You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical Wiring for a TBucket

- Thread starter Indycars

- Start date

8

87vette81big

Guest

The T-bucket has an idiot light bulb.

I would use along with voltmeter.

Just period correct.

Your CS144 build photos has part number.

Also taught not to make it too easy for others.

Always keep a few secrets for yourself.

That way I stay Usefull till I am dead Rick.

Just the Italian Sicilian way.

Now everyone knows how the CS144 build should look inside taken apart.

BR

I would use along with voltmeter.

Just period correct.

Your CS144 build photos has part number.

Also taught not to make it too easy for others.

Always keep a few secrets for yourself.

That way I stay Usefull till I am dead Rick.

Just the Italian Sicilian way.

Now everyone knows how the CS144 build should look inside taken apart.

BR

8

87vette81big

Guest

Grumpy does the same Rick.

He is sneaky too.

He is sneaky too.

8

87vette81big

Guest

I'm moving onto other winter time projects Rick.

Dana 60 build. 3 1957-58 Pontiac Olds 9.3 Rear Diff builds for my card.

Dana 60 build. 3 1957-58 Pontiac Olds 9.3 Rear Diff builds for my card.

8

87vette81big

Guest

I'm moving onto other winter time projects Rick.

Dana 60 build. 3 1957-58 Pontiac Olds 9.3 Rear Diff builds for my cars.

Dana 60 build. 3 1957-58 Pontiac Olds 9.3 Rear Diff builds for my cars.

well?

how much longer until

you can drive that T-bucket?

how much longer until

you can drive that T-bucket?

I hope to post some more meaty info soon, but for now and in no particular logical sequence ......

The fan ground wire was 14 AWG, but I used 12 AWG to extend the wire to a ground

point on the frame. The barrel connector was for 10-12, so I stripped and extended

both wires completely thru the barrel connector. Then I crimped and soldered the

connection and sealed with heat shrink.

The braided sleeve is a bit fragile when it comes to heat. I couldn't use a lighter of

any kind or it would immediately burn thru the sleeving. So I bought this heat gun

from Harbor Freight. It has worked well so far and plenty of adjustment. The low

heat setting has a slower fan than the high heat setting. It even has a cool down cycle,

when you turn it off, it runs the fan for another 60-120 seconds.

It stands up for hands free operation.

http://www.harborfreight.com/12-interva ... -9184.html

Last edited:

8

87vette81big

Guest

Looking Great Rick.

Do Sub Assembly wiring work.

Then connect alltogether.

Hand scetched wiring schematic eliminates errors for me.

Sure you made a full Color printout.

Put NASA Engineers to shame.

Real fancy heat gun.

Nicer than my Snap On.

It does not have LED bar graph heat setting lights.

Gets real hot though . Up to 1400 F. Scary hot.

Do Sub Assembly wiring work.

Then connect alltogether.

Hand scetched wiring schematic eliminates errors for me.

Sure you made a full Color printout.

Put NASA Engineers to shame.

Real fancy heat gun.

Nicer than my Snap On.

It does not have LED bar graph heat setting lights.

Gets real hot though . Up to 1400 F. Scary hot.

Got lucky, the alternator went in without any modifications. With a couple

Gates #7420 V-Belts, I'm good to go in that area.

The fan positive wire is only 12 AWG, but I ran a 8 AWG wire from the fan

controller's 10 AWG wire to make the connection. Seems strange that the

fan ground wire is only 14 AWG, since the current is the same everywhere

in the circuit. I used 10 AWG for the 12 inches I needed to get to the frame.

It's hard to find Adel clamps with larger mounting holes than 1/4 inch, so I had

to enlarge one so I could use a 3/8 inch motor mount hole. The clutch ball

mounting hole is 1/2 inch, which is larger than the available material. So I made

my own Adel clamp. If you look closely you can see the rubber washer between

the engine and the clamp to keep heat away from the wires. Actually it's a rubber

washer for a garden hose.

Now that I'm finished at the front of the car, I moved the the other end of the

wiring under the seat where the fan controller and battery is located.

No body makes a ring or spade connector for 8 AWG, so I opened up a 10-12

AWG slightly to get the wire in the connector, then I closed it back around the

wire. Next I crimped it, soldered it and installed heat shrink. I crimped,

soldered and heat shrinked all connections.

Notice the old 10 AWG wire that charged the battery from the old 10SI alternator. Now

I'm using a 4 AWG wire from the Custom Built by Brian(87vette81big) CS-144 alternator.

Below is the Flex A Lite fan controller I'm using.

http://www.flex-a-lite.com/accessories/ ... ensor.html

http://www.summitracing.com/parts/flx-31163/overview/

Battery Terminals:

Positive Post - http://www.oreillyauto.com/site/c/searc ... word=tz620

Negative Post - http://www.oreillyauto.com/site/c/searc ... word=tz625

Last edited:

great pictures and post info

everything looks like its coming along nicely!

when do you think your going to be able to fill the fluids (coolant,oil,trans fluid, brake fluid etc.) and start and drive the car?

everything looks like its coming along nicely!

when do you think your going to be able to fill the fluids (coolant,oil,trans fluid, brake fluid etc.) and start and drive the car?

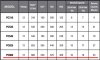

This confirms that I needed to use dual V-Belts for the new alternator.

I have two Gates 7420 belts, they are 1/2 inch wide.

https://www.westmarine.com/WestAdvisor/Selecting-an-Alternator

Belt Load Limitations

Drive belt width is a critical factor in selecting a replacement alternator.

Commonly-installed vee-belts and multi-groove serpentine belts have specific

limits regarding the amperage and horsepower loads they can support.

As a rule of thumb, 12-volt alternators use one horsepower for every 25 amps

of output, or to put it another way, their ratio of output to horsepower load is

25:1. So, when selecting a new alternator, you need to size it for the limits of

the capacity of its drive belt. Otherwise, your system will be plagued by

premature belt wear, belt slippage and potential damage to your alternator

and engine. See the following chart, and note that dual vee-belts and serpentine

belts can support much larger loads.

Last edited:

8

87vette81big

Guest

The chart is nice Rick but does not factor in belt speed limit in feet per second.

For your applications and useage OK.

Cruising and moderate spirited driving

For 7-8K RPM Sustained must use a 5 inch diameter pulley. My experience .

Violent acceleration another factor.

4k to 8k Rpms in 1 second.

Power I am used to.

For your applications and useage OK.

Cruising and moderate spirited driving

For 7-8K RPM Sustained must use a 5 inch diameter pulley. My experience .

Violent acceleration another factor.

4k to 8k Rpms in 1 second.

Power I am used to.

My Odyssey PC680 battery came in, cost was about $110 from Amazon. It's just

hard to believe this battery can start a V8 engine, but several guys are using it,

so it should work just fine.

This type of battery has several advantages,

DESIGN LIFE 8-12 years (Float) @ 25˚ C (77˚ F)

SERVICE LIFE 3 to 10 years

ELECTROLYTE Drycell (“starved electrolyte”) no external leakage or corrosion

STORAGE LIFE 2 years before needing charge @ 25˚C (77˚F)

SHIPPING Air transportable; US Department of Transportation classified non-spillable (less expensive) Ground transport

END OF LIFE Battery slowly loses power at end of life; no catastrophic failure

http://www.odysseybattery.com/literature.html

Last edited:

87vette81big said:The chart is nice Rick but does not factor in belt speed limit in feet per second.

For your applications and useage OK.

Cruising and moderate spirited driving

For 7-8K RPM Sustained must use a 5 inch diameter pulley. My experience .

Violent acceleration another factor.

4k to 8k Rpms in 1 second.

Power I am used to.

I'm running a 1/2-inch on a niiiiice 200 amp alt. I NEVER had any problems except violent acceleration. Or actually violent rev spikes - that will throw the belt.