on the dowel pins to be a good connection. My block is painted where the starter mates with the block, so only the threads are making contact thru some oil I put on the threads.

The intake.. only electrical thing that ground off of it is the choke and distributor wich your going to move to the heads anyway... dont need a 8 awg for just that.

and the starter to frame.. you have engine to battery(and battery is ground to frame).. your just wasting your money and time man.

Engine to battery .... not sure what cable you are referring to here ???

probably creating ground loop with soo many grounds. or magnetic fields(if you ever worked with vacuum tube electronic.. you know what i mean).

Overkill is good, but not this time i think so.

I read the article you posted the link for. I can see there being a problem when you have something other than DC current, where its going to induce a voltage in another wire by a magnetic field.

Good discussion Mathieu!

For example this guy wrote two books on automotive wiring and sell grounding kits that have 8 ground wires.

Kit includes

Battery Negative (-) to Body

Frame to Core Support

Rear End Housing to Frame

Bell Housing to Firewall

Cylinder Head to Cylinder Head

Cylinder Head to Frame

Top Post Battery Adapter

Grade 5 Hardware

Full Color Step-By-Step Instructions

Last edited:

mathd

solid fixture here in the forum

Well, i dont care, i was just saying i think its overkill.

with that many bolt on the head, and with the torque they have, i dont think there will be a electrical contact problem ever there.

With the block painted where the starter mate. if you didnt buy the cable yet, i would said to try it before adding a ground there. I guess it can't hurt to have a extra ground there anyway.

Engine to battery..

Don't you have a big negative wire from the battery post to the engine block?, every car i have seen have one.

Dont get fooled by DC current only(i did not read this link fully but).

Just look at our car with the lm-2, the unit power on dc, it work on dc, computer USB also DC the sensors connected to it are all DC.. yet we got ground loop problem and can't keep it connected to the pc once the car is running+some singal AC noise to the sensor...

While all your car's equipment work on DC, i see what your thinking.. but dont forget they may induce some AC like the electrical FANS or the alternator/ignition...

Electrical can be tricky, and usually car's electonic is far from perfect.

bob, from the picture i think he is grinding some paint at the frame's ground point for better contact.

with that many bolt on the head, and with the torque they have, i dont think there will be a electrical contact problem ever there.

With the block painted where the starter mate. if you didnt buy the cable yet, i would said to try it before adding a ground there. I guess it can't hurt to have a extra ground there anyway.

Engine to battery..

Don't you have a big negative wire from the battery post to the engine block?, every car i have seen have one.

Dont get fooled by DC current only(i did not read this link fully but).

Just look at our car with the lm-2, the unit power on dc, it work on dc, computer USB also DC the sensors connected to it are all DC.. yet we got ground loop problem and can't keep it connected to the pc once the car is running+some singal AC noise to the sensor...

While all your car's equipment work on DC, i see what your thinking.. but dont forget they may induce some AC like the electrical FANS or the alternator/ignition...

Electrical can be tricky, and usually car's electonic is far from perfect.

bob, from the picture i think he is grinding some paint at the frame's ground point for better contact.

mathd said:Well, i dont care, i was just saying i think its overkill.

I hope there is no hard feelings here! One thing we all like about cars, is doing it our way after listening to everyone's input.

with that many bolt on the head, and with the torque they have, i dont think there will be a electrical contact problem ever there.

With the block painted where the starter mate. if you didnt buy the cable yet, i would said to try it before adding a ground there. I guess it can't hurt to have a extra ground there.

Engine to battery..

Don't you have a big negative wire from the battery post to the engine block?, every car i have seen have one.

Since the battery is under the seat, the negative cable has always gone straight to the frame. The 1/0 cable I'm making for this now, is 13 inches long. That makes me think ..... I should have the same size 1/0 cable from the starter to the frame. The Powermaster starter can pull over 400 amp initially.

Dont get fooled by DC current only. While all your car's equipment work on DC, i see what your thinking.. but dont forget they may induce some AC like the electrical FANS or the alternator itself. That remind me of CB Radio high pitch squeal.

mathd

solid fixture here in the forum

But i don't know man, i know each one do it there own way, but i have more electrical ability that you do and i got a feeling something is wrong(or that it could be better with this nice hardware you have, am not trying to tell you exactly what to do).. I did not really spent time thinking about your electrical wiring but i got a feeling something is not right and this feeling will not let me

I had to completely pull the wiring harness out of the car that I made to connect

the fan, fan temp sender and CS144 alternator. The very fragile 24 gauge wire

from the sender broke in the middle where I had soldered a 16 gauge wire to the

smaller 24 gauge sender wire. Not surprising, I've had problems all along trying

to crimp or solder such a small wire. I don't have a wire stripper or wire crimper

for that small a wire. It's NOT hard to pull apart or break such a wire. Now it

seems that the wire is broke at the sender, so I may be replacing the sender.

I got the idea from a Painless wiring harness instruction to use a small battery charger

for testing. So I used a 12 volt, 1 amp wall wort to power the system. Hard to burn up

any components or wiring with power supply SO Small.

Last edited:

8

87vette81big

Guest

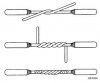

Are You Familiar with WESTERN UNION WIRE SPLICES Rick ?

Its how I join 2 separate wires together.

It makes for a super strong mechanical joint connection & ultra low resistance .

It dates back to the late 1800's Telegraph line days when the Lineman would join 2 copper telegraph lines together in the field.

Its a bit of an art to make correct. Practice makes perfect.

I learned it back in Freshman year in high school 1983. Been doing it ever since. Looks super clean when silver soldered & heat shrinked.

I don't like crimp spliced much myself.

You take each wire & strip back 1 to 1-1/2 inches of insulation.

Small wires I Skim insulation off with a sharp pocket knife like shaving wood.

Take each wire & form a 90 degree bend about 1/3rd to 1/2way up.

Place the Two 90 degree wire bends against each other inline.

Then twist both exposed wire ends in opposite directions with your Thumbs & index/ fore fingers.

stop twisting when you run out of wire. Solder the joint. Heat shrink. Your Done.

It works with even heavy gauge copper wire of 8- gauge but you use a pair of Lineman pliers to twist tight in Unison.

Be sure to install the heat shrink tubing of your choice on one end of the the wire 1st.

Lineman connections work great on wires of dissimilar diameters too.

Just use the Chinese wrap to protect the wires. Don't heat shrink the entire length. Likely strained wires in the middle when it cooled off. Caused the break.

BR

Its how I join 2 separate wires together.

It makes for a super strong mechanical joint connection & ultra low resistance .

It dates back to the late 1800's Telegraph line days when the Lineman would join 2 copper telegraph lines together in the field.

Its a bit of an art to make correct. Practice makes perfect.

I learned it back in Freshman year in high school 1983. Been doing it ever since. Looks super clean when silver soldered & heat shrinked.

I don't like crimp spliced much myself.

You take each wire & strip back 1 to 1-1/2 inches of insulation.

Small wires I Skim insulation off with a sharp pocket knife like shaving wood.

Take each wire & form a 90 degree bend about 1/3rd to 1/2way up.

Place the Two 90 degree wire bends against each other inline.

Then twist both exposed wire ends in opposite directions with your Thumbs & index/ fore fingers.

stop twisting when you run out of wire. Solder the joint. Heat shrink. Your Done.

It works with even heavy gauge copper wire of 8- gauge but you use a pair of Lineman pliers to twist tight in Unison.

Be sure to install the heat shrink tubing of your choice on one end of the the wire 1st.

Lineman connections work great on wires of dissimilar diameters too.

Just use the Chinese wrap to protect the wires. Don't heat shrink the entire length. Likely strained wires in the middle when it cooled off. Caused the break.

BR

8

87vette81big

Guest

Yes Rick.

Like That.

Like That.