Thanks Gentlemen!

The pan I had fit - however it cannot be slid in and out from underneath. For the moment I can get the stock pan in an out fairly easily by freeing the block from its mounts and lifting the engine as high as possible.

Having slept on it, here's is what I think.

I think it was a confluence of problems: low oil (Crummy Lokar dipstick? I checked the oil level regularly.) and too much pan-to-pickup clearance. Clearance was over a 16th or two over 1/2 an inch.

Measure and place your own mark on the dip stick for full.

This would explain why the oil pressure would climb fast from idle pressure to 35-40 PSI. At 40-PSI 2000 rpm highway cruise it was probably already cavitating, more so at higher RPM. This in turn would heat up the oil, aerate it and increase bearing clearances.

I don't see how this would make the bearing clearances larger. If it did, then you have hurt the bearings and will need replacement.

During a short, harder 4000 RPM run the needle would dip eratically - heating things up even more, cavitating and aerating the oil. Therefore and thereafter returning to idle and cruise, I'd lose another 5-8 PSI.

Is this diagnosis sound?

So far here is my plan: Until I am sure this was indeed what happened, I do not want to purchase a deep pan. I might need the $$$ to yet fix a problem that lies elsewhere -the deep/baffled pan will come after that. I think it makes sense to be sure that proper oil level + pan-to-pickup clearance will solve the problem.

Unless you don't have the time and need the car, I would wait for the better pan. In my opinion, a bigger oil pan is REQUIRED.

This weekend, I will pull the first and last cap off, as per Grumpyvette's suggestion, and check for damage. If the bearings look ok (and I am expecting them to be) I will not pull the others. (If there is excessive damage I have no clue what to do other than yank the engine and start over.)

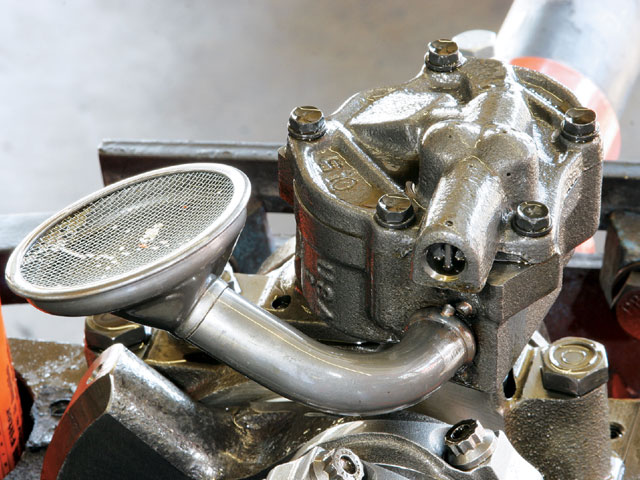

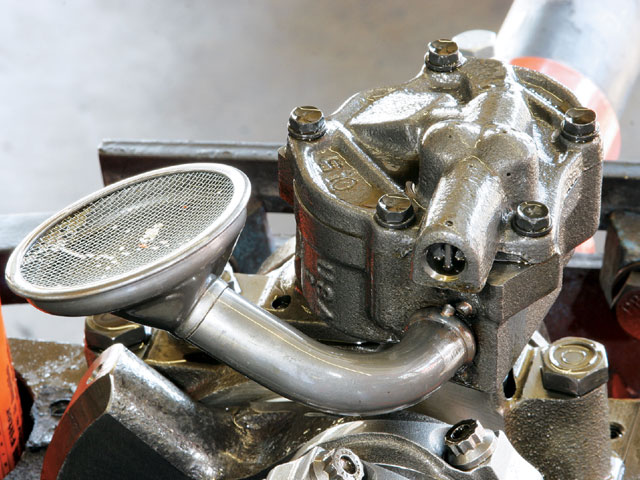

From there I will go through the pump; put back on the stock oil pan (with a standard oil pan gasket and my old high volume pump); and ensure that the clearance is spot on WITH the gasket.

If this solves the problem, I will order a deep/baffled pan for the September race. I might have to pull the engine to install it.

Also - put in another dipstick + 20w50

Again, make your own measurements and confirm or remark the dip stick.

Makes sense?

Questions:

- Is there anything else I should look at as a potential source of issue while I am down there?

- Should I RTV the gasket to the pan? Or use grease to hold gasket to the block? (Since I am working on my back.)

- Locktight on oil pump case bolts?

I would suggest you use RED loctite. When I called Melling about their 10552 pump, they said torque the cover bolts to 80-106 in lbs. Maybe impossible to do in the car.